Conceptual Model for Engineer‐To‐Order (ETO) Construction Supply Chain

Info: 7557 words (30 pages) Dissertation

Published: 19th Nov 2021

Tagged: ConstructionSupply Chain

LIST OF FIGURES

Figure 1: Conceptual Model for the ETO Supply Chain Management in the United Kingdom

Figure 2: Semi-Structured Questionnaire – Respondent’s Age

Figure 3: Semi-Structured Questionnaire – Respondent’s Gender

Figure 4: Semi-Structured Questionnaire – Respondent’s Experience

Figure 5: Semi-Structured Questionnaire – Respondent’s Professional Designation

Figure 6: ETO construction supply chain management in UK placed significant influence on both materials and resources.

Figure 7: UK companies defined the relationship between the Order Penetration Point and their production planning strategies at the design stage in an effective manner.

Figure 8: Which of the technical challenges are most affecting the supply chain management of the ETO construction projects in UK?

Figure 9: Which of the personnel challenges are most affecting the supply chain management of the ETO construction projects in UK?

Figure 10: Which factor do you believe that is the most influential factor affecting the supply chain management of ETO construction projects of UK?

Figure 11: Which production-planning framework is adopted within the UK ETO construction sector?

Figure 12: Which process-oriented production planning framework is adopted within the UK -ETO construction sector?

Figure 13: Which operation process is identified as highly crucial for the UK ETO construction sector?

Figure 14: Which types of project risks are subjected to affect mostly the ETO construction projects?

Figure 15: Kindly confirm whether or not the UK ETO supply chain consider the contextual and geographic factors such as culture in optimization of their supply chain pipeline.

CHAPTER ONE: INTRODUCTION

1.1 Introduction

This chapter tends to introduce and explain the purpose of the current investigation undertaken on the chosen topic of the supply chain management. The chapter aims to present an outline overview of the contents, approach and structure that is used to write the research.

1.2 Background Context

Management of supply chain has been one of the crucial business processes where the flow of goods and services from their raw material to the finished form is managed. It is all about controlling the movement of the products from point of origin until they have reached their final destination i.e. point of consumption (Ross, 2016). Supply chain, specifically, is referred as a network of organisations contributing individually as well as collectively for the transformation of raw materials, products or services into a finished product to make it fit for the client. Like other industries, supply chain in construction companies also requires effective procurement of products and services. Close management is essential for the minimization of adverse impacts. Construction companies, therefore, require adopting appropriate and consistent supply chain management process in order to reap the long term and short-term benefits (Hicks, et al., 2000).

Engineer-to-Order (ETO) construction environments are different from the other manufacturing environments due to different typology involved in production planning and controlling process (Modrák, 2014). The main attributes of this environment are the demand completion methods and shop floor configuration. Customisation of the construction projects is the essence of such projects as companies are ready to make modifications and changes to the standard designs for design specific order for the customers. In the process of making modifications, lead-time is identified as one of the vital aspect (Jonkman, 2014). ETO system is specifically comprised of three specific elements i.e. customer order, the customer-specific product specifications and the product and production uncertainty (Jonkman, 2014). It is very clear that ETO is generally a manufacturing approach whereby a product and service is designed, engineered and built based on very specific customer requirements (Addo-Tenkorang, 2016).

1.3 Research Problem

The emerging nature of the ETO in different fields of study has resulted in rising interests of the construction sector participants too, where they are also adopting this manufacturing environment for the effective supply chain management like various industries. There is limited research on the ETO construction supply chain management for the UK projects due to which it is quite difficult to identify the specific conceptual model for the UK companies to deal with the challenges involved in ETO implementation in the operational stage. In one of the research undertaken by the Tezel, et al., (2017) on the UK construction projects, four highways construction projects with respect to the modular and offsite construction (O/M) agenda were researched and investigated. Although the researchers in this study have investigated the importance of transition from the engineer-to-order to assembly-to-order in civil infrastructure projects, but they did not target the challenges faced by the highway-construction supply chain projects specifically in context of the ETO manufacturing typology. Similarly, studies are presented in the existing literature to understand the problems of the collaboration and management in generalised supply chain management in the construction industry of UK. No specific focus is placed on development of a structured model for the UK supply chain management.

The current investigation was therefore necessary to focus specifically on the intrinsic practices of the ETO construction companies in order to design a conceptual model. The model should be based on requirements for customised projects, minimum repeatability, fixed layout, early OPP (Order Penetration Point), planning the project as per the demand of customer, early supplier engagement (Hicks, et al., 2000), as these factors lead to generation of the great challenges in the field of supply chain management.

1.4 Research Aim and Objectives

The key aim of research was to develop a conceptual model for Engineer‐To‐Order (ETO) construction supply chain based on the best practices. The developed conceptual model was expected to help the UK construction companies in resolution of the challenges encountered in ETO construction related projects. The set of research operational research objectives (given below in chapter 3) were developed for supporting the accomplishment of the key research aim.

1.5 Research Questions

Past academic studies have emphasized that construction industry needs to be recognised as a manufacturing process (Jonkman, 2014). In these studies, researchers have highlighted the importance of multiple factors responsible behind the value creation in the ETO construction projects among which the key factors include quality, service, cost, and lead time (Matt, 2014; Jonkman, 2014). The past findings have also suggested the range of challenges and issues from a manufacturers’ perspective associated with the supply chain management (SCM). Material, labour and expenditures related challenges are the part of a typical manufacturing operation in the construction industry. This research is specifically targeted to investigate the challenges faced in the ETO construction project. Uniqueness of the ETO construction industry due to its operational performance based on specific customers order makes the current investigation as quite interesting. The key stages of ETO construction projects such as engineering design, production and installation would be helpful in examining various factors affecting the operations in these departments (Dallasega, et al., 2015). Moreover, different approaches to SCM have been used and discussed in the academic literature to show how the ETO construction companies align their demand with supply. Among some of these approaches include Constant Work in Progress (CONWIP) control circuit, Workload control (WLC), Drum-Buffer-Rope approach, Kanban, and Material Requirements Planning (MRP) (Jonkman, 2014).

The research questions are therefore developed to examine which factors and approach are required to be taken into account for the ETO construction projects.

- What method can be utilised for the development of the conceptual model in ETO construction supply chain?

- How can the challenges be positioned related to supply chain in ETO construction projects?

- How can the appropriate practices be implemented and evaluated in the conceptual model?

- How can a particular practice be implemented in the construction projects for resolving the supply chain management related challenges?

1.6 Research Methodology Brief

Current research had selected mixed research approach to gather and analyse both the quantitative and qualitative data related with the ETO construction projects in United Kingdom. Pragmatism research paradigm was chosen due to its potentials of solving the real problems by focusing on the research questions under investigations. The practicality of pragmatic paradigm was recognised as helpful in relating the current practices (actions), approaches (interventions) to develop the conceptual model for dealing with ETO construction challenges. For the accumulation of multiple viewpoints, range of existing evidences were reviewed and discussed related to the practices in UK supply chain and construction projects. Additionally, semi-structured questionnaires and interviews were conducted to gather the opinion. Data analysis method for the questionnaire responses was statistical approach while the findings of interview respondents were analysed through the thematic analysis. Based on the integrated set of findings, conceptual model was developed.

1.7 Research Significance

The findings of the current research are expected to have significant theoretical and practical implications for the future researchers as well as for the UK construction companies. The conceptual model developed in context of the ETO construction companies would help in bridging the existing literature gap and would subsequently help the upcoming researchers in further investigating the ETO construction projects supply chain in diversified directions. The conclusions of the current investigation are further expected to help the project managers in the UK construction projects in gaining an in depth idea behind the level of delivery of the project through the examination of the contextual based practices. The companies would be able to understand the complexity of the UK construction environments and the challenges associated with it.

CHAPTER TWO: LITERATURE REVIEW

2.1 Introduction

The chapter discusses the findings of the existing literature about the present frameworks on supply chain management in the construction industry. The critical overview of these frameworks has further helped in identifying the factors necessary to be taken into account for dealing with the supply chain management. A detailed review of approaches to supply chain management in ETO construction is also incorporated in the investigation. Such investigation would help in identification of the challenges related to supply chain in ETO construction projects.

2.2 ETO Supply Chain Management

With the ongoing changes in the manufacturing and controlling technologies in construction industry, the organisations in this industry are facing immense difficulties and complexities. This complexity is calling for the extension of the limited boundaries of the construction sector in which supply chain management is given relative significance. Examination of the past records has shown that ETO related construction companies in the United Kingdom have possessed numerous parallel projects in their portfolio. The differences and variations in these projects are of utmost importance due to their different intrinsic practices (Blecker, et al., 2010; Dallasega, et al., 2015; Kujala, et al., 2012).

Academic researchers have specifically categorised the ETO supply chains in the construction industry into three different macro-phases such as engineering, fabrication and installation on sites. The construction companies need to focus on materials, processes as well as people aspects of these projects in order to stay competitive (Tezel, et al., 2017). Practices reported in the available literature have further mentioned that most of the global construction projects including the UK ones, similar materials such as concrete, cement, reinforcement steel are used and same set of companies’ resources such as technology, quality, standard principals and guideline materials is utilised (Thunberg, 2016; Uusitalo & Lidelöw, 2015). It is crucial to highlight that despite of the similarities in the materials and resources, for different construction projects great variation is examined in context of the projects specifications (Johnsson, 2013). In discussing how the construction projects develop their specificities, Cooper, et al., (1997) identify ETO elements such as structural steel, precast concrete structure and some of the key resources in the business organisations such as specialised team, safety support and managerial guidelines. These historical studies’ findings have substantiated the importance of performing mapping of the supply chain management for the specific construction companies in order to understand its process. Customisation aspect can be recognised as vital aspect of the ETO supply chain management.

In the similar context, Gosling, et al., (2015) have investigated the principles for the design and operation of engineer-to-order supply chains in the construction sector. The study integrated the valuable approaches to supply chain design and titled it as FORRIDGE principles. The effectiveness of these principles was tested on the ETO industries. The key FORRIDGE principles are related with the time compression, control system, synchronization information transparency, and echelon elimination. According to these principles, by modifying these factors construction companies can lead towards the sustainable supply chain processes (Dallasega, et al., 2015). The study found that by applying the principals of good practice in material flow, it turns out as easier for the construction companies to design and govern their specific supply chain process in the supply chains (Towill, 1997).

Furthermore, researchers have also investigated the ETO related construction projects in UK to identify the importance of multidisciplinary skills required for the designing and fabrication of the supply chains. In order to integrate the requirements of the customers at different stages of construction, effective skills turned out as necessary to deal with the requirements of the upstream and downstream operations.

2.3 Approaches to Supply Chain Management

Academic literature has also discussed the range of production and manufacturing approaches in relation to the supply chain management. These approaches are developed to control the relationship in between the OPP (Order Penetration Point) also known as COPD (Customer Order Decoupling Point) and various production strategies. The literature researchers have conceptualised OPP as the key element in the value chain of the company, to show the interrelation between the product and customer order. Due to the specificity of the ETO projects, researchers have proposed that ETO related construction projects possess their own positioned OPP at the initial stage of designing (Gosling, et al., 2015; Olhager, 2003; Koskela, 1992). Researchers in their past studies have also acknowledged that OPP holds significant place among the construction companies due to its role in categorising and demanding multidisciplinary skills in relation to the design as well as fabrication from the supply chain management. From this perspective, the projects of the ETO construction possess OPP earlier or at the time of design phase. For this reason, ETO construction projects are based on the requirements of the supply chain system in line with the particular demands of the customers.

In specific discussion to the production planning and controlling approaches, Jonkman, (2014) has categorised these according to the push system and pull system. These two systems are similarly applicable to the manufacturing processes in the construction industry similar to that of the other studies. Researcher has described the pull production system as the system that restricts the proportion of work in process in the system by application of various planning and controlling techniques. On the other side, push based system is employed by the organizations in the dealing with the products having low level of demand uncertainty.

Among the widely recognized approaches for the sustainable supply chain management of EOT construction projects, ConWIP (Constant Work in Progress) was examined as vital approach for dealing with the sustainable supply chain management in construction (Jonkman, 2014). In order to deal with the low synchronization in ETO supply chains with respect to engineering, fabrication of parts and installation on-site, ConWIP has been recognized as effective conceptual approach. It helps in dealing with the problems of synchronization in more systematic manner. Thus, with the help of ConWIP, it becomes easier for the construction companies to optimize their economic, ecological, and social point of view (Jonkman, 2014). According to Matta, et al., (2014), close coordination is required between the factory and construction sites in the ETO projects because of discontinued installation on site and scale effects of large batch productions. ConWIP allows the construction companies in eliminating work in progress by maintaining the parts of the product required to be produced and by determining the sequence in which such production of parts is required. The system uses card, which is passed to a standard container in order to allow the use of raw material on first come first serve basis. However, the system does allow reworking and recodification to break the standardized approaches.

Another approach to the EOT construction supply chain management is Kanban approach. Matta, et al., (2014) have discussed that Kanban is also a pull system approach like ConWIP, which works on the core objective of minimising the work-in-progress. The approach is used for steady flow of materials based on the emerging demands related to specific orders. These approaches in the construction industry projects are effective because they allow effective pulling of the production process from the production building and transfer it to the site to avoid the intermediate stocks. For this reason, the construction companies are able to make timely modifications in the consumption process at the construction site based on the quantity requirements. Thus, the project managers adopt a demand driven organisation and synchronisation of the orders as they are received without concentrating on the predefined production planning (Matta, et al., 2014). Additionally, Dallasega, et al., (2015) in the process of discussing the approaches of effective supply chain management have identified that for the effective demand fulfilment in the overall supply chain, it is necessary that continuous improvement process is carried out, which can further result in productivity. Challenges associated with the different approaches cannot be undermined in the process of selecting these for the effective process. Jonkman, (2014) states the challenge associated with the use of Kanban production system specifically in relation to the number of Kanban cards required.

In contrary to the Pull system methods, Push system methods are also used as approach to deal with the complex production processes involved in the construction companies. Among different push method approaches, material requirements planning (MRP) is recognised as one of the significant approach. It is a periodic push-based system developed for dealing with the complicated production environments. The tailor-made process of this approach makes it universalistic approach to be used across the different companies. In selection of the MRP packages too, researchers have highlighted to ascertain the company size as an effective variable (Jha, 2011; Thunberg, 2016). Jonkman, (2014) has further discussed another push system designed for the production based on the customised customer orders i.e. workload control (WLC). WLC approach is extremely useful in specific designing of the flow of materials and resources through the main decision points. Main decision points described under this approach are order acceptance, release, and order dispatching. In selecting WLC for the construction process, researchers stress on the need to take account of the parameter settings in order to identify extra dimensions (Jonkman, 2014).

The need to examine these production system is necessary for the current investigation because to deal with the challenges associated with the construction supply chain in an organised and structured manner, understanding of the construction supply chain management is necessary (Dallasega, et al., 2015). The initial researches in the supply chain management have emphasised that understanding of the process-oriented models are needed to deal with the interrelated network activities. There are sufficient evidences in the past studies in which researchers have acknowledged the analogy between the supply chain management in construction and the production process. Three major interconnected stages of the construction industry’s supply chain project cannot be undermined i.e. operation, design, and improvement (Souza & Koskela, 2012). It can be examined that the different production approaches are focused around the operational stage of the process to maintain the flow of materials and resources in order to assist in the design and development in the supply chain management in ETO construction projects.

The examination of these approaches to the production in ETO construction would help in examining which approach would be helpful for the UK construction companies specifically. The selection of the appropriate approach is necessary for the development of conceptual model for the ETO supply chain in the construction industry. Choice of significant approach to the ETO supply chain for UK is necessary to help the companies in dealing with the range of challenges.

2.4 Challenges related to Supply Chain in ETO Construction Projects

Since the progressive investigation in the field of supply chain management, ETO companies are recognised as significant due to their specific activities and their intrinsic characteristics (Matt, 2014; Dallasega, et al., 2015). Generally, the construction supply chain management is discussed in relation to specific challenges faced at the production level, such as low repeatability of the same construction activities, development of the temporary basis and stages of the early order point. Researchers have shared further that in case of the ineffective supply chain in ETO construction projects, companies are subjected to face severe issues in relation to the inappropriate order specifications and larger processing time per order. Other issues include absence of trust, lack of commitment over deadline, weak synchronism in the supply chain management and alteration at the last minutes (Vrijhoef & Koskela, 2000; Roehrich & Lewis, 2010; Rother & Shook, 1999). From these findings, it can be examined that past researchers have significantly pointed out towards the need of focusing on products, processes as well as people in the process of managing the supply chain. Synchronised intrinsic attributes can only help the organisations in management of the standardised building components and for the development of effective relationships with the partners in the supply chain process.

Another study conducted by Uusitalo & Lidelöw, (2015), researchers highlighted the challenges involved in transition of the construction companies from one supply chain management system into another SCM i.e. from made-to-stock to engineer-to-order. In such transitions, construction companies face significant issue of failed prediction or forecasting in the designing stage as the customers can make frequent changes in the designs. It can be examined that academic researchers have acknowledged the importance of accurate measurement in design as vital for the operational management and subsequent supply chain management. Management of changing customers’ requirements comes out as vital aspect in the supply chain management specifically in the ETO companies.

Gosling, et al., (2015) have discussed that human resource related challenges can also play vital role in the development of the challenging supply chain in ETO construction projects companies. The key challenge they face is in relation to the efficient usage of the human resources due to the existence of wide ranging projects. Researchers have showed that construction companies mainly work on multiple projects at same time and therefore allocation of personnel on different projects ultimately turn out as demanding for them. In similar context, researchers have highlighted that construction companies need not to switch frequently between the different projects for meeting critical deadlines. Such approach to human resource management in ETO projects ultimately reflects the inefficiencies in resource usage. The construction companies need to ascertain that they have separate groups of personnel to be allocated to the different projects. However, it is also an issue that not everyone can be assigned to the ETO projects as only educated and highly skilled process engineers with a concertation on the efficient and sustainable supply chain are capable of performing well in the project management. Inconsistency within project team is subjected to place significant effects on the overall performances of the supply chain management (Gosling, et al., 2012).

Dallasega & Rauch, (1888) have examined the application of lean management principle as challenging part of dealing with the planning and controlling of the production in the ETO construction projects. Waste management in the ETO construction project must be monitored in timely manner to minimise the cost. Supply chain management needs to control the activities, which can lead to severe gap among the engineering, manufacturing and onsite synchronization. Academic literature has highlighted the list of five wastes in the construction industry waste, which are threatening for the suppliers of the ETO construction. These wastes include overproduction, waiting time, motion, inventory, and failure correction. Researchers have showed that since the production is carried out onsite in the ETO projects therefore, errors detection and management can result in cost explosions in the process of separating. Studies have also identified overproduction as one of the common types of construction industry waste. Therefore, it is extremely necessary for the construction industry personnel to look after the synchronised

2.5 Existing Frameworks on Supply Chain Management in Construction

In the academic literature, past researchers have also focused on the different models and frameworks for the supply chain management in construction (Autry, et al., 2013). Understanding of these frameworks is extremely important for applying these to the ETO construction companies of United Kingdom. Some of the construction companies use project oriented models for the management of their supply chains as well as for dealing with the challenges associated with their supply chain (Liu, 2016).

2.5.1 Process Oriented Model

The process oriented models and framework are based on the network activities needed to be observed in line with the interrelated components of the network. Among the existing frameworks, process oriented model is examined as one of the vital model. Liu, (2016) has shown that ETO supply chains generally follow the typical process oriented approach based on inputs, process, and outputs. Framework provided by the researchers Pandit & Zhu (2007), has categorised each of the three stages in the ETO process into six sub-steps to show the flow of products and activities in the ETO construction process. The analysis of activities and people in these steps can allow support in the development of effective supply chain management strategies and for dealing with the challenges associated with different supply chain management phases. In the process-based step, it can be seen that companies pursuing a process-oriented approach focus on the placement, procurement, management, designing, building, and usage of product. Any issue in any of these steps can result in severe process failure and therefore construction companies need to remove the barrier in order to move forward in the process (Liu, 2016). Process oriented models look like a flow, which cannot start subsequent stage before completing the earlier phase. Researcher has defined process-oriented models as the one, which can pull together absolutely everything necessary for delivering of the significant component of strategic value (Liu, 2016). The resource needs for the process-oriented frameworks are higher relative to the product and project oriented models. According to Artto, et al., (2007), both tangible as well as intangible elements come out as vital in the process-oriented models. This is so because the measuring process for achieving the target of the supply chain is not easy for everyone. Skills are needed for the effective process management and for the identification of the performance gaps. Artto, et al., (2007) have further added that in the process-oriented supply chain model, core business processes form central component.

In discussing related perspective about the process related aspects researchers Koskela and Souza (2012) have characterised a correlation in between the CSCM and the concept of the production process, through the categorisation of the production process into the three key different stages. These phases include operation, design, and improvement. For better understanding of the process oriented models, it is necessary to analyse these three phases in detail to show that how the three stages can result in the development of the influential impacts on the operation. The examination of the studies have shown that there is ample evidence about the operational stage of the supply chain management in the ETO construction sector, while there is limited number of studies found for the design and development in the supply chain management in ETO construction projects (Lu, Olofsson & Stehn, 2011; Melnyk, Davis, Spekman and Sandor, 2010).

Vinicius & Souza, (2013) have discussed comprehensive findings about the design phase of the ETO construction SCM. Among the different design components, include customization, positioning of the decoupling point, supply chain mapping, enterprise project interface management, earlier supplier involvement, governance management, supplier base management, risk management, sustainability management, and flexibility management. On the other side improvement related aspects were also highlighted in order to improve the construction supply chain such as variability reduction, performance measurement, improvement prioritization, knowledge management, supplier development, communication management, and standardization. Researchers have mentioned that ETO construction supply chain management should be dealt at strategic level and therefore operational level elements need not to be considered in it. The findings of this study in contrast to other academic researchers have highlighted that by focusing on designing and improvement stages, value can be added to the supply chain process of the system. The importance of design elements in the ETO construction projects are also highlighted as significant by the (Eastman, et al., 2011) in stating that ETO construction projects have also been considered by necessitating multidisciplinary design and fabrication skills from their supply chains (Eastman et al. 2011).

On the other side, (Dallasega, et al., 2015, p. 9) have highlighted the importance of the operational stage in the ETO supply chain management. They stated that, “The construction industry is generally considered to be some way behind those sectors where effective supply chain management is regarded as key to gaining competitive advantage and dealing with the need to constantly improve operations to satisfy the increasingly sophisticated demands of end users”. The operational factors can lead to successful accomplishment of the ETO projects as well as can ruin the entire project by not meeting the customised demands of the customers of that ETO construction project. Onsite allocations and production ultimately has increased the roles and responsibilities of the supply chain of the business in order to drive it as sustainable.

Uusitalo & Lidelöw, (2015) have stated that flexibility in supply chain management of the construction companies is necessary due to multiple stakeholders involved in supply chain. Uusitalo & Lidelöw, (2015) in their studies have mentioned that according to the recent trends in the ETO construction industry, supplier firms are found to increase their association with the construction clients for maintaining the diversified supply chain structures. However, for the ETO construction companies, this is a matter of resource utilisation, for strong operations management strategies. Academic researchers have acknowledged the differences between the different operations management based on the different production approaches such as ETO, make-to-order (MTO), and others. However, before moving into the investigation of the ETO operations connected with supply chain, it is necessary to recall the definition of the operations management. According to Naylor, et al., (1999) operations management is defined as the central function of any organisation, where the business processes are functioning for the efficient transformation of inputs and outputs. In this context, the operations manager has turned out to be vital in managing co-operation with other relevant business processes. Theoretical philosophies are developed by the operation management researchers focused on the structured and synchronised thinking, functional integration and to exhibit compatibility and consistency with the organisational structure. Among some of the common operations management philosophies include total quality management (TQM), just-in-time, (JIT), lean manufacturing (LM), theory of constraints (TOC), six sigma (SS) and supply chain management (SCM) (Uusitalo & Lidelöw, 2015).

In talking about the ETO construction supply chain management, Slack, et al., (2013) have categorised the operations management functions into three main functions such as sales and quotation [(order process), only a fraction of orders are cancelled], design process, and production. These three functions work different in the ETO construction supply chain management, while operations management is required to look after resource allocation in line with the type and quotation of the orders. ETO construction industry faces severe challenges in terms of cost and the production process. Obtaining quotation from the other supply chain member can lead to time-consuming nature of the business operations. ETO quotations are complex compared to the supply chain quotations in other production and manufacturing processes. It can be examined that existing studies have shown that due to inefficiencies in making the quotation for the ETO projects, construction companies are able to hardly get the 15% of the total ETO bidding as an order (Slack, et al., 2013). Johnsson, (2013), in similar context, have admitted that too many resources in the quotation phase can disturb the entire supply chain since the subsequent phase are connected with the bigger problems. Construction companies need to place significant consideration on the quotation details. In developing the quotation for the ETO orders, it becomes quite challenging for the companies to predict and forecast the sales scenario for their business. Researchers have stated that sales process is also an important function of the ETO construction operations management. Researchers have highlighted that sales process is highly impacted because of the different supply chain management. Construction companies can prevent high cost and time delay by using right resources in this sales and tendering phase.

2.5.2 Project Oriented Model

Academic literature has further shown that ETO construction companies have started pursuing the project-oriented approach, which was earlier focusing on the designing of their supply chain management based on the different product categories (Eyob, 2012; Addo-Tenkorang, 2016; Blecker, et al., 2010). Since ETO construction projects are based on customisation efforts, therefore, academic literature has further shown that ETO construction companies design their supply chain management based on the different project oriented model for different clients (Liu, 2016; Kujala, et al., 2012). The construction companies in dealing with the ETO construction projects adopt project management approach, which starts from the leads and ends with maintenance. Academic researcher has stated that

“The project-oriented company is defined as a company that have traditionally focused on product-centric project deliveries as their core business, and increasingly complementing their deliveries with different types of service offerings to create customer specific solutions” (Kujala, et al., 2012) cited in (Liu, 2016, p. 38).

Project based companies are mainly concentrated to enhance their activities with an ultimate aim of achieving the solution. For this reason, unlike the process-oriented models, it is easier for the ETO construction companies to carry on the work in parallel manner for their different steps such deigning and procurement. Therefore, the challenges in different steps of the project can be resolved simultaneously. The researchers to show the similarities and differences in the supply chain management under the two processes also relatively discuss existing frameworks (Kujala, et al., 2012).

In discussing the propositional differences between the project oriented and process oriented supply chain, Kujala, et al., (2012) have discussed that for the supply chain based on project-oriented framework, number of the strong supply chain stakeholders comes out as vital. The higher the number of stakeholders, higher would be the chances of successfully accomplishing the project. Additionally, procurement has been reviewed as one of the vital supply chain management phases like the design and manufacturing within a project-based organisation. Project oriented models do not assign much value to the process owners’ roles as given in the process oriented supply chain frameworks. Similarly, researchers have identified the structure of the project-oriented model around the customers, which exhibits that all the effective understanding of the business needs to be aligned according to the customer’s need associated with a specific construction ETO project.

2.6 Overview of the ETO Construction Supply Chain UK

The construction industry of United Kingdom has been taking great support from the modern construction methods such as ETO production practices. Among the different types of activities covered in the supply chain management operation for the ETO construction projects include customization of the items such as steel trusses, HVAC ductwork, systems piping for chillers, and plumbing (Forbes & Ahmed, 2010). However, despite great efforts UK construction industry companies are far behind the other service sectors in making timely and quality improvements in their performances through the application of performance improvements and optimisation techniques. There has been limited supply chain research focusing on ETO construction as a vital area of discussion. Like the other regions, in the construction industry supply chain of United Kingdom, companies give priority to the customer Order Decoupling Point, in order to design multidisciplinary and fabricated design (Tezel, et al., 2017). Currently, ETO supply chain approaches have been applied for determining the improvements needed within the modular and offsite construction. Companies is the UK ETO construction have been involved in different types of ETO supply chain either based on the in-house production or based on the outsourcing. It can be examined that construction industry items are large and heavy, with their performances related with the complex geometry and machining processes. The construction companies in the United Kingdom are facing severe challenges in respect of their supply chain management in context of mainly analysis of risk and uncertainties associated with challenges, in optimisation of the pipeline and with respect to the development of strategic flexibilities. The companies need to adopt contextual based frameworks to allow their understanding and development of the relationships and networks between different entities (Gosling, et al., 2015).

The current investigation through the collection of both the primary and secondary data findings tend to target the limitations and expect to make improvements in the existing supply chain of the UK construction companies dealing with the ETO projects in UK.

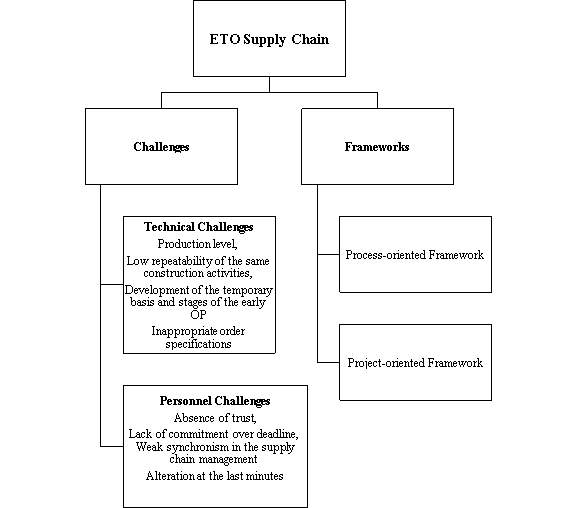

2.7 Conceptual Model

From the findings gathered from the literature review, it was identified that effective supply chain management practices in the ETO construction companies should focus on both the challenges as well as the supply chain management framework suitable to deal with the operational factors of the supply chain process. It can be examined that the process of supply chain in the ETO construction companies need to be focused around the sub stages involved in converting the inputs into the output consistent with the needs of the customers and clients of the construction industry. It can be depicted that operational level challenges for the ETO construction supply chain can be categorised into the technical as well as personnel level challenges to be used for the subsequent analysis of the ETO supply chain. The analysis of the challenges highlighted in the academic literature would help the companies in determining the existing position of the construction companies in UK for improving the supply chain management.

Figure 1: Conceptual Model for the ETO Supply Chain Management in the United Kingdom

2.8 Conclusion

Thus, it can be concluded from the review of the past studies findings that there is no best practice framework to deal with the challenges associated with the supply chain management in ETO Construction Projects in UK. There are several approaches and frameworks for the ETO construction supply chain management like process-oriented models and projects-oriented model. It can be examined that academic researchers have discussed the operational stage of the supply chain management process higher than any other stage i.e. design and procurement. The evidences have shown that construction companies do face more issues and challenges in the UK ETO construction supply chain management in UK. The review has also confirmed the presence of multiple perspective challenges faced by the companies mainly related with the technicalities as well as personnel related challenges. These findings have further helped in developing a conceptual model for the evaluation of the primary participants’ responses. In the next chapter of the study, research methodology is given to highlight the data collection and data analysis methods chosen.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Supply Chain"

A Supply Chain is a system in place between companies and their suppliers, from producing a product to distributing it ready to be sold. An effective and smooth running supply chain can contribute to the successful running of a business.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: