Development and Performance Test of an Air Washer Model

Info: 10642 words (43 pages) Dissertation

Published: 11th Dec 2019

Tagged: Technology

ABSTRACT

The air washer, because it is of another outline and of various developments than customary air washer, is specifically noteworthy.

In this way it was the choice of gathering that the specific attributes of the air washer, as set up in this framework may be of impressive value. Not just for future guideline purposes, but likewise in the expansion of hardware coveted for RAC research centre improvement and development of the institute. The warm and stream qualities of the air washer are thought to be of essential significance. It is perceived that this data would be required sooner rather than later. Subsequently, on the grounds that there were no quick issues concerning the cleanliness of the research facility air, the air cleaning adequacy of the washer would not be considered. Along these lines, the venture is constrained to the assurance of the air washer warm and stream characteristics. Which chip away at evaporative cooling framework and play out the assignments.

- Cooling and humidification

- Dehumidification

List of Tables

| Table No | Table Description | Page No |

| 1 | Fan Speed 1: 9.20 m/s | 46 |

| 2 | Fan Speed 2: 10.95 m/s | 48 |

| 3 | Cost Estimation: | 54 |

Graph:

| Graph No | Graph Description | Page No |

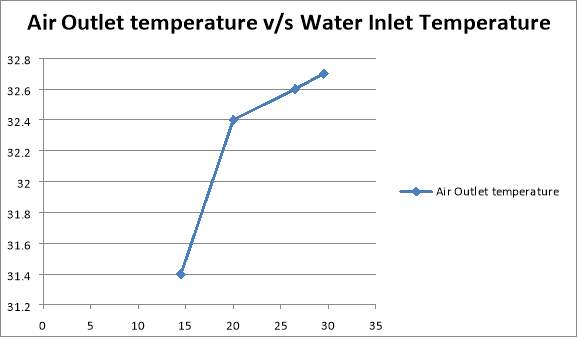

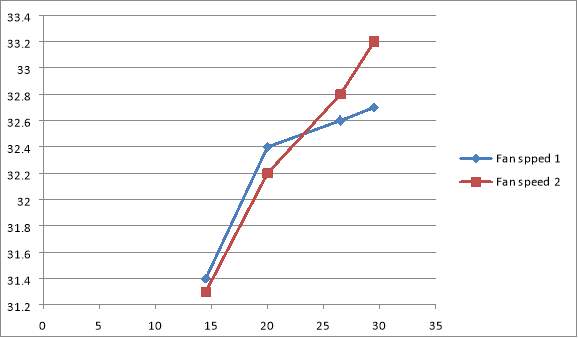

| 1 | Air Outlet temperature v/s Water Inlet Temperature | 46 |

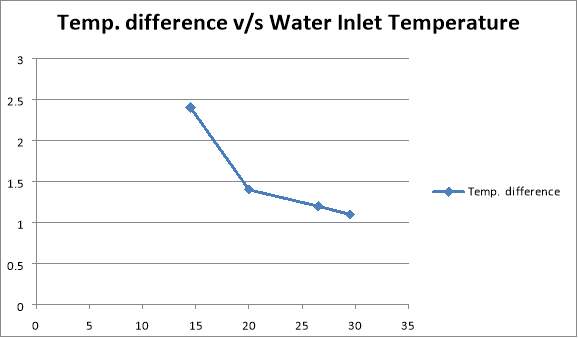

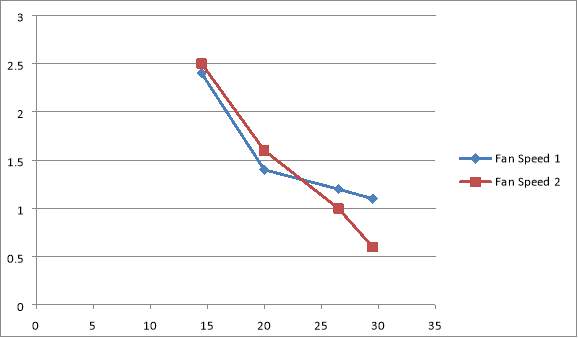

| 2 | Temp. difference v/s Water Inlet Temperature | 47 |

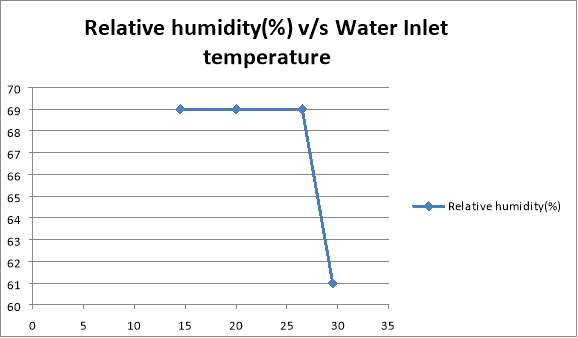

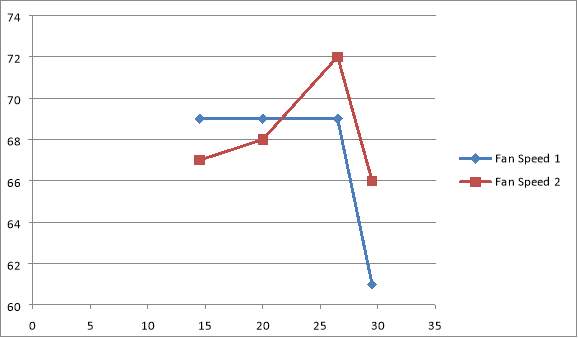

| 3 | Relative humidity(%) v/s Water Inlet temperature | 47 |

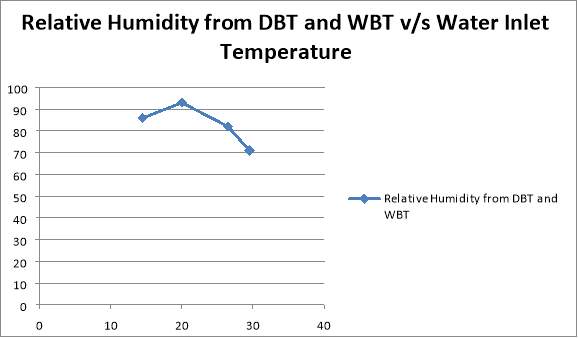

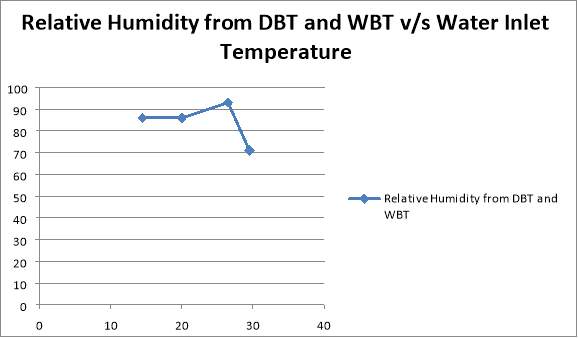

| 4 | Relative Humidity from DBT and WBT v/s Water Inlet Temperature | 48 |

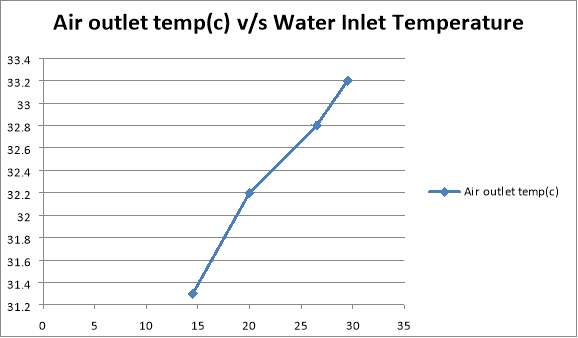

| 5 | Air outlet temp(c) v/s Water Inlet Temperature | 49 |

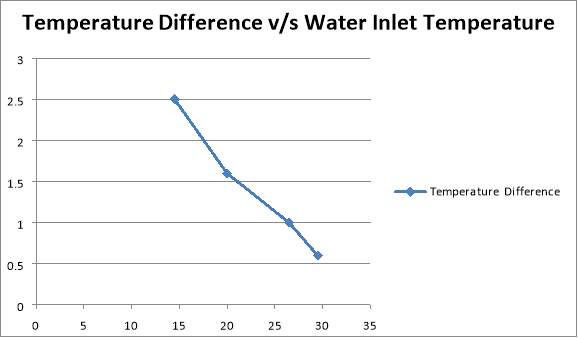

| 6 | Temperature Difference v/s Water Inlet Temperature | 49 |

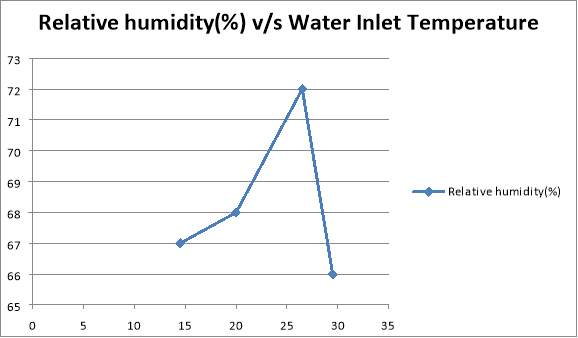

| 7 | Relative humidity(%) v/s Water Inlet Temperature | 50 |

| 8 | Relative Humidity from DBT and WBT v/s Water Inlet Temperature | 50 |

| 9 | Air Outlet Temperature v/s Water Inlet Temperature | 51 |

| 10 | Temperature Difference v/s Water Inlet Temperature | 51 |

| 11 | Relative Humidity v/s Water Inlet Temperature | 52 |

| 12 | Relative Humidity from DBT and WBT v/s Water Inlet Temperature | 52 |

List of figures

| Figure No | Figure Description | Page No |

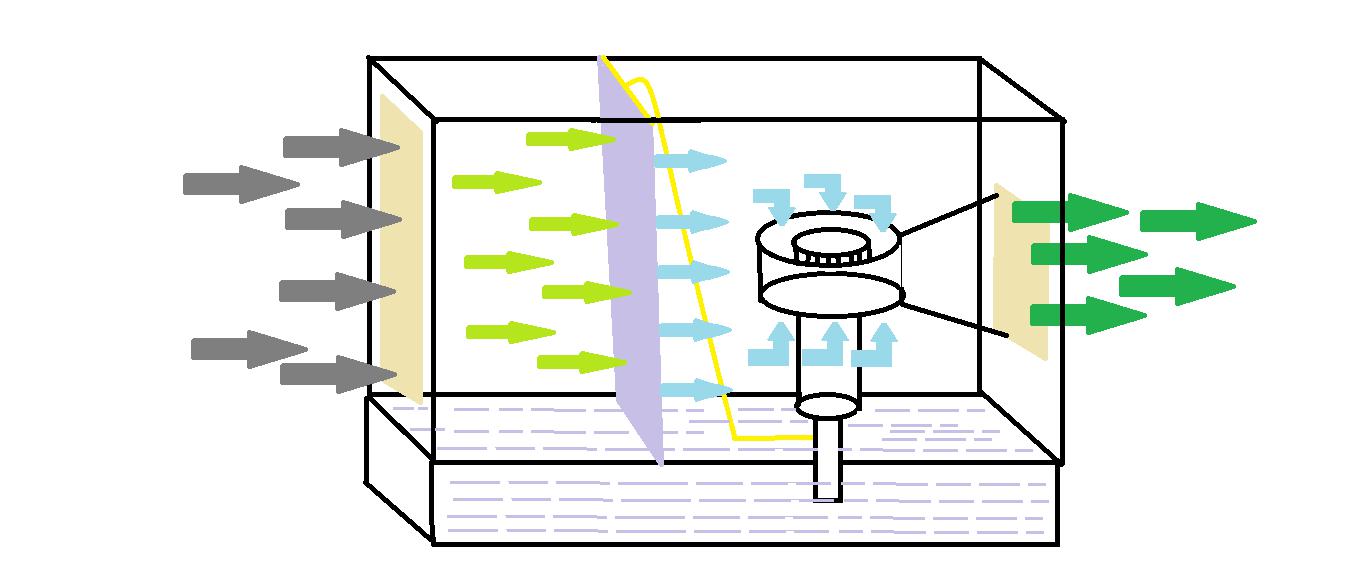

| 1 | Air washer | 14 |

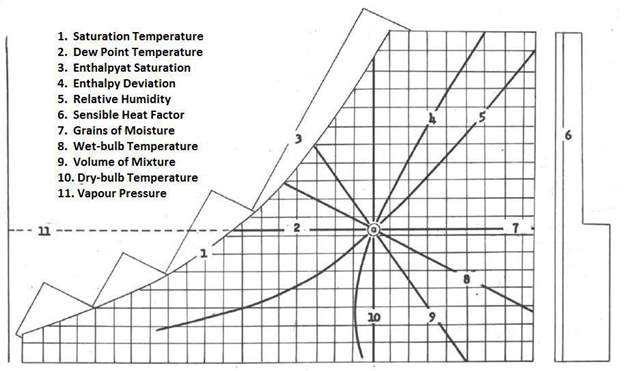

| 2 | Psychometric outline | 23 |

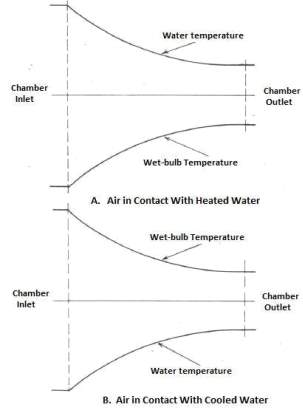

| 3 | Air in contact Cooled Water | 25 |

| 4 | Green Houses | 27 |

| 5 | Manufacturing Facilities | 27 |

| 6 | Vegetable and Fruit Storage | 27 |

| 7 | Workshops | 27 |

| 8 | Office Complexes | 27 |

| 9 | Textile Processing | 27 |

| 10 | Modern Area | 28 |

| 11 | Office Industries | 28 |

| 12 | Tea Processing | 28 |

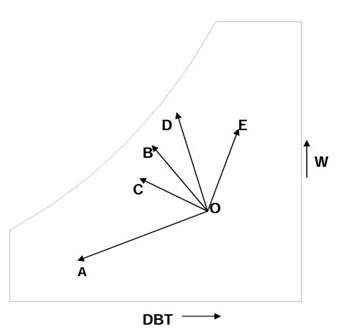

| 13 | Psychrometric graph | 31 |

| 14 | Water tank | 37 |

| 15 | Blower | 37 |

| 16 | Pump | 38 |

| 17 | Pipes and fittings | 39 |

| 18 | Chamber | 39 |

| 19 | Exhaust fan | 40 |

| 20 | Regulator | 41 |

| 21 | Filter | 41 |

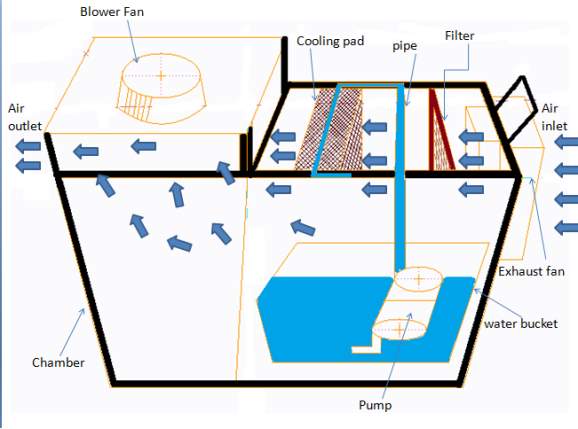

| 22 | Schematic Diagram of Air Washer | 42 |

| 23 | Mild Steel | 43 |

Table of Contents

- Introduction

- Authentic foundation

- Standard and Work Application of Air Washer

- Extend Work

- Components of an air washer

- Fabrication of Air Washer

- Experimentation

- Future Scopes

- Cost Estimation:

- Conclusion

- References

INDEX

| CHAPTER | TOPICS | PAGE

NO. |

| 1 | Introduction | 9 |

| 1.1 The Importance of Air Conditioning | ||

| 1 Temperature: | ||

| 2. Humidity: | ||

| 3. Motion: | ||

| 4. Distribution: | ||

| 5. Dust: | ||

| 6. Bacteria: | ||

| 7. Odors: | ||

| 8.Toxic gasses : | ||

| 1.2 Air washer: | 13 | |

| 2 | Authentic foundation | 15 |

| 2.1History of Evaporative Cooling Technology | 15 | |

| 2.2 Early Evaporative Cooling in the Southwest | 16 | |

| 2.3 Evaporative Cooling Equipment Design Challenges | 17 | |

| 2.4 Improving Pad Performance | 18 | |

| 2.5 Re-flowing Coolers-both Solve and Introduce Issues | 19 | |

| 3 | Standard and Work Application of Air Washer | 21 |

| 3.1 The Air Washer | ||

| 3.2 The Psychometric Chart | ||

| 3.3 Adiabatic Saturation | 24 | |

| 3.4 Heat Exchange between Air and Water | ||

| 3.5 Application of air washer: | 27 | |

| 4 | Extend Work | 29 |

| 4.1 Objective of Project: | ||

| 4.2 Working standard | 30 | |

| 4.2.1 Advantages over VCR refrigeration framework | ||

| 4.2.2 Evaporating cooling framework utilizing air washer | ||

| 4.3 Advantages and hindrances of dissipating cooling frameworks: | ||

| 4.4 Application of air washer : | 35 | |

| 5 | Components of an air washer | 36 |

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

| 6 | Fabrication of Air Washer | 42 |

| 7 | Experimentation | 44 |

| 7 Testing | ||

| 7.1 Internal part of the washer: | ||

| 7.2 Hydraulic network: | ||

| 7.3 External part of the washer: | ||

| 7.4 Washer starts up: | ||

| 7.5 Instruction on how to stop the washer: | ||

| 7.6 Precautions: | 45 | |

| 7.7 Experiment procedure: | ||

| 7.8 Observations: | 45 | |

| 8 | Future Scopes: | 53 |

| 9 | Cost Estimation: | 54 |

| 10 | Conclusion: | 55 |

| References | 56 |

1.INTRODUCTION

1.1 The Importance of Air Conditioning :

In this day and age a worldwide temperature alteration is one of the most concerning issues confronted by human. The most extreme temperature amid the late spring has been expanding each year. Diverse sorts of aerating and cooling frameworks are utilized as a part of today’s reality in light of various standards of thermodynamics.

The field of aerating and cooling has turned out to be progressively critical over the most recent couple of years. The businesses worried with the development of aerating and cooling device have extended quickly in view of the expanded need of gear. This displays the acknowledgment of an incredible open door for architects with the best possible foundation and preparing.

The utilization of cooling in industry and open walled in areas has expanded in huge extents. A portion of the critical applications are as per the following:

1 Controlled moistness in the produce of candy parlour the handling and weaving of manufactured silk, and the printing and lithographing industry.

2 Controlled moistness and temperature in programmed wrapping machines, utilized for wrapping sustenance items. Cigarettes and candy parlour.

3 Controlled temperature of response and controlled encouraging and impeding of vanishing in certain branches of the compound business.

4 Control of the dampness substance or air supplies to impact heaters in the make of pig iron.

5 Air moulding tor human solace in profound mines, in coated ironware fabricating, and in the lithographing business.

6 Air moulding for human solace and perishable sustenance safeguarding in lodgings, eateries, other open nooks, and private homes.

7 Air moulding for human solace in theatres, office structures, and other open structures where extensive gatherings of individuals may accumulate.

8. Air moulding tor human solace in the flying machine, train, and other transportation ventures.

Ventilating might be thought to be the synchronous control or all or if nothing else the initial three of the accompanying elements which influence the physical and compound conditions or the environment inside any structure. These variables the greater part of which influence human wellbeing or solace include:

1 Temperature:

Temperature is straightforwardly worried with human solace, it is called warm solace. Warm solace is the state of mind that communicates fulfilment with the warm condition and is surveyed by subjective assessment. Keeping up the benchmarks of warm solace for tenants of structures or different fenced in areas is one of the vital objectives of HVAC configuration engineers. Warm impartiality is kept up when the warmth created by human digestion is permitted to scatter, therefore keeping up the warm balance with the environment. Temperatures of spots differ with change in elevation, climate, atmosphere and skylines.

Room temperature is casual expression for the run of the mill or favoured indoor temperature to which individuals are for the most part usual. It speaks to the little scope of temperature at which the air feels neither hot nor cool, roughly 70o F (21o c).

2. Humidity:

Relative moistness levels underneath 25% are related with expanded inconvenience and drying of mucous films and skin, which can prompt drying and bothering. Low relative moistness additionally builds electricity produced via friction which causes distress and ca obstruct the operation of PCs and paper preparing supplies. High dampness levels can bring about build up inside building structure and on inside and outside surfaces and the ensuing improvement of molds and parasites.

3. Motion:

Air development is an imperative figure warm solace. While thedormant air in falsely warmed spaces regularly adds to a sentiment solidness and advances scent develop, even the littlest air development in icy conditions is frequently viewed as drafty. In warm or muggy conditions, be that as it may, air development can build warm misfortune with no adjustment in air temperature.

4. Distribution:

Most HVAC frameworks warmth or cool constrained air. The parts and design of mechanical air dispersion are critical on the grounds that they can enhance both the solace of involved spaces and decrease vitality utilize. In spite of the fact that the fans that disperse the air don’t devour so much vitality s the hardware that produces the warming and cooling. It doesn’t make a difference how productive the gear if the air is not circulated well. Facilitate leakier ventilation work can bring about 20-40% of warming and cooling vitality misfortune

Effective air dissemination is measured by both its warm solace execution and its vitality proficiency. The effectiveness of air taking care of framework can be comprehensively measured by measuring the power utilization of the fans.

5. Dust:

Indoor Air Quality (IAQ) is involved by contaminations, for example, clean, dust, shape, mold and unpredictable natural mixes. These poisons can originate from furniture, research facilities, cleaning arrangements and building tenants, wellbeing and issue can start not long after introduction to poor Indoor Air quality. Tenants might be experienced irritated eyes, cerebral pain and weakness. Long haul presentation to poor IAQ can add to constant respiratory disease, for example, asthma.

6. Bacteria:

Microbes in our condition can reason for the disease, for example, typhoid, hypersensitivities and migraine.

7. Odors:

Smell is additionally connected with human solace. Awful smell is immaterial to human we can’t get by in condition with awful scent. It is generally produced indoor by taking after sourses: Human sweat, cigarette, drugs, human inhale, clothings and so on.

8.Toxic gasses

The components in home or office furtively influence soundness of our condition. They cause respiratory issues or hypersensitivities.

Dangerous/unsafe substances are:

•Toxic trio (Toluene – dissolvable part) in nail clean,

•Scented candles and metal wicks,

•Aerosol paint items,

•Chemicals in cleaning items.

•The smoke of cigarette or other smoking.

A focal aerating and cooling framework infers that the gear, for example, fans, loop refrigerating device, warm exchangers, AIR WASHERS, channels, and their encasements are intended for a get together on the field instead of in the manufacturing plant as a unit. A focal framework might be adjusted for any coveted conditions, may serve a few unique fenced in areas from a far off-focal area, and is effectively open for overhauling. This was thought to be the appropriate circumstance for the gathering in light of the fact that the specific pieces or device could be put being used as required.

1.2 Air washer:

Air washer is one of the gadgets utilized for aerating and cooling. It depends on the psychrometry. It is investigation of the properties of sodden air.

An air washer is a gadget utilized for molding air. As appeared in Fig, in an air washer air comes in direct contact with a splash of water and there will be a trade of warmth and mass (water vapor) amongst air and water. The outlet state of air relies on the temperature of water showered noticeable all around the washer. Subsequently, by controlling the water temperature remotely, it is conceivable to control the outlet states of air, which then can be utilized for cooling purposes. Noticeable all around washer, the mean temperature of water beads in contact with air chooses the heading of warmth and mass exchange. As an outcome of the second law, the warmth exchange amongst air and water beads will be toward diminishing temperature slope. Thus, the mass move will be toward diminishing vapor weight inclination.

In atmospheres where the air is to a great degree dry, an air washer can work to expand moistness. Dry air can be hard for individuals to relax. It can likewise add to the advancement of dry skin and may harm objects kept in the earth. The air washer expels particulates from the air and adds an infusion of dampness to keep the atmosphere at a relentless mugginess level for expanded solace. Conditions like historical centers and files require exact atmosphere control to ensure their accumulations and an air washer can help with this. Essentially utilizing a fan to draw air over a holder of cool water can clean the air and make a situation more lovely. Air washers draw upon this essential idea. The outline can incorporate additional components like channels to trap unsafe particulates so as to expand the immaculateness of the air. Like different gadgets that perfect air, an air washer can eat up a considerable measure vitality. Some are intended to be more proficient and may have highlights that are proposed to lessen vitality utilization.

Fig. (1) Air washer

2. Authentic foundation

2.1 History of Evaporative Cooling Technology

Discovery of Evaporative Cooling

We have all accomplished the evaporative cooling impact that happens in the wake of leaving a swimming pool on a hot sunny day. It most likely did not take long past the underlying revelation of material for early man to take down to earth favourable position of this physical cooling conduct of water when living in hot and bone-dry locales.

Frescoes or mortar artistic creations from around 2500 B.C. demonstrate slaves fanning jugs of water to cool spaces for eminence. The most punctual archaeological trail of structures consolidating systems for evaporative space cooling begins in Ancient Egypt with ways spreading rapidly to different districts having hot and dry atmospheres. These components incorporate the utilization of permeable water pots, water lakes, pools, and thin water chutes coordinated in different routes into thick walled and shaded fenced in areas to yield regions that would have been cool and gave an escape from the warmth of the day. While unmistakably our progenitors exploited evaporative cooling, it wasn’t until later circumstances that the material science of dissipation and the hydrological cycle were obviously seen so that parts and elements could be adequately built to yield enhanced and repeatable execution comes about.

2.2 Early Evaporative Cooling in the Southwest

Pioneers of the 1930s in the Southwest rested in screened in yards, rooftops, or other outside offices and hung wet sheets to increase some help from the late spring heat. The Arizona Republic reports that visitors at the Ford Hotel in Phoenix mulled over the overhang while young fellows sold to power overhead fans. There were instances of pneumonia amid the late spring as some wrapped themselves in wetsheets to increase some alleviation from the mid year warm. The Arizona Republic reports that visitors at the Ford Hotel in Phoenix mulled over the gallery while young fellows sold to power overhead fans. There were instances of pneumonia amid the mid year as some wrapped themselves in wet sheets and rested before an electric fan.

The 1986 version of Dr. John Watt’s Evaporative Air Conditioning Handbook distinguishes the starting points for present day American evaporative cooling as either from the East Coast or Southwest. In the mid 1900s, air washers were designed in the East and air coolers were created in Southwest (Arizona and California). The air washers went air through water shower, which cleaned and cooled the air in material plants and industrial facilities in New England and the Southern coastline. The South-western air coolers included aberrant coolers, where air ignored a water-cooled curl, and direct coolers where air was cooled by direct contact with water.

The soonest plan of the immediate coolers comprised of wooden edges secured with wet burlap material with fans constraining air into the space being cooled. As they advanced, sumps and recycling pumps were joined into the plans. After a couple dissipation passes, scale would shape on the cushions. To moderate this, a portion of the water would be released or seeped to a deplete.

In the long run, the plan for direct coolers (called wet-boxes, forsake coolers, dribble coolers, and after that marsh coolers) developed to the normal setup of two-inch excelsior (wood chip or aspen) cushions sandwiched between chicken wire and nailed to the cooler edge. The primary aspen cushion cooler was exhibited in the Adams Hotel in downtown Phoenix June 20, 1916. In 1939, Martin and Paul Thornburg distributed mimeographed guidelines, “Cooling for the Arizona Home.” The two educators at the University of Arizona had led tests to enhance execution of these direct evaporative coolers.

About that time, early large scale manufacturing of evaporative coolers started as the coordinated engine and fan units produced by Emerson Electric Company ended up noticeably accessible. Among the first of these mass created coolers were from Goettle Brothers Inc. By 1939, most houses and organizations in the hot and parched southwest were utilizing dribble coolers. By the mid 1950s, countless had joined the market and were creating coolers for a market that secured a significant part of the USA, Canada, and seaward to nations, for example, Australia.

2.3 Evaporative Cooling Equipment Design Challenges

Cooling for business applications requires expansive wind stream rates. Early endeavours consolidated bigger cushions and supplanted the water trickle application frameworks with slinger wheels, shower frameworks, or revolving cushions. This progression was essential since trickle frameworks circulated water inadequately. This condition existed in little coolers constraining their execution and was enhanced in bigger cushions. In the slingers wheel design, a somewhat submerged, pivoting wheel creates a sheet of water in the plane of the wheel. Vanishing happens as air travels through this sheet of water and in the cushions where the un-dissipated water is gotten.

It was rapidly found that slingers were not the appropriate response. The issue with slingers is that the thickness of the airborne water made by the slinger differs conversely with the square of the remove from the focal point of the slinger plate. This variety is additionally bothered as the air stream crashes into the water subject to slinger pivot speed, course, and the air speed profile. Essentially, shower frameworks experience the ill effects of variety in physical spout scope and arrangement, water weight after some time, spout disintegration, spout stopping up, and non-uniform airstream air speed profile. Each of these frameworks neglected to accomplish coveted air and water dissemination to successfully wet the cushions consistently. Regions of the cushion that are not wetted viably permit air to go through without being cooled and at the edges amongst wetted and un-wetted surface build up destinations for scale development.

2.4 Improving Pad Performance

Aspen cushion dribble coolers gave some alleviation in the southwest from the more than 100 F temperatures with the exception of amid the rainstorm season. Also, these Aspen cushion trickle coolers experienced the accompanying inadequacies that drastically restricted their execution:

All trickle coolers produced up to the 1960s included excelsior cushions made of aspen wood. Different woods were attempted alongside fiberglass and woven paper yet each was found to have shortcomings that exceeded their points of interest. Aspen cushions keep on being sold today as an ease, restricted advantage cooling choice. In the 1960s, Munters presented unbending media fortified with uncommon pastes and comprising of either glass-fiber materials or thin ridged sheets of solid cellulose (paper) impregnated with chemicals to oppose listing and rot. Inflexible media could keep up its shape and bolster its own weight when wet. The photograph beneath demonstrates an example area of inflexible media on the left and aspen cushion on the privilege.

As should be obvious by looking at the open voids and creases of the inflexible media with the arbitrarily situated, firmly settled filaments in the aspen cushion, the two sorts have critical contrasts in both water and air dissemination and imperviousness to wind current. Aspen cushions counteract uniform air and water stream bringing about the dissipation rate and cooling viability to shift over the cushion. It requires more energy to draw or push air through the aspen cushions than through inflexible cushions because of the agonizing way air must travel.

2.5 Re-flowing Coolers-both Solve and Introduce Issues

Wetting the thicker unbending media cushions required a move from various tube “insect” dribble frameworks (utilized as a part of bog coolers) to beat mounted funnels with equitably dispersed openings and higher recycling streams. The points of the layering in the inflexible media were protected by Munters to accomplish viable air and water connection in the channels, which advances water vaporization while constraining the air-initiated relocation of water to the back of the cushion that makes dry spots on the substance of the cushion.

The advantage of a distribution framework is that the stream coordinated over the media can be adequately higher than the dissipation rate to accomplish a sensible dispersion and limit the measure of un-wetted zones. Notwithstanding, these frameworks bring their own particular arrangement of plan prerequisites and execution issues. A portion of the more critical of these issues are distinguished underneath:

- Water gathering and capacity sump must be situated in the cooler under the media, which restricts the alternatives for cooler size and area and requires extra basic support because of the extra weight of the cooler.

- The sump water level must be kept up and cooler producers regularly select minimal effort, questionable, and high upkeep drift changes like those found in the family unit can to serve this capacity.

- The higher distribution stream rate builds the volume of water at the air to water interface, which expands the inclination for water entrainment and continue at lower air speeds.

- The higher water stream rate makes a water cover, which limits warm exchange and water vapor relocation.

- The higher water stream rate and consistent inundation of the media in water diminish the compelling existence of the media by wash the rigidifying operators from the media at a quickened rate.

- Draining the sump at start up and shutdown takes essentially more. Not depleting the sump in that grouping makes stale water that backings the development of green growth and form. These molds are unfortunate as well as are commonly joined by a stale smell.

- No arrangements are fused in distribution frameworks to expel the remote material that washes out of the air and into the sump. Along these lines, this material either remains in the sump or is re-coursed and saved on the media. Re-saving the material on the media lessens warm exchange and builds the rate of scale arrangement.

8. Many plans have been established to set and control the water drain rate for re-coursing coolers trying to cut off scale arrangement. The outcome accomplished is that scaling keeps on being a critical issue and water utilization is high.

3. Standard and Work Application of Air Washer

3.1 The Air Washer

So as to completely comprehend and translate accurately the terms utilized as a part of association with the air washer, it is attractive that the terms be characterized now.

An air washer might be considered as a fenced in area in which air is drawn or constrained through a shower of water with a specific end goal to scrub, dampness, or dehumidify the air. Purging the air alludes to the expulsion of airborne pollutions, for example, tidies, gasses, vapors, exhaust, and smoke. The expansion in water vapor in a given space is called humidification, and the abatement of water vapor in a given space is the procedure of dehumidification.

3.2 The Psychometric Chart

The psychometric graph gives a helpful methods for speaking to the distinctive procedures which are conceivable in the operation of an air washer and can be utilized to take care of the issues of aerating and cooling which are included.

The psychometric outline indicates graphically the properties of air on the premise of one pound of dry (air free of water vapour) at standard climatic weight, 29.92 creeps of mercury. Psychrometric relates to psychrometry or the condition of the air with reference to dampness. The air properties reachable from the psychrometric graph are spoken to in Figure 1, their definitions being found beneath. This specific graph in widespread is that it has amendments for barometric weight other than standard and enthalpy deviation lines for rectifications of enthalpy of air for non-immersed conditions.

The following are definitions of the properties of moist air found represented on the psychrometric chart:

- Saturation Temperature (T-S). Temperature of saturated air at a particular vapour pressure.

2. Dew-point Temperature (T-DP). Temperature at which condensation of moisture begins when the air is cooled.

3.Enthalpy at Saturation or Total heat (TH). A thermal property indicating the quantity of heat in the air above an arbitrary datum, in BTU per pound of dry air. The datum for dry air is 0° F and for the moisture content is 32° F water.

4. Enthalpy Deviation (d) deviation of enthalpy of unsaturated air from that of saturated air.

5. Relative Humidity (RH). Ratio of actual water vapor pressure in air to the pressure or saturated water vapor in air -at the same temperature.

6. Sensible Heat Factor (SHF). The ratio of sensible heat to total heat load. The total heat load may be composed entirely of sensible heat or may also include some latent heat. Sensible heat indicates that portion or heat which changes only the temperature of the substance involved. Latent heat is a term used to express the energy involved in a change of state. Inthis case the term latent heat refers to the change in heat occurring when moisture is added toor removed from the air.

7. Grains of moisture or Specific Humidity (SH). The weight of water vapor in grains or pounds per pound of dry air.

8. Wet-bulb Temperature (T-WB). Temperature registered on a thermometer whose bulb is covered by a wetted wick and exposed to a current of rapidly moving air.

9. Volume of Mixture (V). Cubic feet of the mixture per pound of dry air.

10. Dry-bulb Temperature(T-DB). Temperature of air as registered by ordinary thermometer.

- Vapor Pressure (Pv). The pressure exerted by the water vapor contained in the air in inches or mercury.

It may be noted from Figure 1 that the dry-bulb, wet-bulb, and dew point temperatures, and the relative humidity are so related that when any two are known, all the other properties represented on the psychrometric chart can be read. When air 1s saturated, contains all the water vapor it can hold at a given dry-bulb temperature, the dry-bulb, wet-bulb and dew point temperatures are the same, and the relative humidity is 100 per cent.

Fig: (2) Psychometric outline

3.3 Adiabatic Saturation

Because the wet-bulb thermometer is important in psyohrometric, it is necessary to understand the basic process behind the result in measurement.

When air below saturation is brought into contact with water, some or the water will vaporize, adding to the moisture content or the air. It no heat is added moisture will be supplied entirely at the expense of the heat of the air and of the superheat or the original quantity of water vapor. Evaporation will continue and the temperature or the air will be lowered until the air is saturated with the water vapor. This process, taking place without heat transfer to or from an outside source, is called adiabatic, end the final temperature that is approached is termed the temperature of adiabatic saturation or the wet-bulb temperature.

Actually, the mixing or water vapor and air at the wetted surface of a wet-bulb thermometer is not adiabatic because the bulb “sees” objects at the dry bulb temperature. The result is a radiation error and a higher reading than the true adiabatic saturation temperature. Also, because of the difference of rate of diffusion between the air and water vapor, a wet-bulb thermometer will tend to read lower than the true temperature of adiabatic saturation. Hence, theerrors are largely compensated and account for the largely close agreement between the observed wet-bulb temperature and the true temperature of adiabatic saturation.

3.4 Heat Exchange between Air and Water

When air is brought into contact with water at a temperature different than the wet-bulb temperature of the air, there will be an exchange or heat, as well as moisture, between the air and water. In any exchange of heat between air and water, the temperature of the water can never fall below the initial wet-bulb temperature of the air if the initial water temperature is greater than the initial wet-bulb temperature. Also, the converse is true; if the initial water temperature is below the initial wet-bulb temperature of the air, the final water temperature will never rise above the initial wet bulb temperature. This relationship is shown in Figure 2, the diagram is shown as parallel flow because the test air washer was of this type. There is only one exception to the rule that whether there is an exchange of heat occurring when air is brought into contact with water, the temperatures of both must change. This occurs in an air washer when the spray water is continually re-circulated without external heating or cooling. The temperature of the spray water will soon assume the initial wet-bulb temperature and will not change thereafter. Aside from this, there is always a change in the temperature of the spray water when it is brought in contact with air. In order to humidify air with spray water, the temperature of the spray water must be higher than the required final dew-point temperature of the air. Such an amount of water must be used that, as the water cools from its initial temperature, its final temperature will still be above the required final dew-point temperature. When dehumidifying, the exact converse is true; the final water temperature must be below the required final dew-point of the air.

Fig. (3) Air in contact Cooled Water

Fig.3.2: Parallel flow of Air and Water through a spray chamber

Thus for the relation between the dew-point temperature of the air and the water temperature has been discussed. In addition, the relationship between the temperature of the water and the inita1 dry-bulb and wet-bulb temperatures of the air must be discussed. There are five general cases which can possibly be simulated in an air washer. The final air condition in each case depends entirely upon the characteristics and construction of the particular air washer in use. The five cases are as follows:

- The temperature of the water is higher than the initial dry-bulb temperature of the air.

- The temperature of the water is at a point between the initial dry-bulb and wet-bulb temperatures of the air.

- The temperature of the water is at a point between the initial wet-bulb and dew-point temperatures of the air.

- The temperature of the water is lower than the initial dew-point temperature of the air.

- The temperature of the water is constant and equal to the initial wet-bulb temperature of the air. This is the only case in which there is no variation in water

- temperature.

3.5 Application of air washer:

- Comfort molding reasonable for shopping centers, inns, article of clothing units, designing units, modern units and so on.

- Industrial ventilation cooling.

- Pre cooling for compressor and gas turbines.

- Hybrid aeration and cooling systems.

- 100% natural air application.

Dust evacuation application.

Dust evacuation application.

4.Green Houses 0 5. Manufacturing Facilities 6.Vegetable and Fruit Storage

7.Workshops 8. Office Complexes 9.Textile Processing

10. Modern Area 11. Office Industries 12.Tea Processing

4. Extend Work

4.1 Objective of Project:

The air washer, since it is of another outline and of various development than common air washers, is quite compelling.

Therefore, it was the choice of gathering that the specific qualities of the air washer, as set up in this framework, may be of extensive esteem. For future guideline purposes, as well as in the expansion of hardware wanted for RAC Laboratory advancement and development of the establishment.

The warm and stream attributes of the air washer are thought to be of essential significance. It is perceived that this data would be required sooner rather than later. In this manner, on the grounds that there were no quick issues concerning the cleanliness of the lab air, the air cleaning adequacy of the washer would not be considered. In this way, the venture is restricted to the assurance of the air washer warm and stream attributes. Which takes a shot at evaporative cooling framework and play out the undertakings

1. Cooling and humidification

2. Dehumidification

3. Increasing immaculateness of air by:

a. Removing dust particulates

b. Removing poisonous/hurtful particulates

4.2 Working standard

Noticeable all around washer, the mean temperature of water beads in contact with air chooses the course of warmth and mass exchange. As a result of the second law, the warmth exchange amongst air and water beads will be toward diminishing temperature angle. Thus, the mass move will be toward diminishing vapor weight slope. Here a few circumstances are clarified.

- Cooling and dehumidification: tw< tDPT. Since the leave enthalpy of air is not as much as its bay esteem, from vitality adjust it can be demonstrated that there is an exchange of aggregate vitality from air to water. Thus to proceed with the procedure, water must be remotely cooled. Here both idle and sensible warmth exchanges are from air to water. This is appeared by Process O-An in Fig.

[Dew-point temperature: If unsaturated soggy air is cooled at consistent weight, then the temperature at which the dampness noticeable all around starts to gather is known as dew-point temperature (DPT) of air.]

- Adiabatic immersion: tw = tWBT. Here the sensible warmth exchange from air to water is precisely equivalent to inert warmth exchange from water to air. Subsequently, no outside cooling or warming of water is required. That is this is an instance of immaculate water distribution. This is demonstrated process O-B in figure. This is the procedure that happens in a splendidly protected evaporative cooler.

[WBT-wet globule temperature is characterized as that temperature at which water, by dissipating into air, can convey the air to immersion at a similar temperature adiabatically.]

- Cooling and humidification: tDPT<tw<tWBT. Here the sensible warmth exchange is from air to water and inactive warmth exchange is from water to air, yet the aggregate warmth exchange is from air to water, thus, water must be cooled remotely. This is appeared by Process O-C in Fig.

Fig (13) Psychrometric graph

- Cooling and humidification: tWBT<tw<tDBT. Here the sensible warmth exchange is from air to water and dormant warmth exchange is from water to air, however the aggregate warmth exchange is from water to air, consequently, water must be warmed remotely. This is appeared by Process O-D in Fig. This is the procedure that happens in a cooling tower. The air stream extricates warm from the high temp water originating from the condenser, and the cooled water is sent back to the condenser.

[Dry globule temperature (DBT) is the temperature of the damp air as measured by a standard thermometer or other temperature measuring instruments.]

- Heating and humidification: tw>tDBT. Here both sensible and idle warmth exchanges are from water to air, subsequently, water must be warmed remotely. This is appeared by Process O-E in Fig. Along these lines, it can be seen that an air washer acts as a year-round aerating and cooling framework. In spite of the fact that air washer is an and to a great degree valuable straightforward gadget, it is not usually utilized for solace cooling applications because of worries about wellbeing coming about because of bacterial or parasitic development on the wetted surfaces. Nonetheless, it can be utilized as a part of mechanical applications.

4.2.1 Advantages over VCR refrigeration framework

- Introduces the outside air. Try not to flow the air.

- Refrigerant is not required.

- Compressor is killed which devours much power. Around 90% less working expense.

- Installation is simple.

- Full ventilation debilitates scents and germs.

- Increased cooling limit as outside temperature rises.

4.2.2 Evaporating cooling framework utilizing air washer

Evaporative cooling has been being used for a long time in nations, for example, India for cooling water and for giving warm solace in hot and dry areas. This framework depends on the rule that when wet yet unsaturated air interacts with a wetted surface whose temperature is higher than the dew point temperature of air, some water from the wetted surface dissipates into air. The inert warmth of vanishing is taken fromwater, air or them two. In this procedure, the air loses sensible warmth yet increases dormant warmth because of exchange of water vapor. Accordingly the air gets cooled and humidified. The cooled and humidified air can be utilized for giving warm solace.

Characterization of evaporative cooling frameworks:

1. Direct vanishing process

2. Indirect dissipation prepare

3. A mix or multi-organize frameworks

4.3 Advantages and hindrances of dissipating cooling frameworks:

Compared to the conventional refrigeration based air conditioning systems, the evaporative cooling frameworks offer the accompanying points of interest:

- Lower hardware and establishment costs.

- Substantially lower working and power costs. Vitality investment funds can be as high as 75%.

- Ease of creation and establishment.

- Lower upkeep costs.

- Ensures great ventilation because of the extensive wind current rates included, henceforth, are great particularly in 100 % outside air applications.

- Better air circulation in the adapted space because of higher stream rates.

- The fans/blowers make positive weights in the molded space, so that penetration of outside air is averted.

- Very condition neighborly as no hurtful chemicals are utilized.

Compared to the conventional systems, the evaporative cooling systems suffer from the

taking after hindrances:

- The dampness level in the molded space could be higher, henceforth, coordinate evaporative coolers are bad when low moistness levels in the adapted space is required. Notwithstanding, the aberrant evaporative cooler can be utilized without expanding stickiness

- Since the required wind stream rates are considerably bigger, this may make draft as well as high clamor levels in the molded space

- recise control of temperature and mugginess in the adapted space is impractical

- May prompt medical issues because of smaller scale creatures if the water utilized is not perfect or the wetted surfaces are not looked after legitimately.

4.4 Application of air washer :

- Comfort molding reasonable for shopping centers, lodgings, article of clothing units, designing units, modern units and so on.

- Industrial ventilation cooling.

- Pre cooling for compressor and gas turbines.

- Hybrid aeration and cooling systems.

- 100% natural air application.

- Dust evacuation application.

5.Components of an air washer

Air washer assembly consists of several important parts. It has a blower to draw the air in and out the chamber. An insulated water tank for storage of water. Spray drain for providing fine droplets of water. Different types of equipments are also used for carrying out the performance.

Different components of air washer are as below:

- Water tank

- Blower

- Pump

- Pipes and fittings

- Chamber

- Exhaust fan

- Regulator

- Filter

All the components are explained briefly below.

- Water tank:

Water tank is located below the air washer. Water pipe is connected to water tank for supply of water. Quantity of the water increases with increase in the number of room to be cooled. For better performance of the air washer we have to ensure that sufficient supply of the water is provided continuously. The water in tank is ordinary water. Joint water tank is used in the experiment setup so that temperature of water remains constant for a while. The necessary amount of water is supplied to the air washer continuously.

Fig.14 Water tank

- Blower

Blower is used to draw the air out the chamber so that supply of conditioned air is possible. Speed of the fan is changed to provide different air flow rates, through the regulator.

Fig.15 Blower

Specification:

Power consumption – 90 W

Speed – 1400 rpm

- Pump:

Pump is required for supplying water from tank to the spray drain with pressure. Pump is selected on the basis of no pressure loss for providing water at required height. To improve performance location of pump is selected carefully. The aim is to select a height where sufficient head is provided. Numerous pumps are available according the application. Flow rate and cooling are two parameters based on which pumps vary in types. For larger capacity centrifugal pump is used.

Fig 16. Pump

In our experiment we used a small centrifugal pump as the flow rate and capacity of setup is small. The specifications of the pumps are as below:

- I/P – 160-230 V/50 Hz

- AC power – 18 W

- Head max – 1.5 m

- O/P – 780 l/hr

- Pipes and fittings:

Pipes and joints are used to connect water tank and pump. Leak-proof set up is required so that air washer performs efficiently without the loss of pressure and flow rate .Right angle joints and T-joints are used to facilitate different connections. According to the flow rate diameter of pipe varies. In this experiment setup pipes used for purifying purposes is used.

Fig 17 Pipes and fittings

Fig 17 Pipes and fittings

- Chamber:

It is a box made of sheet in which the process takes place. The dimensions of the chamber vary according to the application. It should be such that it can accommodate the fan for drawing air. Make sure that all air passes through the chamber without leakage. It should also provide the provision for the accommodation of the nozzles. For water exit it should also provide provision at bottom of chamber so that water can be collected and its temperature can be measured. The main requirement of chamber is to provide leak proof passages so that desirable results can be achieved.

Fig 18. Chamber

Specification:

65*30*43 cm3

- Exhaust fan:

Fig 19. Exhaust fan

Specification:

- Sweep – 8 inch

- Max. speed – 2400 rpm

- Air displacement – 650 cmh

- Power Consumption – 40 W

- Regulator:

In an electric power distribution system, voltage regulators may be installed at a substation or along distribution lines so that all customers receive steady voltage independent of how much power is drawn from the line.

Regulator is used for the regulate and control the speed of blower fan.

Fig 20. Ragulator

- Filter:

Filter is used for the purification purpose of the air washer. Many types of filters are used in specific air washers, like cellulose pads, nylon filter etc. But in this model AIR WASHER CELLULOSE PAPER PAD filter is used which is fixed in a panel frame.

Fig. 21 Filter

6. Fabrication of Air Washer

We have discussed the different parts of the air washer assembly required in previous articles. From all the parts of the air washer most are standard equipment available in the market. Fan with the regulator, centrifugal pump with adapter, pipes and fittings are standard parts which is easily available. Only chamber, blower casing, tank and the spray drain with husk are fabricated according to the requirement. The fabrication of each portion is explained briefly below.

Schematic Diagram of Air Washer :

Fig 22.Schematic Diagram of Air Washer

Water Tank:

Water tank is made up of GI sheet, which is snipped of from whole length GI sheet measurements are shown in figure. Riveting is done to attach the parts.

Body:

Body of an air washer model is made of Mild steel. Size of body is 65*30*43 cm3.body is made by with the help of submerged arc welding.

Fig 23. Mild steel

Wooden sheet:

3 wooden sheets are used in model. Size of two wooden sheets is 65*30 cm2. One wooden sheet is placed on evaporative cooling pad its size is 30*30 cm2.

Wooden sheets are cut by hack-saw.

Wooden sheets are attach on body with the help of screw and nut.

7 Experimentation

Now the experiment setup is ready for the performance. But before beginning the experiment setup should test to check whether it works according to the specification. Some precautions are made for getting desirable results.

Testing

7.1 Internal part of the washer:

- Spraying drain and husk should be centered in the chamber.

- Check the pipe connection for the leakage.

7.2 Hydraulic network:

- Feed the water tank and inspect for dirt build-up from assembly operations.

- If there is dirt, drain the tank and re-feed it.

- Operate the system and eliminate leaks.

7.3 External part of the washer:

- Check seals and access doors for perfect seating to prevent leaks.

Actuate the fan .

7.4 Washer starts up:

- The water circulation system must be the first one to be operated.

- The system must operate at full pressure to deliver spraying. Check all nozzles for normal operation.

- Make sure all access doors, passageways, ducts and other openings are closed, locked and bolted.

- Check the fan and regulator.

7.5 Instruction on how to stop the washer:

- First turn off the fan.

- After fan, disconnect the hydraulic network.

7.6 Precautions:

- Condition of pump and fan.

- Make sure there are no loose bolts in the whole set.

- Check the pipe joints for leakage.

After all these steps experiment setup is ready for use.

Now in experiment we determine the effect of water flow rate and air flow rate on the cooling effect. So we take the reading for two different water flow rates and air flow rate with help of the fan regulator.

7.7 Experiment procedure:

- First check the all connection and electric supply.

- Place the wet-bulb thermometer on the outlet of air washer

- Now measure the ambient temperature.

- Keep the inlet open and measure the water temperature in water tank

- Now measure the flow rate at still condition.

- Start the fan at full speed and turn on the pump, which supply the water from the water tank. Water from pump is supplied to the nozzles and fine spray is produced in the chamber.

- Now measure the air velocity at exit portion with the help of the anemometer.

- Measure the exit air temperature.

- Now change the speed of the fan with help of regulator to minimum and take all the readings as mentioned above.

- Change the water temperature to 10*, 12*, 14* C and repeat all the procedure and note down the readings.

- After completion of the experiment turn off the fan and the pump.

7.8 Observations:

- Exit area: 72 sqr inch

- Ambient temperature: 33*C

- Velocity of air leaving at maximum speed of fan: 10.95 meter per second.

- Velocity of air leaving at minimum speed of fan: 9.20 meter per second.

- Relative humidity of moist air(ambient) : 67%.

| No.

Fan Speed 1: 9.20 m/s |

Tw (Water inlet temperature ,c) | Air outlet temp(c) | Relative humidity(%) | Dry Bulb Temp(c) | Wet Bulb Temp(c) | Relative Humidity from DBT and WBT |

| 1 | 29.5 | 32.7 | 61 | 31 | 26.5 | 71 |

| 2 | 26.5 | 32.6 | 69 | 32.8 | 30.0 | 82 |

| 3 | 20.0 | 32.4 | 69 | 30.5 | 29.5 | 93 |

| 4 | 14.5 | 31.4 | 69 | 31 | 29 | 86 |

Table No. 1

| No.

Fan Speed 2: 10.95 m/s |

Tw (Water inlet temperature ,c) | Air outlet temp(c) | Relative humidity(%) | Dry Bulb Temp(c) | Wet Bulb Temp(c) | Relative Humidity from DBT and WBT |

| 1 | 29.5 | 33.2 | 66 | 31.5 | 27 | 71 |

| 2 | 26.5 | 32.8 | 72 | 31 | 30.0 | 93 |

| 3 | 20.0 | 32.2 | 68 | 31.5 | 29.5 | 86 |

| 4 | 14.5 | 31.3 | 67 | 31 | 29 | 86 |

Table No. 2

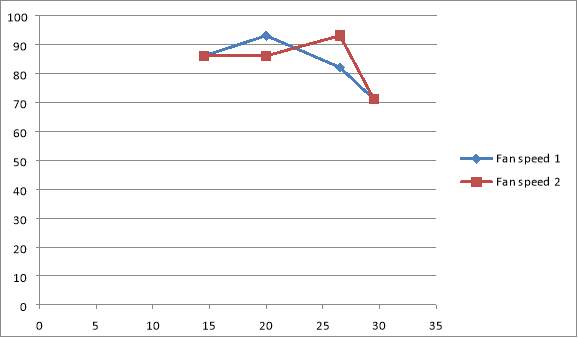

*Impact of fan speeds:

Fan speed 1: 9.20 m/s

Fan speed 2: 10.95 m/s

Air Outlet Temperature v/s Water Inlet Temperature

Temperature Difference v/s Water Inlet Temperature

Relative Humidity v/s Water Inlet Temperature

Relative Humidity from DBT and WBT v/s Water Inlet Temperature

- Future Scopes:

In future if improvement is done the same model of this project, following suggestions are established to improve the model:

- Auto controlling of blower and pump according to the requirements.

- Thermocouple can be included in the model.

- Separate control unit can be installed for humidification and dehumidification.

- Spraying of water mechanism can be improved.

Cost Estimation:

| Sr. No. | Item | Cost (INR) |

| 1. | Exhaust fan | 1350 |

| 2. | Blower fan | 1500 |

| 3. | MS | 2000 |

| 4. | Wood Sheet | 600 |

| 5. | Regulator | 200 |

| 6. | Pump | 270 |

| 7. | switch | 50 |

| Total | 5970 |

Table No. 3

5. Conclusion:

From the graph we can conclude that

- As the velocity of air decreases, mass flow rate of air decreases which increases the cooling effect.

- For constant water flow rate it is advisable to keep air mass flow rate low.

- For constant air flow rate it is advisable to keep the water flow rate as high as possible.

- Also the cooling effect increases as the inlet water temperature decreases.

Better results can be obtained by providing 100 % leak proof setup and improving the performance of nozzle by producing more atomized water spray.

6. References

- Test Book of Refrigeration and Air Conditioning: R K Rajput

- http://hvacinfo.com

- http://google.co.in

- http://wikipedia.org

- Ashrae handbook

- http://nptel.com

- Departmental Library

- Central Library

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Technology"

Technology can be described as the use of scientific and advanced knowledge to meet the requirements of humans. Technology is continuously developing, and is used in almost all aspects of life.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: