Contact Lens: Materials and Manufacturing Processes

Info: 3783 words (15 pages) Dissertation

Published: 29th Sep 2021

Tagged: MedicalManufacturing

Abstract

As an extensively used vision correction device, the contact lens is a type of soft matter that improves people’s quality of life. Although not popular until the 20th century, the theory of the contact lens has been developed since the 16th century. The first practical version was made from glass. Then, different types of materials, especially polymers were widely researched and utilised in research and productions. There are two major types of the contact lens in today’s market: soft contact lens made from hydrogel and the rigid contact lens that is not flexible. The former has highly hydrophilic structure whilst the latter tend to be hydrophobic. The materials and manufacturing processes are discussed in this report, along with the development of techniques and evolvement of materials.

Introduction

As an alternative to glasses, the contact lens is a portable, lightweight lens that can be applied directly on the eye to correct visual defects. There are two major types of contact lenses: soft contact lenses and rigid contact lenses and they are both made of polymers (Efron, 2010). As a widely accepted and used product, its invention was in the 20th century. However, the concept and prototypes of contact lenses can be dated back to 16th century.

Contact lenses are extensively used globally by an increasing number of people, which was 125 million wearers worldwide (Barr, 2004). The contact lens market value was estimated around 7.2 billion USD and the growth rate of sales in 2016 was near 5% (Nichols, 2017). It is also a growth industry in Australia whose market value is around 41 million AUD in 2016 and has experienced solid growth over the past five years (Allday, 2017). The major players in contact lens industry are Johnson & Johnson Services, Inc., Alcon, CooperVision Inc., and Bausch & Lomb Inc.

Although the public acceptance of contact lens is rising, its potential health risk has been a major concern of users since its invention. Keratitis is a severe eye infection that is significantly associated with wearing contact lenses and could cause corneal injury (Dart, 1988). The pathogens could come from contaminated contact lens solution or simply from the air (Chang et al., 2006). Dry eye syndrome is also common among contact lens wearers. Therefore, high standards, strict regulations should be followed to ensure the safety of products.

In this report, a brief history of contact lenses is introduced. In addition, the development of materials and technologies in this area are reviewed and concluded. The manufacturing process of two major types of contact lenses is elaborated in the result and discussion. At the end of the report, the conclusion of the research will be given.

Result and Discussion

1. Historical perspective of contact lens

The primary principle of the contact lens was introduced by Leonardo da Vinci in 1508, he suggested that the corneal power could be altered by immersing the eye in a bowl of water (Heitz and Enoch, 1987). Later, René Descartes invented a tube with glass lens which could be directly attached to the eye in 1636. This device was improved by Thomas Young in 1801 who designed an eyecup that was filled with fluid and allowed the wearer to blink (Young, 1801). In 1845, Sir John Herschel came up with suggestions that were close to modern contact lens: attach a spherical glass filled with animal jelly to the eye or create a mold of the cornea and impress it on transparent medium (Herschel, 1845).

In 1888, there was a few researcher who individually reported their inventions of glass scleral contact lens, including Adolf Eugene Fick, Eugene Kalt and August Muller (Pearson, 1989). However, these lenses were in the clinical trial stage and there was no breakthrough in the following 50 years until 1936. Thanks to the introduction of polymethyl methacrylate (PMMA), contact lenses became lightweight and easy to fabricate with lathing technique. Moreover, PMMA was considered inert to the eye. Nevertheless, the contact lens was not popular until the development of corneal lenses, which are called rigid lenses today. However, the disadvantages of that lens were also obvious: It could cause corneal damage since PMMA was hard plastic, and it could easily come off, causing troubles to wearers (Efron, 2010).

Inspired by the research of hydrogels, Otto Wichterle developed soft lenses using hydroxyethyl methacrylate (HEMA) for biocompatibility and comfort it provided. It soon became successful in the market and it was then improved by making the lens thinner and have higher water content, which makes the lens more air permeable and biocompatible (McMahon and Zadnik, 2000). At the same time, researchers also managed to improve the biocompatibility of rigid contact lens by changing the material to polysiloxanylalkyl ester and added in other ingredients such as styrene (Gaylord, 1974).

As wearers constantly complained the complications and discomfort of wearing contact lenses for a long time, ophthalmologists found that regular lens replacement was beneficial for patients (Holden et al., 1985). However, the cost of lenses was too high to be practical for the majority of patients. A low-cost manufacturing process: moulding process was developed by a group of Danish ophthalmologists and engineers. This technology was purchased by Johnson & Johnson and Acuvue lens, a weekly-replacement product was released to the US market in 1988 and soon became successful worldwide. The developments in manufacturing process finally lead to the release of daily disposable lenses in 1994 when Award and Johnson & Johnson introduced to their daily disposable lens products into UK and USA respectively.

Researchers have always been focusing on improving the oxygen permeability of the contact lens. Silicon hydrogel is the latest type of the contact lens that provides better comfort and eye health for wearers. In 1998, CIBA Vision and Bausch & Lomb introduced their silicone hydrogel lenses to the market and have become the 1st choice of wearers, which was 67% in 2016 (Nichols, 2017). Although it is the most advanced type of contact lenses, most wearers still could experience dryness and discomfort (Fonn and Dumbleton, 2003).

In conclusion, the pursuit of contact lenses never stopped since the 16th century. The development of contact lenses reveals the fact that the human comfort and the impact on health are the two greatest concern in the research of contact lens. In order to achieve these goals, different types of materials have been tested and the composition of polymers has been constantly adjusted to achieve greater oxygen permeability, flexibility, and comfort for wearing. Moreover, disposable contact lenses were developed to alleviate the negative impacts on eye health. The manufacturing processes were constantly improved so that the cost of lenses could be affordable for wearers.

2. Soft Contact Lenses

Soft contact lenses are medical devices with great biocompatibility that can improve wearer’s visions. They are widely accepted and fitted globally for the clear vision and great comfort they provide. In this section, a brief introduction of the materials, optics and manufacturing process of soft contact lenses is given.

2.1 Soft Lens Materials

Soft contact lenses are made from polymers. Polymers are large molecules formed by polymerization reactions of multiple repeating units which can be synthetic or biomolecule. The softness and flexibility of soft lenses are because they are made from a particular type of polymer – hydrogel. The most significant difference between the hydrogel and other polymers is that the hydrophilic structure of hydrogels has the ability to take up a large quantity of water, which allows the product to be biocompatible and tailored mechanical strength (Ahmed, 2015).

There are several properties of hydrogel that are critical for contact lenses products, including optical transparency, mechanical properties, surface properties, water content and oxygen permeability etc. (Efron, 2010). These factors affect the optical and mechanical properties of soft contact lenses. They are determined by the types of monomer, degrees of polymerization, the thickness of the lens and other ingredients.

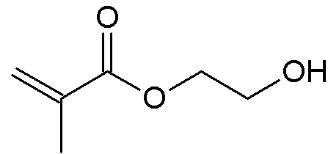

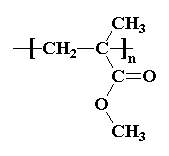

Poly(hydroxyethyl methacrylate) or pHEMA, is the earliest and the most widely used monomer in the production of conventional hydrogel contact lenses. The structure of monomer can be found in Figure 1. The hydroxyl group at the end of the molecule is mainly responsible for the hydrophilicity of the polymer. According to Efron and Brennan, the in vivo water content of HEMA soft lenses is around 40% and dryness of the eye is relevant to water content (Efron and Brennan, 1988).

Copolymers of HEMA were then added to achieve higher water content. The most commonly used one is N-vinyl pyrrolidone (NVP). The amide structure in the NVP molecule can form hydrogen bonds with water, resulting in higher water content in the gel matrix. The copolymer of HEMA and NVP is known as HEMA/NVP copolymers.

Alternatively, NVP can form a copolymer with hydrophobic monomers such as methyl methacrylate (MMA), which is also the monomer of the rigid content lens. Their copolymer MMA/NVP is able to achieve greater water content (70%) compared to pHEMA with the same order of flexibility (Hosaka et al., 1980). Nevertheless, there are obvious defects of this copolymer such as greater level of bacteria deposit (Miller and Ahearn, 1987) and protein build up (Hosaka et al., 1983).

As mentioned in previous sections, Gaylord developed silicon rubber with higher oxygen permeability. The monomer was tris(trimethylsiloxy)-methacryloxy-propylsilane (TRIS) (Gaylord, 1978). The products in the market are based on TRIS material which is presumably the copolymer of TRIS and hydrophilic monomers such as NVP.

2.2 Soft Lens Optics

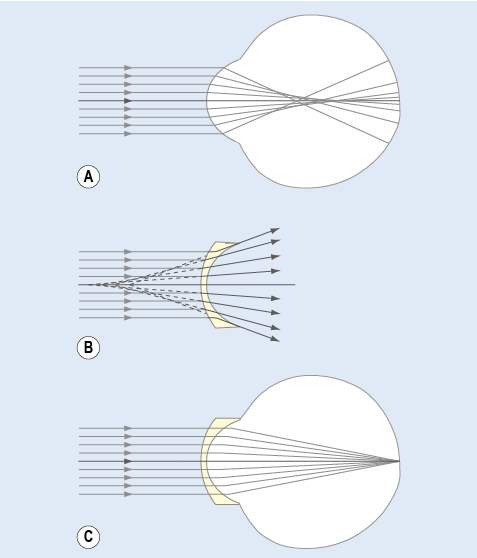

Soft lenses are extensively used in the correction of myopia or short-sightedness. As shown in Figure 2A, when the focus of the eye is in front of rather than on the retina, patients cannot see the distant objects clearly. Soft lenses are concave lenses that can diverge the light received by the eye. Therefore, the combination of a proper lens and the eye can correct myopia by compensating the positive spherical aberration and direct the light right on the retina (Efron, 2010).

Figure 2. Balancing the positive spherical aberration of a myopic eye with a negative lens

2.3 Soft Lens Manufacture

There are three major processes that are used in the manufacturing of soft lenses: lathe cutting, spin casting, and cast moulding.

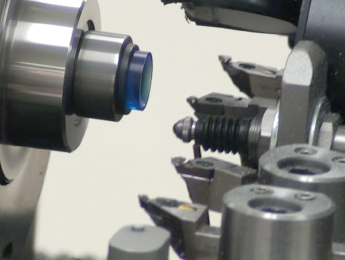

In lathe cutting, the anhydrous polymer is firstly cut to small buttons with required diameter. Then the first surface of the lens is cut by lathe tool to the required curvature. After one side is finished, the button is transferred to another lathe to cut the other surface. Both sides are carefully polished to remove any edge before it is soaked in saline solutions to hydrate the lens. Each lens is properly sealed in a glass vial and undergoes sterilization process in 120 °C for approximately 20 minutes to kill any potential pathogens in the final product. However, it is a labour intensive and high-cost process that is not suitable for bulk production.

Figure 3. Lathe cutting of a soft lens

Instead of mechanical cutting, spin casting is a method to produce contact lenses by centrifugal force. As Figure 4 shows, the monomer liquid is injected into a spinning mould (Menicon, 2017). When the mould rotates at a stable rate, the polymerization reaction is initiated by either heat or ultraviolet light (Buazza, 1999). The shape of the base curve is formed by centrifugal force whilst the shape of the front curve is determined by the mould (Neefe, 1983). After taken from the mould, lenses need to be rehydrated before packaging. Overall, this process has high throughput and lower manual cost. However, due to the complexity of equipment design and modelling, it is not widely used yet.

Figure 4. Spin casting for contact lenses

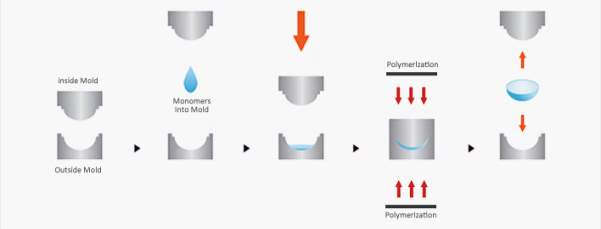

The most dominant manufacturing process of soft lenses is cast moulding. As shown in Figure 5, there are two parts of the mould: anterior (or inside) and posterior (or outside) mould. The monomer is added into the posterior mould and it is then capped with anterior mould, forming a curved shape of the lens (Morrill, 1998). The polymerization is initiated by ultraviolet light as the mould travels along the production line and the lens hardens. After careful inspection, the lens is hydrated and ready to package.

Figure 5. Cast moulding of contact lenses

3. Rigid Contact Lenses

Although the popularity has been declining over the past few decades due to high production cost and pricing, rigid contact lenses once played an important role in the development of the contact lens. In this section, the materials, optics and production of the rigid contact lens are briefly introduced.

3.1 Rigid Lens Materials

Poly(methyl methacrylate) or PMMA, is a thermoplastic that is widely used in rigid lens productions. It is an ideal material for lens since it has great transparency and is easy to fabricate. However, soon after the popularization of rigid lenses, practitioners soon noticed that the low oxygen permeability of PMMA lenses would affect the normal functions of the eye, causing dryness, redness and corneal edema (Holden and Mertz, 1984). Therefore, a lot of methods were researched and developed to improve the oxygen permeability along with the searcher of better materials.

Figure 6. Structure of PMMA

As delineated in Chapter 2.1, Gaylord successfully developed the commercial silicon rubber known as TRIS that was widely used in rigid lenses, which was a breakthrough of oxygen permeable lens. Later, researchers found that by adding fluoroalkyl acrylate into silicone rubber, the permeability and rigidity of the material could be significantly improved (Ichinohe et al., 1984). At the same time, another group of Japanese researchers found the copolymer of MMA and fluorine-containing was also oxygen permeable and had great hydrophilicity (Kawamura et al., 1985). With these developments available, oxygen permeable rigid lenses were commercially produced and introduced to the market.

Nowadays, most of the rigid lenses in the market are still made from siloxane based polymers, most of which are copolymers of siloxy-fluromethanc or siloxy-methac-itaconate (Efron, 2010).

3.2 Rigid Lens Optics

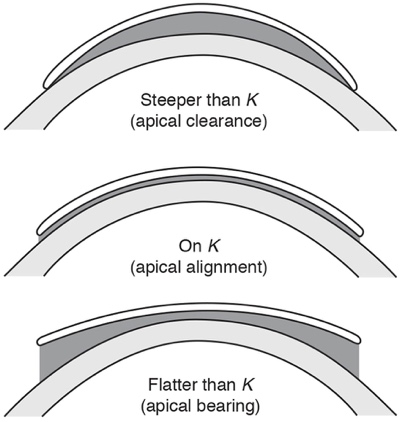

As the name suggests, a rigid lens is not flexible or elastic as a soft lens. Consequently, a layer of fluid will present between the lens and the cornea as shown in Figure 7, which is also called a tear lens. Its shape and thickness are determined by the curvature of the lens and the corneal. Therefore, it must be taken into account when fitting the rigid lens in order to determine the exact compensation required. Apart from that, the correction theory of rigid lenses is the same as soft lenses.

Figure 7. Demonstration of tear lens created by a rigid lens

3.3 Rigid Lens Manufacture

Since rigid lens are made from hard, glassy materials, the most used method of producing them is lathe cutting. As delineated in Chapter 2.3, polymer buttons are cut by lathing tool to create front and back surfaces of the lens. However, rigid lenses can often be customized such as engraving. These steps are controlled by computers, which allow manufacturers to adjust as they wish. Polishing is an important step in rigid lens manufacture, inspections must be performed thoroughly. The final product can be packed either in solutions or dry.

4. Conclusions

The contact lens is a typical application of soft matter in the biomedical field. A brief history of the contact lens development is given, showing the important theories, persons, materials and products involved in the development of contact lenses. The materials and manufacturing processes have constantly evolved to create greater comfort for wearers, reduce cost and increase production efficiency. Soft and rigid contact lenses are two major types of products in the market. They are intrinsically different since different types of polymers are used. Future development is needed to eliminate the complications and discomfort associated with contact lens wearing.

5. References

AHMED, E. M. 2015. Hydrogel: Preparation, characterization, and applications: A review. Journal of Advanced Research, 6, 105-121.

ALLDAY, A. 2017. IBISWorld Industry Report: hotographic and Optical Goods Manufacturing in Australia. Melbourne.

BARR, J. T. 2004. 2004 Annual Report [Online]. ContactLens SPECTRUM Available: http://www.clspectrum.com/issues/2005/january-2005/2004-annual-report [Accessed 17 Apr 2017].

BUAZZA, O. M. 1999. Methods for eyeglass lens curing using ultraviolet light. Google Patents.

CHANG, D. C., GRANT, G. B., O’DONNELL, K. & ET AL. 2006. Multistate outbreak of fusarium keratitis associated with use of a contact lens solution. JAMA, 296, 953-963.

DART, J. 1988. Predisposing factors in microbial keratitis: the significance of contact lens wear. British journal of ophthalmology, 72, 926-930.

EFRON, N. 2010. Contact lens practice, [Oxford] : Butterworth-Heinemann/Elsevier, 2010. 2nd ed.

EFRON, N. & BRENNAN, N. A. 1988. A survey of wearers of low water content hydrogel contact lenses. Clinical and Experimental Optometry, 71, 86-90.

FONN, D. & DUMBLETON, K. 2003. Dryness and Discomfort with Silicone Hydrogel Contact Lenses. Eye & Contact Lens, 29, S101-S104.

GAYLORD, N. 1974. Oxygen-permeable contact lens composition, methods and article of manufacture. Google Patents.

GAYLORD, N. G. 1978. Method for correcting visual defects, compositions and articles of manufacture useful therein. Google Patents.

HEITZ, R. & ENOCH, J. 1987. Leonardo da Vinci: An assessment on his discourses on image formation in the eye. Advances in Diagnostic Visual Optics, 19-26.

HERSCHEL, J. 1845. Encyclopaedia Metropolitana, B. Fellowes.

HOLDEN, B. A. & MERTZ, G. W. 1984. Critical oxygen levels to avoid corneal edema for daily and extended wear contact lenses. Investigative ophthalmology & visual science, 25, 1161-1167.

HOLDEN, B. A., SWEENEY, D. F., VANNAS, A., NILSSON, K. T. & EFRON, N. 1985. Effects of long-term extended contact lens wear on the human cornea. Investigative ophthalmology & visual science, 26, 1489-1501.

HOSAKA, S., OZAWA, H., TANZAWA, H., ISHIDA, H., YOSHIMURA, K., MOMOSE, T., MAGATANI, H. & NAKAJIMA, A. 1983. Analysis of deposits on high water content contact lenses. Journal of Biomedical Materials Research Part A, 17, 261-274.

HOSAKA, S., YAMADA, A., TANZAWA, H., MOMOSE, T., MAGATANI, H. & NAKAJIMA, A. 1980. Mechanical properties of the soft contact lens of poly (methyl methacrylate‐N‐vinylpyrrolidone). Journal of Biomedical Materials Research Part A, 14, 557-566.

ICHINOHE, S., TAKAHASHI, K. & TANAKA, Y. 1984. Oxygen permeable hard contact lens. Google Patents.

KAWAMURA, K., YAMASHITA, S., YOKOYAMA, Y. & TSUCHIYA, M. 1985. Oxygen-permeable hard contact lens. Google Patents.

MCMAHON, T. T. & ZADNIK, K. 2000. Twenty-five years of contact lenses: the impact on the cornea and ophthalmic practice. Cornea, 19, 730-740.

MENICON. 2017. Miru 1 day Menicon Flat Pack [Online]. Available: https://www.menicon.com/pro/our-products/soft-lens/1day-miru/ [Accessed 19 Apr 2017].

MILLER, M. J. & AHEARN, D. G. 1987. Adherence of Pseudomonas aeruginosa to hydrophilic contact lenses and other substrata. Journal of clinical microbiology, 25, 1392-1397.

MORRILL, T. J. 1998. Method of cast molding contact lenses. Google Patents.

NEEFE, C. W. 1983. Spin casting of contact lenses. Google Patents.

NICHOLS, J. J. 2017. Contact Lenses 2016 [Online]. Contact Lens SPECTRUM. Available: http://www.clspectrum.com/issues/2017/january/contact-lenses-2016 [Accessed 17 Apr 2017].

PEARSON, R. M. 1989. Kalt, keratoconus, and the contact lens. Optometry & Vision Science, 66, 643-646.

YOUNG, T. 1801. The Bakerian Lecture: on the mechanism of the eye. Philosophical Transactions of the Royal Society of London, 91, 23-88.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Manufacturing"

Manufacturing describes the process of using raw materials to produce goods. Manufacturing involves workers making use of heavy machinery, tools, and other resources throughout the process.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: