NT Constructions Risk Management Plan

Info: 8938 words (36 pages) Dissertation

Published: 9th Dec 2019

Tagged: ConstructionRisk Management

Risk Management Plan

Table of Contents

2.0 SCOPE OF PROJECT – 79 STATION ST BURWOOD

9.0 APPROVAL OF RISK MANAGEMENT PLAN

1.0 INTRODUCTION

NT Constructions Risk Management Plan into 79 Station Street Burwood project is to guarantee that NT Constructions completes all objectives and goals established out by the project management team through the completion of a risk management plan.

The main reason of our risk management plan is to guarantee that we surpass the client’s expectancies of the project, recognize preceding development, the dangers related with the venture, deal with the risks, meet task spending plan and timetable and surpass the organization’s objectives/goals by way that we convey the last item to the customer. We expect to guarantee that all dangers and unverifiable strategies are recognized before development and appropriately oversaw all through the undertaking to guarantee that the end conveyance objective is accomplished with least effect to our task. We will guarantee that dangers are controlled on 79 Station Road Burwood through our hazard administration approach which will distinguish, survey and oversee chances all through the undertaking while constantly observing the risks. By alleviating and controlling danger among our building site, we are further protecting the wellbeing and prosperity of all close to home on and off site while likewise conforming to the Word related to OHS Acts.

In making this risk management plan, we aim to get each goal set out in the scope of works, throughout the completion of risk management method as established out in ISO 31,000:2009 by creating the environment (company strategies) the ID of risks like constructional, financial, legal factors that will impact the project and analysis and evaluation of risks such as dealing and working around the risks, management of risks such as the insurances reviews, the monitoring and review of the risk management plan and the communication throughout the project implementing the risk management plan.

The risk management plan obeys all the necessities of the AS/ISO 31000:2009 and ISO/IE 31010:2009 risk management procedures. NT Constructions will follow to put in risk management culture on the project team and internal staff by providing all internal staff with the risk management plan and getting all staff to sign off on it once it has been read. This will ensure that the risk management plan has been understood by the team and for any recommendations/questions/alterations to be forwarded to the project manager to further improve the risk plan prior to construction commencement.

1.1 INTERNAL CONTEXT

NT Constructions method to risk management is reliant on the internal and external context of our company. At (79 Station Street Burwood) is the top difficult and maximum project income construct we have done.

Our aims/image is to stay as a tier 2 construction company. Our projects will not be of more complexity to 79 Station Street Burwood of an apartment extension on a retail shop. We wish to stay as a key player in the tier 2 sector in terms of our build, but wish to increase our portfolio and profits annually by $2,000,000-$3,000,000. Our risks associated will that way be maintained as the project team and construction managers will be more familiar and experiences with the risks associated with the builds. Through the implementation of the risk management plan, specifically the monitor/review process of the plan, we will ensure that all the risks identified by the project team prior to the start of construction.

As we are looking to stay as a tier 2 company, we don’t plan to be expanding our company structure or changing the roles and responsibilities of our employees. As there is no change in the context of the objectives/vision of our company for the next 5 years, it is not deemed necessary to expand. The employees will be trained and have the experiences/knowledge to handle the risks associated with the construction of our future projects.

The risk management systems we have put in place for 79 Station Street Burwood are managed by the construction team and the project management team. It has been constructed in accordance with AS/ISO 31,000:2009 & ISO/IEC 31,010:2009 and will meet the needs of the project.

The systems, employees and processes we have put in place in accordance with the risk management standards ensures that we have carefully identified and planned for any risks that may arise on 79 Station Street Burwood and have put in place approach methods to any unaccounted risks.

1.2 EXTERNAL CONTEXT

17 Cardigan Street Burwood project’s external context in relation to our approach to risk management will be defined by the environment that our firm operates. As we operate in Inner Melbourne suburbs and our project is in the suburb of Burwood, external context that will affect our risk approach include;

- Whitehorse local council

- Victorian state government including the building codes of Australian and building standards

- Local public

- WorkSafe Victoria

- CFMEU

- Environmental Protection Agency

- Neighbouring retail shops

- Local suppliers and sub-contractors

MK Construct has a strong, steady relationship with our external stakeholders including our client for 79 Station Street Burwood, the suppliers and sub-contractors working on the project and the local council (Whitehorse City Council). The financials and funding of the project is through our client (James Harden) who will be funding the funds and processing our progress payments monthly. The project is situated within a busy strip of retail shops; therefore they impose threats through noise complaints, parking issues and possible disruption to business.

2.0 SCOPE OF PROJECT – 79 STATION ST BURWOOD

79 Station Street Burwood project is a two storey extension on an existing retail building which will consist of an additional 6 (six) apartments with 3 (three) on each level while retaining the ground floor retail.

The main objective of this project will be to ensure the smooth running of the retail shop and other shops along the strip with minimum construction setbacks.

Scope of the project in more detail includes;

- Solar panels will be situated on the roof and will supply the buildings Hot Water Systems and electricity

- Roof structure to be constructed out of Metal roofing

- Retail store that the new construction will be building on top of is of a single Brick Veneer construction

- The power supply services will be increased to service the extra 6 apartments

- Consists of I-Cube External Cladding

- Consists of Seam External Cladding

- Single brick veneer construction

- Total building height of 11.045m

- Consists of 6 balconies (one servicing each apartment)

- Single bedroom apartments with one bathroom

- Fire rated concrete stairs servicing all apartments

- Boral wall apartment separation system

- Cantilevered entry canopy

- Replacement of existing retail glazing with new commercial grade glazing

- Bike and bin storage to be constructed at ground level

- Construction site is located amongst a busy strip retail shops

- Busy foot traffic and vehicle traffic (traffic management plan will need to be implemented)

- Gantries and hoardings will be set up along the border of the construction site

- Temporary power will be sourced from a temporary power pole conducted by CitiPower

- No demolition will be conducted

- The site is located on a corner block

- 3.0m high ceilings (standard height)

- 52 week project deadline (January 2018 start date)

- Defects Liability cost of $1,400 per week

- Project cost = $2,500,000

- Deliveries will need to be conducted under strict traffic management and site supervisor instructions to ensure no disruptions to public

- Construction of new apartments must not interfere with retail shop

- Retail shop will still operate during construction (therefore noise must be kept to a minimum)

- Extensive safety measures to ensure safety of retail shop below

- Minimise noise during shopping hours for surrounding retail shops

3.0 RISK MANAGEMENT APPROACH

Our company (MK Construct) will implement our risk management approach in accordance with ISO 31,000:2009. The project manager in charge of the project is Sam Hanna, who will have the responsibility of constructing and implementing the risk management approach and plan into the project.

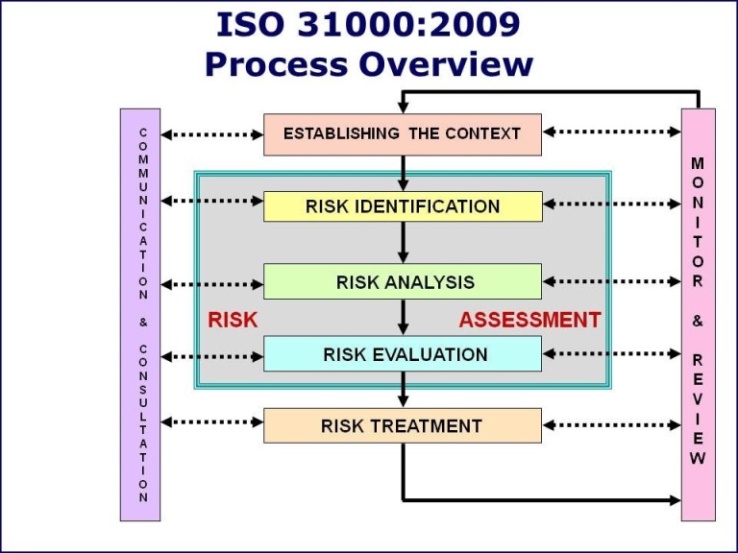

ISO 31,000:2009 sets out a process overview for every step to be undertaken in order to identify and control the risks associated with the project. Our risk management approach will follow the process overview that is given below;

The process overview risk assessment of ISO 31,000:2009 and how we will implement each of the steps into our risk management approach

Establishing the context: The project manager (Sam Hanna) will assess the internal and external context factors in relation to our project (79 Station Street Burwood). He will assess the internal factors in relation to our company to such as the objectives and strategies we will put in place in order to achieve the objectives and policies set out, the capability of our project team and the structure and the risk tolerance and appetite that our company is capable of undertaking. He will also assess the external context factors associated with 79 Station Street Burwood such as the social factors, financial factors, business factors and the external factors of the company. This will determine the capability/tolerance of risks associated with 79 Station Street Burwood that our company is able to take on.

Identifying the risks associated with the project: The project manager, construction manager and project team will discuss/brainstorm prior to construction on the possible risks that may arise on the project. This is done through strategic analysis of the scope of works/work breakdown structure, the experience and knowledge of the project team, ongoing risk identification and through the review/feedback of previous projects.

Determining what control measures to implement: To determine what control measures we will implement for the specified risks associated with 79 Station Street Burwood, the project team will consult with the construction managers and site supervisors on the most effective control measures to be implemented to the associated risk. This will be determined on the results and feedback of previous projects, the cost effective analysis of the control measures will be considered and from the personal experience of the project team, construction managers and site supervisors of the effectiveness of the control measures. If no control measures can be determined, then the help from external experts will be sought out.

Evaluate and define their impact: The control measures that have been put in place to control the risk associated will be evaluated by conducting visual inspections by the project team to ensure that the control measures put in place have controlled the risks associated. If visual inspections can’t determine whether the control measures have worked, then feedback from the project team and construction management team will be sought.

Determining monitoring: Monitoring of the control measures will be discussed by the construction managers and project team. With their relevant experience, qualifications, previous project experience, the project team with the assistance of the construction managers and site supervisors will implement monitoring tools that will evaluate the control measures to be put in place. The construction managers will monitor the control measures of all construction works, with the project team monitoring control measures that are relevant to non-construction risks. The monitoring of the control measures will be brainstormed and discussed between the project team and construction team with the actions being put in place through the risk register.

Communication and consultation process: Communication of the risk management approach at each stage of the ISO 31,000:2009 over processes will be conducted by the project management team and construction team. Each meeting will be noted and minutes will track and list the discussions and processes agreed upon. The project team will implement all actions agreed upon into the project risk register and risk management plan. The minutes of the meeting will be processes and distributed by the administration staff to all the attendees of the meetings. The risk management plan at completion will be finalised and distributed to the relevant stakeholders by the administration team.

Monitor and review: Each step will be monitored and reviewed by the relevant persons with the responsibilities assigned. The project team will collect and analyse the information collected by the stakeholders. Feedback and audits will be conducted at each level for further improvement of the steps and overall plan. Factors such as cost, impact, reduction in likelihood & occurrence, delays, and quality issues will be addressed at every level. All information will be collected to further improve future risk management plans.

4.0 HIERARCHY OF CONTROL

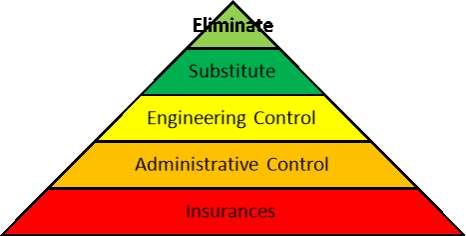

Our risk management plan and our risks will be controlled through our hierarchy. Any risks that arise on 79 Station Street Burwood will need to be assessed according to the hierarchy of controls and will be assessed from the top of the pyramid down. We will control the risks that have been forecasted and any unforseen risks by way of;

Elimination: The first step to control any risk that arises on our project site is to eliminate it. By eliminating the risk (if possible) and physically removing it, it ensures that the hazards and impacts associated are eradicated. The elimination process of the hierarchy control is the most effective and should be used wherever applicable. If the risk cannot physically be removed, then the next step of substitution will be applied to the risk.

Substitute: If the risk cannot be controlled by the elimination approach, then the substitution of the risk will be initiated. This requires the replacement/substitution of the hazard with a different method/approach with a method that doesn’t produce a hazard.

Engineering controls: By implementing this method of risk control, we assume that the risk cannot be eliminated or substituted, so we must put in place engineering control to isolate any persons from the risk by putting in place protection controls. This can include barriers from risks, protection of fall barriers, mechanical aids, and machine guarding to ensure that the hazard has been isolated from the workers or public.

Administrative controls: This step is the last resort for physical control measures to be put in place before insurances. The administrative controls step in controlling risks by changing the workers/public exposure to the risk. This can include specific training for the risk, supervision of the risks, inductions, safe work method statements and maintenance.

Insurances: If we are unable to control the risks through elimination, substitution, engineering control and administrative controls, then we accept that there is a risk that cannot be controlled and must take relevant insurances on the associated risks in the case that they do occur. If they do occur, we will be covered with the insurances reducing the cost impacts associated.

The risk hierarchy that MK Construction will implement into 79 Station Street Burwood is defined below;

5.0 RISK CATEGORIES

The risk categories and their definitions for the project of 79 Station Street Burwood is defined below as;

|

Risk Category |

Definition |

| Natural | Such as fires(lighting strikes), hailstone damage and floods |

| Political | Changes in legislation that affect our construction |

| Contractual | Risk relating to the requirements of the builder-client contract |

| Environmental | Pollution created from construction |

| Weather | Weather impacting site (Heavy rain or heat waves) |

| Economic | Potential economic crisis’ |

| Financial | Financial funds relating to the client |

| Organisational | Shift of powers/exit of significant team members |

| Legal | Legal disputes against our company |

| Security | Security of our sites after hours |

| Occupational Health & Safety | Health and well-being of all persons on site and around our construction site |

| Communicational | Risks relating to the communication of information between stakeholders |

| Transport/Logistic | Risk relating to the deliver/transportation of materials and products to and from the construction site |

| Cash Flow Risk | Monetary funds that run the construction |

| Damage To Reputation | Companies overall reputation in the eyes of the public |

| Increased Competition | Construction companies that may affect suppliers/sub-contractors |

| Supplier/Sub-Contractor | Risk that may affect the sub-contractors/suppliers productivity |

6.0 RISK MATRIX

LIKELIHOOD RATING MATRIX

The likelihood rating risk matrix identifies the likelihood of a certain risk occurring and its probability.

| LIKELIHOOD RATING | ||

| Rating | Likelihood | Likelihood of Occurrence |

| (E) | Rare | Might only occur in exceptional circumstances. Less than 1% chance of occurring |

| (D) | Unlikely | Could occur at some time. 1%-10% chance of occurring |

| (C) | Possible | May occur at some time. 10%-25% chance of occurring |

| (B) | Likely | Most likely will occur. 25%-75% chance of occurring |

| (A) | Almost certain | Is expected to occur. 75%-99% chance of occurring |

RISK ACTION LEVELS

The risk action levels matrix identifies what actions will be taken for the severity of risks associated.

| RISK ACTION LEVELS | |

| EXTREME | Work site shut down/ stop process. Project Manager & Construction Manager to make a decision/action. Removal action required |

| HIGH | Construction Manager to assess risk and put in place an action to control the risk. May require a removal action |

| MODERATE | Site manager to put in place a remedial action |

| LOW | Procedures put in place to ensure risk is maintained |

RISK MATRIX

| RISK MATRIX (AS/NZS 4360) | |||||

| CONSEQUENCES | |||||

|

LIKELIHOOD |

INSIGNIFICANT (1) |

MINOR (2) |

MODERATE (3) |

MAJOR (4) |

CATASTROPHIC (5) |

| ALMOST CERTAIN (A) | Medium

(1A) |

High

(2A) |

High

(3A) |

Extreme

(4A) |

Extreme

(5A) |

| LIKELY (B) | Medium

(1B) |

Medium

(2B) |

High

(3B) |

High

(4B) |

Extreme

(5B) |

| POSSIBLE (C) | Low

(1C) |

Medium

(2C) |

High

(3C) |

High

(4C) |

High

(5C) |

| UNLIKELY (D) | Low

(1D) |

Low

(2D) |

Medium

(3D) |

Medium

(4D) |

High

(5D) |

| RARE (E) | Low

(1E) |

Low

(2E) |

Medium

(3E) |

Medium

(4E) |

High

(5E) |

RISK CONSEQUENCES MATRIX

| RATING | CONSEQUENCE | REPUTATION/ IMAGE | FINANCIAL | OH/S | ENVIRONMENTAL/ COMMUNITY | MANAGEMENT IMPACT | LEGAL |

| 1 | INSIGNIFICANT | *No impact on staff turnover

*No costs incurred *Business reputation not affected |

$0 – $1,000 | *Minor injury treatable on site no long term effects | *No environmental damage | *Management able to absorb activity | *Minor breach of regulation no actions imposed |

| 2 | MINOR | *No customer complaints

*Minor effect of reputation |

$1,000 – $50,000 | *Causing injury that requires medical attention | *Minor environmental damage

*Damage can be rectified with no costs |

*Requires management attention over several days | *Minor breach of regulations

*Minor legal issues (VCAT) |

| 3 | MODERATE | *No team members leave

*Customer complaints *Local news coverage |

$50,001 – $99,000 | *Serious injury resulting in long term physical impairment | *Some environmental damage

*Costs incurred on rectifying damage |

*Requires significant attention by management team | *Breach of regulations

*Moderate fines imposed |

| 4 | MAJOR | *Media coverage (State)

*Significant team members leave *Costs incurred |

$99,001 –

$500,000 |

*Multiple serious injuries resulting in long term physical impairment | *Extensive environmental damage

*Significant costs incurred to rectify damage |

*Requires significant attention by management 1 week + | *Litigations costing $10,000-$500,000

*Significant time lost on process |

| 5 | CATASTRPOHIC | *Management leaves

*Government inquiry *Nation-wide media coverage *Costs incurred |

$500,001 + | *Fatality/loss of life

*Permanent disability |

*Major environmental damage incurred

*Company faces fines *Significant costs incurred to rectify damage |

*Requires extensive attention by management 1 month + | *Litigation costing $500,000+

*Class actions *Possible bankruptcy |

7.0 RISK REGISTER

| Project Name: | 79 Station Street Burwood | Project Number: | 04_2017_0221 | ||

| Developed By: | Sam Hanna | Signature: | S.Hanna | Date Signed: | 29.09.2017 |

|

Item |

HAZARDS / ISSUE DESCRIPTION |

INHERENT (BEFORE) RISK LEVEL |

CONTROLS |

MONITORING TOOL |

RESIDUAL (AFTER) RISK LEVEL |

RESPONSIBLE |

| 1 | Natural | |||||

| 1.1 | Fires causing damage to the structure of the building | 5A | -Emergency evacuation plan in place

-Adequate Fire fighting equipment held on site |

-Monthly project team review of the evacuation plan

-Fire fighting equipment tested and inspected as per Australian Standards |

5D | Project team

Local authorities |

| 1.2 | Damage to construction site due to heavy hail | 2A | -Take out insurance to cover hail damage | -Quarterly review of insurance policies | 2A | Project manager |

| 1.3 | Injury to workers due to hail hitting the workers | 2D | -Work to halt and workers to move undercover is hail persists | -Meeting with project team in regards to control measure | 2E | Project team |

| 1.4 | Heavy rain causing aesthetic damage to façade | 2C | -Weather forecast to be reviewed for the week | -Quality checks/physical inspection on façade | 2E | Construction manager |

| 1.5 | Heavy rains during concrete pour causing delay | 2A | -Site supervisor to check weather forecast 1 week prior to commencement of site pour | -Construction schedule still on track | 2D | Project manager |

| 2 | Political | |||||

| 2.1 | Housing policy changed affecting overall profits | 4E | -Ensure 60% of units are sold prior to commencement of construction

-Project manager to monitor any possible political changes |

-Financial reporting review of sales

-Daily news updates |

1E | Project manager |

| 2.2 | Government legislations impacting the sales of our apartments | 4E | -Weekly news reports to be read in possible changes in legislation impacting our sales | -Physical review of reports | 4E | Project team |

| 2.3 | GST laws changed decreasing profits | 3E | -Petition/lobby against changes to GST policy/laws | -Meetings with management | 2E | General manager |

| 2.4 | Government laws placed on international buyers restrictions | 5D | -Petition/lobby against changes to buyer restrictions | -Meetings with management | 5E | General manager |

| 2.5 | Changes to working visas restricting work on building sites | 4E | -Procurement of sub-contractors to be only of Australia citizenship | -Citizenship of workers to be checked upon induction | 2E | Project manager |

| 3 | Contractual | |||||

| 3.1 | Project runs into liquidated damages due to construction delays | 3C | -Put a construction schedule in place | -Daily monitoring of progress of schedule | 1D | Project manager & construction manager |

| 3.2 | Materials used on site aren’t as per the contract | 2D | -Drawings to indicate building materials to be used on site | -Clear and concise drawing and plans | 2E | Architects and project manager |

| 3.3 | Client is disputing variations | 2C | -Records of variations to be noted | -Records of variations and details to be put into company portal | 2D | Admin team |

| 3.4 | Inclement weather accounted for in contract is surpassed | 4D | -Estimate on total rain for year to be calculated and included in contract | -Meetings and checklists of contract details | 4E | Project manager |

| 3.5 | Construction start date delayed due to site handover from client | 4D | -Site handover date to be defined in contract | -Liquidated damages applied to the client for delay in site handover | 2D | Project manager |

| 4 | Environmental | |||||

| 4.1 | Rubbish flying onto the street due to uncovered waste bins | 3A | -Waste bin mesh covers to be used | -Physical inspection by site supervisor every day to ensure it is covered | 3D | Site supervisor |

| 4.2 | Spillage of hazardous materials into drainage system | 5D | -Site induction to notify sub-contractors of handling of hazardous materials | -Hazardous materials treatment log book | 4C | Construction Manager |

| 4.3 | Spillage of hazardous materials into earth/soil | 5B | -Hazardous materials to be stored in site container and locked | -Site supervisor to ensure that the container is kept locked when necessary | 5D | Site Supervisor |

| 4.4 | Excessive dust created through demolition | 3A | -Water hoses to be used during demolition | -Site supervisor to physically check that a water hose is being used | 3D | Sub-contractors & site supervisor |

| 4.5 | Dirt/rock run off from trucks leaving site | 2A | -Rumble grid to be put at entry/exit points | -Site supervisor to physically inspect that no dirt is running off on the street | 2D | Site supervisor |

| 5 | Weather | |||||

| 5.1 | Flooding due to overflow of stormwater pits | 2B | -Put stormwater mesh protectant

-Ensure that there are no leaves clogging it |

-Weekly stormwater physical checks | 2C | Site supervisor |

| 5.2 | Delay in project due to heavy rains | 3B | -Project schedule to include float time taking into account inclement weather | -Meeting with project team to review controls | 3C | Project team |

| 5.3 | Damage to property caused by high winds | 2D | -All loose items to be tied down and covered during high winds | -Checklists are being ticked off during high winds | 2E | Construction manager |

| 5.4 | Damage to plasterboards on site due to heavy rain | 2A | -Plasterboards to be covered with plastic sheets at all times if not being used | -Site supervisor to conduct physical inspections | 2D | Site Supervisor |

| 5.5 | Delays caused by crane halting operation due to high winds | 2B | -Allow for extra time in construction schedule to account for this risk | -Review of contract to include this possible risk delay | 2C | Project manger |

| 6 | Economic | |||||

| 6.1 | Price increase of timber that is sourced overseas | 2C | -Put in place a procurement plan with a backup timber supplier | -Procurement plan to be reviewed monthly | 1C | Project manager |

| 6.2 | Downfall of the Chinese dollar impacting the sale of our apartments | 5B | -Business insurances will be taken out | -Quarterly review of insurance policies | 3C | Project manager |

| 6.3 | Australian dollar decrease, increasing our overseas bulk tile supply | 4B | -Put in place a procurement plan with a backup timber supplier | -Procurement plan to be reviewed monthly | 3B | Project manager |

| 6.4 | Change in minimum wage increasing our sub-contractor agreement packages | 4E | -Sub-contractor agreement packages to outline a fixed wage for the entirety of the project | -Project manager to review sub-contractor agreements at end of project | 1D | Project manager |

| 6.5 | Economic recession | 5E | -Business insurances will be taken out | -Quarterly review of insurance policies | 5E | Project manager |

| 7 | Financial | |||||

| 7.1 | Construction termination due to bankruptcy of client | 5D | -Business insurances will be taken out | -Quarterly review of insurance policies | 3D | Project manager |

| 7.2 | Progress payments from client received a month late | 3C | -Remainder e-mail and calls to be made to client every day after due date | -Checklists | 3D | Project manager |

| 7.3 | Variations from clients not being paid | 3C | -Records of variations to be noted and e-mailed to client | -Checklist | 3D | Project manager |

| 7.4 | Client withholding final progress payments due to contractual disputes over quality | 4D | -Quality checks to be conducted | -Quality audit to be conducted | 4E | Construction manager |

| 7.5 | Inflation increasing overall prices of project | 4D | -Account for inflation of total project length in contract | -Contract checklist | 4E | Project manager |

| 8 | Organisational | |||||

| 8.1 | Higher management staff leaving the company without adequate notice | 4D | -Penalties to be applied if 4 weeks’ notice is not provided | -Contract checklist | 2E | Human resources |

| 8.2 | Project manager leaving the project due to maternity leave | 4D | -Employees to notify company of maternity application 6 months prior | -Meetings and contract audits | 2E | Human resources |

| 8.3 | Construction manager receiving a better job offer and leaving the project | 4E | -Employment contracts to clearly define exiting penalties | -Contract checklists | 3E | Human resources |

| 8.4 | Employee taking too many sick days | 2D | -Termination of employment if sick days exceed 10 in one year without medicals | -Employee timesheets | 1D | Human resources and general manager |

| 8.5 | Construction manager taking extended annual leave without notice | 3C | -Annual leave approval clearly defining dates | -Checklist | 3D | Project manager |

| 9 | Legal | |||||

| 9.1 | Client taking legal action against our company | 5D | -Insurances to be taken out | -Quarterly review of insurance policy | 5E | Project manager |

| 9.2 | Local council fining the company for parking on nature strips | 1B | -Site induction to include parking requirements | -Traffic management plan | 1D | Project manager |

| 9.3 | Injury to worker causing shut down of site imposed by the unions | 4A | -Occupational health and safety management plan | -Incident report logs | 4D | Construction manager |

| 9.4 | Environmental Protection Agency imposes a fine on our company due to loud excessive noise | 3B | -Occupational health and safety management plan in place | -Noise level audits to be conducted | 3D | Site supervisor |

| 9.5 | Person taking legal action due to injury caused by materials on side of road | 3B | -Occupational health and safety plan implemented | -Physical inspection of public surroundings | 3E | Site supervisor |

| 10 | Occupational Health & Safety | |||||

| 10.1 | Slips due to excess water on hard surfaces | 3A | -Labourers to sweep excess water with squeegee every morning before site opens | -Site supervisor to conduct visual inspection every morning | 3D | Labourers

Site supervisor |

| 10.2 | Falling off the roof | 5B | -Erect guard rails along the roof barrier

-Harnesses to be worn by all persons on roof -Persons on roof to be watched/supervised by site supervisor |

-Visual check that guard rails are installed correctly

-Visual check that harnesses are being worn -Inspect guard rails and harnesses that they meet safety measures |

5D | Site supervisor |

| 10.3 | Faulty wiring causing electrocution | 5A | -Electricians conducting works are licenced and insured | -Construction manager to cross reference qualifications at inductions | 5D | Construction manager |

| 10.4 | Materials being lifted by a crane hitting someone | 3C | -Sirens to alert workers when the crane is in motion

-PPE to be worn by all personnel on the construction site -Spotter to look watch the motion of the crane lift and ensure it is not near any personnel |

-Visual inspections by construction managers ensuring OHS requirements followed

-Crane operator to conduct siren tests prior to commencement of works |

3D | Construction manager

Crane operator |

| 10.5 | Injury to worker due to manual handling | 2C | -Site induction to include the safe manual handling processes | -Construction manager to visually inspect and evaluate SWMS | 2E | Construction manager |

| 11 | Security | |||||

| 11.1 | Materials/tools container door is being left unlocked | 2A | -Put in place a checklist that includes locking the containers at the end of the day. Checked by site supervisor | -Site supervisor to visually inspect and conduct checklist to ensure containers are locked. | 2D | Site supervisor |

| 11.2 | Theft due to lights not being turned off at the end of the working day | 2A | -Site supervisor to conduct an end of day site walk | -Visual inspection that all lights are switched off | 2C | Site supervisor |

| 11.3 | Company online portal being hacked and files wiped | 5E | -I.T company to set up online security systems | -External audit to be conducted by secondary I.T company | 5E | Construction manager |

| 11.4 | Tools and equipment stolen from construction site | 2A | -Security company to conduct visual inspection after hours | -External company to audit monthly | 2C | External security companies |

| 11.5 | Construction site vandalized | 2B | -Security company to conduct visual inspection after hours | -External company to audit monthly | 1C | External security companies |

| 12 | Transport/Logistics | |||||

| 12.1 | Delivery requests not received from suppliers | 4C | -Confirmation e-mails to be sent to suppliers to ensure information is received | -Project manager to monitor that the e-mails are being sent | 4E | Construction manager

Project manager |

| 12.2 | Deliveries unloaded in incorrect location | 2A | -Site supervisor to notify driver where items needs to be unloaded | -Delivery plan reviewed weekly by site supervisor | 1E | |

| 12.3 | Deliveries that have been left are imposing a health and safety risk | 2C | -Site supervisor to conduct site walks and assess whether materials that are an OHS hazard need to be moved | -Delivery plan reviewed weekly by site supervisor

-Physical inspection of deliveries |

1D | Site supervisor |

| 12.4 | Incorrect items have been delivered to site | 2C | -Site supervisor to issue returns to the supply company as soon as practical | -Delivery dockets | 1E | Site supervisor |

| 12.5 | Delay in delivery of concrete truck resulting in total project schedule delay | 5E | -Construction manager to contact concrete company day before and an hour prior to arrival to ensure delivery is on schedule | -Purchase orders revised weekly | 3E | Construction manager |

| 13 | Communicational | |||||

| 13.1 | Painters paint wrong colour of internal walls due to miscommunication with site supervisor | 2C | -Construction manager to show colour samples to painters prior to commencement of painting | -Physical inspection during painting stage | 2D | Site supervisor |

| 13.2 | Changes to plans/drawings lost | 3B | -Admin to process revisions and amendments to plans and drawings in the company portal | -Project manager to review the company portal weekly ensuring revisions have been submitted | 3E | Project manager |

| 13.3 | Sub-contractors mixing up dates to start works due to miscommunication | 4B | -Construction manager to send confirmation e-mail to sub-contractors on due on site dates | -Schedule and checklists | 4D | Construction manager |

| 13.4 | Crane operator crew radio transmitters faulty and causing delay | 4B | -Back up radio transmitters held in site office in case of emergency | -Maintenance inspection | 2D | Crane crew |

| 13.5 | Incorrect items delivered to site due to miscommunication between suppliers and site supervisor | 1B | -Construction manager to send e-mail confirmation of supplies order | -Checklists and schedule | 1E | Construction manager |

| 14 | Supplier/Sub-Contractor | |||||

| 14.1 | Sub-contractors taking their time with works and not meeting deadlines | 2C | -Sub-contractor-builder contracts to set out start and finish times for the works with liquidated damages | -Schedule tracked | 2D | Construction manager |

| 14.2 | Suppliers not delivering correct materials | 2D | -Site supervisor to double check delivery dockets with delivery orders | -Delivery dockets | 2E | Site supervisor |

| 14.3 | Poor quality of workmanship by sub-contractors | 4B | -Site supervisor to conduct visual quality inspections during works | -Physical inspection | 4E | Site supervisor |

| 14.4 | Incorrect installation conducted by sub-contractors due to language barriers | 2B | -Translator/Google translate to be used if the sub-contractor is unsure of requirements | -Drawing and plans revised | 2E | Construction manager |

| 14.5 | Sub-contractors arriving on site earlier than expected due to miscommunication | 3B | -Confirmation text messages and e-mail to be sent to sub-contractor once a date has been scheduled | -Site supervisor to request reply on agreed date | 3D | Site supervisor |

| 15 | Damage to reputation | |||||

| 15.1 | Workplace harassment within the company | 5C | -Human resources to conduct quarterly meetings in regards to workplace behaviour

-Signs posted in regards to workplace harassment -Human resources to monitor the behaviour of employees |

-Meetings, physical inspections and surveys | 5E | -Human resource team |

| 15.2 | Negative media coverage/news | 5E | -Management processes in place to ensure company complies with

-Legal team to address the matter with media |

-Management meetings

-Quality assurance checks |

3E | Management team |

| 15.3 | Failing to pay our sub-contractors due to the client not paying our progress claims | 5D | -Accounts team is adequately trained and experienced

-If progress payments are not made within two working days of submission then the site will be shut down -Ensure that there is adequate funds in assets to pay sub-contractors if claims are received |

-Meetings

-Checklists -Financial reports |

5E | Project manager |

| 15.4 | Failing to meet quality standards | 5D | -Visual inspections

-External auditor to inspect the quality of work in relevance to Australian Standards -Procurement process reviewed to ensure that quality of sub-contractors increase |

-Physical quality audits

-Physical inspections -BCA and AS are met |

5E | Construction manager |

| 15.5 | Customers/clients unsatisfied with the delay in construction | 4D | -Construction managers and project team adequately qualified and experienced in scheduling

-Increase labour if delays occur -Extensively review contract during dates and ensure that schedules met is reviewed and of practical construction period |

-Schedules

-Procurement process -Meetings |

4E | -General manager |

8.0 REVIEW PROCESS

The first step of the review processes is to ensure that the risk management processes that we have put in place for 79 Station Street Burwood are meeting the requirements set out and is reducing the impact and frequency of risks that we have planned for.

This will be done by;

- Meeting with project team members and discussing the outcomes

- Conducting external audits that will review the processes

- Conduct interviews/meetings to gather feedback from stakeholders

- Analyse data from measuring tools and techniques

- Questionaries

- Review of financial reports

- Key performance indicators review

- Quality audits

- Indecent report logs

If our findings show that we have not reduced or minimised the risks associated with the categories that are necessary for the construction of our project, we must pinpoint the reasoning why. The first step is to assess whether we are doing what we said we would do? If we are doing what we said we would do (processes) but the objectives still aren’t being met, this may be due to the following possibilities;

- Might be using the incorrect processes

- Setting our expectations to high

- Measuring wrong aspects

- Engaging people who aren’t skilled enough

- Use of wrong materials

If our findings show that our objectives aren’t being met due to the processes not being followed, then the following possibilities may be the cause;

- Staff don’t want to

- Staff aren’t capable

- Expectations of staff are too high

- Processes are too complex for staff to undertake

- Don’t have necessary equipment to undertake the processes

- Staff not made aware of the processes or not trained adequately

Before we put any new recommendations/changes in the risk management plan, we need to analyse the cost benefit of the changes/recommendations. This would be done by firstly brainstorming the costs and benefits. Secondly assigning a monetary value to the costs. Third step is to assign a monetary value to the benefits.

Fourth step is to compare costs with the benefits and assess if the costs outweigh the benefits, if so, then the changes are not in the interest of the company due to the reduction in profit.

The information gathered from meetings, questionaries, audits, review of reports etc. will further improve our risk management plans for the future. It will identify any new risks that may have occurs during the project that we did not account for, therefore know that this risk may arise again and the appropriate approach to managing the risk may be implemented in the future.

9.0 APPROVAL OF RISK MANAGEMENT PLAN

This document has been read, reviewed and signed off for implementation by the relevant bodies of MK Construct.

General Manager

Signed______________________________Dated:______________________

Miodrag Knezic

Project Manager

Signed______________________________Dated:______________________

Sam Hanna

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Risk Management"

Risk Management is a process for identifying, understanding and mitigating any risks that are associated with a particular task or event. Individuals and organisations implement Risk Management to provide a layer of protection, allowing them to minimise risk in their operations.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: