Beered Guys Brewing Company

Info: 9788 words (39 pages) Dissertation

Published: 9th Mar 2021

I. Operations Management

A. Significant Forces

Beer breweries have been using a Materials Requirements Planning (MRP) system ever since the creation of the industry. This is a planning methodology broken down into time phases and subsections of required raw materials that results in a final product (Stevenson, 2018). Some key forces that have helped shape the current beer brewing industry would be technology involved the manufacturing processes, as well as limitations of raw materials from suppliers.

There are many technological advancements that have impacted the industry such as refrigeration and pasteurization which certainly improved longevity and shelf life of beer products. Operationally some of the more recent advancements have improved brewery manufacturing equipment, which have significantly impacted quality control and automation of production (Moore, 2009). Virtually all brewing equipment today is made of stainless steel for optimizing sanitary conditions. Additionally, brewing equipment is fitted with sophisticated heating and cooling technologies that improve quality control and minimize waste. Other specialized equipment also allows breweries the benefit of canning or bottling product in-house allowing them to another opportunity within quality control.

As a new startup brewery many of the most recent technological advancements improve operational efficiencies greatly. The advancements of the brewing equipment needed in the manufacturing process creates a beneficial opportunity for the brewery to reduce operational inefficiencies, including quality controls. However, these technological advancements to brewing equipment have come at a price. The cost for the beer manufacturing equipment has significantly increased. The cost for essential equipment alone can be purchased in the smallest capacity of 1 barrel, which is 31 gallons of beer, equal to 320 12-ounce beers for $100,000 or less if you buy it used. Additionally, a brewer could pay up to $1 million or more for a brand-new, 30-barrel system, which is equal to 9,600 12-ounce beers, says Leonard Kolada, the founder of Smokehouse Brewing Company in Columbus, Ohio (Nicastro, 2016).

The majority of the impact these advancements in technology is the initial cost of the equipment, installation, or the cost of repairs. This specific force would affect our brewery by increasing the startup cost substantially, by purchasing equipment brand new or transportation and professional installation of used equipment. The technical training involved in utilizing such equipment could also impact the operations of our brewery.

Raw materials in the beer brewing industry are a precious commodity. Considering the various ingredients such as wheat, barley, yeast, and hops that are involved in the production of beer, it is no wonder why there are so many exponential ways of combining different levels and types of these ingredients to achieve a wide variety of flavors and types of beers. However, one difficulty brewers face if the suppliers of these key ingredients are not so exponential. With more than 7,000 breweries operating and another 1,000 scheduled to open in 2019 within the United States, it comes as no surprise that there is stiff competition to acquire high-quality key ingredients for beer manufacturing (Snider, 2018). Beer breweries do not manufacture one product, they produce multiple products, which requires a variety of key ingredients.

Some concerns in the raw materials area for our brewery would be the lack of buying power. It is very obvious that it does not cost large breweries such a MillerCoors or Anheuser-Busch as much to brew beer products as it does for smaller craft breweries. Buying power plays an important role in the cost of purchasing malted barley, hops and other ingredients, which ultimately affects a smaller brewery’s profitability (Gebers, 2018). Among the difficulties of climate changes or unforeseen shifts in the weather affecting the supply of these key ingredients, some of the sources of the supply are being purchased by large corporate breweries to add additional revenues. Water usage is another force that is certainly catching traction in the industry. It typically takes seven gallons of water to manufacture one gallon of beer. Many craft beer consumers are seeking brands that have good sustainability programs and processes (Watson, 2018).

These environmental concerns have fueled many technological advancements to improve sustainability efforts for breweries. Additionally, these advancements have also enabled breweries to improve operational efficiencies as well as quality assurance efforts. The improvements in this area has helped many breweries and is also a driving force in how the consumer selects craft beer products. The concerns for our brewery’s operations would be the upfront costs associated with utilizing these types of advancements. Some additional concerns are the installation and specialized training and facility outfitting that may also be required.

B. Key Obstacles

Our brewery was not operational during the many of key issues that arose during the evolution of operational changes or advancements in the beer brewing industry. Therefore, our responses to these issues are speculation of how we as a company would have handled them, or good examples of how other breweries overcame some of these obstacles.

Every manufacturing company seeks ways to improve efficiencies, output, quality, quantity of production, as well as costs of production. The beer brewing industry is no different, everything from large barrel roasters, refrigerated rail cars, automated bottling and canning machinery, as well as fully automated stainless-steel brewing systems. The first obvious obstacle is the cost of improvements to brewing equipment. Some ways for our management staff to overcome these associated costs of purchasing improved technology, could come from setting aside a percentage of revenues, taking the company public, or perhaps selling older equipment to provide additional funding. Considering the exponential growth and attractiveness of the craft beer brewing industry has experienced there would also be an opportunity for the brewery’s management team to seek outside funding from financial institutions as well.

Another concerning obstacle associated with acquiring advanced equipment is the space available within the brewery’s facility. Facing this type of strategic decision making, our brewery’s management would need to conduct and review an in-depth financial analysis. This analysis would ensure that the cost and benefit of acquiring advanced equipment that required relocation to another space would not be an overwhelming financial loss for the brewery.

Some advancements to manufacturing technologies can come with steep learning curves. These additions to manufacturing equipment would be considered long-term investments to the company and its operations. Our brewery’s management team would need to establish periodical training programs for its workforce to ensure the longevity of equipment, safety of staff, and reduction in manufacturing downtime.

Another key operational obstacle that has affected the craft beer industry is the availability of some of the raw materials needed for production. Considering the technological advancements of beer brewing equipment will considerably help with quality control, another factor to maintain high quality levels is the consistent access to quality ingredients. Higher quality ingredients such as specific hops that give beer its flavor can significantly increase production costs, which is then in most cases passed down to the customer. Some ways our brewery’s management team could overcome these raw materials challenges might be contractual agreements with suppliers, increase buying power by collaborating with neighboring breweries, or perhaps creating unique partnerships with farmers or suppliers.

C. Changes

Operations management is the concern of controlling production processes in the most efficient ways possible and it involves two key responsibilities. One of which is utilizing the minimal but necessary amount of resources possible but still ensuring to meet the customer’s demands of the highest quality economically feasible (McClay, 2017). A company’s workers and their skills, creativity, analysis, and technological knowledge are all important in the effectiveness of a company’s operational management.

Some key changes to management’s philosophies in the beer brewing industry revolve around utilization of newer technology to improve operational efficiencies. The utilization of newer technology has also helped breweries improve sustainability efforts, which has a dual impact on improving production and cost efficiencies as well as improving brand intrinsic value.

An example of some technological equipment advancements would be the use of internet-connected sensors used during brewing processes. The use of these sensors provides data that can be used by brewing companies to improve efficiencies within their manufacturing processes. Deschutes Brewery is one of the breweries using this technology and it has resulted in reducing the fermentation or production times by 24-48 hours (Morris, 2019). The Deschutes Brewery brew master explains that utilizing big data sets can assist breweries in perfecting flavors they are attempting. It is very common for a brewery to attempt nearly one hundred flavor variations in order to find the precise flavor they want to achieve. Utilizing these data sets along with the assistance of computer software, breweries are now able to reduce these attempts for a perfect flavor down to only ten (Morris, 2019).

Beer brewing companies use a lot of water, however there are ways to recycle and efficiently reuse a brewery’s waste water to improve operational as well as cost efficiencies. In 2013 the National Resources Defense Council collaborated with two dozen well respected breweries to launch the “Brewers for Clean Water Campaign.” (Jenkins, 2013). A large number of breweries in the U.S. as well as globally are joining the Clean Water Campaign.

D. Business Operations

The utilization of improved technologies with regards to brewing equipment allows our brewery to not only maintain, but improve quality and standards that meet or exceed the craft beer consumer’s expectations. The use of sophisticated automation and software enhances the replication of recipes with little variances improving quality significantly. Automation also reduced cost of production which improves profitability as well as an economic value to our customers. This type of organizational process not only improves the final product that is offered to our customer it also creates a value for our brand that is consistent with our mission and values. Our brewery’s mission is to provide unique and flavorful craft beers to our customers that enriches their experiences, as well as to be servants for our community.

Creating and using an effective CSR program improves our brewery’s sustainability. This also has a duel effect on our operational efficiencies as well as improving the value of our brand in the eyes of consumers as well as our community. Technological advancements in equipment enable our brewery to establish Sustainable Development Goals (SDGs), which can be a valuable asset that helps guide or develop a company into a purpose driven business (Agnew, 2019). A good sustainability example in the beer brewing industry, would be the Hieneken brewing company. Hieneken has implemented sustainability programs to reduce carbon emissions as well as other environmental areas the business may make an impact. Between 2015 and 2016 Hieneken’s initiatives have saved the company over 1,000 olympic size swimming pools of water. These suitability programs have also resulted in savings for the company in the amount of 13.5 million euros from 2009 to 2016.

These appropriate sustainability programs not only make a profitability impact on our brewery, but also our operational efficiencies to reduce waste as well as improve quality for our products. Additionally, these programs align with our company’s mission and values of making a positive impact in our communities in which we operate. Our brand and the perception of how our company is viewed by aligning our sustainability efforts with our mission and values provides a unique value in the eyes of the consumer.

E. Key Trends

Key trends in the craft beer brewing industry have primarily focused in the two previously mentioned areas of improvement to operations with the advancements of production equipment technology as well as improving operations by becoming more efficient through sustainability. The improvement of sustainability has caught the eyes of many smaller breweries because these efforts can add a unique value to their brand. Another key trend for many craft breweries within their operations is the utilization of technology through social media. Many breweries are creating positions within their companies just to not just monitor and respond to their customers through social outlets, but also to learn from them. Many, customers feel their voice is louder on social media, where these customers can describe positive and negative features about a brand or its products or even its location. These opinions and outspoken voices are a perfect opportunity for breweries to learn what their customers, love, dislike, or want.

By utilizing this type of technology and incorporating it into our brewery’s operational model enables us to learn about our customers, their needs and requests. Our brewery can take advantage of this opportunity by preventing mistakes, reducing the creation of less desired products, as well creating a unique valuable bond between our customers where they feel they have a voice.

One additional key trend in the craft beer industry is the collaboration between smaller breweries. Considering the intense number of competitors within the industry that are not only engulfing shelf space, but other areas that affect their business models such as tariffs on imported aluminum and steel, access to quality ingredients at reasonable prices. Craft brewer’s welcome other brewery brethren through their doors. They often share equipment including assisting in training one another’s staffs. Secrets, craft brewers take pride in having none and sharing openly with one another (Brown, 2015). When a business sector that can be described as “craft,” “artisan” or “local” will benefit from collaboration among competitors, according to Stanford University management science and engineering professor Bob Sutton and Atholl McBean professor of organizational behavior at Stanford’s Graduate School of Business (Brown, 2015).

F. Impact

The overall impact these key trends have on our brewery’s operations absolutely significant in our business model as well as the products we produce for our customers. The importance of utilizing new and improved beer brewing equipment technologies is essential for our brewery’s success on many fronts. The use of advanced equipment allows our company to produce high quality beer products consistently for our customers, while minimizing loss financial as well as product loss. These equipment improvements allow for a more stabilized and consistent manufacturing methods. Additionally, technological advancements allow our brewery to improve our sustainability, which not only affect profitability but also improves our brand in the eyes of the consumer.

Another important impact of key trends is the use of social media to improve operational efforts and reduction of waste of either time, materials, or efforts by meeting or learning the demands of customers. Social media is another communication outlet to connect our customers to our brewery’s staff and our unique creation of products. This type of connection allows our company to develop and foster unique relationships with our customers that cannot be easily replicated.

The impact of the trend of collaboration between breweries is an all-around mutual benefit. The benefits of sharing resources, successes, failures, staff, or even support can create an environment within the industry that fosters growth and consistency. Perhaps, this is one of the main causes for such a David versus Goliath success story of the craft beer industry versus the large domestic beer corporations. The benefit of our new brewery being able to collaborate with three nationally recognized craft beer breweries located in the state of Georgia is overwhelmingly impactful. This allows our brewery to take advantage of an opportunity towards success operationally as well as managerially

II. Operationalization

A. Projected Costs

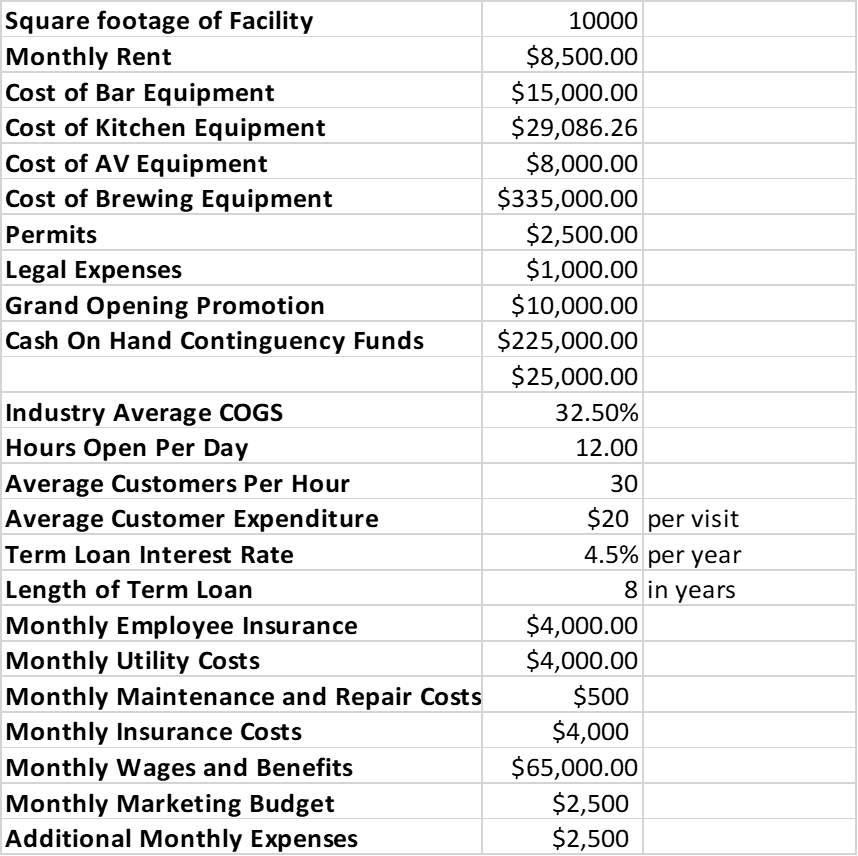

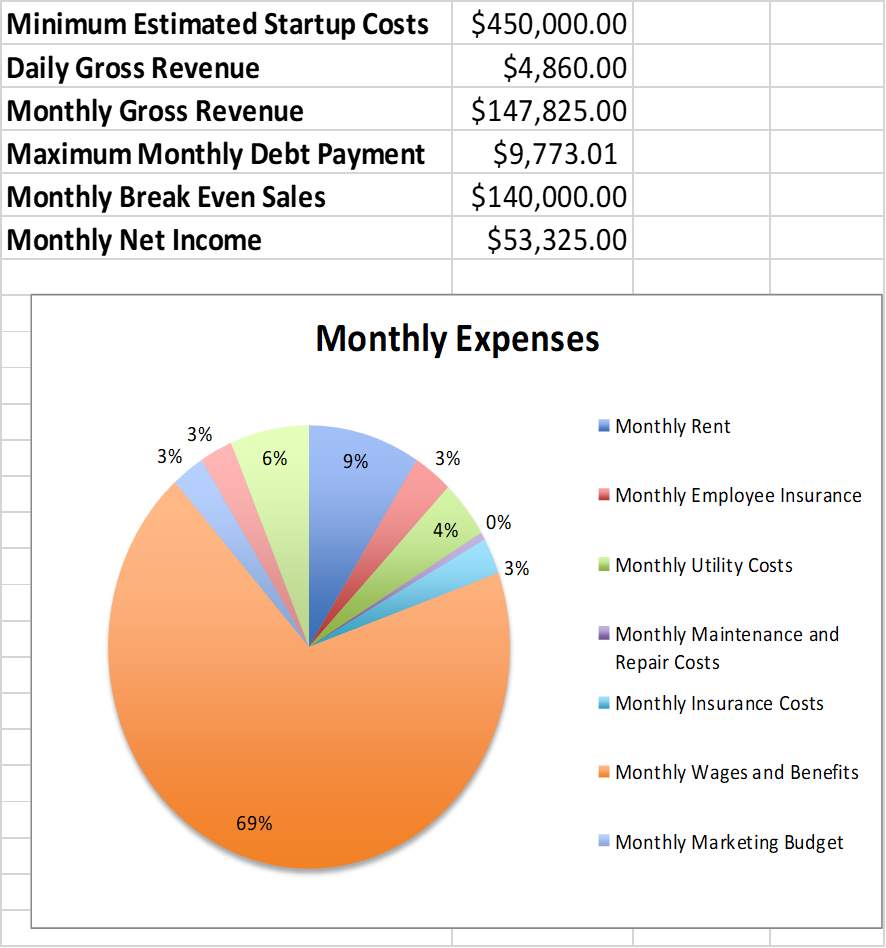

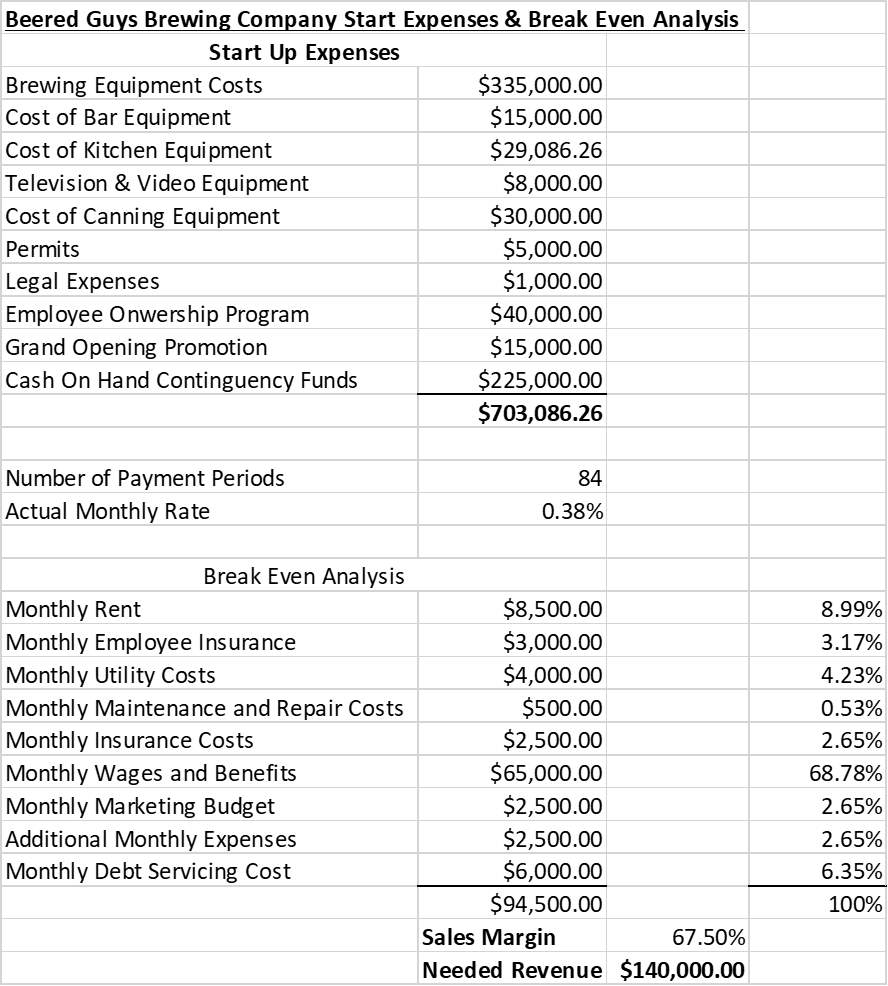

Considering our business is a startup the costs of operationalizing our brewery has been broken down into a budget to assist in forecasting as well as planning. Our analysis for our brewery begins with our budget and financial backing to open our business. The initial budget for the Beered Guys Brewing company will be between $700,000 and $750,000. This budget will be funded by both co-owner’s personal equity as well as a VA backed business loan. The CEO Enzo Fabbro and COO Bill Banks are military veterans and are eligible for $ 450,000 VA business loan according to the U.S. Small Business Administration (SBA, 2018). Our brewery’s initial budget and funding will be used to purchase the necessary brewing equipment, facility, tasting room furniture, raw materials, as well as all fees associated with licensing, as well as our payroll. There are four very important reasons why a micro-brewery should utilize a budget, cash-flow, expenditure planning, reflection (Farmand, 2015).

Our brewery’s assets and liabilities will be accessible in our company’s income statement. The Beered Guys Brewing company’s assets will include equipment, furniture, raw materials, as well as the financial equity of the business. In addition, the liabilities of our brewery will be comprised of business loans, payroll, and vendor fees. The purchase cost of our 10BBL brewing system is approximately $250,000 from a brewery equipment manufacturer and installer (JNVW, 2019). Additionally, our management staff will purchase four additional fermentation tanks as well as three additional serving tanks. These additional purchases combined will roughly total $85,000, which enables our brewery to produce multiple flavors or types of product simultaneously minimizes operational interruptions. Purchasing new equipment offer a benefit of free installation of the equipment, which additionally comes with a warranty for 3 years at no additional cost. An additional asset purchased by our brewery will be an automated canning machine, which will cost $20,000 and will also benefit from a warranty and installation.

Some recent cost concerns have surfaced due to the recent trade tensions between the United States and China. Recently, the President enacted 10% tariffs on imported aluminum and stainless steel not originating from Mexico or Canada (Furnari, 2019). Considering that our brewery’s necessary equipment is primarily comprised of stainless steel and aluminum these imposed tariffs will increase our purchase costs. Depending on the increase in cost, our brewery’s management staff may have to resort to purchasing used equipment, which could come at a higher cost. The purchase of used equipment will not include free installation nor a warranty on the equipment. Additionally, training will most likely not be included as well.

The purchase of raw materials is essential for the efficient operation of our brewery. These materials include, beer brewing ingredients, aluminum cans, labels and other packaging materials. Certain raw materials needed for brewing beer products have a limited shelf life, this combined with the uncertainty of future growth. Considering these limitations our brewery will order six months of raw materials in advance, which will come at a cost of roughly $25,000. The advantage of this larger material order during the initial startup of the business will enable a constant production level maintained to build up inventory levels. Additionally, an analysis can be done to better determine the appropriate amount of materials needed for subsequent orders according to sales and growth.

Cost concerns of purchasing packaging materials lies with the current trade tariffs of aluminum, as this is the primary packaging material needed in the production process. The concerns regarding raw materials such as ingredients is within the purchasing of hops. Considering the explosive growth of the industry and the exponential number of entrants into the industry has created competitive difficulties in securing this primary ingredient. As the industry has been maturing the number of hop farmers has also increased, this providing a plentiful supply. However, the concern of poor weather could affect crop production, which could result in difficulties acquiring hops.

B.) Work Breakdown Structure

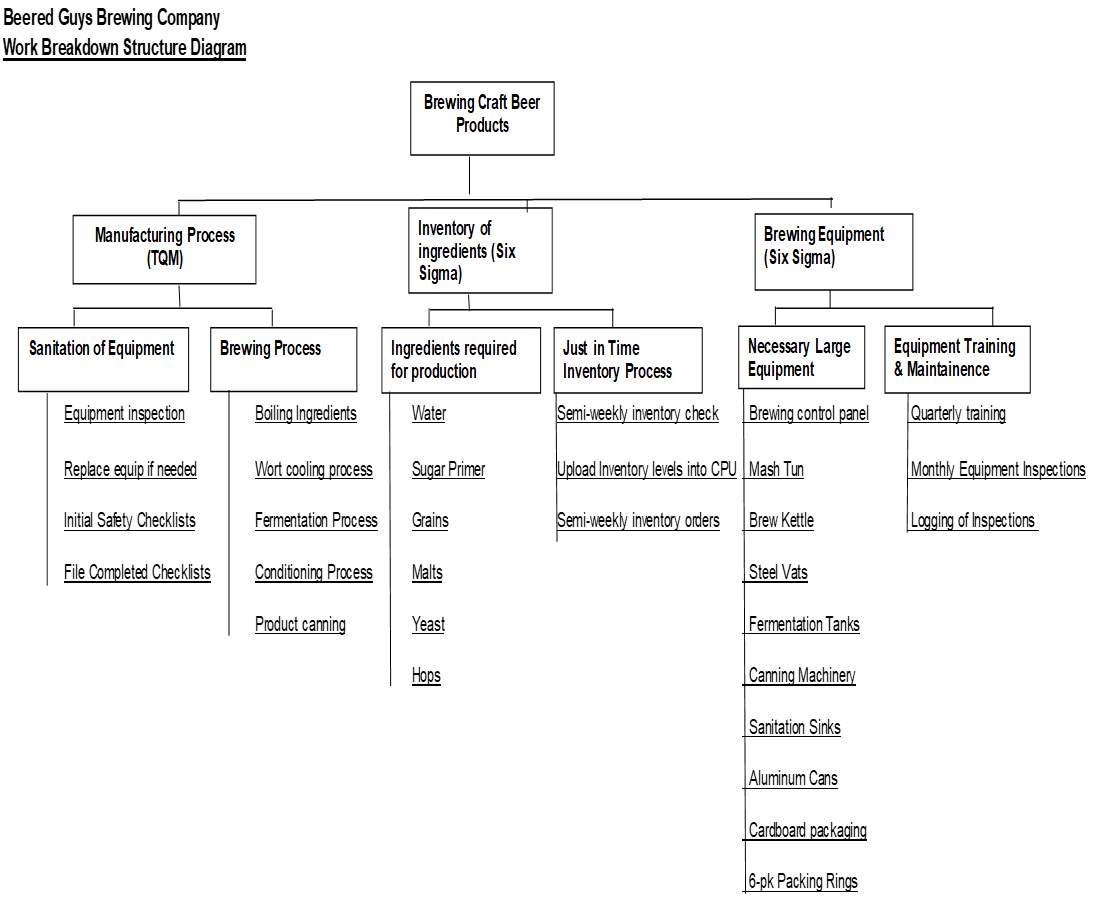

Brewing beer can be considered a detailed process, which typically involves a numerous number of tasks. A breweries’ staff and management must use some way to determine exactly what tasks need to be completed, which allows the staff to strategically estimate how long it will take to complete tasks (Stevenson, 2018). A work breakdown structure can identify the tasks in sequence to manufacture products. Our brewery’s WBS has been developed to define the tasks of the creation of our products. With the assistance of our WBS our brewery has ability to assign tasks, created a standard of quality, as well as the ability to measure production and achievements of high-quality. Furthermore, this will allow our staff to collect and analyze data, which will be transformed into communication that can be delivered to necessary staff and stakeholders.

In Table 1 is the WBS that will be utilized by the Beered Buys Brewing company to manufacture craft beer products.

Table 1.

C. Narrative

Given nature of our business model and the craft beer products we manufacture, high-quality is an essential ingredient to our brewery’s success within the marketplace. To ensure we not only meet but exceed the consumer’s quality expectations, as well as maximize our operational efficiency our brewery must have a well-developed work breakdown structure. Our WBS will be comprised of two key components, which will be broken down further into additional sub-components or tasks.

The first component our brewery will utilize is the Total Quality Management (TQM) method, which involves everyone within the company to strive for continuous improvement of quality and customer satisfaction (Stevenson, 2018). This type of method is based on three philosophies; one is a focus on continuous improvement; the second is the involvement of everyone within the company; and the third is the maximizing customer satisfaction (Stevenson, 2018). These three focuses are essential in our business model, as a continuous effort to improve maintains operational efficiencies and customer satisfaction. The involvement of everyone within the brewery directly ties into our company’s culture and diversity strategies. The second component of our WBS will be the use of the Six Sigma method. This method is a focus on improving quality, reducing costs, saving time, which improves operating efficiencies and customer satisfaction (Stevenson, 2018).

The manufacturing procedure for brewing craft beer hasn’t changed much over the past 100 years. The beginning point of the process is ensuring that the grains used during manufacturing is well-milled. During the milling process the grains needs to be broken into larger pieces, if the barley is too fine it will result in an unusable batch of beer. After the grains are milled properly, they are then added to the mash tun. During this portion of the brewing process water and a primer sugar are combined with the grains in the mash tun. The liquid in the mash tun is heated to a specific point where sugars within the barley or grains are activated, which converts starches into sugars. Temperature is vital during this process as certain temperatures determine different types of beers and a lack of control of temperature can ruin a batch (Siebenthal, 2014).

The next part of the manufacturing process is Lautering, which the separation of the mash grains into a sugary liquid called wort. The wort is then transferred into a kettle and brought to a controlled boil where hops are slowly added to it. Depending on the type of beer being produced, hops can be added continuously to increase flavor as well as alcohol by volume (Siebenthal, 2014). New trends within the industry have emerged to reduce waste of the separated grains. These used grains can be donated to local farms to feed live stock or used in the creation of pet treats as these spent grains are still edible and very nutritious (Teotonio, 2017). The transfer of the wort and its sterility is a vital part of the brewing process. If the wort becomes contaminated the entire batch of product is lost and must be started over.

After the boiling of the wort has completed and the specified amount of hops, depending of the type of beer being brewed, the wort is then allowed to cool. After the wort’s cooling process has completed is then transferred into fermentation tanks and combined with yeast. At this point in the process the yeast will devour the sugar in the wort and create alcohol, which additionally produces carbon dioxide as a byproduct (Siebenthal, 2014). This carbon dioxide explains how beer products get a portion of their carbonation. The length of time for the fermentation process to be completed varies depending of the type of beer being produced. Fermentation could take only several days or as long as a month.

The next process in the production of craft beer is the maturing or conditioning process. At this point in the process the added yeast has consumed any remaining sugars and the fermentation process has been ceased, resulting in a finished level of alcohol by volume percentage. The completion of the maturing process typically takes one week to complete. During the completion of the maturing stage, yeast within the holding tanks will fall to the bottom. This is an important part of the final stages of production as brewers will filter the yeast out of the beer by using specialized drains and filters. After the yeast has been filtered out of the beer it can then be transferred to the canning or bottling process.

The filtered beer product is then slightly carbonated and forced into packaging containers such as aluminum cans or bottles. Our brewery will utilize a canning machine that place our manufactured beer product into safely sealed aluminum cans. Our selection of cans is a strategy the offers the benefits of longer shelf life, better product protection, transportation benefits, as well as offers better sustainability for our CSR program.

Utilization of the six-sigma method will play an important role in our brewery’s operational efficiencies. Equipment inspections and sanitation of our brewing equipment are FDA requirements and must be followed. These tasks will take place each and every time a batch of beer is brewed. A more in-depth equipment inspection will take place monthly and all procedures during these processes will be recorded and uploaded into project management software. This will allow create accountability as well as physical evidence of FDA guidelines are being followed. Training our staff is also a key component to ensuring the production of high-quality products. Our training schedules will be refreshed every quarter and will also be provided in the addition of new hires.

D) Key Milestones

In project management milestones can be utilized to identify key sections in a project’s timeline. These key sections can highlight vital objectives needed for the success of a project, as the objectives are progression points within the project that enhance or maintain quality. Project goals or milestones should assist in eliminating operational downtimes, operational flexibility, and the reduction of waste including excess inventory or financial loss. Our brewery will also use the just in time method for our inventory and brewery processes. Another key method our brewery will utilize to track and successfully complete milestones will be a Gantt chart. This type of method uses a chart as a visual aid for scheduling and task identifications (Stevenson, 2018).

The Beered Guys Brewing company will place key milestone information in a Gantt chart form, specifically during critical points in the brewing process. Lautering would be an example of a critical point where a Gantt chart will be used. These critical key points continue throughout the brewing process. This would day one of the production of wort as well as the start of the fermentation process. On day two the fermentation process will be fully taking place and continue for 1-2 weeks to complete depending on the type of beer being brewed. After the fermentation process has completed the beer will be transferred to holding tanks for conditioning. Depending the beer product being brewed the conditioning process will be completed within 5-7 days. After the completion of the conditioning process the yeast will descend to the bottom of the holding tanks, which then the beer will be filtered as it begins to be transferred into cans during the canning process. During approximately week three the canning process as begun and this process should last for one day. After the completion of the canning process our beer product will be ready to ship to distributors. The entire brewing and packaging process should take between two and half to three and half weeks to complete depending on the type of beer product being manufactured. The use of a Gantt chart will help ensure that key milestones of the process are followed and completed on time. The use of this method also provides the opportunity to improve production efficiencies, which can improve and refine our company’s brewing processes.

The raw materials needed to brew our beer products require specific types of hops. The popular types of hops used to create IPA’s, which is considered the most popular type of craft beer, are Simcoe, Centennial, and Amarillo. The majority of the hops that are grown in the U.S. are grown within the Pacific Northwest, specifically Washington State and further north such as Michigan. To prevent any hop vendor disruptions our brewery will develop relationships with HopHead Farms in Michigan, as well as utilizing multiple vendors in the Pacific Northwest to supply our brewery with a variety of hops (Allen, 2018). By creating multiple hop vendor relationships our brewery can ensure that we have access to a key ingredient that would prevent production disruptions.

E) Potential Obstacles

The craft beer industry continued to realize growth of 4% in 2018 (Brewers Association, 2019). This growth continues to fuel the fire of new entrants into the industry. Considering the consistent growth within the industry, it is can strategically assumed that the demand for raw materials as well as equipment continues to grow as well. This increase in demand for raw materials could disrupt our brewery’s production due to a competitive rise to purchasing raw materials. Considering basic economies of scales, any limitations or restrictions to hops would be followed by a price increase. The concern of only developing or utilizing one or two vendors for hops would significantly impact our brewery’s production in the event of limitations or restrictions to this resource. The same theory would and should be considered with regards to aluminum canning materials and the recent 10% tariffs in place. These restrictions or limitations could result in a reduction of production levels or perhaps even a halt of production all together. If this is the case then our business model would begin suffering a financial loss. Another potential obstacle that should be considered is the ability to purchase new equipment considering the current 10% tariff on foreign steel and aluminum. An increase in these costs could push our brewery’s management staff to purchase used brewing equipment would could affect other cost models such as training, installation, and repairs due to a lack of warranty.

F) Risk Mitigation

Risks should be considered and expected to be a part of any project or process. These risks are associated to events that impose on a project such as, increasing costs, delays or disruptions, or the lack of meeting minimum specifications required for a product. Essentially any business including our brewery wants to eliminate or minimize risks enough so that it does not affect production or operations. One way our brewery will help mitigate risk will be to utilize the Critical Path Method (CPM). This method is a resource-utilization algorithm to schedule project activities required to complete a project and the dependencies between tasks (Slate,2018). This method will prove to be an essential tool to reduce and overcome risks in the prevention of disrupting brewing operations.

As previously mentioned, the creation of multiple vendor relationships with hop farmers as well as aluminum canning vendors will prove essential for our business. This strategy will provide our brewery access to multiple channels in the event of raw material shortages. Another concern of cost increases during a shortage could be overcome by combining raw ordering efforts with neighboring small breweries in the state or in geographically close proximality. By combining the ordering of hops or aluminum packaging materials will increase our buying power, which will enable us to gain traction with vendors and prevent production disruptions.

The concern of current tariffs on imported steel and aluminum products raising the purchase costs of our essential manufacturing equipment could be reduced by an in-depth cost analysis and use of the CPM method. Portions of our necessary equipment could be purchased new, which our company can benefit from no installation costs, warranty, and complimentary training. Non-essential equipment such as additional fermentation and holding tanks could be purchased used from other breweries. Additionally, our canning system could be purchased used as well as certain management team members have experience in installation, training, and repair of common brands of this type of equipment. This is where the CPM method will play an important part within our brewery, as it can assist our management staff in identifying critical project activities and the dependencies they have on other activities.

III. Life Cycle

Product life cycle management (PLM) is considered to be the handling of a good or product throughout the stages of its life. These stages of life cycle are development, introduction, growth, maturity, and decline (Segal, 2019). There is an article that offers some ideas of how to use product life cycle management to effectively utilize the concept as a competitive advantage or managerial competitive power (Levitt, 1965). When the Beerded Guys Brewing company will release our beer products we have an expectation that our beer products will be successful in the market. Our expectation for our products and their success is based on our efforts of identifying customer needs, expected sales and profits, however to maximize our efforts and achieve our expectations our brewery should incorporate a product life cycle management plan. The stages of a products life cycle are utilized in the marketing of the product. Product life cycle stages are an important part in marketing by identify the ideal timeframe for advertisements, price reductions, identifying newer markets, as well as developing packaging or redesign of packaging (Segal, 2019).

The stages of a products life cycle are the support from creation or development all the way through the final stage. Lifecycle management provides a foundation of key data to support management and their strategies, as well as the needs of the product during the lifecycle. This key data provided by product life management will be essential for our brewery and how successful our products will be in the market. Our brewery’s beers will need to successfully transition through these product life cycle stages to meet our company’s goals and milestones. Our products will transition through the introduction stage, growth, maturing, and then finally the decline or removal stage.

There are advantages and disadvantages of each of these stages and our brewery will have to recognize and realize these advantages and disadvantages. To ensure the success of the Beered Guys Brewing company we will need a product life cycle that will provide our company and management staff solutions to problems or concerns we will encounter. Our management staff has to realize and understand how our products move through our production process as well as the supply chain to effectively create a product lifecycle management plan.

A) Life Cycle

The main focus of most production firms such as breweries is customer satisfaction, after all it is largest contributors to a brewery’s success. Specifically, a brewery’s process of acquiring and utilizing materials to produce beer products and how supply chain management plays an important role in the entire process. For our brewery an effective and efficient use of supply chain management will play a vital role in our company’s success. To optimize our supply chain and its effectiveness the goal will be to reduce our costs as well as improve our speed of delivering our product to customers and the market. A company should focus on reducing bottlenecks of inventory as well as attempting to reduce cost (Taylor, 2018).

Our brewery will utilize supply chain management to create a distribution network in our state. Our supply chain is production ingredients such as hops and barley purchased from farmers. This established relationship with farmers creates a sound supply of essential ingredients needed for production. Additionally, our relationships with farmers will give us the opportunity to purchase larger quantities of materials at a lower cost to improve our profitability. The benefit of a steady supply of materials will enable our brewery to meet the market demands as well as consistently maintaining a greater profitability. If our brewery experienced any interruptions or difficulties in our supply chain it would most certainly affect our customer’s experience and or satisfaction in regards to the availability of our product.

Because our brewery uses a distributor that has a well-established distribution channel throughout the state of Georgia, our products are available throughout a very large geographic area. This benefit will prevent the loss of sales as well as extending our marketability throughout a large geographic area. Additionally, the benefit of partnering with a well-established distributor will assist in our inventory management and our products lifecycle plan. Our brewery’s products will have a lifecycle with stages that our products will need to go through on their way to the market. Additionally, these stages could overlap one another. It is possible for products to enter another stage before completing the prior stage. Overlapping of stages can decrease the timeframe needed to move products throughout their lifecycle, which can lead to cost savings as well as competitive advantages (Stevenson, 2018).

The beginning stage of a product’s lifecycle is the introduction stage. In this stage products are developed and then delivered to the market. The purpose of the introduction stage is to effectively deliver value to consumers by meeting their expectations and needs, while attempting to maintain an appropriate level of return on investment (Levitt, 1965). The introduction stage is typically more costly to a company as well as the most demanding of all of the products lifecycle. Within the introduction stage there are 5 sections; creation validation, conception and specification designs, product testing, then production. This stage also results in slow sales due to the early market exposure. Our brewery can expect to spend capital to bring new products to market. This is another justification of utilizing our taproom to gain consumer views and opinions of new products or flavors we are developing.

Our brewery’s growth stage will start after our beer products successfully transition through introduction as our products are more widely recognized by consumers. As consumer demand increases so does the market, which is referred to as the takeoff stage (Levitt, 1965). It is essential for our brewery to increase market share to improve revenues to ensure the success of products to transition into and through the growth stage. As with most business models we hope our beer products will stay in this stage the longest. Within this stage a consistent improvement of growth will result in a greater level of production, which in-turn can offer a lower cost of production. In this stage our management staff will need to be fully aware of our products’ potential of failing and may call for the product’s exit of the market. Being too hopeful of a products success and too slow to exit unsuccessful products could prove to be costly to our business. One of the key elements of our beer products success will be marketing, which will hopefully increase product awareness. Improving consumer awareness will most likely result in increasing production as well as profitability.

During the maturity stage our beer products will begin to slow, stall, and or begin to slightly decline. It is common that this stage of the lifecycle to be the longest. As demand begins to level off future growth is typically limited to product replacement (Levitt, 1965). Considering the large amount of competitor products in the market, our brewery will need to make strategically sound decisions with regards to the amount of time products stay in the maturity stage. Leaving products in this stage too long could significantly affect our brewery’s profitability, as we may need to reduce price points to remain attractive in the market. Our brewery’s profitability can also be affected due to increasing marketing efforts to improve sales, which may not be effective. If our brewery found our company in this situation, strategically it would be ideal for our company to minimize the cost of production or to use a portion of our revenues for product development.

The last stage of the lifecycle is the decline stage. In this stage beer product sales have begun to consistently decline. Because of the consistent decline of revenue, the production of a beer product may no longer be a viable option to manufacture the product any longer (Levitt, 1965). Return on investment from a product during this stage may suffer greatly and the beer product should be discontinued. Management of a product’s lifecycle uses a series of activities that assists the development of the product during the lifecycle itself. Our brewery will certainly need our products to be very successful during the introduction and growth stages to ensure the success of our company.

When the Beerded Guys Brewing company brings to new beers to the market the development phase is vital as this is the stage where ideal strategies should be created. Ideally, our brewery can gain customer feedback in our taproom before mass production begins. Additionally, we can also identify processes to improve production methods or processes as well as profitability. In this stage our brewery should not be confined to a timeline. However, we should focus on vital aspects of the development of a product and maximizing the introduction efforts of the product.

Typically, breweries use financing to maintain a beer product through the introduction stage and then promotion within the growth and maturity stage. However, additional financing of a beer product in the growth and maturity stages might come from sales. During this stage financing concentrations should be re-invested to continue promotion to increase market expansion, which will continue to fuel growth. During the declining stage financing efforts of a product should be reconsidered to maintain profitability.

Along a beer product’s lifecycle, a brewery should monitor marketing efforts and maximize or reduce these efforts depending on which stage the product is in. It is possible for consumers in the marketplace to change their views of products, this is important to our brewery. Our brewery can possibly improve consumers view through marketing efforts or our brewery can minimize loss by removing a product from the market to prevent tarnishing the overall brand. Additionally, a good strategy for our brewery could be during the growth stage of one beer product to move an additional new product through the introduction stage. This strategy could be beneficial as the financial benefits of the product in the growth stage could assist in supporting the newer introduced product’s needs. Our brewery would also be able to benefit market exposure of the product in the growth stage to assist the newly introduced product to gain consumer traction within the market.

B) Profit Generation

When a beer product is introduced in the market, it is typical for revenues to be low during the early stages. The break-even point is particularly important during this stage, because for a period of time during this stage the revenues may not be enough to break-even. During the later phases of this stage our beer products will begin to increase recognition among consumers, which will result in increasing revenues and profitability (Levitt, 1965). Again, referring to the break-even point may play a vital role in assisting in identifying how a product moves through the introduction stage to the growth stage. During the growth and maturity stage will be where our brewery will identify the most profitability. This is typical, because as production increases, the cost-per product will decrease as larger quantities of a raw materials yield a greater cost break. Profitability can also improve due to improving manufacturing and delivery processes.

Our brewery’s CSR program and sustainability efforts will also assist in streamlining our manufacturing operations will in-turn will assist in decreasing our products break-even points (Simple-PDH, 2017). As these operational efficiencies lead to lower break-even points, this in return also gives our products a competitive advantage to allow our products the ability to remain in the introduction stage for a longer timeframe because minimal financial loss is realized. Our sustainable improvements may additionally lead to lowering our price point to increase how quickly new products can enter and exit the launch phase into the growth stage.

D) Phase-out Plan

The phase-out stage of the manufacturing process is vital and is often missed by a company’s management staff. For the Beerded Guys Brewing our phase-out process assist our company in maintaining the brewery’s sustainability, protecting our profitability, as well as adding value to our brand without letting stagnant product to diminish the overall value of our brand. This will require our brewery to continue to add creative and flavorful beers into the market when specific products have declined in the market. This phase-out stage will require us to no longer manufacturer certain products, which will require some progressive steps in order to be successful.

The starting point of phasing out a beer product will be planning the product’s exit from the market. This is an important part of this stage as many of our brewery’s key relationships and external stakeholders such as, vendors, distributors, and customers will require a well-planned exit. An abrupt exit of a product not due to contamination or cause for a drastic exit will most certainly affect customers, retail locations, distributors, and vendors in an unexpectedly, specifically financially. Therefore, a well-developed plan and exit strategy will be needed. Our brewery will notify vendors and distributors one year in advance of a products exit from the market. This will create a dual benefit for our business model as well as our vendors and distributors, by minimizing loss and allowing for future planning of the reduced production.

This planning phase also enables our brewery to slowly sell the remaining product combined with reducing down raw material ordering in an attempt to maximize profitability. This will lead us to the second point of phasing the beer product out, by actually ceasing production. Considering our business model and remaining raw materials can be utilized for existing products as well as the creation of newer products or flavors. During this phase our management staff should ensure to collaborate with distributors and vendors that all marketing materials for the phased-out product have been removed from the market to prevent mis-communication to consumers.

One additional benefit to our business model is the opportunity to temporarily phase-out seasonal products to re-introduce them later to improve our brewery’s ability to offer unique value to our customers. An example of this is offering unique seasonal flavors such as a pumpkin or winter ale that receives good customer feedback and strong sales. In this particular type of scenario our brewery can temporarily phase-out these products to bring back to the market at a later date. One way to ensure this is done effectively and efficiently is acquiring phase-out feedback from our vendors, distributors, as well as our customers. This follow-up would be considered the last phase of our brewery’s phase-out stage and is essential data that our brewery must utilize. By using key follow-up data will allow our brewery to improve our product lifecycle management for permanent and temporary products.

(Appendix 1)

(Appendix 2)

(Appendix 3)

References

- Agnew, M. (2019). The thirsty business of beer: How breweries are confronting the industry’s water problem. Retrieved from https://growlermag.com/the-thirsty-business-of-beer-how-breweries-are-confronting-the-industrys-water-problem/

- Allen, R. (2018). Michigan grows to No. 1 in hops production outside Pacific Northwest. Retrieved from https://www.freep.com/story/entertainment/2018/02/14/michigan-hops-farms/314513002/

- Association, B. (2019). Brewers Association Releases Annual Growth Report. Retrieved from https://www.brewersassociation.org/press-releases/brewers-association-releases-annual-growth-report/

- Farmand, C. (2015). Four reasons why brewers should build a budget. Retrieved from https://www.craftbrewingbusiness.com/business-marketing/four-reasons-why-brewers-budget/

- Furnari, C. (2019). Beer Institute: Aluminum Tariffs are Hurting US Beer Industry | Brewbound.com. Retrieved from https://www.brewbound.com/news/beer-institute-aluminum-tariffs-are-hurting-us-beer-industry

- Gebers, S. (2018). Barley shortage could affect craft beer | Cronkite News. Retrieved from https://cronkitenews.azpbs.org/2018/12/14/craft-beer-barley-shortage-tied-to-climate-change/

- Jenkins, M. (2013). Beer Brewers for Clean Water. Retrieved from http://business-ethics.com/2013/05/06/1152-beer-brewers-for-clean-water/

- Jvnw.com. (2018). JVNW | BEER TANKS & SYSTEMS. [online] Available at: http://jvnw.com/beer/.

- Levitt, T. (1965). Exploit the Product Life Cycle. Retrieved from https://hbr.org/1965/11/exploit-the-product-life-cycle

- McClay, R. (2017). What is operations management theory?. Retrieved from https://www.investopedia.com/ask/answers/050715/what-operations-management-theory-and-how-can-it-help-business.asp

- Moore, J. (2009). Retrieved from https://ezinearticles.com/?Beer-Brewing-Methods-Have-Changed-Greatly-Over-the-Years&id=3275764

- Morris, C. (2019). http://fortune.com. Retrieved from http://fortune.com/2019/01/29/iot-big-data-beer-industry/

- Nicastro, S. (2016). How to Start a Craft Brewery – NerdWallet. Retrieved from https://www.nerdwallet.com/blog/small-business/how-much-does-it-cost-to-start-a-craft-brewery/

- Siebenthal, C. (2014). Learn the Step-by-Step Process Of Brewing Beer. Retrieved from https://firstwefeast.com/drink/learn-how-to-brew-beer-with-these-fun-animated-gifs

- Slate, A. (2018). Critical Path Method: A Project Management Essential. Retrieved from https://www.wrike.com/blog/critical-path-is-easy-as-123/

- Snider, M. (2018). The year in beer: Cheers, there’s more than 7,000 breweries operating in the US.Retrieved from https://www.usatoday.com/story/money/business/2018/12/18/craft-beer-expands-more-than-7-000-breweries-us/2206013002/

- Sba.gov. (2018). SBA Business Loan Information for Veterans | The U.S. Small Business Administration | SBA.gov. [online] Available at: https://www.sba.gov/offices/district/pa/pittsburgh/resources/sba-business-loan-information-veterans

- Teotonio, I. (2017). How spent grain, used to make beer, gets repurposed | The Star. Retrieved from https://www.thestar.com/life/2017/10/05/how-spent-grain-used-to-make-beer-gets-repurposed.html

- Segal, T. (2019). How Product Lifecycle Management (PLM) Works. Retrieved from https://www.investopedia.com/terms/p/product-life-cycle-management.asp

- Stevenson, W. J. (2018). Operations management (13th ed.). New York, NY: McGraw-Hill Education.

- Sustainability in New Product Development. (2017). Retrieved from https://simple-pdh.com/sustainability-in-new-product-development/

- Taylor, E. (2018). Differences in Supply Chain Designs for a Manufacturing Industry vs. a Service Industry. Retrieved from https://smallbusiness.chron.com/differences-supply-chain-designs-manufacturing-industry-vs-service-industry-14610.html

- Watson, G. (2018). Craft Beer Industry Faces Multiple Challenges, Issues in Marketing and Public Relations. Retrieved from https://today.ttu.edu/posts/2018/05/craft-beer

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: