STEP/STEP-NC as a Solution for Data Interoperability in the CAx Chain

Info: 7335 words (29 pages) Dissertation

Published: 16th Dec 2019

Tagged: Computer Science

STEP/STEP-NC as a solution for data interoperability in the CAx chain

Since the arrival of the first Numerically Controlled (NC) machines in the 1950s, there have been many advances in CAx system capabilities. In this competitive market, a number of different CAx systems have been developed. As a result, data interoperability between different systems, and also between CAD/CAM/CNC has become a substantial issue, preventing manufacturers from realising their full production capacity. A key inhibitor in allowing for data exchange between CAD/CAM/CNC is the outdated use of G-code (ISO 6983) in the programming of CNC machines. Research has been undertaken on the use of a neutral data format as a solution to address this interoperability issue. This article will first provide an introduction to STEP/STEP-NC. A discussion on the most recent research and developments on STEP/STEP-NC are then provided. Developments on STEP-NC include some international-level projects as well as projects carried out by research groups in countries such as Germany, Switzerland, UK, Korea, USA, and New Zealand. Finally, conclusions made from the research, and suggestions for future work are outlined.

Keywords: interoperability; data exchange; STEP; STEP-NC

1. Introduction

Considerable advances in the manufacturing industry have been made over the last 50 years with the support of CAx systems (CAD, CAPP, CAM, etc) and CNC tools. Due to the increasing number of CAx systems developed by different vendors, product data exchange (PDE) between different CAD systems has become very common. Different companies prefer to use different CAD systems; there is even variation in the CAD systems used within a company. Rapid growth has resulted in collaborative design becoming more common in the product development process as part models and drawings are often passed back and forth between designers and manufacturers at various phases of a product lifecycle and across global networks. Difficulty in this data exchange as well as the transfer of data from CAD to CAM to CNC arises from the substantial differences in which parts are defined on different systems – often in the conversion process of a CAD model from one system to another, some geometry can be lost or inaccurate. According to Brunnermeier and Martin (2002), imperfect interoperability or model transfer between CAD packages costs about $1 billion a year in the US automotive industry alone. This cost of poor interoperability is primarily from the time spent looking for the issues, and fixing CAD data translations.

For manufacturing companies to be able to stay competitive and adaptable in a market with frequent and unpredictable changes, data interoperability along the manufacturing supply chain needs to be realised. Robust data exchanges could reduce the development time and overall cost of a product significantly. The continued use of G-codes (ISO 6983) with vendor specific formats by CNC machines for part programming is seen to be a serious impediment in truly obtaining flexible and interoperable CNC machines (Xu et al. 2006). A potential solution is to have a common neutral language for the whole product development process for use among multiple systems to describe the design, manufacturing, and other necessary product data. International Standards Organisation (ISO) developed ISO10303, informally known as STEP (STandard for Exchange of Product model data) in an attempt to overcome the data interoperability issue (Xu and He 2004). STEP is hoped to be able to aid in the integration of different systems at various stages of the product development process.

This paper discusses the current research activities on CAD interoperability with a focus, particularly on STEP/STEP-NC. The advantages, drawbacks, and possible opportunities of STEP/STEP-NC are reviewed.

2. Interoperability in the CAx chain

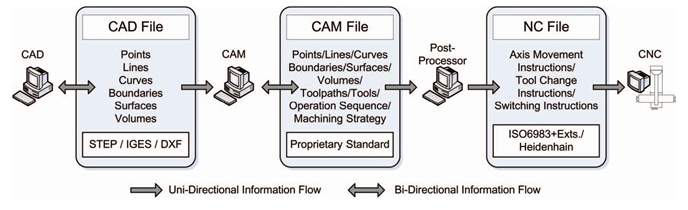

The information flow in a product development manufacturing chain is shown in Figure 1. A 3D model of the product is created using CAD. The product design information such as surface and volume definition and boundaries are stored in a CAD file. Most commercial CAD packages allow this CAD file to be exported into neutral data formats such as IGES, DXF, and STEP. The CAD file containing the design data is then passed onto a CAM software package where information regarding the sequence of operations and tools is added to the design data by the user. This information is used to determine the toolpath appropriate for machining the part. The information output is stored in a proprietary CAM file format.

This CAM file is then inputted into a postprocessor which uses the CAM file tool paths to produce machine specific instructions for axis movement and tool change and coolant control operations. An NC file is generated from the postprocessor, which usually follows G-code (ISO 6983) format.

Figure 1 CAD-CAM-CNC information flow (Nassehi et al. 2008)

The data format used at the machine level is seen to be the obstacle in obtaining interoperability in data transfer between CAD/CAM/CNC systems. This data format results in data loss during the product development process, single direction data exchange and static and non-synchronous data exchange (Bianconi et al. 2006). Machine tool capabilities have improved radically while, over the last 60 years, CNC machine tool programming has remained the same with the use of G-code (Živanović and Vasilić 2017, Hardwick et al. 2013). G-code focuses on describing the tool path with respect to the machine axes rather than the machining tasks to produce a part. The CAD data is not used by the machine tool but is post processed by machine-specific postprocessors to output a set of low-level incomplete machine-specific data that is very difficult to make modifications to. The output from a CAM system is inflexible, which in turn does not allow the CNC machine tools to be adaptable. In addition, G-code only supports one-way information flow – modifications made on the shop floor cannot be relayed back to the designer or to other areas of the company. For interoperability within the CAD-CAM-CNC chain to be a reality, there needs to be a system that is not reliant on a specific machining process. This system should be able to output NC programs for different CNC machines based on a complete set of manufacturing information.

In 1980, the International Graphics Exchange Standard (IGES) format was developed to provide a mechanism for the translation of data between different CAD systems (Xu and He 2004). It translates the CAD model to basic geometric data. Although successful in some applications, IGES falls short in that only geometric Boundary REPresentation (BREP) data is translated – all associative links between features are broken, and design intent is lost. In addition, due to IGES being an American National Standards Institute (ANSI) standard, translation outside the USA is difficult.

A redesign of the IGES was created in 1984 (Xu and He 2004). The STandard for the Exchange of Product model data (STEP) aims at a more database-oriented and integrated solution based on product lifecycle data. The International Organisation for Standards (ISO) developed STEP as ISO 10303 such that rather than translating data between different software systems, STEP would provide a complete computer-interpretable data format for product data.

2.1 STEP/STEP-NC as enablers of interoperability

STEP is an international standard for product data which is intended to provide a mechanism that describes a complete product definition throughout the product life cycle, independent of any particular system (Gerbino 2003, Wang and Xu 2015). STEP contains different application protocols (APs) for various types of product data (Wang and Xu 2015). The STEP-NC (AP238 and ISO 14649) standard is a result of a 10-year international collaboration to replace the G-code standard, currently under development by ISO TC184 SC1 and 4. STEP-NC builds upon the previous efforts of 10 years of developing the STEP neutral data standard and is specifically targeted towards NC programming.

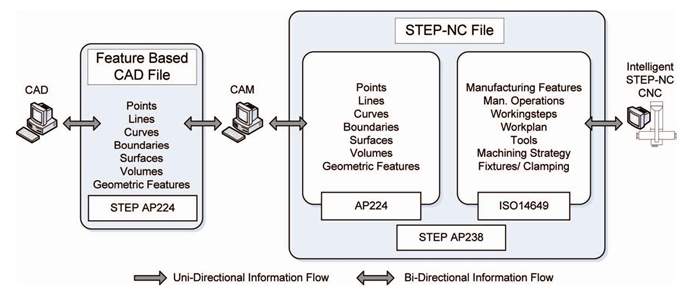

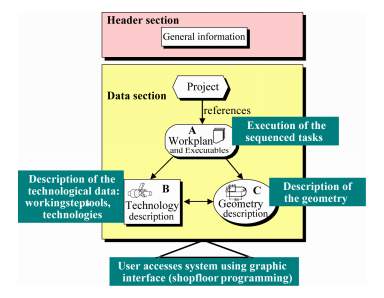

STEP-NC is an interface that has been developed for bi-directional data exchange between CAD/CAM systems and CNC systems using EXPRESS language to allow for seamless data exchange (Xu and He 2004). Figure 2 shows the information flow between CAD-CAM-CNC with STEP-NC. Comparing STEP-NC (ISO 14649) to G-code, STEP-NC differs in that it does not describe the sequence of the machining processes for a specific CNC machine tool. Rather, it is a detailed feature-based process plan describing what is to be machined instead of how to. The NC programming of a part is described as part of a project, where a range of information is defined such as the features to be machined, the workingsteps needed for each feature, and the technological requirements of each workingstep for the CNC controller (Xu et al. 2006). The working step is used to relate a manufacturing feature to an operation (Liu et al. 2006). The data structure of a STEP-NC file can be seen in Figure 3.

Figure 2 Bi-directional information flow with STEP-NC (Nassehi et al. 2008)

Figure 3 Data structure of the STEP-NC file (Živanović and Vasilić 2017)

The concept of workingsteps simplifies manufacturing processes in that a CNC machine will receive STEP-NC data and be able to interpret the information and manufacture the part with no further input required. In addition, this high-level object-oriented data model allows for programs to be transferred between different machines with no changes required as the STEP-NC file is not machine tool specific. The complete package of information about the part in the part program is delivered to the CNC machine, allowing for CNC machines to be adaptable and interoperable. The use of STEP-NC should, therefore, be able to decrease the manufacturing time as companies will be able to quickly respond and adapt to changes in design.

Two versions of STEP-NC exist and are being developed by ISO: Application Reference Model (ARM), and Application Interpreted Model (AIM) (Xu et al. 2006). ARM serves a common standard particularly for NC programming (ISO 14649), while AIM represents an object-oriented data model for CNC machines (ISO 10303-238). ARM is more likely to be used in a situation where CAM systems have exact information from the shop floor, while AIM is more suited towards a complete design and manufacturing integration. AIM contains the what to do design information such as information regarding the stock piece, its manufacturing features, tool/fixture requirements, the sequence for the manufacturing process, etc. – the manufacturing tasks are described, but how to execute them is not detailed. The AIM data is fed into a STEP-NC controller to then generate this how to do information, which may be documented in an ARM file.

3. History of research on STEP/STEP-NC based interoperable CAx manufacturing

Several research groups around the world have been developing STEP/STEP-NC since the 1990s. The global STEP-NC research has mainly been organised under an Intelligent Manufacturing System (IMS) project that brings about an international set of undertakings with researchers from the European Union, Korea, Switzerland, and USA (Xu and Newman 2006). This project is seen as an integration of a number of regional projects by different research groups in particular the European ESPRIT STEP-NC Project, the Super Model Project, the STEP Manufacturing Suite (SMS) Project, the Rapid Acquisition of Manufactured Parts (RAMP) Project, and National Institute of Standard and Technology (NIST). Partners in the EU, USA, Korea, and New Zealand are amongst the most active in performing research in this area.

The STEP-NC community in Europe focuses on milling, turning, and inspection. In Korea, research has been carried out by Pohang University of Science and Technology (PosTECH) and Seoul National University focusing on milling and turning architectures for STEP-NC compliant controllers. Loughborough University in the UK have focused their research on developing an Agent-Based, STEP compliant CAM (AB-CAM) system. The research in New Zealand has focused on creating a STEP-compliant CAPP system for collaborative manufacturing using the AIM of STEP-NC. STEP-NC research in the USA has progressed in the use of STEP (AP 238) for allowing the CAD to CNC process to be autonomous.

3.1 ESPRIT STEP-NC Project – Europe

In Europe, the ESPRIT STEP-NC project began in 1999 and concluded in 2001 (Xu and He 2004). 20 partners from both academic and industrial backgrounds with vast experience in the field were involved in the project with the goal of developing the ISO 14649 model for CNC control. The prototype for milling was completed in 2001 and demonstrated in Aachen, Germany. Commercial systems from Siemens, Open Mind, and Dassault Systems were used to base this prototype off of. CAM modules from Open Mind and Dassault Systems were used to produce the STEP-NC programs, which were then passed onto the shop floor, where a Siemens’ NC programming tool (Siemens Sinumetric 840D control and ShopMill) was modified to execute the STEP-NC programs.

This project was used by industry end-users Daimler Chrysler and Volvo with CATIA and Open Mind systems to trial the new NC programming interface. With this new interface, last minute alterations to the program sequence or geometry were able to be realised. These alterations were made at the machine tool and recorded in the STEP-NC file to guarantee no loss of data.

The work on the milling prototype has been extended to CNC turning in the development of STEPTurn software model prototype by ISW Stuttgart. This software, working with a Siemens 840 control on a Boehringer NG200 lathe, takes CAD geometry and machining features as input, determine strategies for machining and output a STEP-NC file. The controller takes this output and uses a STEP-NC import facility to translate it into the Siemens ShopTurn system.

3.2 Super Model Project – USA

The aim of the Model Driven Intelligent Control of Manufacturing (MDICM) project ie. “Super Model Project” funded by the National Institute of Standards and Technology (NIST) was the integration of the CNC model into STEP to create ISO 10303-238 (Xu and He 2004). A database was to be built using XML, containing all the information required in the product development process to make a part. This project validated STEP-NC’s ability, providing an introduction to the benefits for manufacturers in the industry.

The first two stages of this project were working towards determining whether a STEP-NC file would be informative enough for CNC machining and whether it would be able to be used on traditional CNC machinery without alterations to the system hardware. The main focus was on translators that would be able to translate a STEP AP203 or AP224 file to G-code that the CNC machine would be able to read.

The first demonstration was held in November 2000 at the Benet Laboratories of Watervliet Arsenal in the USA. This demonstration involved the use of BA Solutions’ (a CAM manufacturer) GibbsCAM STEP Translator to interpret a part in STEPAP203 format. Programming of the part was then performed using a GibbsCAM graphical user interface.

The second demonstration was in February 2002 at the Experimental Machine Tool and Plating Company Inc. in Troy, New York. The aim of the second demonstration was to demonstrate the capability of STEP-NC using an AP238 file containing all the part information needed for manufacture. This AP238 file was downloaded from the internet and then was inputted into a GibbsCAM STEP-NC Adaptor plug-in to create the appropriate toolpath without human intervention, demonstrating that STEP-NC has the ability to automate CAM processing and toolpath generation. In January 2003 at the NASA Jet Propulsion Lab (JPL) in Pasadena, California, STEP Tools Inc. alongside JPL, established the conversion of an AP203 file to AP238 (AIM version of STEP-NC). The AP238 data was then transferred to GibbsCAM, and then to a five-axis Fadal machining centre.

The third part of this project involved integrating GibbsCAM with an Open Modular Architecture Controller (OMAC) machine tool. The goal of this stage was to be able to process STEP-NC data in a CNC controller through integrating a STEP-NC interpreter into a controller that can implement the specified tasks. An AP238 file containing all the required manufacturing data was inputted into GibbsCAM to generate the tool path. This tool path information was then given to the OMAC controller on a horizontal machining centre through a “stroke-level inter-process communication” rather than G-code. This shows that OMAC API allows for a higher level of CAM/CNC integration than what is provided by G-code.

3.3 Rapid Acquisition of Manufactured Parts (RAMP) Project

The RAMP project began in 1986, with the purpose of creating application standards for electrical and mechanical manufacturing (Dalgarno et al. 2001). The implementation of STEP standard AP224 was the major milestone in this project. In RAMP, a translation of the original file to STEP AP224 files is performed by STEPTrans, a software tool, to eliminate any dependence of the file to proprietary products.

3.4 STEP Manufacturing Suite (SMS) Project

The SMS Project was coordinated by South Carolina Research Authority (SCRA) with the collaboration of countries such as Germany, Canada, UK, USA, Japan, and Sweden, and companies such as Boeing, General Dynamics Land Systems, LSC Ltd, SCRA, and STEP Tools Inc (Xu et al. 2005). The focus of this project was to define the Suite of STEP APs and the implementation architecture for STEP-enabled parts production.

4. Latest developments in STEP-NC research

4.1 Research in Korea

4.1.1 Intelligent control in STEP-NC

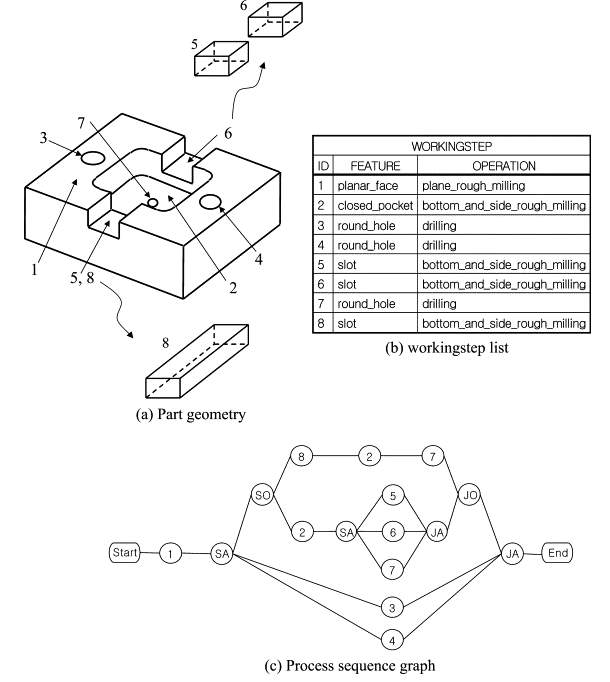

The National Research Laboratory for STEP-NC Technology (NRL-SNT) was formed by the Ministry of Science and Technology in Korea in conjunction with PosTECH. The research in PosTECH is focused on realising intelligent control in STEP-NC. Compared to G-code, STEP-NC provides the CNC machine with all the product information, thus allowing CNC machines/controllers to undergo intelligent activities such as process optimisation. An autonomous STEP-compliant CNC (ASNC) was proposed, which takes in ISO 14649 and from this, autonomously and intelligently controls the machining tasks. ISO 4649 data is converted into ASNC format, then processed into a process sequence graph (PSG) (eg. Figure 4 (c)) which represents a non-linear sequence of workingsteps in terms of machining_feature and manufacturing_operation using an AND-OR relationship. This provides a bit of flexibility for STEP-NC to be resilient to unexpected events or process sequence optimisation.

Figure 5 (a) Part geometry with multiple feature interpretations, (b) workingstep list (c) Process sequence plan (Suh et al. 2003)

4.1.2 STEP-NC in XML format

A recent trend has been to use XML (ISO 10303 AP28) rather than EXPRESS (ISO 10303 AP21) language to describe the STEP-NC data due to its ability to be used for data transfer and enable e-manufacturing. Steps to creating an XML-enabled STEP-NC enabled model for milling are being taken at the Engineering Research Centre for Advanced Control and Instrumentation (ERC-ACI) in Seoul National University (Lee et al. 2006). This data model is able to locate, extract, and archive tool paths in XML format. The milling machine used consists of an XML Data Input module, an Interpreter, a Tool Path Generator, and Motion Control Board. The Input Data module along with the Interpreter produces STEP-NC programs from CAD files; the Tool Path Generator and the Motion Control Board then generate and executes native CNC process plans. The milling machine that has been developed is PC based with an open architecture to allow for ease of modification and expansion.

An issue moving forward is a lack of a standardised XML model for STEP-NC. This will cause a variety of different formats of XML to appear from different research groups. Standardisation is, therefore, something that needs to be addressed before the benefits of XML can be realised in industry.

4.2 Research in New Zealand

4.2.1 STEP-compliant CNC machine tool

The Manufacturing Systems Laboratory at the University of Auckland has developed a STEP-compliant CNC machine to be able to run without the use of G-code in an attempt to create an intelligent STEP-NC scenario (Xu 2006). In this research, a CNC machine was retrofitted, and a STEP-NC compliant converter was developed. CompuCam’s motion control system replaced the CNC controller in the CNC machine, communicating with other CAPP/CAM programs using programming languages such as Visual Basic, Visual C++, and Delphi. With regards to the STEP-NC converter, it is able to understand and interpret STEP-NC data and communicate with the CNC controller using a Human-Machine Interface.

With the goal of STEP-NC enabled manufacturing, Native STEP-NC Adaptor, a native STEP-NC mapping system, has been developed (Wang et al. 2006). Within the adaptor, there is a native CNC system knowledge database, a translator, and a human-computer interface. The native CNC system database is the main component of the whole system as it contains all the native information of a specific CNC machine. The generic information is converted by the adaptor into the native manufacturing information for a specific machine tool to use.

4.2.2 Collaborative data exchange – DIMP

The use of STEP/STEP-NC is a potential solution to alleviate system interoperability. However, issues with synchronisation and confidentiality may arise in a cooperative context. In a cooperative environment, a number of different people involved in different aspects of the product development process need to communicate with each other for their work to be synchronous and traceable with relation to the work done by others. Confidentiality may be an issue in that the work done can be viewed by the other users. Distributed Interoperable Manufacturing Platform (DIMP) has been proposed to resolve these problems – the data integrity of STEP is combined with data confidentiality and traceability (Wang and Xu 2012, Wang and Xu 2015).

Within DIMP, there is a concept of a data packet (DP). A DP is a self-contained set of mobile data clusters. DP maintains data confidentiality by providing the right amount of data to the right people. If a specific data subset is required, the data localisation mechanism extracts and provides a file to the user. After the user is finished modifying the DP, the data integration mechanism updates the information that was modified and combines the data back with the data source. To validate and further develop the algorithms and results obtained by Wang and Xu (2012, 2015), DIMP will need to be further tested in an industrial environment to determine its feasibility.

4.3 Research in Germany

The focus of the research in Germany is in the development and implementation of STEP compliant CAPP/CAM software applications.

4.3.1 STEPTurn

The University of Stuttgart alongside Siemens has developed STEPTurn, a CAPP system linking CAD and CAM for implementing STEP/STEP-NC for turned parts (Kržič et al. 2009). The geometry information of the workpiece is read from a STEP AP203 file by STEPTurn. From this, STEPTurn performs feature recognition and defines the sequence of workingsteps and produces a STEP-NC file.

4.3.2 STEP-compliant NC controller & GUI

The WZL Laboratory at RWTH Aachen University focuses research on STEP compliant NC controls and CAM software. The first prototype of a STEP-compliant NC controller based on the Siemens 840D controller has been developed here. WZL has also developed a graphic user interface (GUI) to work with STEP-NC files using Shop Mill (an NC programming tool for the shop floor) and Sinumerik 840D HMI (Human Machine Interface) (Xu et al. 2005). This interface is able to parse STEP-NC files.

4.4 Research in the UK

4.4.1 Agent-Based CAM (AB-CAM)

The Agent-Based CAM (AB-CAM) system was developed at the Advanced Manufacturing Sciences and Technology Centre at Loughborough University (Allen et al. 2003, Allen et al. 2005). This agent-based approach generates various generic solutions while allowing for manual adjustments for preferred working methods. This system has a STEP-compliant data structure. In the system, the STEP-compliant process plan generator can select a process type, machine tool, cutting tool, cutting parameters, fixture methods, and clamping locations to output a STEP-NC file from converting a feature in AP224 format.

Future work in this area would include an intelligent approach where the agents are able to adopt the preferred planning methods. The problem in knowledge-based planning regarding the ability of the NC programmer to maintain and update the manufacturing knowledge such as changes in tool technology will also need to be addressed.

4.4.2 Cross-technology interoperability

Under the leadership of Professor Stephen Newman, work has been done in cross-technology interoperability using STEP-NC. A recent endeavour was a prototype framework for cross-technology interoperability tested by Safaeih, Nassehi, and Newman (2013) by converting a STEP-NC program written for a 4-axis milling machine to an appropriate program for a turn-mill machine. Identical results were achieved when the part was machined on both machines. With the success of this trial, future work would focus on further developing this framework for more CNC machines with different technologies and sufficient capabilities and more complex parts with complex features.

4.5 Research in Switzerland

Various vendors and institutes in Switzerland such as Starrag, AGIE, AMT, CADCAMation, EIG i-tech, Derendinger, EPFL, and Wyss are working on the development of STEP-NC (Xu et al. 2005). Most of the work has been focused on STEP-NC support for WEDM. Agie-Charmilles controllers have been used to develop a prototype STEP-compliant wire EDM system in which Solidworks has been used as the CAD system to generate solid models. AlphaCAM and a STEP-NC data generator are then used to translate the design data into STEP-NC files.

4.6 Research in the USA

In the USA, STEP-NC related research is done by three different research groups: government research institutions (NIST), small privately owned companies (STEP Tools Inc), and major companies (Boeing) (Xu et al. 2005).

4.6.1 Research by the NIST

The NIST focuses research on the development of the Feature-Based Inspection and Control System (FBICS) (Xu et al. 2005). The architecture of FBICS allows for the automatic generation of process plans and control of machining execution and inspection of parts (Kramer et al. 2001). One of the central purposes of FBICS is the validate the usability of STEP methods and models. Its implementations have demonstrated the feasibility of two-stage planning, feature-based manufacturing, and the use of A Language for Process Specification (ALPS) for process planning (Xu et al. 2005).

4.6.2 Research at STEP Tools Inc

A STEP compliant system named ST-Plan has been developed to link CAD with CAPP. A ‘STEP in, STEP out’ approach is taken to generate CNC control data that is machine independent. FBMach (Feature-Based Machining) and FBTol (Feature-Based Tolerancing) are two modules of ST-Plan – these modules are respectively used to recognise machining features and define tolerances. FBMach contains a database of machining features and algorithms for feature recognition.

4.6.3 Boeing

A variety of five-axis CNC machines are used by Boeing to manufacture complex parts. A CNC machine currently makes use of part programs based off G-code to machine a part. Boeing organised a pilot program for STEP-NC to be used to program a CNC machine rather than G-code. A Catia v5 Section 3 (CL) file was translated to a STEP-NC file, which was then converted into cutter coordinate descriptions for the specific machine configuration. This was one of the early demonstrations that was able to verify the feasibility of STEP-NC.

4.7 The FOFdation Project

The FOFdation project is dedicated to creating a next-generation commercial controller that has the ability to enable intelligent machining based on real-time information, adaptive decision making and optimisation where a number of components are combined to create a “smart factory” (Hentz et al. 2013). STEP-NC is one of these elements which is used to describe micro process plans to control the machine tool. The implementation of this has the potential in reducing manufacturing costs and improving output quality through shorter time to market from shorter production time.

4.8 The STEPMAN Project

The STEPMAN project began in November 2011 (STEPMAN Report Summary 2014). The overall aim of the STEPMAN project is to increase the competitiveness of SMEs by facilitating bidirectional communication in the CAD-CAM-CNC chain. Creating an STEP-NC compliant integrated platform that stores product design and manufacturing data, as well as knowledge of the capabilities of those in different companies or different departments in a company working on the same project, is the main objective of this project. Having this platform, where all the required data is in one place will reduce the time to market and therefore significantly increase the competitiveness of SMEs.

5. Advantages of implementation of interoperability/STEP-NC in manufacturing

Ample opportunities are associated with implementing interoperability for all of those in the manufacturing industry as described below.

- Interoperability will allow for manufacturers to use legacy data on modern and future machine tools without the need to re-plan the fixtures, tooling, and tool paths. This will allow for future parts to be produced without the need to rely on old and outdated machinery and programs.

- For manufacturers, individual workstations for specific jobs/components will not be necessary. Interoperability will allow for flexibility on the shop floor – parts will be able to be interchangeably manufactured across different workstations and CNC machines. For these manufacturers, this flexibility will minimise production delays due to bottlenecks at specific workstations, enabling more resiliency in responding to unexpected demand, and resulting in a more streamlined manufacturing process.

- For those partners working together in different regions, interoperability will allow for those involved to have confidence in the integrity of the information transferred between one another.

- With the implementation of a neutral data format such as STEP-NC, a comprehensive structured data model containing geometrical and technological information is available such that no information is lost between each of the stages of the product development process. With no data loss throughout the product development process, this allows for bi-directional data flow.

- With complete product information available at all stages of the product development process, STEP-NC allows for autonomous and intelligent CNC. Autonomy for a CNC controller involves little human control for machining tasks, while intelligent CNC controller would have the ability to optimise and self-correct.

- With the implementation of STEP and STEP-NC, it is anticipated that:

- the time to program a CNC will be 35% shorter as the tasks required to manufacture a part are easier to describe,

- the drawings sent from design to manufacturing will be 75% less as STEP-NC data self-documents,

- the time required to machine small to medium sized job orders will decrease by 50% as the CNC controller will have the ability to optimise (Hardwick et al. 2013, Xu and He 2004).

- An autonomous, intelligent system would provide standardised product information by eliminating the reliance on the experience of the machine operator, and on machining data books for repeatability and tolerancing.

6. Challenges associated with implementing interoperability/STEP-NC in manufacturing

The development of a neutral data format such as STEP-NC provides an abundance of information about the part to the CNC machine, allowing for a more robust, and interoperable control. However, a number of issues will need to be resolved before interoperability can be fully realised in the market, especially given millions of CNC machines have been using ISO 983 for a long time.

- Interoperability across the CAx system allows for the users to utilise complete product information on each stage of the product development process, regardless of the vendor of the CAx system. Most vendors have recognised the fact that interoperability results in users not being obliged to purchase solutions from a specific company to minimise compatibility issues.

- From the perspective of the end-users of CAx systems, the implementation of a new system to replace a system that has been used for over 50 years would not be easily accepted. Currently, STEP-NC is not at a stage where it is developed sufficiently enough to be able to outweigh the profitability G-code produces.

7. Concluding Remarks and Future Work

For a manufacturing company to stay competitive in today’s market, adaptability plays a major role. Interoperability within the CAD-CAM-CNC line is especially vital for achieving adaptability for those manufacturers who extensively utilise CNC machinery in their operations.

The use of neutral data formats such as STEP/STEP-NC is a feasible method to achieving interoperability and data portability. STEP-NC was created with the sole intention of changing the CAM-CNC interface to allow for interoperable data exchange. STEP-NC entails a single database containing all the CAD/CAM/CNC data for each CAx system or NC controller to have access to. Implementation of STEP-NC into the CAD-CAM-CNC chain will allow for bidirectional information flow; the knowledge gained on the shop floor can be fed back to the initial stages of the process which will reduce production cycle time and cost.

A number of sources have been consulted to gain an in-depth understanding of the current state of STEP-NC in industry. This paper has reviewed the STEP-NC related research performed by different research groups around the world. The research performed has shown that STEP-NC provides complete product information for all stages of the product development process to allow for intelligent control of the CNC machine. The implementation of STEP-NC allows for an NC controller to perform more intelligent functions, thus making the machine tool more intelligent and autonomous.

Collaboration among a wide variety of research groups, academia, and industry partners has produced promising results such as the successful development of DIMP in New Zealand, the successful use of STEP-NC in XML format and development of intelligent control in STEP-NC in Korea, and the creation of STEPTurn in Germany. The European STEPMAN and FOFdation projects are focusing on preparing STEP-NC for industrial use. However, major changes and more work needs to be done to make the integration of STEP-NC in industry a reality.

Although research into STEP/STEP-NC has been ongoing for over a decade, a fully interoperable STEP-NC system for commercial use in industry is still a long way away. This is most likely due to the complexity in developing a STEP-NC controller. This, in addition to a paradigm shift in programming as well as overcoming the resistance of CAx vendors and end users who may not be open to change, needs to be addressed before interoperability becomes a reality in manufacturing. Several demonstrations of STEP-NC have been made – however, for implementation of this new level of intelligent manufacturing, coordination from the government, research organisations and from industry are required for cooperation in a coordinated implementation roadmap.

References

Abouel Nasr, E.S. and Kamrani, A.K., 2006. A New Methodology for Extracting Manufacturing Features from CAD System. Computers & Industrial Engineering, 51 (3), 389-415

Allen, R.D., Harding, J.A., and Newman, S.T., 2005. The application of STEP-NC using agent-based process planning. International Journal of Production Research, 43 (4), 655-670

Allen, R.D., Newman, S.T., Harding J.A., and Rosso Jr., R.S.U., 2003. The design of a STEP-NC compliant agent-based CAD/CAM system. Proceedings of the 13th International Conference on Flexible Automation and Intelligent Manufacturing FAIM 2003, Tampa, Florida

Bianconi, F., Conti, P., and Di Angelo, L., 2006. Interoperability among CAD/CAM/CAE systems: a review of current research trends. Proceedings of the Geometric Modeling and Imaging – New Trends,82-89

Brunnermeier, S.B. and Martin, S.A., 2002. Interoperability costs in the US automotive supply chain. Supply Chain Management: An International Journal, 7 (2), 71-82

Dalgarno, K.W., Pearson, M.A., and Woods, M., 2001. The UK Navy RAMP Project: improving the spares provisioning process through the rapid acquisition of manufacturing parts. Proceedings of the Institution of Mechanical Engineers, 215 (3), 283-296

Gerbino, S., 2003. Tools for the interoperability among CAD systems. In: International Conference on Tools and Methods Evolution in Engineering Design,Cassino-Napoli-Salerno, Italy

Hardwick, M., Zhao, Y.F., Proctor, F.M., Nassehi, A., Xu, X.W., Venkatesh, S., Odendahl, D, Xu, L., Hedlind, M., Lundgren, M., Maggiano, L., Loffredo, D., Fritz, J., Olsson, B., Garrido, J., and Brail, A., 2013. A roadmap for STEP-NC-enabled interoperable manufacturing. International Journal of Advanced Manufacturing Technology, 68 (5), 1023-1037

Hentz, J.B., Nguyen, V.K., Maeder, W., Panarese, D., Gunnink, J.W., Gontarz, A, Stavropoulos, P., Hamilton, K., and Hascoët, J.Y., 2013. An Enabling Digital Foundation Towards Smart Machining. Procedia CIRP, 12, 240-245

Kramer, T.R., Huang, H., Messina, E., Proctor, F.M., and Scott, H., 2001. A feature-based inspection and machining system. Computer-Aided Design, 33 (9), 653-669

Kržič, P., Stoic, A., and Kopač, J., 2009. STEP-NC: A New Programming Code for the CNC Machines. Journal of Mechanical Engineering, 55 (6) 46-417

Lee, W., Bang, Y.B., Ryou, M.S., Kwon, W.H., and Jee, H.S., 2006. Development of a PC-based milling machine operated by STEP-NC in XML format. International Journal of Computer Integrated Manufacturing, 19 (6), 593-602

Nassehi, A., Newman, S., Xu, X.W., and Rosso Jr., R.S.U., 2008. Toward interoperable CNC manufacturing. International Journal of Computer Integrated Manufacturing, 21 (2), 222-230

Newman, S.T., Nassehi, A., Xu, X.W., Rosso Jr., R.S.U., Wang, L., Yusof, Y., Ali, L., Liu, R., Zheng, L.Y., Kumar, S., Vichare, P., Dhokia, V., 2008. Strategic advances of interoperability for global manufacturing using CNC technology. Robotics and Computer-Integrated Manufacturing, 24, 699-708

Safaieh, M. and Nassehi, A., 2012. A Novel Methodology for Cross-Technology Interoperability in CNC Machining. Robotics and Computer-Integrated Manufacturing, 29 (3), 79-81

Safaieh, M., Nassehi, A., and Newman, S.T., 2013. Adapting STEP-NC programs for interoperability between different CNC technologies. Proceedings of the 37th International MATADOR 2012 Conference, 45-48

STEPMAN Report Summary, 2014. Retrieved from http://cordis.europa.eu/result/rcn/141497_en.html

Suh, S.H., Lee, B.E., Chung, D.H., and Cheon, S.U., 2003. Architecture and implementation of a shop-floor programming system for STEP-compliant CNC. Computer-Aided Design, 35 (12), 1069-1083

Wang, H., Xu, X.W., and Des Tedford, J., 2006. Making a process plan adaptable to CNCs. International Journal of Computer Applications in Technology, 26 (1/2), 49-58

Wang, X.V. and Xu, X.W., 2012. DIMP: An interoperable solution for software integration and product data exchange. Enterprise Information Systems, 6 (3), 291-314

Wang, X.V. and Xu, X.W., 2015. A collaborative product data exchange environment based on STEP. International Journal of Computer Integrated Manufacturing, 28 (1), 75-86

Xu, X.W., 2006. Realization of STEP-NC enabled machining. Robotics and Computer-Integrated Manufacturing, 22, 144-153

Xu, X.W. and He, Q., 2004. Striving for a total integration of CAD, CAPP, CAM, and CNC. Robotics and Computer-Integrated Manufacturing, 20 (2), 101-109

Xu, X.W. and Newman, S.T., 2006. Making CNC machine tools more open, interoperable and intelligent – a review of the technologies. Computers in Industry 57, 141-152

Xu, X.W., Wang, H., Mao, J., Newman, S.T., Kramer, T.R., Proctor, F.M., and Michaloski, J.L., 2005. STEP-compliant NC research: the search for intelligent CAD/CAPPCAM/CNC integration. International Journal of Production Research, 43 (17), 3703-3743

Xu, X.W., Wang, L., and Rong, Y., 2006. STEP-NC and Function Blocks for Interoperable Manufacturing. IEEE Transactions on Automation Science and Engineering, 3 (3), 297-308

Yusof, Y. and Latif, K., 2015. New technique for the interpretation of ISO 14649 and 6983 based on open CNC technology. International Journal of Computer Integrated Manufacturing, 29 (2), 136-148

Zhang, X., Nassehi, A., and Newman, S.T., 2011. Process comprehension for interoperable CNC manufacturing. Proceedings of the 2011 IEEE International Conference on Computer Science and Automation Engineering CSAE 2011, 4, 225-229, Shanghai, China

Živanović, S.T. and Vasilić, G.V, 2017. A New CNC Programming Method Using STEP-NC Protocol. FME Transactions, 45 (1) 149-158

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Computer Science"

Computer science is the study of computer systems, computing technologies, data, data structures and algorithms. Computer science provides essential skills and knowledge for a wide range of computing and computer-related professions.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: