Thermal and Photomechanical Properties of Graphene/PDMS Composites for Bio-inspired Morphing Composites

Info: 7288 words (29 pages) Example Dissertation Proposal

Published: 31st Jan 2022

Tagged: EngineeringSciences

Table of Contents

Click to expand Table of Contents

1 Introduction

2 Background (literature review)

2.1 Bio-inspired morphing

2.2 Photomechanical morphing

2.2.1 Materials for photo-thermal activated morphing

2.2.1.1 Photo-thermal conversion

2.2.1.2 Thermal–mechanical responsive

2.3 Architecture and motion of composite

2.3.1 Single layer structures

2.3.2 Multi-layer structure

2.3.3 Patterned structure

2.4 Sample manufacturing

2.4.1 Dispersion

2.4.2 Concentration

2.4.3 Adhesion

2.4.4 Coating

2.4.5 Printing

2.5 Light

2.6 Characterisation

2.6.1 SEM and AFM

2.6.2 RAMAN, IR and UV spectroscopy

2.6.3 Analysing photomechanical

2.6.4 Thermal properties

2.7 Conclusion

3 Outline of project plan experiments

3.1 Sample manufacturing

3.2 Photomechanical bending

3.3 Thermal properties

4 Objectives of research

5 Expected result

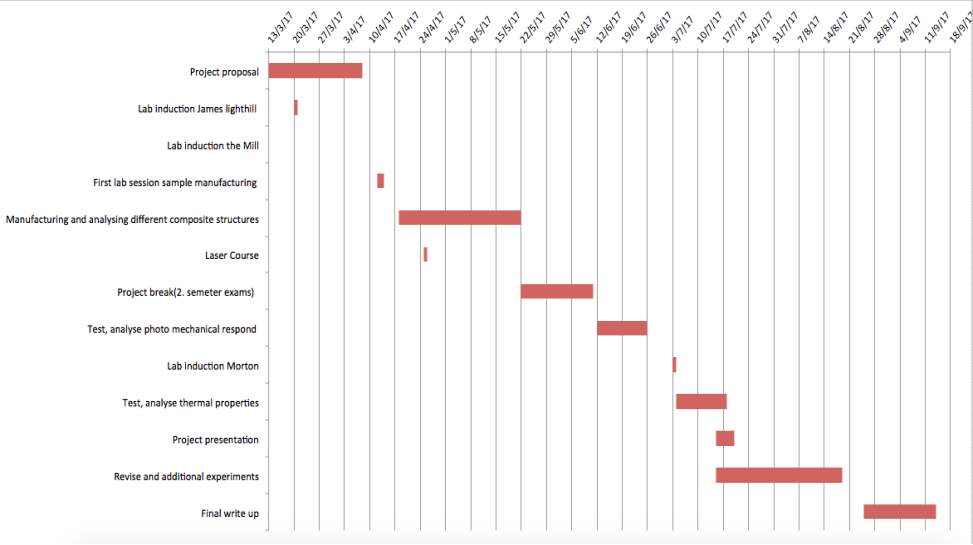

5.1 Time schedule (Gantt chart) experiments, analyses, reporting

Table of Figures

Figure 3

Figure 4

1 Introduction

Attractive photomechanical properties of graphene/polymer composite have in the recent years caught the attention of researchers. The photomechanical effect allows the material to change shape under the stimulus of light, hence future application would have wireless actuation. Thus such material could have great potential for creating bio-inspired materials for soft-robotics, sensors, drug-delivery-systems, tissue-engineering and multipurpose actuators.

PDMS is an interesting material for bio-inspired morphing because of it is non-toxic, optical transparent and have good elastic properties. Combining this with the unique mechanical, electrical, optic, elastic and thermal properties of graphene have opened the possibilities to design composite morphing materials.

It is widely accepted that carbon materials can rapidly and efficiently transform light irradiation into thermal energy, and it is general agreed that the photomechanical behaviour is caused by mismatch in thermal properties of polymer and the carbon-filler.[1]

While the general theory is well understood, it is still an area whit a lot of research ahead in order to utilize the properties for “real life” application. There need to be an even greater understanding of the properties to get faster response rates and improved control over actuation timing and location.

This project concerns thermal and photomechanical properties of a PDMS/graphene based composite. More precisely a bi-layer structure of PDMS and GNP or rGO-chitosan.

The aim of the project is to design and manufacture a PDMS/graphene based composite exhibiting photomechanical morphing. Moreover it is expected to gain a greater knowledge of the thermal properties/behaviour of photomechanical behaviour the composite.

2 Background

Several researchers have reported successful photomechanical behaviour in graphene-polymer based composites. However in most cases the composites are not based on graphene, but on carbon nano-fillers, including CNT, GNP, CB, GO and rGO. Most common in combination with polymers like polyvinylidene fluoride (PVDF), polydiacetylenes(PDA)polyethylene(PET) and polydimethylsiloxan(PDMS) and different hydrogels.

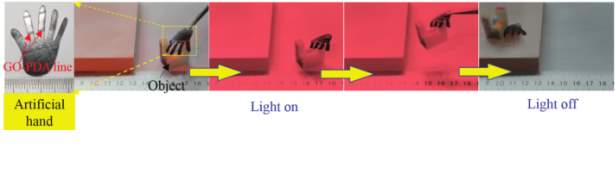

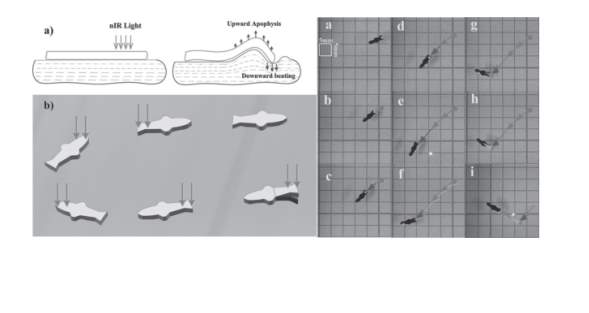

Exploiting the photomechanical properties of these composites research groups have been able to create oscillating films, four legged walkers, self-folding boxes, swimming fish-like robot and a small artificial hand capable to grab and move an object, [1] [2][3][4]

In order to understand how these devices works, and successful create similar composite/behaviour it is necessary to grasp several concepts. Hence the literature review will elucidate following concept/areas, bio-inspired morphing, the principles of photomechanical respond, required properties of materials for morphing, architecture/assembly and manufacturing of the composites and method to analyse/monitor a potential morphing behaviour.

The literature review will have a special focus on previous studies done on photomechanical properties of PDMS/graphene based composite.

2.1 Bio-inspired morphing

Bio-inspired morphing is the concept of nature-grown materials ability to alter there structure adapting to the environment change. Nature provide endless examples of this behavior e.g. plants exhibit a variety of reversible motions, from the slow opening an closuring of pinecones, to the impulsive trap closing of Venusflytrap leaves. [5] These are both examples of nature responding to changing environment and shows that morphing can be triggered by change surrounding environment e.g. in humidity, temperature, light and chemical. Affected by the stimulus changes in the physical or/and chemical properties of the material will cause it to change shape. [6]

The bio-inspired approach have let to a new group of materials, so-called stimulus-sensitive (or “smart”/”intelligent”) materials. Engineers strive to designing materials, which mimic these behaviors, by manipulating material characteristic such as composition, shape and structures. This group of “smart” materials are in general triggered by stimuli including: heat (thermo-responsive materials), stress/pressure (mechano- responsive materials), electrical current/voltage (electro-responsive materials), magnetic field (magneto-responsive materials), pH- change/solvent/moisture (chemo-responsive materials) and light (photo-responsive materials)[6].

Stimulus responsive material such as shape changing alloys and polymers is well-know and relatively explored area of material science. Most of these shape-changing materials will stay changed, however for shape-memory materials the transformation is reversible [6]. Shape changing composite is relatively unexplored area and have so-far shown interesting result with relatively fast and reversible actuation.

This project aims to design bio-inspired composite whit photomechanical properties, hence the following paragraphs will look into then photosensitive mechanism in materials etc.

2.2 Photomechanical morphing

Compared to other stimulus, light have some great advantages in being wireless and remote controllable, additional research have shown that it is also possible to perform more direct control of movement opening the possibility to design more advances systems. [7] Showed that controlling the illumination position single precise movement of fingers in small hand was possible.

The two main principles considering photomechanical morphing including photo-chemical and photo-thermal morphing.[8] Morphing triggered photo chemically are also know as photosensitive polymers. These polymers are driven by deformation of molecules, such as photoisomerizatio, photocycloaddition and photodimerization, and photoionization[8] Since this project aim to design photo-thermal activated morphing composite, the principle of photo-chemical will not be elucidated further.

Photo-thermal activated morphing is a two step process. First step concerns absorption of light and generation of heat(photothermal conversion). Second step is the physical shift in material characteristic caused by the temperature change (thermal–mechanical components)[9]. Hence photo-thermal activated materials needs to own the properties of being photo-thermal converting and thermal–mechanical components.

With this two-step process in mind the following paragraph will cover the materials used to obtain photo-thermal morphing.

2.2.1 Materials for photo-thermal activated morphing

Polymers and graphene nano-fillers are good material choices because they hold the characteristics to fufill the two-step mechanism required for a photo-thermal activated morphing. At the same time this combination allow preserving flexibility of the material by distributing carbon throughout the material or adding it as a thin film on top.

2.2.1.1 Photo-thermal conversion

It is commonly accepted that carbon materials rapidly and efficiently transform light irradiation into thermal energy[1]. This is due to various vibration modes in the honeycomb structure of carbon atoms, such as stretching and bending in the planes, and vibration of carbon atoms with dangling bonds in plane terminations. Under an external light stimuli, the infrared-phonon interactions during the forced resonance vibration process increased the disordering degree, bringing the kinetic vibration energy to exhibit heat motion energy[10].

Besides being able to convert light to thermal energy graphene is also interesting for this application because it’s high thermal conductivity and the low thermal expansion coefficient CTE. High thermal conductivity allows heat to spread more easily in the polymer, which usually exhibit low thermal conductivity. Additional the low CTE of graphene is essential for morphing triggered by mismatch in CTE in bi-layer structures.

Graphene nano-filler such as carbon nanotubes (CNT), carbon black (CB), graphene nanoplates(GNP), graphen oxide(GO), reduced graphene oxide(rGO) are the most common types reported in the literature. The type of graphene nano-filler used has shown to have different magnitude of photomechanical respond.

Loomis&Co [11] investigated the photomechanical effect of different carbon nano-fillers, including CNT, GNP, CB and GO in a PDMS matrix.

Out of these samples, GO/PDMS showed the smallest amount of actuation, where GNP/PDMS in average had 4.5 times larger magnitude of respond. CNT, CB and GNP followed the magnitude of respond from high to low in mentioned order. However previous similar experiments with CNT showed much greater respond[12]. The time of shear mixing in two experiment is significant and it is viable that the reduced respond observed by Loomis&Co [11] is due poor dispersion of CNT in PDMS matrix.

This also implies that GNP with much more ease can disperse in a polymeric matrix, such as PDMS compared to other carbon forms.

GO dispersed in a single-layer PDMS matrix haven’t shown impressive photomechanical respond, however a recent research group[1] have obtained similar result with rGO in a bi-layer structure as bi-layer structures of GNP/PMDS composites.

Where the graphene nano-fillers main function is converting light to heat, polymers viscous-elastic properties have proven to deliver the thermal-mechanical respond.

2.2.1.2 Thermal–mechanical responsive

There are three main mechanisms behind the thermal–mechanical respond, including thermal expansion, thermal-induced phase transitions, and thermal dehydration.

Materials behave different during heating and expand according to their thermal expansion coefficients CTE. Some materials such as PDMS have a relatively[13] high CTE whereas graphene has a CTE close to zero, even measured negative[14]. Hence combing these two materials the differences in CTE create a bimorph structure, which can be used for achieving bending of the material.

Thermal-induced phase transition thermotropic liquid crystals, volume- phase-transition hydrogels, shape-memory polymers, and thermal-phase-transition inorganic are all materials, which have been studied in concerns of their photomechanical properties.

Really good result thermal-induced phase trainsition causing morphing is observed in hydrogels.[15]

Hygromorphic materials change volume by expanding(swell) or contracting(releases) when there is a change in surrounding environments humidity. The water uptake is depending on temperature and undergo a phase transition between a hydrophilic swollen form to a hydrophobic shrunken form at a critical temperature.[16] Several groups have reported on morphing graphene oxide (GO) papers responding by this mechanism[16][17] [3]

Most common reported polymers used for photomechanical morphing are polyvinylidene fluoride(PVDF), polydiacetylenes(PDA)polyethylene(PET)and polydimethylsiloxan(PDMS) and different hydrogels.

Hydrogels have shown impressive morphing result and are able to react to a variety of stimulus, however hydrogels respond best in aquaquries environments which limits the application.[16]Moreover the kinetics of actuation is significantly slow compared to that observed in other polymers.

PDA PVDF PET …. However PDMS have some advances Besides being … …. …

PDMS is ideal because it is transparent allows the photons could effectively interact with phonons during transmission through the entire system and then lead to a high efficiency of photo energy utilization with improved sensitivity.

While the properties of the material are crucial for the photomechanical respond to occur, the architecture of the composite determine the actual motion during actuation.

2.3 Architecture and motion of composite

The structural assembly (architecture) of the composite will determine the marcroscopic motion under stimulus. Expansion-contraction, rotation and twisting are examples of relatively simple motion that can be manipulate designing composites with asymmetric structures. The most common nano-composite is single-layer and multi-layer structures.

2.3.1 Single layer structures

A composite consisting of only one layer with a matrix of polymer with dispersed graphene nano fillers. In such structure photomechanical respond result in expansion and contraction of composite, however such structures requires that the pre-strain be applied to the sample.[11] [12] [18]

For such structure the photomechanical respond is suggested to not only be temperature related, but also an effect of from electrostatic, elastic, polaronic properties of the material.

Loomis & Co[11] report that as pre-strain and thus sample length increase, the amount of graphene exposed to the fixed size irradiation spot decreases due to orientational ordering, and, therefore, the thermal effects also start to diminish. At 40% pre-strain, the maximum temperature increase has fallen to∼60 ◦C, a 15 ◦Change compared to the unstrained sample. At large pre-strain, the overall magnitude of the actuation increases, however the temperature of the composite decreases. This outcome possibly indicates that thermal effects may not be the only effect contributing to the overall actuation mechanism. It is believe that this response is a result of contributions from electrostatic, elastic, polaronic, and thermal effects that cause the photoresponse of GNP/PDMS composites

Similarly to CNT/PDMS composites, the actuation responses of the GNP/PDMS composites depended on the initial applied pre-strain: at low levels (3–9%), the samples showed reversible expansion; at moderate levels (∼10%), the samples yielded negligible effect; and at high levels (15–40%), the samples exhibited reversible contraction. likely a result of orientational effects, As the applied pre-strains increase the overall test sample length, the GNPs within the PDMS polymer become more aligned/re-arranged with respect to one another. As a result, the macroscopic magnitude of the photomechanical response is amplified

2.3.2 Bi-layer structure

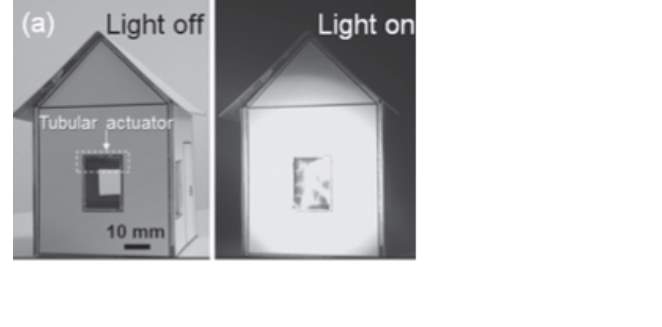

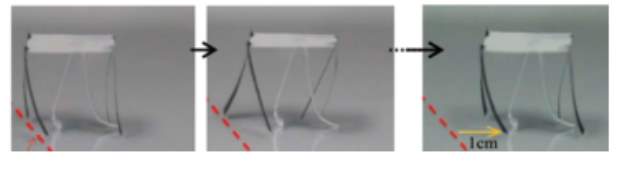

Bi-layer is the term of stacking two or more materials with different properties together. Layering thin sheets with different properties is inspired from the biological morphing observed in many plants. In the bi-layer structures the layers are often defined as being active or non-active. In the case of a bi-layer structure where one layer is responsible for thermal conversion and another layer is responsible mechanical respond, latter will be the active part of the composite. Considering the before discussed morphing behaviour based on volumetric change, a bi-layers structure will result in a bending towards the passive layer. With this type structures several interesting objects have been created, including oscillating films, roller for windows, four legged walkers, self-folding boxes, swimming fish-like robot and a small artificial hand capable to grab and move an object, [1][19] [2][3][4] figure ..

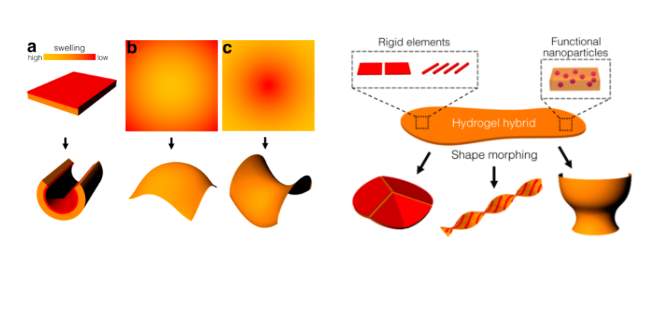

2.3.3 Patterned structure

Patterned structures open the possibilities of designing composites with advances morphing, by localising the bending for specific areas. There are several option to created patterns and asymmetric in the composite to make move differently, including hinge-structures, incorporating stiff elements or assembling layers in alternatively matter.

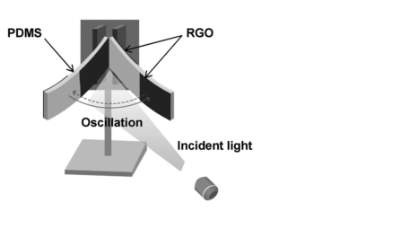

Tang & Co[1] demonstrated designing oscillation motion by creating with an asymmetric multi-layer RGO/PDMS/RGO cantilever structure figure 5. When the NIR light is incident from the RGO side, the sandwiched film cantilever bends to the direction of the incident light. Then the bending film exposes its back side RGO surface to the incident light, which results in the cantilever bending to the opposite side direction of the incident light. The repeated exposure- shield archives an oscillation motion of the bilayer film under light irradiation

Incorporating stiff element is another way of manipulating the movement during morphing. However this is technic is mostly explored with hydrogels. Jeon&Co[20] demonstrates how such structures could be designed to alter more sophisticated motion during morphing figure 6.

Hinge-structures is an origami inspired way of making designing the pattern. In a hinge-structure the active part of the composite determines the bending, making it possible to create self-folding devices. A layer can act like a hinge when it is applied in a thin layer, forcing then bending in toward the active layer.

2.4 Sample manufacturing

As mentioned above the most common structure of such composite is a bi-layer structure consisting of two or more thin layers/film of materials. An effective way to create thin films is by coating, including spin coating, direct coating and dip coating. More complicated composite structures involve printing technics, such as screen-printing and digital jet printing.

Besides the actual sample manufacturing, there are two important parameters to consider when dealing with manufacturing of a bi-layer composite, namely adhesion and dispersion.

2.4.1 Dispersion

A homogeneous dispersion of nano-fillers is important for the final photomechanical properties. As mentioned before various photomechanical respond of CNT-based composite have been reported, and is assumed to be do to variety in dispersion[11][12]. Poor dispersion can lead to agglomerating nano-fillers, which can result in diversity in photo-thermal conversion properties through the film/composite.

To attain good dispersion graphene nano-filler must be prepared in solution and mix by methods, including roll mill, sonicator or shear mixing.

2.4.2 Concentration

Concentration of nano-filler has also shown to have some effect on the photomechanical properties.

Two research groups working with PDMS/GNP based composite have observed deflection increases coherent with increasing the content of graphene with up to 5wt%.[21][11] However the research group investigating the bilayer composite is observing a bigger difference in the photomechanical behaviour from 2wt% – 5wt% compared to the research group studying the pre-strained composite who only experience a marginal difference in the respond by increasing the content of GNP from 2wt% – 5wt%.

Nevertheless actuation kinetics was observed to independent of the GNP concentration. Regardless of the sample concentrations, GNP/PDMS actuators exhibit fast actuation and relaxation and[11] Also [1] reports fast actuation kinetics at low NIR intensity induced a low temperature increase (about 40 °C) on the film, but the film still showed a fast bending response. This result suggests high sensitivity of the bilayer actuator upon light stimulus, which implies that the PDMS film exhibited higher expansion than that of the RGO film

2.4.3 Adhesion

Another important aspect to consider regarding a bi-layer structure is the adhesion between the layers. Since the morphing is depended on mismatch in volume change a weak adhesion could result in separation of the two layers. Adhesion depends on wetting properties of the surface and can be challenging because of the natural hydrophobicity of PDMS. Adhesion can be improved by surface treatment such plasma, where the highly active gas will change the chemical groups on the surface and enhance hydrophillicity.

2.4.4 Coating

Dip and Spin coating are two commonly technics used to create thin films. The process of spin coating requires a small amount of coating material applied in the centre on a substrate. Then the substrate starts rotated at high speed the centripetal force combined with the surface tension of the solution pulls the liquid coating into an even covering. The higher the speed, the thinner film. Nonetheless film thickness also depends on materials viscosity and the concentration of the solvent and the solution.[22]

Dip coating the substrate is immersed in the coating, where thin film will deposit itself upon withdrawing. For flexible film this is often done by continuous roll-to-roll process. Speed of determines the thickness of the coating a fast withdrawing will result in a thicker film.[23]

Liu & Co[21] report that there could be a correlation between thickness of PDMS film and deflection. Increasing the rotation speed in the manufacturing of PDMS film (reducing thickness) has showed to decline the deflection. This observation is believed to be the result of a smaller temperature change because of the decreased thickness of PDMS layer and the bilayer actuators. Conversely before mentioned back-flash deflection was observed to increase as the thickness of the film decreased.

2.4.5 Printing

Inkjet printing and screen-printing are two methods to design more complex

Besides form the actual design of composite light is also an important factor especially in terms of motion.

2.5 Light

Type of light, intensity and projection has great influence on the photomechanical respond. NIR light is the strongest source available, hence able to generate most energy leading to a faster temperature increment of the material and photomechanical respond.

However photomechanical morphing can also be triggered by other sources of light. Tang&Co[1] designed a rGO/PDMS composite which respond to both visible and UV light, nevertheless the temperature raise is weaker and the maximal bending obtained is less than for what obtained with NIR-light.

Furthermore there is a clear correlation between intensity of NIR-light, speed of morphing and magnitude of bending angle.

Liu & Co[21] investigated photomechanical behaviour effect on light intensity in the range of 0.7 W cm−2 to 2.95 W cm−2, and observed that the temperature change profile increase as a function of irradiation time and light intensity. Same observations are made by[1] The higher intensity NIR light induced a higher temperature rise on the bilayer film.

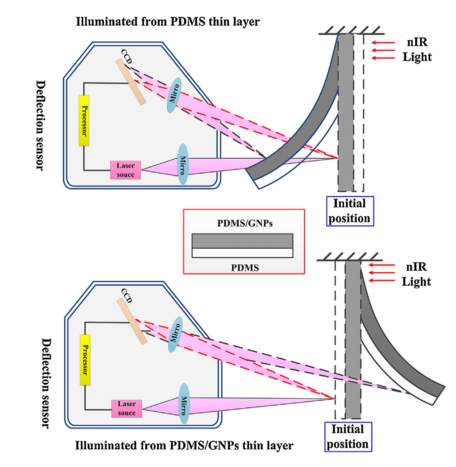

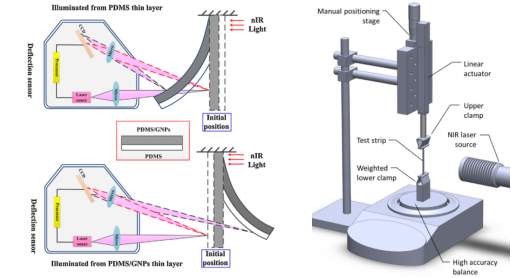

Also the projection of light influence the morphing behaviour. Liu&Co[21] designed a bilayer structure of PDMS and PDMS/GNP and observed a two-step photomechanical bending process. It was assumed that the bending would occur toward PDMS/GNP-layer however when nIR light is incident from PDMS/GNPs thin layer the composite will make a fast bend toward PDMS layer followed by a complete bending toward PDMS/GNP-layer.see figure It is believed that the photomechanical two-step bending is the results of temperature gradient effect and thermal bilayer effect, while the one-step photomechanical bending process is only caused by thermal bilayer effect.

Other research groups have tried with similar structures and haven’t Contrarily Tang&Co [1] bilayer rGO/PDMS composite show bending only toward rGO side under irradiation.

2.6 Characterisation

Characterisation of physical and chemical properties of the material/composite is an important aspect of understanding, alter and eventually utilise the morphing properties for real life applications. Several technics are interesting for evaluating a composite exhibiting photomechanical properties. For investigating material structure and composition a combination of spectroscopy and microscopic technics are useable. Including RAMAN , UV&IR – spectroscopy and optical microscopy, AFM, and SEM. For this project the most important physical properties the parameters are the thermal properties and the photomechanical properties.

2.6.1 SEM and AFM

SEM and AFM are both microscopic technics which can provide information about a material surface based on images. The two methods differ in several ways including how they measure and which material characteristic the measurements can be used to determine.

AFM uses laser to measures the amount of interaction between the probe-tip and the sample. Able to determine the surface topography of a material on the atomic scale vertically, and the nanometer scale horizontally. Hence AFM is able to give very detailed information about surface structure. Moreover AFM can be used to determine properties as stiffness, elasticity, adhesion, magnetic and electrostatic fields, temperature distribution, spreading resistance, and conductivity.

SEM works by sending a beam of electron on the material, when the beam hits the material it releases X-rays and electrons, which are detected and converted into a three-dimensional image. Signals as x-rays and back-scattered electrons can be used to determine respectively elemental composition of material and make-up of sample. [24]

Hence useful characteristic and advantages can be drawn from using both methods, however a material characterisations more reliable in combination with other supporting technics.

2.6.2 RAMAN, IR and UV spectroscopy

Spectroscopy covers a group of technics using different principles to determine the chemical composition and variation in a sample. In most cases a combination of spectroscopy technics is necessary to insure correct verification of the material.

Both IR and RAMAN spectroscopy measure the energy changes associated with vibrations of bonds. Raman measures bond vibration, which causes a change in the polarizability of the bonds, thus the best for covalent bonds. IR measures the bond vibration must cause a change in the dipole moment of the molecule, hence best for polar bonds. The two technics are good complementary because they uses same frequency but are able to detect vibration in different frequencies. In other words what is not detected in IR can be detected in RAMAN and vice versa.

RAMAN is able to detect low frequencies, thus often used to characterize carbon-based materials. Whereas IR confirms composition of material, by detecting the functional groups.

Ultraviolet-visible (UV) is another type of spectroscopy, which can detect how the material absorbs light in the visible part of electromagnetic spectra. Transmittance of light in UV spectroscopy can be used get information about film thickness, dispersion and concentration of a material.

2.6.3 Analysing photomechanical

The photomechanical properties are typically analysed by visual observation, measurement of deflection angle, time of actuation and change in stress.

The bending angle can be measure by a displacements sensor[21] (figure) or by video recording the behaviour and measuring the deflection angle in drawing program.

Additional the photomechanical behaviour can be analysed by measuring the change in stress in a tensile test. This is done by applying a pre-strain to the composite and measuring the stress change during NIR-light.[11] (figure)

Figure 3 Photomechanical

2.6.4 Thermal properties

Thermal properties such as glass transition temperature, melting temperature etc. are important when considering the composite design and manufacturing as well as the application-area. Moreover the thermal properties especially thermal conductivity and thermal expansion are essential for the photomechanical morphing, hence important for this project.

Differential Scanning Calorimetry (DSC)

DSC is technic measuring the heat flow as a function of temperature. Sample and reference are heated or/and cooled in a controlled rate while detecting the temperature of the measurement cell and the difference in the exothermic and endothermic process associated with physical transitions of the material, such as crystallization, melting and glass transition.

Thermal expansion coefficient

The thermal expansion coefficient(CTE) describes a materials change in size in relation to temperature and can be measured based on linear, area or volumetric change. The volumetric CTE is given by:

α=1VΔVΔT

CTE can be determine by several methods including Thermo Mechanical Analysis(TMA) and Dilatometer(DIL). TMA are able to measure several dimensional changes where DIL measures the volumetric change, additionally DIL is able determine CTE for materials with very low to negative CTE, hence useful for carbon materials.

Thermal conductivity

Thermal conductivity describes the materials ability conduct heat, the method to meassure depends on the material. For polymer the Hot Wire Method is the most frequently reported. The hot wire method is a standard transient dynamic technique based on the measurement of the temperature rise in a defined distance from a linear heat source (hot wire) embedded in the test material. If the heat source is assumed to have a constant and uniform output along the length of test sample, the thermal conductivity can be derived directly from the resulting change in the temperature over a known time interval[25].

2.7 Conclusion

Photo-thermal activated morphing is a two step process. First step concerns absorption of light and generation of heat (photothermal conversion). Second step is the physical transformation in material characteristic caused by the temperature change (thermal–mechanical components)[9]. Hence photo-thermal activated materials needs to own the properties of being photo-thermal converting and thermal–mechanical components.

It have been established that temperature changes in the material and (morphing) are strongly related. Nevertheless the photomechanical behaviour depends on several other parameters. Including composite structure single-layer versus multi-layer, dispersion, size and concentration of graphene nanofiller, thickness of film, intensity of light and projection of light.

The architecture/assembly of the composite is essential for how the composite will behave during photomechanical activation. A single-layer composite structure of graphene-PDMS will show morphing inform of expansion and contraction, however such structure is restraint to the applied pre-strain. For such structure the photomechanical respond is suggested to not only be temperature related, but also an effect of from electrostatic, elastic, polaronic properties of the material.

In a multi-layer structure the photomechanical respond is believed to be triggered by a mismatch of thermal expansion in the layers. Forcing the composite to bend towards layer with lower CTE. More complex movement can be designed by inkjet or screen-printing localising the bending for specific areas.

Degree of bending and change in stress have proven to increase with the augment of graphene nano-fillers to the extent of wt. 5%. Dispersion have shown to effect the magnitude of respond and the time of respond is suggested to be related to area size of the graphene, large-area graphene will have faster respond than nano-size graphene.

The most common techniques to manufacture dip-coating and spin coating, both methods allows manipulation of film thickness. In some specific composite reducing the thickness has shown to have shown to decline the deflection.

Light also have great influence on the photomechanical respond. Even though the photomechanical respond have proven to be triggered by UV and visible, the greates respond is observed in NIR light.[1] Moreover increasing the intensity of NIR light have proven to increase the final bending angle and give a faster bending rate. Additional light can be used manipulated the movement. A two-step bending process have been possible by .. light from other side. Furthermore changing the incensity swimming fish

There are several important techniques to help characterise a photomechanical morphing composite, including microscopic technics such as SEM and AFM for defining/investigating surface properties and dispersion of graphene nano-fillers. Spectroscopic technics such as RAMAN, IR and UV for determining material composition. DSC, TMA, DIL and Hot Wire method, for determining thermal properties such as glass transition and melting temperature, thermal expansion coefficient and thermal conductivity respectively. The actual photomechanical respond can be determined based on time and on angle of bending.

On the basis of this literature review following paragraphs will define the preliminary outline for this project.

3 Outline of project plan experiments

This project has three main aspects:

- Sample manufacturing

- Study of photomechanical properties

- Study of thermal properties

3.1 Sample manufacturing

First step is to get familiar with the preparation of the materials PDMS, GNP/rGO-chitosan and the manufacturing process of samples, including spin coating, direct coating and printing, as well as different characterisation technics.

First sample should be a bi-layer construction consisting of two layers. One layer PDMS, topped with one layer of chitosan in mixture with either GNP or rGO. Main purpose of chitosan is ensuring thickness of the top layer, it is necessary that the layer somewhat will correspond to PDMS layer fore the morphing to occur.

Preparation of chitosan- GNP/rGO requires several processes. GNP/rGO and chitosan needs to be prepared in solution separately before mixing together. There are several methods to create the actual film on the top of PDMS layer, including spin coating and direct coating.

PDMS is prepared by … ….

Along the way the raw materials and composite will be characterised based spectroscopic technics such as RAMAN, FTIR and UV and microscopic technics such as optical, SEM and AFM.

The morphing behaviour of the samples will in this stage be evaluated using infrared camera to capture the temperature distribution of sample while heating.

When the sample procedure is familiarised and morphing is achieved. Different bi-layer, patterns etc. structures, variety of wt.% GNP/rGO and different film thickness can be explored.

Based on above experiments some structures of composites should be chosen for further investigation of photomechanical behaviour in NIR light.

3.2 Photomechanical bending

Next step in the experimental plan is to investigate the photomechanical bending. Bending angle and kinetics of respond can be analysed by recording sample behaviour during exposure to IR laser. Additional the affect of different light intensity can be tested.

3.3 Thermal properties

Mismatch in thermal expansion coefficient are assumed to cause the photomechanical morphing hence these will be determined by dilatometer for PDMS and chitosan-GNP/rGO respectively.

Additional the thermal conductivity

Correlation the observed deflection and increasing the difference of thermal expansion between the two layers.

4 Objectives of research

- Manufacture composite with photomechanical properties

- Triggering morphing and analysing bending

- Investigate thermal properties of composite

- Revise composite structures in order to improve or/and adjust morphing properties

5 Expected result

It is expected to:

- Trigger morphing thermally

- Photomechanical triggering of morphing with IR light

- In bi-layer structure it is expected that the composite will bend towards GNP/GO/chitosan layer

- That different composite structures will respond with divert motion.

- It expected that the respond will increase with the increment of GNP/rGO up to 5 wt%

- That the thickness of the bilayer will influence the bending, by resulting in greater respond with increasing the thickness

- That the intensity of light will influence the photomechanical respond, thus increasing the light will enhance the kinetic of respond.

- Decreasing thermal expansion of (GNP/rGO)/chitosan layer with he augment of GNP/rGO

- Increasing thermal conductivity of (GNP/rGO)/chitosan layer with he augment of GNP/rGO

5.1 Time schedule (Gantt chart) experiments, analyses, reporting

Figure 3 Project Plan

Bibliography

[1] Tang R, Sang W, Wu Y, Zhu C and Liu J 2017 Multi-Wavelength Light Drivable Oscillatory Actuator on Graphene-Based Bilayer Film 201600384 1–6

[2] Cheng H, Zhao F, Xue J, Shi G, Jiang L and Qu L 2016 One Single Graphene Oxide Film for Responsive Actuation ACS Nano 10 9529–35

[3] Mu J, Hou C, Wang H, Li Y, Zhang Q and Zhu M 2015 Origami-inspired active graphene-based paper for programmable instant self-folding walking devices Sci. Adv. 1 e1500533–e1500533

[4] Xiao P, Yi N, Zhang T, Huang Y, Chang H, Yang Y, Zhou Y and Chen Y 2016 Construction of a Fish-like Robot Based on High Performance Graphene/PVDF Bimorph Actuation Materials Adv. Sci. n/a-n/a

[5] Li S and Wang K W 2016 Plant-inspired adaptive structures and materials for morphing and actuation: a review Bioinspir. Biomim. 12 11001

[6] Sun L, Huang W M, Ding Z, Zhao Y, Wang C C, Purnawali H and Tang C 2012 Stimulus-responsive shape memory materials: A review Mater. Des. 33 577–640

[7] Wang E, Desai M S and Lee S 2013 Light-Controlled Graphene-Elastin Composite Hydrogel Actuators 1–5

[8] Hu Y, Li Z, Lan T and Chen W 2016 Photoactuators for Direct Optical-to-Mechanical Energy Conversion: From Nanocomponent Assembly to Macroscopic Deformation Adv. Mater. n/a–n/a

[9] Jiang W, Niu D, Liu H, Wang C, Zhao T, Yin L, Shi Y, Chen B, Ding Y and Lu B 2014 Photoresponsive soft-robotic platform: Biomimetic fabrication and remote actuation Adv. Funct. Mater. 24 7598–604

[10] Wu C, Feng J, Peng L, Ni Y, Liang H, He L and Xie Y 2011 Large-area graphene realizing ultrasensitive photothermal actuator with high transparency: new prototype robotic motions under infrared-light stimuli J. Mater. Chem. 21 18584

[11] Loomis J, King B, Burkhead T, Xu P, Bessler N, Terentjev E and Panchapakesan B 2012 Graphene-nanoplatelet-based photomechanical actuators Nanotechnology 23 45501

[12] Ahir S V. and Terentjev E M 2006 Fast relaxation of carbon nanotubes in polymer composite actuators Phys. Rev. Lett. 96 5–8

[13] Kuo A C M 1999 Poly ( dimethylsiloxane ) (Polymer Data Handbook Oxford University)

[14] Balandin A A 2011 Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 10 569

[15] Kim D, Lee H S and Yoon J 2016 Highly bendable bilayer-type photo-actuators comprising of reduced graphene oxide dispersed in hydrogels Sci. Rep. 6 20921

[16] Hines L, Petersen K, Lum G Z and Sitti M 2016 Soft Actuators for Small‐Scale Robotics Adv. Mater.

[17] Ji M, Jiang N, Chang J and Sun J 2014 Near-infrared light-driven, highly efficient bilayer actuators based on polydopamine-modified reduced graphene oxide Adv. Funct. Mater. 24 5412–9

[18] Skandani A A, Chatterjee S, Smith M L, Baranski J, Wang D H, Tan L S, White T J and Shankar M R 2016 Discrete-state photomechanical actuators Extrem. Mech. Lett. 9 45–54

[19] Hu Y, Wu G, Lan T, Zhao J, Liu Y and Chen W 2015 A Graphene-Based Bimorph Structure for Design of High Performance Photoactuators 7867–73

[20] Jeon S-J, Hauser A W and Hayward R C 2017 Shape-Morphing Materials from Stimuli-Responsive Hydrogel Hybrids Acc. Chem. Res. acs.accounts.6b00570

[21] Liu H, Niu D, Jiang W, Zhao T, Lei B, Yin L, Shi Y, Chen B and Lu B 2016 Illumination-oriented and thickness-dependent photomechanical bilayer actuators realized by graphene-nanoplatelets Sensors Actuators, A Phys. 239 45–53

[22] Scriven L 1988 Physics and applications of dip coating and spin coating

[23] Quéré D 1999 “FLUID COATING ON A FIBER” Annu. Rev. Fluid Mech. 31 347–384

[24] Smith B 2015 The Differences Between Atomic Force Microscopy and Scanning Electron Microscopy 1–5

[25] Davis W R, Hot-Wire Method for the Measurement of the Thermal Conductivity of Refractory Materials, in Maglić K D, Cezairliyan A P V E 1983 No Title Compend. Thermophys. Prop. Meas. Methods, Vol. 1 Surv. Meas. Tech. 1 161

This dissertation proposal has been written by a student and is published as an example. See our guide on How to Write a Dissertation Proposal for guidance on writing your own proposal.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Sciences"

Sciences covers multiple areas of science, including Biology, Chemistry, Physics, and many other disciplines.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation proposal and no longer wish to have your work published on the UKDiss.com website then please: