ABSTRACT

Heterotrophic microalgae, capable of converting organic carbons to biofuel, as well as assimilating nutrients, have a great prospective in wastewater treatment. Meanwhile, the knowledge about heterotrophic microalgae is still far less than the autotrophic one. Hence, in this study, 20 heterotrophic microalgal strains were isolated from a domestic wastewater treatment plant, and identified based on morphology and partial 18S and 23S rRNA gene sequences. Further, their biological traits and applicability in real wastewater treatment were assessed in terms of N, P, TOC removal efficiency, growth parameters, self-sellteability and lipids production.

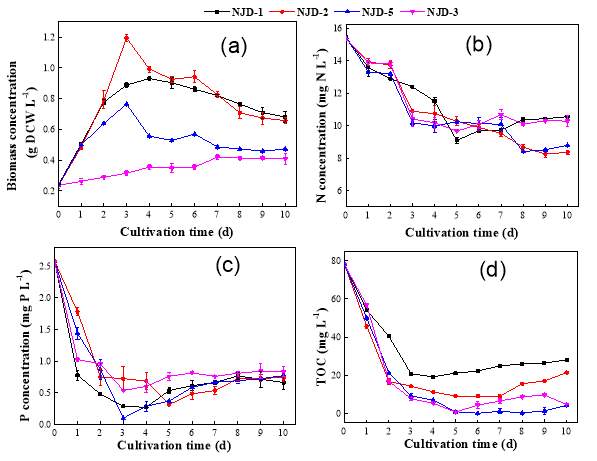

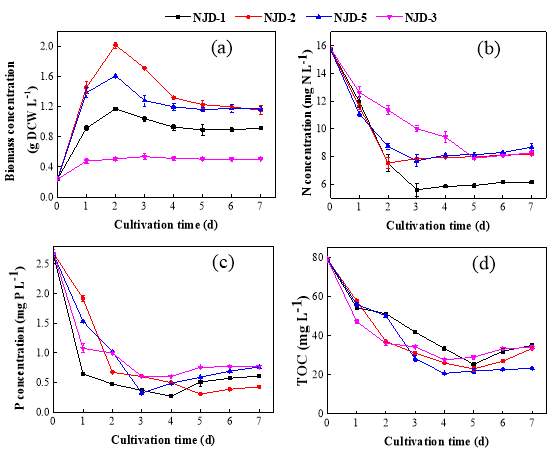

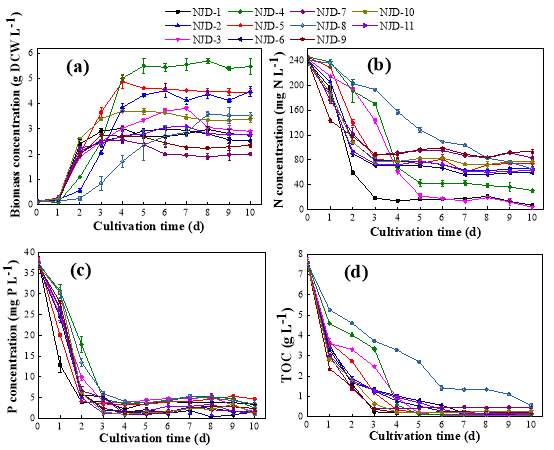

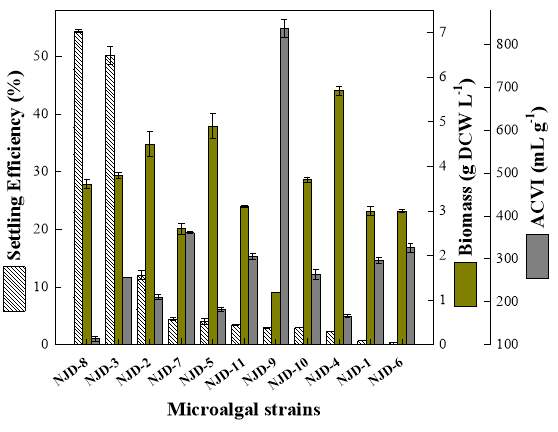

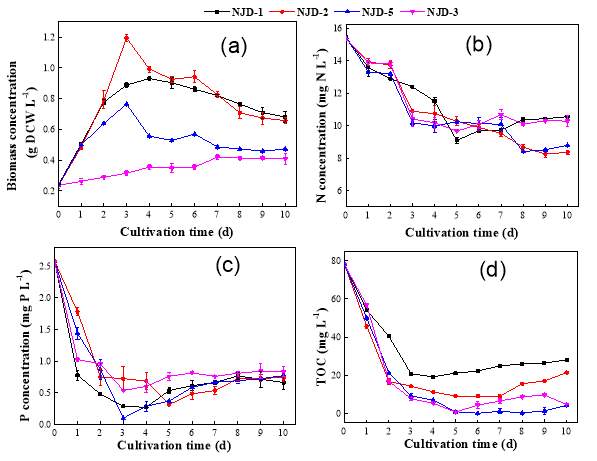

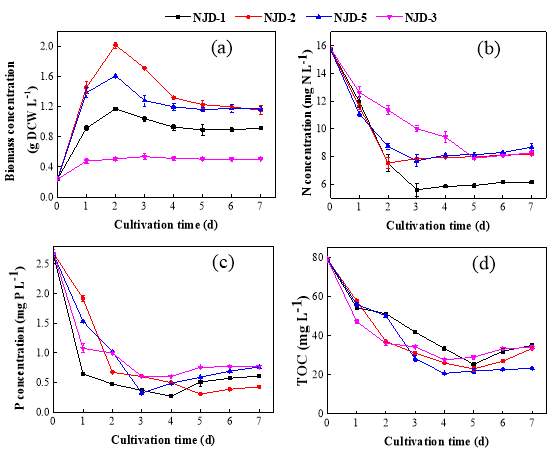

The results showed that four selected strains (i.e.,

Botryococcus sp. NJD-1,

Scenedesmus sp. NJD-2,

Scenedesmus sp. NJD-5 and

Chlorella sp. NJD-3) performed well in untreated domestic wastewater, achieving the maximum biomass yield (g L

-1) of 1.2 ± 0.002, 2.0 ± 0.03, 1.6 ± 0.01 and 0.54 ± 0.03, within the highest lipid content (g g

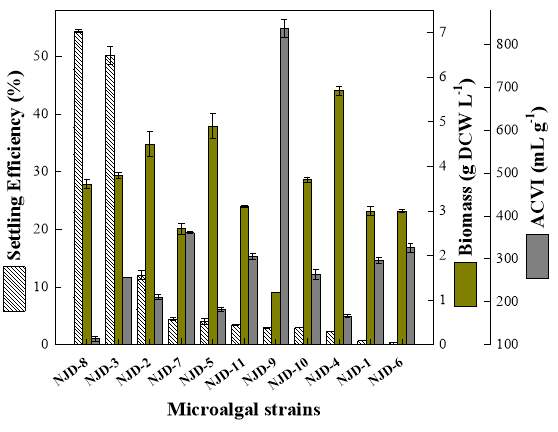

-1 DCW) of 61.7%, 55.9%, 50.4% and 40.1%, respectively. Among 11 isolates tested for the tendency to settle,

Chlorella sp. NJD-8 showed the highest settleability efficiency of 54.2% after 30 min.

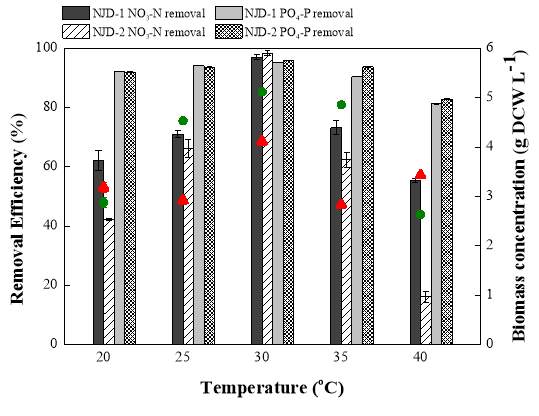

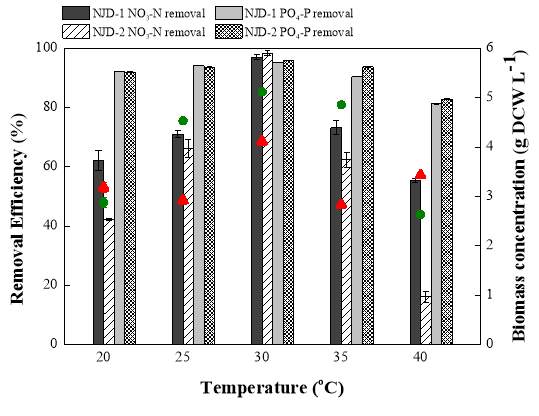

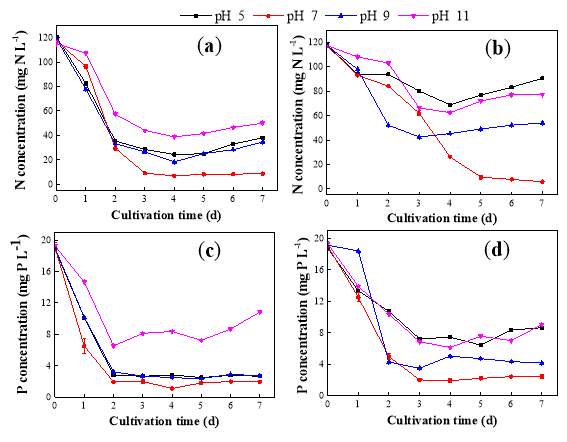

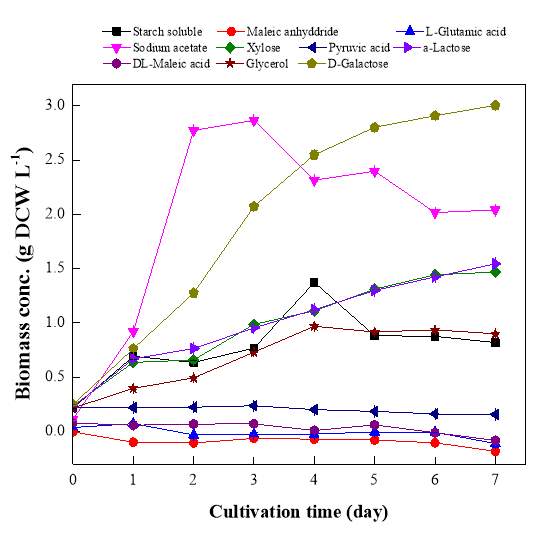

Botryococcus sp. NJD-1 exposed a potential capacity to assimilate a wide range of carbon substrates. Comprehensively, three strains were recommended for real wastewater treatment, i.e.,

Botryococcus sp. NJD-1 with up to 64.5% of N-NO

3 removal,

Scenedesmus sp. NJD-2 by 96.1% of P-PO

4 removal, and

Scenedesmus sp. NJD-5 with 99.9% of TOC removal.

Keywords: Microalgae; Isolation; Wastewater treatment; Heterotrophic cultivation; Biofuel.

ABBREVIATIONS

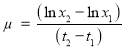

µ Specific growth rate

ACVI Algal culture volume index

ADE Autoclaved dairy effluent

AMWW Autoclaved municipal wastewater

APHA American public health association

AR Analytical reagent

ARDWW Autoclaved real domestic wastewater

ATP Adenosine Triphosphate

BLAST Basic local alignment search tool

BOD Biochemical oxygen demand

CMWW Concentrated municipal wastewater

CO2 Carbon dioxide

COD Chemical oxygen demand

DCW Dry cell weight

DE Dairy effluent

DNA Deoxyribo nucleic acid

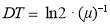

DT Doubling time

DWWTP Domestic wastewater treatment plant

FAMES Fatty acid methyl esters

kWh Kilowatt-hour

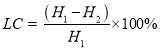

LC Lipid content

MBG11 Modified blue green media

MBold-3N Modified Bold-3N media

MWW Municipal wastewater treatment

NADPH Nicotinamide adenine dinucleotide phosphate

NCBI National center for biotechnology information

OD Optical density

PBR Photobioreactor

PCR Polymerase chain reaction

RDWW Real domestic wastewater

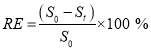

RE Removal efficiency

RNA Ribonucleic acid

rpm Revolutions per minute

RR Removal rate

rRNA Ribosomal ribonucleic acid

SE Settling efficiency

sp. Species

SV Settled volume

SVI Sludge volume index

TN Total nitrogen

TOC Total organic carbon

TSS Total suspended solid

UCMWW Autoclaved concentrated municipal wastewater

URDWW Untreated real domestic wastewater

UV/Vis Ultraviolet–visible

WWTP Wastewater treatment plant

Chapter 1 Literature Review

1.1 Overview of wastewater treatment

1.1.1 Wastewaters

Wastewater is defined as any water that has been adversely affected in quality by anthropogenic activities. Wastewater can originate from a combination of domestic, industrial, commercial or agricultural actions, surface runoff or storm water, and from sewer inflow or infiltration [

1]. {Tilley, 2008 #721;Liu, 2014 #825}Wastewaters provide not only water medium but also most of the necessary nutrients suitable for cultivation of microalgae evidenced by high algae growth rate and productivity and nutrient removal efficiency. Therefore, coupling wastewater treatment with algae cultivation may offer an economically viable and environmentally friendly way for sustainable renewable algae-based biofuel and bio-based chemicals production as well as credits for wastewater treatment [

2]. Municipal wastewater or sewage is usually carried out in a combined sanitary sewer and treated at a wastewater treatment plant. Via an effluent pipe, a treated wastewater is discharged into receiving water. Wastewaters generated in areas without access to centralized sewer systems rely on on-site wastewater systems. These typically comprise a septic tank, drain field, and optionally an on-site treatment unit. The management of wastewater belongs to the overarching term sanitation, just like the management of human excreta, solid waste and storm water (drainage). Sewage is a type of wastewater that comprises domestic wastewater and is therefore contaminated with feces or urine from people's toilets, but the term sewage is also used to mean any type of wastewater. Sewerage as the physical infrastructure, including pipes, pumps and screens, channels etc. used to deliver sewage from its origin to the point of eventual treatment or disposal.

1.1.2 Wastewater treatment

Wastewater treatment is the process of removing pollutants from wastewater through serial physical, chemical and biological processes. Its purpose is to produce an environmentally safe treated effluent and a solid waste suitable for disposing or re-using [

3]. However, there are numerous processes that can be used to clean up wastewaters depending on the type and extent of contamination. Likewise, wastewater can be treated in wastewater treatment plants through several ways including physical, chemical and biological treatment processes. Municipal wastewater treatment (MWW) is treated in sewage treatment plants, which may also be referred to as wastewater treatment plants. Also agricultural wastewater may be treated in agricultural wastewater treatment processes, whereas industrial wastewater can also be treated in industrial wastewater treatment processes.

To deal with the negative effects of wastewater on the recipient, traditional wastewater treatment generally involves three stages [

4]. The first stage is the primary treatment in which wastewater is held in a motionless basin, where heavy solids and colloids can settle to the bottom, while light solids and colloids can float to the top. It targets at removing large particles in the sewage by means of grids or sedimentation. The settled and floating materials are removed and the remaining liquid is discharged to secondary stage. In the secondary wastewater treatment, microorganisms are used to remove dissolved and suspended matter in the wastewater in a managed habitat and then the microorganisms are separated from the liquid. It aims as reducing the biochemical oxygen demand (BOD) in the wastewater by oxidizing organic compounds and ammonium. This process is often carried out in aerated tanks called activated sludge and it involves both heterotrophic bacteria and protozoa. The bacteria degrade the organic material and the protozoa graze the bacteria, and in both cases organic material is converted to CO

2 and water [

4]. Additionally, primary treatment removes about 60 percent of suspended solids from wastewater and also involves aerating the wastewater, to put oxygen back in whereas secondary treatment removes more than 90 percent of suspended solids (https://water.usgs.gov/edu/wuww.html).

The next treatment process after secondary treatment is the tertiary wastewater treatment, in which more advanced techniques such as carbon adsorption; flocculation, precipitation, etc. are used to remove the remaining stubborn contaminants in the wastewater to raise the effluent quality before it is discharged to the receiving environment [

4]. It mainly aims at removing nitrogen (N) and phosphorus (P) nutrients. N may be removed by nitrification-denitrification processes, where the ammonium is first oxidized to nitrate by nitrifying bacteria in aerobic reactors, and thereafter recycled to an oxygen free reactor where it is converted to nitrogen gas (N

2) by denitrifying bacteria. The first step in the nitrification is oxidation of ammonium to nitrite (1.1) and the second step is the oxidation of nitrite to nitrate (1.2):

2NH4+ + 3O2 → 2NO2‐ + 4H+ + 2H2O (1.1)

2NO2‐ + O2 → 2NO3‐ (1.2)

Autotrophic bacteria belonging to the family

Nitrobacteriaceae perform the nitrification. On the other hand, denitrification is carried out by a large number of heterotrophic bacteria, which all need organic carbon for growth. The denitrification reaction, performed according to the following reaction, has also nitrite as an intermediary step:

NO3‐ → NO2‐ → NO → N2O → N2 (1.3)

Phosphorus in wastewater is most often removed by chemical precipitation with aluminium or iron salts to form aluminium or ferric phosphate:

Me3+ + PO43‐ → MePO4 (1.4)

The metal (Me) salts are generally added in excess to compete with natural alkalinity, according to the following reaction [

5]:

Me3+ + 3 HCO3- → Me(OH)3 + 3 CO2 (1.5)

In current decades, microalgae appear to be an ideal key as they can uptake pollutants especially nutrients in wastewaters and thereafter reproduce as a feedstock of biofuel, food and chemicals. Meanwhile, autotrophic cultivation, so far the most common way for algae, is only appropriate when CO

2 is available. And the light shading effect would restrict the high-density growth of phototrophic algae as well. By such, the cost in the heterotrophic cultivation of algae with wastewater can be greatly lessened due to the elimination of aeration, extra substrate material and sterilization. As the quantity of wastewater generated every day is enormous, it is highly possible to utilize the wastewater for microalgae cultivation [

6]. Previous studies demonstrated the success of using microalgae to treat wastewaters rich in nitrogenous and phosphorus compounds [

7-9]. In the earlier reports, isolation and characterization of tolerant microalgal strains from wastewater treatment plant influents were carried out [

7,

8,

10,

11]. Alternatively, study on screening of microalgae capable of removing nutrients and producing high quality biomass while accumulating lipids in effluents from wastewater treatment plants have been currently conducted and produced the best results [

12-17]. Currently, the research on this area is insufficient and the commercial application of biofuel based on heterotrophic microalgae cultivation is limited due to the high cost of the artificial mediums. The industrial cultivation of microalgae faces an economic feasibility issue because of the high price of artificial medium and the low levels of biomass production. However, the use of wastewaters as media can meaningfully decrease the economic cost related to the biomass for biofuel manufacture from microalgae as well as an interesting tool for wastewater treatment. This could reduce the cost of heterotrophic cultivation significantly [

18].

However, the organic substrates that have been reported for heterotrophic cultivation are restricted in a couple of categories, such as glucose, glycerol and acetate [

19]. Actually, it was economically unfeasible to culture microalgae with glucose as that cost can reach up to 80% of the total material [

20]. Thus, it is necessary to acquire more information about the adaptation of the algae in case of unusual organics rather than the preliminary differentiation as heterotrophic or autotrophic.

1.2 Overview of microalgae

1.2.1 Cultivation of microalgae

To realize the commercialization of microalgae-based bioenergy and byproducts, a number of needs must be met: (1) inexpensive culture media, (2) low cost algae production systems that can be easily installed and maintained, (3) sufficient carbon dioxide sources for optimal algae growth, (4) efficient algae harvesting methods, and (5) cost-effective and low-energy input algal lipid extraction methods. Algal growth in nutrient-rich wastewaters could help address the first requirement and, when combined with an economical algae cultivation system, could provide a cost effective supply of algal biomass to downstream processing. Most of the current algae cultivation systems can be categorized into three groups according to their reactor design: open systems, closed systems, and hybrid systems, all of which are used on land. The major difference among these systems is whether the algae are exposed to the surrounding environment. However, they also share one common feature, that is, they all utilize suspended cultures in an aquatic environment.

So far, reactors used for mass cultivation of phototrophic microorganisms (comprising microbial or algal cells) in a photobiological reaction are named Photobioreactors (PBR) [

21]. Depending on whether or not exposure to the air, PBR for microalgae cultivation can be simply classified as open systems or closed systems. The commonly used open systems in wastewater treatment plants include lagoon, high stabilization pond, aerated ponds, raceway pond, multi-layer pond-like bioreactor, etc. The most prominent features of open pond system include simple construction, low cost and simple operation. However, the disadvantages of such system are also obvious, such as large occupation area, not stable culture system, difficult to control, easy to get polluted, water evaporation loss issue and the fact that light intensity decays rapidly with medium depth. Nonetheless, from the perspective of economic viability, advanced raceway pond with paddle-wheel is considered as the most promising culture system for low cost treatment of different types of wastewaters generated from sewage, industry and agriculture as well as biofuels feedstock accumulation [

22]. It is worth noting that although most microalgae in nature are obligate photoautotrophs and their growth strictly depends on photosynthetically derived energy, there are some species that can grow in a heterotrophic mode in the presence of organic carbon under complete darkness or in a mixotrophic culture mode when supplied with both organic and inorganic carbon under light and dark cycle conditions [

23].

1.2.2 Heterotrophic cultivation of microalgae

Heterotrophy is defined as the utilization of organic compounds for growth. In a heterotrophic environment, microalgae are in competition with bacteria and can be disadvantaged by size, metabolic speed and versatility in changing environments. However, the ability to grow in the absence of light or a CO

2 supply puts these algae at an advantage over other phytoplankton species when these resources may be in limited supply. Benefits of heterotrophic growth over autotrophic growth in terms of commercial application for biofuel production include higher growth rates leading to high cell mass, protein and lipid accumulation [

24], heterotrophic microalgae as a feedstock may still provide environmental benefits that other biofuels do not, such as not being in competition for land, ability to recycle waste for nutrients and potentially wastewater treatment, and low energy inputs.

Most domestic wastewater contains organic carbon, nitrogen, phosphorous, and other minor compounds. However, both biomass production and lipid accumulation are limited by several factors of which, nutrients play a key role. Microalgae adopt various routes of metabolism for their growth and survival with autotrophic, heterotrophic and mixotrophic modes. Some microalgae can grow photoautotrophically by using light as a sole energy source that can be converted to chemical energy through photosynthetic reactions and heterotrophically by utilizing only organic compounds as both carbon and energy source and mixotrophically using both organic compounds and CO

2 as energy source [

25]. Among photoautotrophic and photoheterotrophic modes, heterotrophic cultivation of algae offers several advantages including higher growth, good control over cultivation process, minimization of light requirement and easy biomass harvesting [

26]. The heterotrophic cultivation of microalgae can bring new insight to the production of biodiesel through which algae in this mode can be cultivated in a closed system, by significantly reducing the high costs and contamination that usually occur in traditional open systems [

27].

Additionally, heterotrophic cultivation of microalgae in combination with wastewater utilization offers multiple benefits to both the energy sector and to the environment. The nutrients and the other organic compounds existing in the wastewater can serve as a source of nutrient medium for the growth of algae. The process also provides economic mode of lipid production from the treatment of wastewater. Besides growing algal biomass for biofuel use, the wastewater can be treated simultaneously. Thus, the double benefits have attracted extensive attention over the years. But this approach has its shortcomings: (1) some wastewater may be too toxic to support algal growth; (2) due to the outdoor nature, algal growth and wastewater treatment efficiency can be significantly affected by seasonal alterations; and (3) competition among the microbial community in the wastewater may make algal growth very slow. Hence, using microalgae to treat wastewater while expecting high biomass productivity, it can be problematic. Furthermore, to overcome these problems, several research groups have attempted to screen microalgal species that can be dedicated for this dual-process. One example is to select algal strains that are facultative heterotrophic, adaptable to northern climate, able to consume organic carbon, nitrogen, and phosphorous in wastewater, and capable of high yield of biomass and lipid [

28].

1.2.3 Microalgal harvesting

After microalgal growth, the important step is to harvest the biomass. Harvesting microalgal cells from growth culture is a significant challenge in many industries for microalgal biomass production. Currently, the biomass separation and harvesting has posed another tough problem in the field of the algal cultivation, no matter for microalgae production or wastewater treatment. During microalgal cultivation in wastewater treatment systems that employ gravity thickening, filtration, secondary settling tank, and secondary clarifier for separating water and sludge (or biomass), the suitable cost-effective procedure has to be implemented in order to harvest the microalgal biomass prior to biofuel conversion [

29].

Also, the choice of harvesting method is significantly dependent on the economic factors, harvesting efficiency, microalgae species and desired quality of the products [

29]. For chemical harvesting technique, usually chemical flocculation is induced by specific electrolytes, synthetic polymers, organic flocculants and inorganic are normally employed [

30]. For mechanical methods, sedimentation method is used to harvest microalgal cells [

31], filtration, dissolved air flotation [

32,

33], using ultrafiltration membranes and attached algal biofilms [

32], and then centrifugation [

34]. Agreeing to Greenwell et al., [

33], the key factor that limit the commercial use of microalgae as one of the most challenging areas in the algal biofuel research, is the development of a cost effective harvesting method which can reach up to 20–30% of total production cost [

35].

Besides, filtration and centrifugation requires high energy input for operation which would be expensive. Conversely, studies showed that the application of commercial polymers at different concentrations for harvesting algae-bacterial flocs and reported that the flocculation efficiency decreases within increase in concentration of polymers [

36]. Recently, microalgae harvest educing nanoparticles (ex: Fe

3O

4) under in situ magnetic separation yielded maximal recovery efficiency more than 98% at a stirring speed of 120 rpm, with nanoparticles resulted in 55.9 mg-dry biomass mg-particles

-1 for

Botryococcus braunii and 5.83 mg-dry biomass mg-particles

-1 for

Chlorella ellipsoidea [

37]. Organoclays (aluminium and magnesium based amino salines clay) have been effectively used for microalgae harvesting with 100% efficiency in 30 min under neutral pH [

36]. In addition, filtration is a process that separated solid and liquid phases with the help of membrane. This process does not require any chemical agents for harvesting. The major limitation is biofouling of microbes in to the membrane of the filter; in order to overcome anti-fouling, strategies are implemented for fast processing. Dynamic filtration with pH induced flocculation is considered to be effective for more biomass production in open ponds [

38].

Gravity sedimentation is a simple method commonly applied in water and wastewater treatment to separate solids. The rationale of the process is to use gravity to separate liquids and/or solids from another liquid with different densities. Nevertheless it is an easy and simple method, it has several drawbacks since it is time and space consuming and the separation of low density microalgal particles is often unsuccessful [

39]. Centrifugation is a highly efficient and reliable method, where most microalgae particles can be recovered from the liquid cultures, with about 95 - 100% and 80 - 90% efficiency using centrifugation at 13,000 g and at 500 - 1,000 g, respectively [

40]. This is an effective method when dealing with the relatively low biomass concentrations obtained from microalgal cultivation systems with just a slight difference in density with respect to the liquid phase and the small size of microalgal cells. An oil extraction/trans-esterification with 90% efficiency would give 1.89 kg of fatty acid methyl esters (FAMES) containing 19.8kWh. Thus, the centrifugation operation alone would consume 49 kWh to produce only 19.849 kWh which is far from being sustainable [

41]. Bio-flocculants have emerged as an innovative technological approach in flocculation technology in order to minimize the energy consumption of harvesting microalgae. Bio-flocculation methods are flocculation induced by extracellular polymer compounds such as polysaccharides and proteins, derived from microalgae and other microorganisms [

42]. Various latest technologies for harvesting of algal biomass are recently reviewed [

42-44]. Flocculation is an enhanced process of sedimentation, with the addition of flocculants to improve the biomass settling rate.

Flocculation is similarly known as the process where the dispersed particles in suspension are aggregated together by the addition of chemicals (flocculants) to form larger particles that can easily settle. On behalf of harvesting purposes the dispersion induced by the electric charge increases the difficulty of separating the biomass from the water. The use of flocculants to surpass this characteristic is an efficient and common solution widely used in similar applications (e.g. wastewater treatment systems) and has been shown to be efficient with microalgae as well. The rational is to use positively charged ions or polymers (e.g. FeCl

3, Al

2(SO

4)

3, Fe

2(SO

4)

3 or natural and starch derivatives), which aid coagulation and improve algal biomass settling.

In

Mara [45], it is shown that the chemical flocculants used either inorganic or organic vary in effectiveness depending on their ionic charge and algal strain, but a report claimed to achieve up to 80% harvesting efficiency using pH induced Fe

3+ flocculation for various algal species. Chitosan as an important flocculants, by-product of shrimp and crab industries produced from the chitin of these animals is currently being tested in different industries such as chemical, food, pharmaceutical and in agriculture. In Riano et al., a non-toxic and biodegradable polycationic polymer has shown promising results as microalgae flocculant [

46]. The typical flocculants should be effective in low concentrations, low cost, non-toxic and have no effect on medium recycling (e.g., polyelectrolytes, aluminium sulphate and ferric chloride [

35]. To this, during chemical flocculation, microalgal harvesting involves bioflocculation, whereby microalgae spontaneously flocculate with bacteria and settle in the ponds. Microalgae-bacterial flocs from secondary treatment sewage can remove 97.5% of biomass from the culture medium in 30 min [

41]. In contrast, flocculation in large scale pond systems, was reported as ineffective harvesting method [

47].

Moreover, the choice of biomass harvesting method is mainly driven by economics and strictly depends on the value of the product. For example, gravity sedimentation possibly enhanced by flocculation, may be used for low value products and sewage based processes [

48], while high value products, such as those for food, feed and nutraceuticals may permit the use of cost intensive continuous centrifuges. Indeed, there is no universal best method for microalgal harvesting and mainly depends on algae species, size, density, production costs, growth medium and the end product. It was demonstrated that a universal harvesting method does not exist but in order to concentrate large microalgae culture volumes, a suitable harvesting method may involve one or more steps and be achieved in several physical, chemical, or biological ways [

49].

Therefore, according to Gutiérrez et al. [

50], the commonly employed biomass harvesting techniques (e.g. flocculation, filtration, centrifugation etc.), may account for up to 20-30% of the total cost in microalgae production. Thus, promoting the spontaneous flocculation and gravity sedimentation by increasing the dominance of the self-settleable microalgae rose as an appealing strategy for algae harvest in recent years [

51]. In this sense, microalgal strains with high self-settleability are of great interest in any cultivation system.

1.3 Cultivation of microalgae in wastewater

1.3.1 Sampling and isolation of microalgae from natural environment

Microalgae are normally found in aquatic bodies including freshwater, marine ecosystems and brackish water systems. Microalgae grow in most of the natural environments including water, rocks and soil, but interestingly also grow on and in other organisms. Local microalgae species should be collected because it can be expected to have a competitive advantage under the local geographical, climatic and ecological conditions. Microalgae may also be found in environmental conditions such as hot spring lakes, acid mine drainage and ice-lakes [

52,

53]. Some microalgal strains can grow even on land such as rocks and ionizing radiation fields such as nuclear reactors [

54], whereas some microalgae are capable to display only in brine and require saturated salts for their growth [

54]. Cyanobacteria, considered as microalgal, are photosynthetic prokaryotes often found in normal as well as in extreme environments, forming thick microbial mat during their growth and are found in extreme environments, such as hypersaline aquatic environments, dry and hot deserts, and sub-zero temperatures in the polar regions [

55]. Nubel et al., have isolated six different strains of cyanobacteria belonging to the genera of spirulina, which are tolerant and able to survive at a high temperatures [

56].

Some other microalgal species (e.g.,

Chlorella sp.,

Euglena mutabilis and

Pinnularia sp.) exhibit photo-inhibition and typically located at the bottom of the river bed [

54],

Massimi and Kirkwood [57] isolated forty-three algal strains including several strains from natural habitats with the exception of one cyanobacterial strain and Chlorophyta [41]. Nevertheless most microalgae are photoautotrophic with a great diversity in the natural habitat and can be found and collected from lakes, ocean, river, pond, and other water bodies [

58]. Isolation is a necessary process to obtain pure cultures and presents the first step towards the selection of microalgae strains with potential for biodiesel production. After collecting samples, methods to isolate axenic cultures are essential to get rid of other unwanted microorganisms (e.g. bacteria, fungus) through series of dilutions, sub-culturing, plating and anti-bacterial procedure.

Isolation of microalgae is normally practiced by three different plating methods, which are popularly known as streak plate, spread plate, and pour plate methods [

54,

59]. Streaking method is accomplished by streaking the loop containing algal sample over the agar surface and the numbers of algal cells are reduced at the end of the streaking helping to form a single colony. Pour plate method is done in case of those microalgae which don’t grow on the surface of the agar. In pour plate, direct dilution of algae is achieved while being suspended in the poured agar, ensuring separation at the time of plating. In addition, solidifying substance of the liquid medium containing microalgal cells traps the individual cells in place. In agar medium, they produce a fixed colony of cells or filaments and grow as separate colonies. In spread plate method, the microalgal culture is dispersed all over the surface of solid media, which leads to the isolation of the independent colonies [

55].

There are several other techniques available. One simple but effective method for isolation is the serial dilution method. It is a common technique used to bring down the concentration of microscopic organisms or cells in a liquid sample. By using this technique, an axenic culture may grow in one of the higher dilution tubes [

55]. Pure culture may also be obtained using picking up method (capillary method), which follows the dilution method, but inoculum is prepared by selecting single cells of the desired species by operating a capillary pipette handled under a microscope [

60]. Another effective method for isolation is Fluorescence Activated Cell Sorting (FACS) using Flow Cytometer enabling the selection of specific strains of microalgae and subsequent isolation [

61].

Another cost effective and high-throughput isolation and identification method for marine microalgae has been reported. This system consolidated high throughput isolation by streaking cells from enriched cultures on agar plates with subsequent development in multi-well plates [

62]. Satpati et al., reported that approximately 150,000 different microalgal species have already been identified from different habitats and many more are yet to be identified and to be included in the database [

63]. To this, more than 50% of identified algal species are from the marine and approximately 40% are from the freshwaters while 99% screened from aquatic bodies mainly belongs to

Chlorophyceae,

Bacillariophyceae,

Chrysophyceae,

Euglenophyceae, etc. [

63]. Also, each microalgae strain requires careful selection and optimization in order to increase biomass and lipid productivity with the aim to provide a cropping system with improved biofuel production and performance properties [

64].

1.3.2 Isolation of microalgae from natural environment

Previous studies are mainly focused on several locally isolated microalgal strains such as

Chlorella [

65]. Heterotrophic cultivation of algae with wastewater still faces many obstacles in practice. The primary problem is that there is a limited number of microalgal species that can grow heterotrophically. Indeed, most known microalgae species are obligate autotrophs instead of heterotrophs or mixotrophs [

66]. However, researchers tried to isolate and cultivate the heterotrophic microalgae in various categories of wastewaters. Tian-Yuan et al. [

67] isolated 5 heterotrophic microalgae from a domestic wastewater treatment plant and heterotrophic metabolism of isolates were evaluated for biofuel production using the Biolog method. Wang et al. [

68] isolated

Chlorella sp. from local wastewater, cultured it in different MWWs and observed significant heterotrophic growth rates and nutrient removal. Zhou et al. [

9] realized the heterotrophic cultivation of microalgae in concentrated municipal wastewater (CMWW), Ummalyma and Sukumaran [

69] used heterotrophic microalgae to treat dairy effluent for oil production and organic removal. Also Zhang et al. [

7] treated real wastewater using the newly isolated heterotrophic microalgae where the algal densities of

Scenedesmus and

Chlorella species were increased by 203.0% and 60.5%, respectively while Ramsundar et al. [

70] assessed the potential of

Chlorella sorokiniana in MWWs at various stages of treatment.

Currently, only few heterotrophic microalgae species have been isolated and a little work has been carried out in real wastewater treatment by heterotrophic microalgae without additional nutrients supplementation. In order to move forward the prospects of large-scale cultivation of microalgae in wastewater, potential microalgae isolated from local wastewater treatment plants to serve as candidates for pollutants removal and biofuel production are needed. The rationale for this is that microalgal isolates would have inherently higher tolerance to wastewater compared to isolates from natural systems, as well as an increased capacity to grow heterotrophically to exploit wide range of organic substrates in wastewaters.

Another challenging task to the researchers worldwide is the morphological identification of interesting algae as it lacks precise morphological markers for identification. Microalgae can change the cell size and shape during different stages of their life cycle; hence, it requires great effort to analyze the microalgae by conventional microscopic techniques [

71]. Morphological identification of microalgae requires experienced, taxonomical and technical expertise. Molecular identification tools can complement microscopic identification, and vastly improve the reliability of taxonomic classification of the identified algae. Molecular identification by ribosomal DNA sequencing is rapid, accurate and has proved to be very useful in understanding the evolutionary relationship among different species of algae [

72].

1.3.3 Nutrients requirements

Carbon, Nitrogen and Phosphorous are key components for the algae for nutrient assimilation. The nitrogen mainly comes from the sewage by the metabolic conversion and more than 50% phosphorous comes from the detergents. The principal forms in which they occur in wastewater are NH

3 (ammonia), NO

2 (nitrite), NO

3 (nitrate) and PO

4 (orthophosphate). From Perez-Garcia et al. [

73], these two elements are known as nutrients and their removal is known as nutrient stripping.

The rapid development of human activities has greatly increased the input of nitrogen and phosphorus into bodies of water. This input induces eutrophication and causes deterioration in natural water quality. As such, the removal of nitrogen and phosphorus from wastewater is a fundamental way to prevent eutrophication and water bloom. The main pollutants in a variety of wastewater sources are nitrogen and phosphorus in different forms, which contribute to eutrophication of water-bodies (e.g. lakes, rivers or oceans worldwide) if discharged improperly. On the other hand, these pollutants are ideal nutrients to stimulate fast algae growth. All organisms require basic nutrients for growth and multiplication, and most microalgae can meet all their cellular needs for their growth with a few key compounds; macronutrients, micronutrients (trace elements) and vitamins [

74]. Jimenez-Perez et al. [

75] reported that microalgae isolated from wastewater treatment plant sites or real bodies of water can adapt to practical conditions better and grow well. Cultivation of microalgae system in wastewater helps to reduce the organics by synthesizing biomass production and there by preserving fresh water resources [

76]. Thus the main mechanisms for nutrients removal in wastewater by microalgae include typical photosynthetic assimilation and chemosynthetic assimilation by heterotrophic or mixotrophic metabolic pathway.

1.3.4 Microalgae-based wastewater treatment

1.3.4.1 Nitrogen removal in algal cultures

Nitrogen is the most important nutrient contributing to the algal biomass production and is a key constituent of many algal cellular components such as amino acids, DNA, RNA proteins, alkaloids, vitamins, amides, enzymes and hormone accounting for 1-10% of dry cell weights, depending on the supply and availability [

77,

78]. Furthermost microalgae species are able of employing a variability of nitrogen sources comprising organic nitrogen (e.g., peptone, yeast extract, urea, glycine, glutamine, etc.) and inorganic nitrogen (e.g., nitrate, nitrite and ammonia, etc.) [

77]. It has been reported that nitrogen metabolism is related to carbon metabolism in microalgae because they share organic carbon and energy supplied directly from photosynthetic electron transport and CO

2 fixation as well as from the metabolic pathway of organic carbon through heterotrophic cultivation [

77]. For instance, assimilation and uptake of inorganic nitrogen (e.g., nitrate) by algae to form amino acids requires carbon skeletons in the form of keto-acids (2-oxalogutarate and oxaloacetate) and energy in the form of ATP and NADPH to synthesize the glutamine and amino acids glutamate [

79]. Among the above nitrogen forms, ammonium is the most preferred form of nitrogen source for microalgae in part because its uptake and utilization by microalgae is most energy-efficient [

77]. From above discussion, it is obvious that the preference for microalgae nitrogen uptake and assimilation by most microalgae species is: ammonium > nitrate > nitrite > urea [

77]. Nitrogen removal from wastewater treatment processes is mainly achieved by algal cells assimilation.

1.3.4.2 Phosphorous removal in algal cultures

Microalgae, like all organisms, need phosphorus to grow. The phosphorus is used in the algal cells mostly for phospholipids production, nucleic acids and ATP. Likewise, microlgae assimilate phosphorus as inorganic orthophosphate, possibly as H2PO4‐ or HPO42-. Phosphorous (demonstrating about 1-3% of microalgae in dry cell weights), as a major macronutrient, plays a significant role in cellular metabolic routes including production of nucleic acids, DNA, energy transfer and probably forms various functional constituents and structures essential for development and growth [

21]. Then, orthophosphate is merged into organic compounds through several kinds of phosphorylation procedures. Growing algae in phosphorus rich wastewaters could display the competent uptake of phosphorus stored in polyphosphate bodies influenced with a multiplicity of factors such as temperature, phosphate, light intensity and concentration in wastewater.

Nevertheless, the mechanisms of how these factors affect luxury uptake are not fully agreed [

21]. The ratio of N:P also plays an important part in N and P removal in algal based wastewater treatment system as it not only determines the potential productivity but also is important in maintaining the dominance of candidate species in culture [

21]. The inorganic N:P ratio varies with different types of wastewaters. A range of approximately 6.8-10 is considered as the optimal N:P ratio for algae growth. A ratio of N:P much higher than the optimal ratio indicates a high probability of phosphorus limitation while N:P ratio much lower than the optimal ratio indicates a high probability of nitrogen limitation [

80]. Apart from photosynthetic and chemosynthetic assimilation by microalgae, N and P removal from wastewaters are also affected by abiotic factors significantly. For example, at high pH, ammonia could be easily removed through stripping and phosphorous could be coagulated with metal ions that naturally existed in wastewaters and removed through precipitation [

81]. Therefore, the N and P removal in wastewater based algal cultivation system were attributed to assimilation by microalgae as well as volatilization and precipitation caused by abiotic factors.

1.3.4.3 Organic pollutant removal in algal cultures

Numerous microalgae are capable of growing photoautotrophically using inorganic carbon and sunlight as carbon and energy sources, respectively, heterotrophically using organic compounds as carbon and energy source, and mixotrophically by combining phototrophic and heterotrophic metabolisms [

19]. To this, microalgae synergistically interact with aerobic heterotrophs and autotrophs via exchange of substrates. These metabolic abilities and interactions support the biodegradation of biodegradable organic pollutants, energy use and its associated impacts, and reduce the risks of spreading of hazardous pollutants and pathogens [

82].

Carbon is one of the important sources for microalgae for cell growth as inorganic carbon dioxide, in autotrophic mode of cultivation. It would be organic carbon source for heterotrophic and mixotrophic mode of cultivation. Heterotrophic cultivation of microalgae has been reported to provide not only a high cellular oil content, but also a high microalgal biomass productivity [

83]. So, heterotrophic cultivation of algae suggests a promising way in the circumstance of wastewaters, in which organic carbon can be simultaneously used as energy and carbon source. By such, the cost in the heterotrophic cultivation of algae with wastewater can be greatly lessened due to the elimination of aeration, extra substrate material and sterilization. Additionally, the operation and daily maintenance turn to be much simpler than the autotrophic method. With all these merits, heterotrophic cultivation has been reported to enhance the algal biomass yield up to 25-fold of the autotrophic mode [

84]. Although, in the process of fixation, microalgae use CO

2 as an inorganic carbon source, while water acts as an electron donor for production of glucose, which is further transformed to various complex sugar forms such as carbohydrate, starch etc. Many microalgae species are able to utilize carbonates such as sodium carbonate (Na

2CO

3) and sodium hydrogen carbonate (NaHCO

3) for cell growth [

85]. Some studies have indicated that about 25–50 % of the algal carbon in high rate algal ponds is derived from heterotrophic utilization of organic carbon. The organic carbon sources can be assimilated either chemo- or photoheterotrophically. In the first case, the organic substrate is mused both as the source of energy (through respiration) and as carbon source, while in the second case, light is the energy source. In several algal species, the mode of carbon nutrition can be shifted from autotrophy to heterotrophy when the carbon source is changed; this is the case with e.g. of the green algae

Chlorella and

Scenedesmus [

74].

1.3.5 Microalgae biomass production in wastewater

Fast urbanization worldwide impacts the intensification in usage of water means in daily accomplishments which lead to depletion of freshwater resources. According to this statement, wastewater treatment has been mainly implemented widely to reuse the wastewater in order to conserve the available freshwater. Wastewater is a potential support for the life of various organisms as it contains more organic and inorganic compounds. Among the wastewater sources (i.e., industries, agricultural and domestic etc.), municipal wastewater has been showed a potential microalgal growth [

36]. Preceding investigators have considered the cultivation of microalgae in domestic wastewater collected from several wastewater treatment plants [

86,

87]. In those reports, the microalgae strains were suitable to produce high density biomass for multiple applications. From Li et al., it is highly possible to utilize the wastewater for microalgae cultivation, as the quantity of wastewater generated every day is huge [

6]. The microalgal cultivation conditions as reported by Kovar et al., may be photoautotrophic (where sunlight produces energy and transforms inorganic ingredients into organic ones), mixotrophic (assimilation of organic carbon substrates accompanied by inorganic compounds in light existence) and heterotrophic (unable to synthesize its own organic carbon compounds from inorganic sources and use organic matter as carbon source and energy simultaneously from other organisms) [

88].

However, the isolation of microalgae capable of high biomass and lipid concentration production is the foundation for biofuel development. Therefore, effective mutual advanced wastewater treatment and biomass production, selecting the proper microalgae species is the key point of research in this field. It has been reported that heterotrophic cultivation of microalgae is an effective way to support a much higher density of microalgae biomass than autotrophic cultivation [

89], it has been realistic in the large-scale production for several years ago [

90], it could also decline the land area needed and water evaporation significantly [

91]. In addition, heterotrophic cultivation of microalgae, glucose [

92] and acetate [

93] have been successfully used as carbon source whereas the type and concentration of nutrient sources were also supplemented to the medium [

92]. Thus, the heterotrophic cultivation of microalgae using wastewaters is a promising way to improve the feasibility of large-scale application of microalgae in biomass production for biofuels.

1.3.6 Biofuel production in wastewater

Biodiesel production from microalgae has received special attention as it contains hydrocarbon in the form of lipids, which is the most important criteria for biodiesel production. Nitrogen shortage in growth culture supports microalgae to accumulate more lipids in cells but in contrast, growth of cells was limited due to fewer nutrients in the medium [

94]. Previously, several studies attempted to use green microalgae in numerous wastewaters to generate biodiesel forms such as fatty acids and lipid. For example, in sewage,

Chlorella species produces 0.12 g biodiesel L

-1 [

81],

Chlorella ellipsoidea YJ-I accumulates 11.4 mg L

-1 of lipid content [

86],

Scenedesmus AMDD yields approximately 10 – 18 mg FAMES L

-1 day

-1;

Chlorella sp

. produces 6.9 mg lipid L

-1 d

-1 [

95]. When using industrial wastewater like citric acid effluents,

Chlorella vulgaris C9-JN 2010 reached 342 mg g

-1 lipid. In piggery wastewater,

Chlamydomonas mexicana produces 0.03 g lipid L

-1,

Chlorella pyrenoidosa harvests 6.3 mg lipid L

-1 d

-1,

Chlorella vulgaris produces 0.07 g lipid L

-1,

Botryococcus braunii produces 0.95 g hydrocarbon L

-1, whereas, in dairy wastewater,

Chlorella pyrenoidosa earnings 6.5 mL biodiesel while in soya bean wastewater,

Chlorella pyrenoidosa revenues 0.35 – 0.54 g lipid L

-1 d

-1.

Moreover, microalgal cultivation in collective wastewater from carpet mill industry and sewage produces 63.9% of oil from microalgae which can be converted in biodiesel yield. The involvement of diverse wastewater may prevent overwhelm of the growth of microbe due to certain constituents present in wastewater. Apart from the lipid content, microalgae also possess carbohydrates content which can be used for synthesis of bioethanol production. Also,

Scenedesmus species cultured in a raceway pond reactor produces 29% of sugar with dark/light cycle. Though, utilization of enzymes for cultivation of

Chlamydomonas reinhardtii for manufacturing ethanol using yeast produces 235 mg of ethanol from 1g of microalgal biomass. Under discrete hydrolysis fermentation,

Chlorella vulgaris FSPE produced 11.7 g ethanol L

-1 [

94].

1.4 Objectives of the study

1.4.1 Main objective

The purpose of this study is to screen the isolated microalgal strains from domestic wastewater treatment plant aimed at algal biomass production under heterotrophic cultivation. It aims in reviewing the potential of newly isolated strains with the high heterotrophic growth capacity to assimilate nutrients and biomass production using domestic wastewater as a resource.

1.4.2 Specific objectives

The specific objectives of this study were:

(1) To screen algae from domestic wastewater.

(2) To characterize isolated microalgal strains.

(3) To evaluate their performance in terms of high-dense growth, organics tolerance, nutrient removal, lipid recovery and self-settleability.

(4) To select suitable microalgae strains to realize the heterotrophic cultivation with real domestic wastewater.

(5) To evaluate the effects of selected microalgal strains on the environmental factors (Temperature and pH).

(6) To evaluate the effects of carbon sources on selected microalgal isolates.

Chapter 2 Materials and Methods

2.1 Equipment and Reagents

2.1.1 Equipment

The following apparatuses were used throughout this study:

Table 2.1 Equipment

| Serial No. |

Name |

Model |

Manufacturer |

| 1 |

Analytical balance |

Practum 224-1CN |

Sartorius (Germany) |

| 2 |

Autoclave |

HIclave TM HV-119 |

HIMALAYA (Japan) |

| 3

4 |

Centrifuge

Centrifuge |

Ankle TGL-16B |

Hunan XINKE Scientific Instruments Co., Ltd, (China) |

| 5804 R |

Eppendorf (USA) |

| 5 |

Shaker incubator |

SKY-2102C |

SUKUN (China) |

| 6 |

Microscope |

DM500 |

Leica (Switzerland) |

| 7 |

Freeze dryer |

FDU-1200 |

EYELA (Germany) |

| 8 |

Vortex shaker |

WH-861 |

SMT Max Corporation (USA) |

| 9 |

pH meter |

Delta 320 |

Mettler Teledo (China) |

| 10 |

Spectrophotometer |

UV-1780 |

Shimadzu, (Japan) |

| 11 |

TOC Analyzer |

TOC-L CPH |

Shimadzu (Japan) |

| 12 |

Microplate Reader |

SpectraMax 190 |

Molecular devices (USA) |

| 13 |

Oven |

DHG-9070A |

SHINOVA (China) |

| 14 |

Centrifuge tubes |

NEST |

NEST Biotechnology Co., Ltd. (China) |

| 15 |

Petri dishes |

MCD-000-090 |

JET BIOFIL (China) |

| 16 |

Microplates |

NunclonTM |

Thermo Fisher Scientific (China) |

2.1.2 Reagents

The following reagents were used throughout this study:

Table 2.2 Reagents

| Serial No. |

Reagent name |

Design |

Manufacturer |

| 1 |

Glucose |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 2 |

NaNO3 |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 3 |

K2HPO4.3H2O |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 4 |

KH2PO4.3H2O |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 5 |

MgSO4.7H2O |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 6 |

Ferric ammonium citrate |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 7 |

H3PO4 |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 8 |

HCL |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 9 |

EDTANa2 |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 10 |

Glycerol |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 11 |

Citric acid |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 12 |

Agar |

BR |

Solarbio Science & Technology Co., Ltd. |

| 13 |

Na2CO3 |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 14 |

CaCl2.2H2O |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 15 |

NaCl |

AR |

Guandong Guanhua Sci-Tech Co., Ltd. |

| 16 |

NaOH |

AR |

Guandong Guanhua Sci-Tech Co., Ltd. |

| 17 |

Methanol |

HPLC |

Sinopharm Chemical reagent Co., Ltd. |

| 18 |

Soluble starch |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 19 |

MgSO4.4H2O |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 20 |

ZnSO4.2H2O |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 21 |

Na2MoO4.2H2O |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 22 |

CaSO4.5H20 |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 23 |

Co(NO3)2.6H2O |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 24 |

Xylose |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 25 |

Na-acetate |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 26 |

α-Lactose |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 27 |

Glycerol |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 28 |

D-Galactose |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 29 |

Puruvuc acid |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 30 |

DL-Malic acid |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 31 |

Maleic acid |

AR |

Sinopharm Chemical reagent Co., Ltd. |

| 32 |

L-Glutamic acid |

AR |

Sinopharm Chemical reagent Co., Ltd. |

2.2 Sampling site and wastewaters

In this study, the mixed liquor in the aeration tank was sampled in Xiapu Wastewater Treatment Plant in Xiamen, China. After settling, the pellet was used as the original source for algae screening, and the supernatant was used as the real (without any other sources of substrates) domestic wastewater (RDWW) in the treatment experiment. All the samples were placed into a cooler and stored at 4

˚C or -20

˚C to avoid variation of wastewater composition.

Table 2.3 Media used in isolating microalgal strains and concentration of chemical components

| Component |

Concentration in media |

| MBG11 (mg L-1) |

MBold-3N (mg L-1) |

| NaNO3 |

82.57 |

82.57 |

| K2HPO4 |

12.46 |

12.46 |

| KH2PO4 |

- |

88 |

| MgSO4 .7 H2O |

75 |

75 |

| CaCl2·2H2O |

36 |

25 |

| Citric acid |

6 |

- |

| Ferric ammonium citrate |

06 |

- |

| FeCl2.6H2O |

- |

1770 |

| EDTA (disodium salt) |

1 |

2440 |

| Na2CO3 |

20 |

- |

| H3BO3 |

2860 |

- |

| MnCl2·4H2O |

1810 |

- |

| MnSO4.5H2O |

- |

0.589 |

| ZnSO4·7H2O |

222 |

0.073 |

| Na2MoO4·2H2O |

390 |

0.00148 |

| CuSO2·5H2O |

79 |

- |

| Co(SO4)2·7H2O |

- |

0.016 |

| Co(NO3)2·6H2O |

494 |

- |

| NaCl |

- |

25 |

| NiCl2.6H2O |

- |

0.00149 |

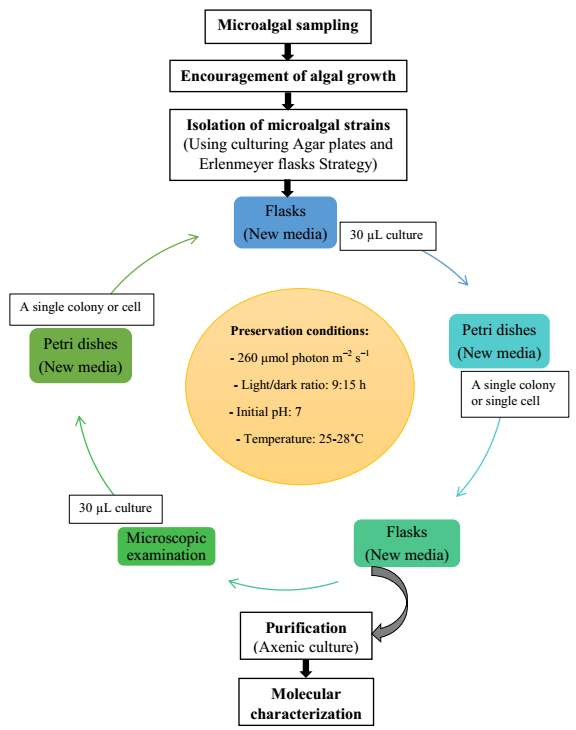

2.3 Isolation of microalgal strains

The isolation method was modified from Wang et al. [

7]. Briefly, 100 mL of wastewater samples were placed into sterile 250 Erlenmeyer flasks (triplicate) and placed on continuous light bank to encourage algal growth in whole-effluent for 30 hours.

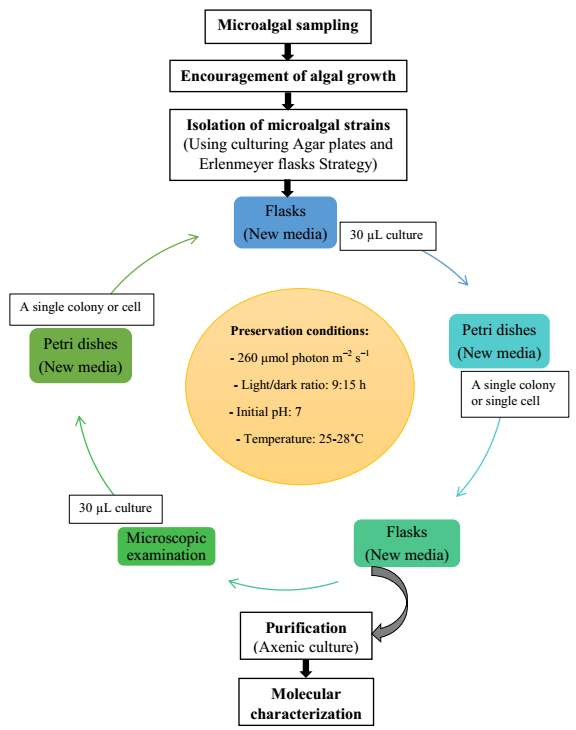

Fig. 2.1 Process diagram for isolation strategy of heterotrophic microalgal

When growth was confirmed either by naked eye or microscopic examination, 4 mL of wastewater sample was transferred to 250 mL flask containing either modified blue green (MBG11) [

96] or modified Bold-3N media (MBold-3N) [

97] in each medium. Compositions of isolation media were shown in Table 2.3.

After growth establishment in media, 2 mL of culture were added to fresh media and grown for 10 days. This process was repeated two successive times to ensure the compatibility of the algal culture under laboratory conditions. The algae were subjected to purification by serial dilutions followed by inoculation onto Agar plates containing flesh medium solidified by 12 g L

−1 of agar (triplicate). Two types of media were chosen in an attempt to isolate a larger diversity of isolates (Table 2.3).

Nitrate and phosphate were used as the nitrogen and phosphorus sources, respectively. The contents of nitrogen (NO

3-N) and phosphorus (PO

4-P) in the media were set as 13.6 mg L

-1 and 2.22 mg L

-1, respectively. Two types of media were chosen in an attempt to isolate a broader diversity of isolates. To avoid the contamination of bacteria, the citric acid was added. The purity of the cultures was ensured by repeated streaking on the nutrient agar plates and repetitive microscopic examination. Morphologically, unique strains were selected and maintained for further experimentation (Leica DM500, Switzerland).

Microscopic checking also allowed us to monitor the isolation process to ensure the presence of a single strain culture. Microscopic observation of these microalgal strains indicated their colonial existence and purity. The preservation conditions used to isolate the microalgal strains were 260 μmol photon m

−2 s

−1, light/dark ratio was 9:15 hour, initial pH 7 and the temperature range of 25 - 28

˚C for 15 days of incubation. The overall isolation route of heterotrophic microalgae was shown in Fig. 2.1 and each step was carried out in triplicate.

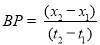

During the growth periods, the cultures were manually shaken 3 times per day to avoid sticking. In order to obtain the hopeful microalgal strains in biomass production for lipid production and nutrients removal from wastewaters, all isolates were grown in MBG11 medium for 10 days under dark cultivation. After this, the top growing isolates were cultured to assess their biomass productivity, nitrate concentration, phosphate concentration, residual total organic carbon and total lipid content. In addition, selection of the optimal strains was also performed (Fig. 2.2).

![Description: C:\Users\NDAYAMBAJE\AppData\Roaming\Tencent\Users\2115859462\QQ\WinTemp\RichOle\_V3T]9KI3L%UMXPCEXKRY4F.jpg](https://images.ukdissertations.com/18/0031520.003.jpg)

Fig. 2.2 Selection process of the most promising candidates among the isolates strains

2.4 Identification of microalgal isolates

2.4.1 Molecular Characterization and identification of isolated microalgae

Morphological identification of algae of interest is a challenging task to the researchers worldwide as it lacks precise morphological markers for identification. Microalgae can change the cell size and shape during different stages of their life cycle. Hence, it requires great effort to analyze the microalgae by conventional microscopic techniques and also obliges experienced, taxonomical and technical expertise. Molecular identification tools can complement microscopic identification, and vastly improve the reliability of taxonomic classification of the identified algae. Molecular identification by ribosomal DNA sequencing is rapid, accurate and has proved to be very useful in understanding the evolutionary relationship among different species of algae [

71,

98]. Identification of algal taxonomy is normally based on microscopic characteristics particularly morphology and color. There are a number of situations in which molecular techniques have taken priority, such as: No clear morphological characteristics are available (for unicellular blue-green algae), when algae are relatively inaccessible and difficult to visualize (case for biofilms or a very heterogeneous community of organisms), when diversity is being studied within species (when strains are often distinguished in biochemical and genetic terms). Finally, species proof of identity in both prokaryote and eukaryote algae may depend on molecular analysis, with determination of unique and defining DNA sequences followed by development of species-specific nucleotide probes [

99].

2.4.2 DNA extraction

Apart from the microscopic examination, molecular identification can improve the consistency of taxonomic classification of the targeted algae. In this work, the total cellular DNA was extracted from the microalgal isolates by using DNA Isolation Kit (MO BIO Laboratories, Inc., USA) based on the manufacturer's instructions. The genomic DNA was stored at -20 ˚C until PCR amplification.

2.4.3 PCR amplification and gene sequencing

The polymerase chain reaction (PCR) is a powerful and sensitive technique which amplifies specific DNA sequences [

100]. It has been reported that the 16S rRNA gene can be considered as molecular marker more effective in identifying some species of microalgae [

101]. Currently, analysis of the corresponding 23s rRNA sequences provided more information concerning phylogenetic relationships. 23s rRNA is about twice as big as 16s rRNA, so it is assumed that 23s rRNA contains more variable regions and hence is more discriminative than the smaller 16s rRNA. There has been renewed interest in the use of the 23S rRNA gene with the decrease in sequencing costs and the growing popularity of techniques such as microarrays [

102] analysis of the 16S-23S inter-genetic region, fluorescence in situ hybridization, and quantitative PCR. Compared to 16S rRNA genes, 23S rRNA genes contain more characteristic sequence stretches due to a greater length, unique insertions and/or deletions, and possibly better phylogenetic resolution because of higher sequence variation [

103].

A recent study indicated that 23S rRNA genes also contain conserved regions for designing broad-range primers with a similar degree of universality to the broad-range primers for 16S rRNA genes [

102]. There has been renewed interest in the use of the 23S rRNA gene with the decrease in sequencing costs and the growing popularity of techniques such as microarrays [

102] analysis of the 16S-23S inter-genetic region, fluorescence in situ hybridization, and quantitative PCR. Compared to 16S rRNA genes, 23S rRNA genes contain more characteristic sequence stretches due to a greater length, unique insertions and/or deletions, and possibly better phylogenetic resolution because of higher sequence variation [

103]. In the other hand, 18S rRNA gene is one of the most frequently used genes in phylogenetic studies and an important marker for random target PCR in environmental biodiversity screening [

104]. The S in 18S represents

Svedberg units. 18S rRNA is a component of the small eukaryotic ribosomal subunit, the structural RNA for the small component of eukaryotic cytoplasmic ribosomes, and thus one of the basic components of all eukaryotic cells. It is the eukaryotic nuclear homologue of 16S ribosomal RNA in Prokaryotes and mitochondria. The 18S gene is part of the ribosomal functional core and is exposed to similar selective forces in all living beings.

In this study, taxonomic determination of isolates was confirmed by sequencing using two oligonucleotide primers (Forward: 5'-GTAGTCATATGCTTGTCTC-3'of NS1; Reverse: 5`-CTTCCGTCAATTCCTTTAAG-3` of NS4) and (23SF: 5'-GGACAGA-

AAGACCCTATGAA-3'; 23SR: 5'-TCAGCCTGTTATCCCTAGAG-3') were used for PCR amplification of partial 18S rRNA and 23S rRNA genes respectively [

57,

71]. The primers were prepared by Sangon Biotech Co., Ltd (Shanghai). Each PCR reaction consisted of a 25 µL solution containing 1 µL of genomic DNA, 1 µL of forward primer, 1 µL of reverse primer, 12.5 µL of 2 x PCR TaqMixture (Himedia, India) and 9.5 µL of sterile water. The PCR amplification was performed using following thermal program for 18S rRNA and 23S rRNA amplifications: Preheating at 96 ˚C for 4 min followed by 33 cycles of denaturation at 94 ˚C for 60 s, annealing at 62 ˚C for 60 s, and extension at 72 ˚C for 60 s followed by another 10 min extension at 72 ˚C.

However, the PCR products were sequenced by Sangon Biotech Co., Ltd. (Shanghai, China) and comparison for similar sequences was carried out by BLAST Program (NCBI BLAST, USA). The sequences of the newly isolated algae were deposited into the NCBI GenBank database (National Center for Biotechnology Information, http://www.ncbi.nlm.nih.gov/) [

105] and the accession numbers were obtained (KY656445-KY656464). The isolated strains were identified according to the method described by

Wehr and Sheath [106]. Multiple sequence alignment and phylogenetic tree construction were executed using the Molecular Evolutionary Genetics Analysis v5 (MEGA5) software [

107].

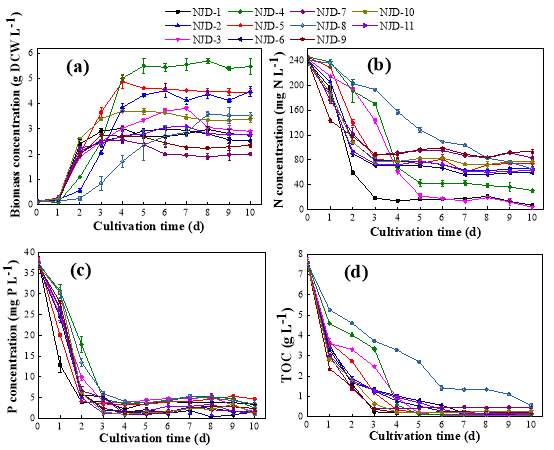

2.5 Wastewater treatment experiment

In order to narrow down the promising isolates in biomass production for lipid accumulation and pollutants removal from wastewaters, all 20 algal isolates were preferably selected conferring to their growth properties, nutrient removals, lipid accumulation self-settleability and algal culture volume index when cultivated in synthetic wastewater that contained MBG11 medium and 10 g L

-1 glucose, for 10 days under dark cultivation (Fig. 2.2). The cultivation of microalgal strains in real domestic wastewater were split into two groups, specifically, using ARDWW and URDWW, so as to check the application scope of these algae considering the symbiotic interactions between microalgae and bacteria. Each culture was conducted in a 250-mL sterilized Erlenmeyer flask with 150 mL URDWW or ARDWW. The dry cell weight (DCW) of microalgae inoculum was around 0.22 g DCW L

-1. The cultivation conditions were under dark condition, pH 7, 150 rpm agitation and 30˚C for 10 days. The mixed liquor was periodically sampled from the flask algae in the course of cultivation. All experiments were conducted in triplicate.

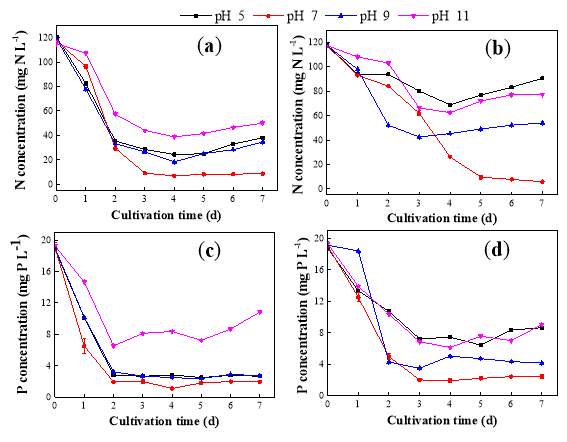

2.6 Adaptation test

The effects of potential microalgal strains in wastewater environment in terms of different temperature, pH and organic sources were investigated after being selected. On behalf of temperature, in order to optimize the promising strains in biomass production and nutrient removal, experiments were carried out at 20, 25, 30, 35 and 40 ˚C temperature levels for carefully chosen strains (due to their performance in RDWW)

Botryococcus sp. NJD-1 and

Scenedesmus sp. NJD-5. Those algae were cultivated under dark cultivation in MBG11 medium supplemented by 10 g L

-1 glucose. The cultivation conditions were pH 7, 150 rpm agitation. Similarly, the performance of microalgal culture at different pH, experiments were done at pH 5, 7, 9 and 11 by the same strains. Growth parameters and nutrient removal rates were determined. The cultivation conditions were 30˚C and 150 rpm agitation. The culture medium used was MBG11 and supplemented by glucose (10 g L

-1) as carbon source.

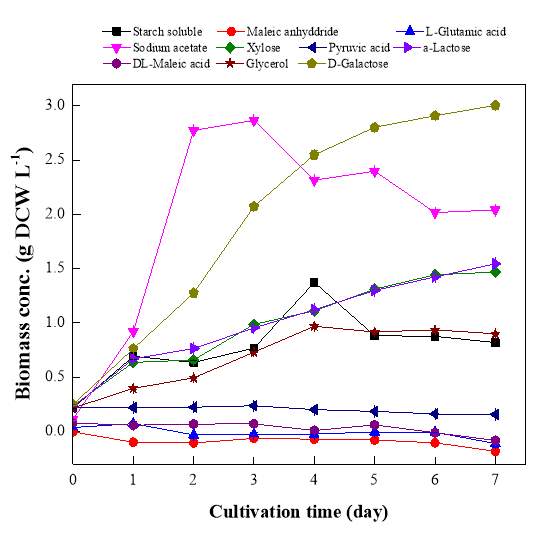

So far, the adaptation of

Botryococcus sp. NJD-1 strain within numerous carbon types was performed in 10 different kinds of carbon substrates and the growth properties were evaluated. The cultivation conditions were pH 7, 150 rpm agitation and 30˚C and the MBG11 medium complemented with each carbon type was utilized. All experiments were conducted in 250 mL Erlenmeyer flasks with 100 mL culture medium (in triplicate) for 7 days under dark condition using shaker incubator. The dry cell weight (DCW) of microalgae inoculum was around 0.3 g DCW L

-1. The samples were taken periodically after 24 h from the algal flasks in the sequence of the cultivation time.

2.7 Analytical methods

2.7.1 Quality of domestic wastewater used as the culture medium

The concentration of trace metals in domestic wastewater was determined by a multi-channel inductively coupled plasma optical emission spectrophotometer, ICP-OES (PS-4; Baird Co., Bedford, MA, USA). Total organic carbon (TOC) was measured by total organic carbon analyzer (TOC-L CPH, Shimadzu, Japan).

2.7.2 Determination of dry cell weight and evaluation of growth parameters

All 20 microalgal isolates were firstly cultured in heterotrophic conditions and evaluated by measuring the optical density of the sample at absorbance of 685 nm (OD

685 nm) using a Microplate Reader (SpectraMax 190, Molecular devices) after proper dilution with de-ionized water and then selected for other experiments. Each sample among 11 selected candidates was collected during by centrifugation at 10,000 rpm for 10 min with centrifuge (Ankle TGL-16B), and the cell pellets were washed twice with de-ionized water to remove medium salts, dried at 105 ˚С in an oven (DHG-9070A) for 22 h and weighed gravimetrically. The tubes were weighed on a precision analytical balance (Practum 124-1CN, Sartorius) and dry cell weights (DCW) were determined by subtracting the predetermined weight of the empty tube. The initial culture supernatant after the first centrifugation step was carefully removed and used for nutrients analysis. Optical density (OD

685) values was converted into biomass concentration (g L

-1) via appropriate calibration between OD

685 and dry cell weights [

108]. The relationship between OD and DCW was determined through linear regression and converted to (g L

−1). The biomass productivity (

BP, g L

-1 d

-1), the specific growth rate (

μ) and the cell doubling time,

DT in d

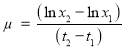

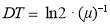

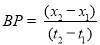

-1 (or generation time) were calculated through the Eqs. (2.1) to (2.3), respectively.

(2.1)

(2.2)

(2.3)

In which

x1 and

x2 are the dry cell weights (g L

−1) on days

t1 (start of the exponential phase) and

t2 (maximum of exponential phase), respectively.

2.7.3 Determination of nutrient concentrations and removal rates

The nitrogen (NO

3-N) concentration in the medium was determined by UV spectrophotometric method. The culture supernatant was collected by centrifugation 10,000 rpm for 10 min by a centrifuge (Ankle TGL-16B). Then the optical density of the sample was measured at a wavelength of 220 nm using a UV/Vis spectrophotometer (UV-1780, Shimadzu, Japan) after proper dilution with deionized water [

97]. The calibration between the absorbance and nitrogen concentration was established using sodium nitrate (NaNO

3) as the standard [

97]. The concentration of phosphorous (PO

4-P) in the medium was determined by ascorbic acid method. Briefly, 0.5 mL supernatant was put in a 10 mL test tube, de-ionized water was added to 5 mL and 0.8 mL color reagent was added. Then, after color development (after 10 min), the absorbance was read at 880 nm using a UV/Vis spectrophotometer (U-1780, Shimadzu, Japan) after proper dilution with de-ionized water. The calibration between the absorbance and phosphorous concentration was established using potassium phosphate monobasic (KH

2PO

4) as the standard in APHA 4500-P [

97]. Total organic carbon (TOC, g L

-1) was measured by total organic carbon analyzer (TOC-L CPH, Shimadzu, Japan). Nutrient removal efficiencies (

RE, %) were calculated using Eq. (2.4). The rate of nutrient removal (

RR, g L

-1 d

-1) was calculated according to Eq. (2.5).

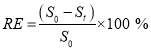

(2.4)

(2.5)

In which

RE is the removal efficiency of substrates (NO

3–N, PO

4–P and TOC);

S0 is the initial concentration and

Stis the maximum concentration of substrates at initial (

to) and final (

tt) time (in days) respectively.

2.7.4 Total lipids extraction by single-step method

Total lipids extraction was performed according to the modification of the method that was previously reported by Axelsson and Gentili [

109]. Freeze-dried biomass (40 mg) by a Freeze dryer (FDU-1200, Eyela) was placed in pre-weighted (

H1) centrifuge tubes, and then 8 mL of chloroform–methanol (2:1 v/v) mixture was added for each strain. Algal biomass was suspended manually by shaking vigorously the centrifuge tubes about 1 min. The mixture was centrifuged at 9,000 rpm and 4 ˚C, for 10 min (Centrifuge 5804 R, Eppendorf). After addition of 2 mL of 0.73 % NaCl aqueous solution to produce a 2:1:0.8 system of chloroform: methanol: water (v/v/v), the mixture was shaken for 20 seconds (Vortex shaker, WH-861) and centrifuged at low speed of 3000 rpm for 2 min to allow phase separation. The upper phase was siphoned and the solvent was evaporated. After the solvent was completely evaporated, lipid fractions were quantified gravimetrically by reweighing (

H2) the centrifuge tubes with a precision analytical balance (Practum 224-1CN, Sartorius).

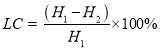

The percentage of total lipid content (

LC, %) was determined by dividing the weight of recovered lipids by the weight of the dried biomass as Eq. (2.6). All experiments were conducted in triplicate.

(2.6)

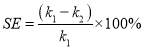

2.7.5 Self-settleability test

After screening all 20 isolates, eleven top growing candidates referring to their optical densities, were tested. The settleability of the microalgae was determined according to the method modified from Manheim and Nelson [

110]. Briefly, it referred to the decrement on the change of OD

685 in 10 mL microalgal suspension distributed in 15 mL centrifuge tubes after 30 min settling. The cultures were gently mixed in 1 min and settled for 30 min at room temperature. An aliquot of the microalgal culture was withdrawn at a height of two-thirds from bottom of the tubes; the OD

685 nm of the cultures at different settling time was measured by UV/Vis spectrophotometer. The settling efficiency (

SE, %) was calculated by Eq. (2.7). All experiments were carried out in triplicate.

(2.7)

In which

k1 and

k2 are the values of OD

685 nm for the algal suspension at 0 min and 30 min sedimentation time respectively.

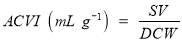

2.7.6 Algal culture volume index

The sludge volume index (SVI) is the volume occupied by 1 g of a suspension after 30 min of settling. It is used to monitor settling characteristics of activated sludge and other biological suspensions [

111]. From this, the microalgal cultures were considered. Although SVI is not supported theoretically [

112]. In this particular instance,

ACVI was referred to as algal culture volume index, TSS as microalgal dry cell weight (DCW). In order to calculate the

ACVI, the settled volume (

SV) and the total suspended solids has to be measured. The volume of culture at 30-min of sedimentation was recorded as the settled volume. Algal culture volume index (

ACVI) was calculated as per (Eq. 2.8), also used by Yousuf [

113] with little modifications.

(2.8)

Where

SV is the settled volume in 30 min and

DCW is the dry cell weight after 14-day cultivation of each microalgal candidate.

2.8 Statistical analysis

To determine statistically significant differences between growth condition treatments and strains, OrginPro 8.6 was used to run analysis. Average values of the results of three independent experiments with two analytical replications in each were used.

Chapter 3 Results and Discussion

3.1 Isolation and identification of microalgae from wastewater

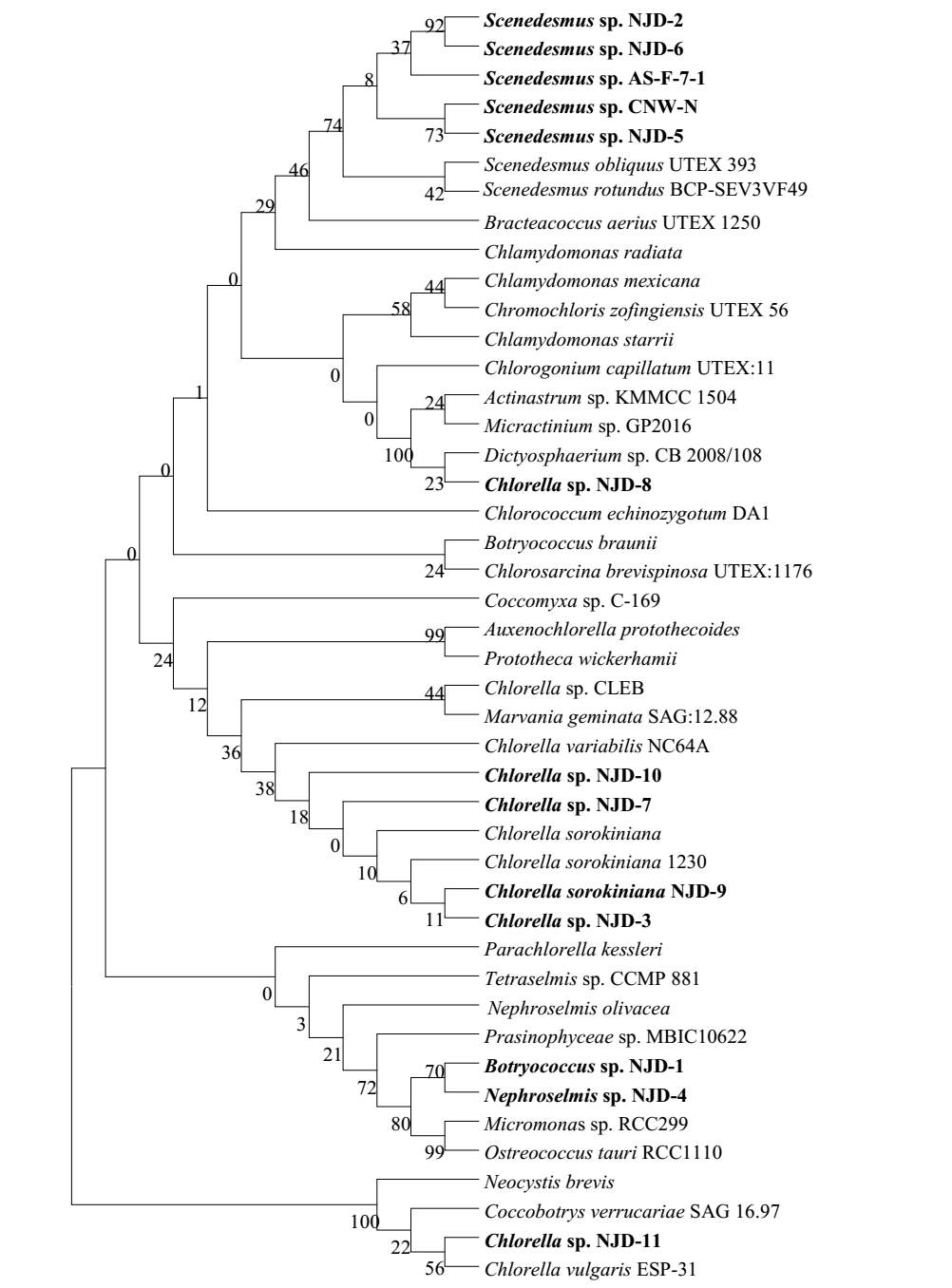

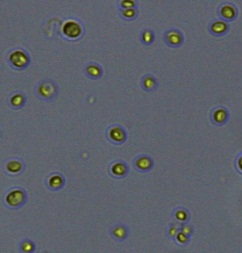

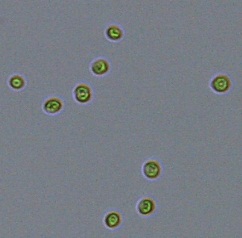

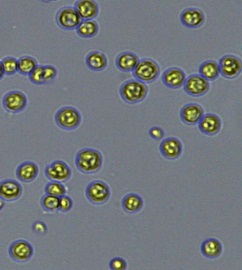

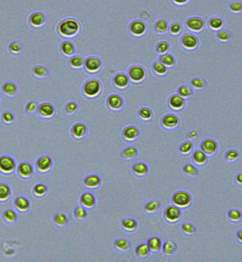

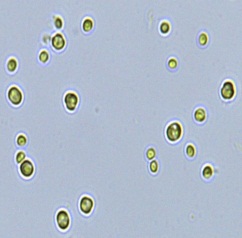

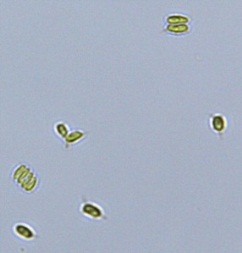

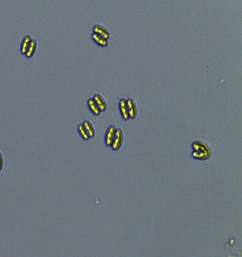

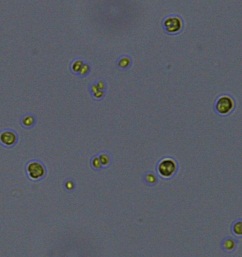

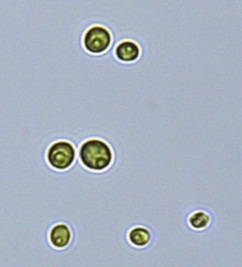

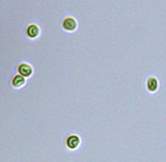

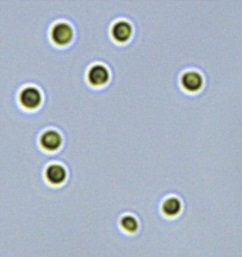

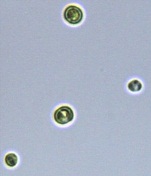

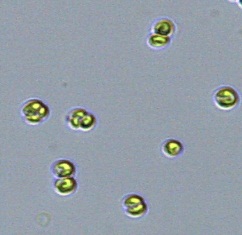

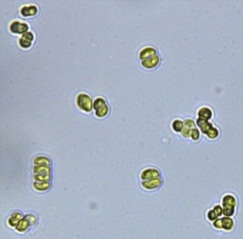

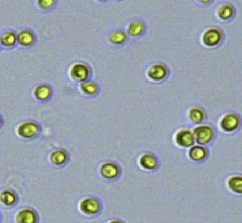

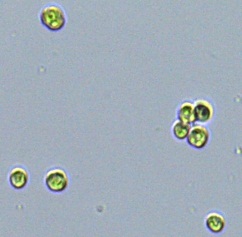

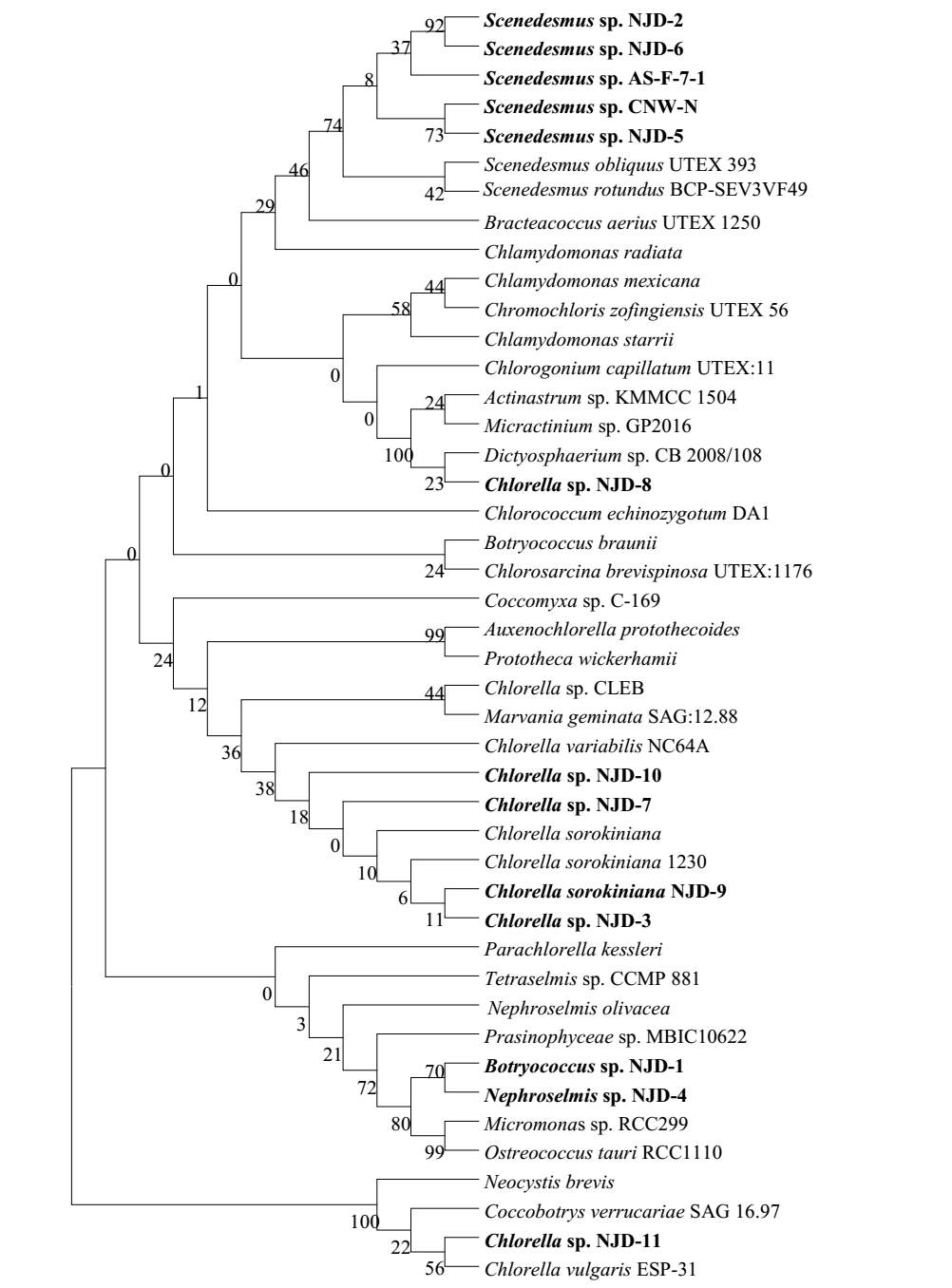

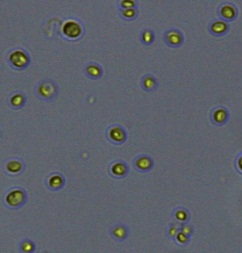

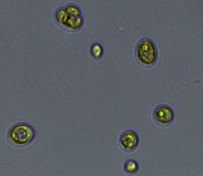

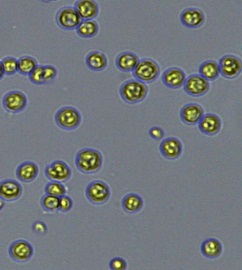

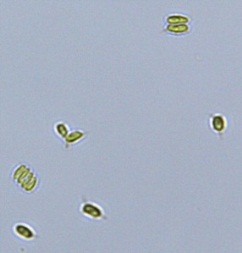

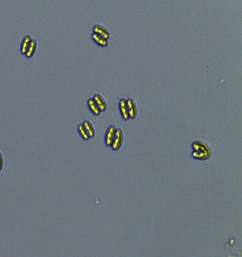

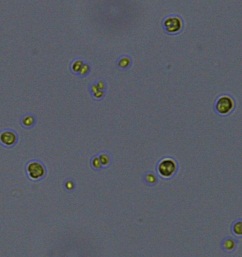

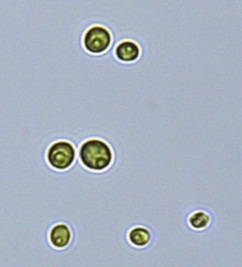

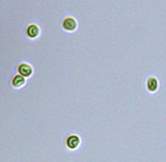

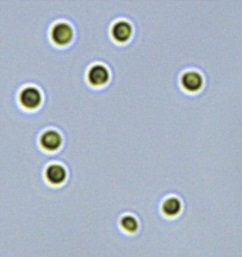

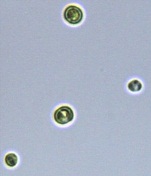

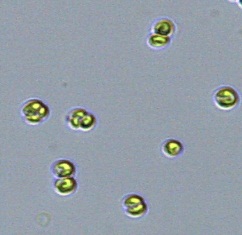

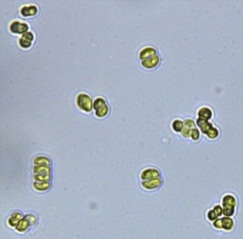

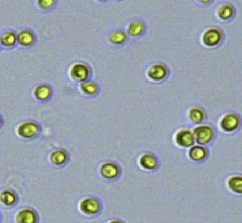

A total of 20 heterotrophic microalgal strains were successfully isolated from the local WWTP as summarized in Table 3.1 and 3.2. MBG11 medium isolated higher number of strains than MBold-3N medium. It was observed that all media can support the microalgal growth. An unrooted neighbor-joining phylogenetic tree for the selected 11 strains was reconstructed based on the sequencing results (Fig. 3.1). The morphological analysis and molecular identification of microalgal cultures showed that all the isolates belonged to the genera of

Botryococcus, Chlorella, Scenedesmus, and Nephroselmis. This reflects a diversity of algal strains in domestic wastewater. As shown in Table 3.2, the morphological features of 4 isolates (NJD-2, NJD-5, NJD-6 and NJD-18) that belong to the genus of

Scenedesmus, the family of Scenedesmaceae and the class of Chlorophyceae, were small, non-motile, cylindrical, elongated or fusiform in shape with pointed ends. The colonies were usually observed in groups of 2 or 4 spindle-shaped cells aligned laterally with concave outer side. These observations consist with literature that

Scenedesmus cells are approximately 2-10 µm wide and 5-30 µm long, each cell contains a chloroplast with a pyrenoid and lacks the presence of spines [

114].

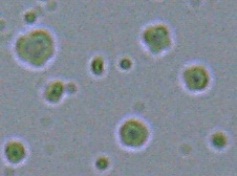

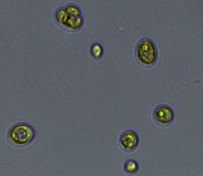

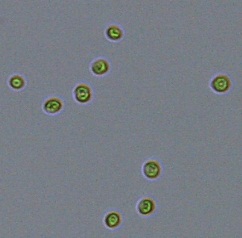

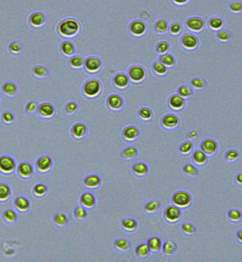

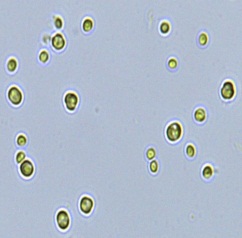

Meanwhile, 11 strains among 20 isolates (NJD-3, NJD-7, NJD-8, NJD-9, NJD-10, NJD-11, NJD-12, NJD-13, NJD-14, NJD-15 and NJD-19) were

Chlorella species, i.e., small, non-motile, single-celled green algae, belonging to the family of Chlorellaceae and the class of Trebouxiophyceae. They also conform to the features of

Chlorella species. Specifically, cells were solitary, 2-10 µm in diameter and spherical, globular or ellipsoidal in shape, devoid of flagella, having a parietal and cup-shaped chloroplast (sometimes plate-like) with or without a pyrenoid, and usually overlooked because of their small size. Stemmler et al. [

8] reported that

Scenedesmus and

Chlorella species were mostly isolated species from wastewater treatment effluent, which explains their high occurrence in wastewater samples.

Fig. 3.1 Phylogenetic tree of 11 isolated microalgae and closely related strains from the NCBI nucleotide database. Numbers at the branch nodes are bootstrap values obtained

Table 3.1 Morphology of 20 microalgal strains isolated from WWTP in this study, at 400× magnification

| Strain ID |

Microscopic images (400×) |

Strain ID |

Microscopic images (400×) |

Strain ID |

Microscopic images (400×) |

| NJD-1 |

|

NJD-8 |

|

NJD-15 |

|

| NJD-2 |

|

NJD-9 |

|

NJD-16 |

|

| NJD-3 |

|

NJD-10 |

|

NJD-17 |

|

| NJD-4 |

|

NJD-11 |

|

NJD-18 |

|

| NJD-5 |

|

NJD-12 |

|

NJD-19 |

|

| NJD-6 |

|

NJD-13 |

|

NJD-20 |

|

| NJD-7 |

|

NJD-14 |

|

|

|

Table 3.2 Molecular identification of 20 microalgae isolated from WWTP in this study

| Serial No. |

Microalgal isolates |

Closest BLAST equivalent

and accession number |

Similarity (%) |

Isolating medium |

| 1 |

Botryococcus sp. NJD-1 |

Botryococcus braunii, KM462884.1 |

84% |

MBG11 |

| 2 |

Scenedesmus sp. NJD-2 |

Scenedesmus sp. AS-F-7-1, HE717104.1 |