Sugarcane as a Source of Biofuel

Info: 11599 words (46 pages) Dissertation

Published: 11th Dec 2019

Tagged: Energy

Chapter 1: Introduction

Aims

Objectives

Background

Research question

Chapter 2: Literature review

- Biofuel related literature

- Ethanol production process

- Feedstock review

- Biofuel production cost

- Advantages and benefits

- Sugar production related

- Production process

- Sugarcane as feedstock

- Residue and its recycling

- Costs and prices

- Literature on trade-off between sugar production and biofuel production

Chapter 3: methodology

Approach to trade-off analysis

Data and inputs

Identification of alternative cases for analysis

Chapter 6: results and discussions

Conclusion and recommendation for further work

References

Chapter 1: Introduction

During last couple of years, in serious consideration for the worldwide economy and the environmental pollution that burning fossil fuels causes, there has been an increased interest in the production of renewable energy. Gasoline provides the single biggest percentage of the world’s energy and the total world consumption in 2015 was 95 million barrels per day. [1] Burning gasoline is responsible for a high percentage of carbon dioxide emitted to the atmosphere. In Brazil, most of the gasoline produced is used in the transportation of vehicles which leads to pressure being put on the supply of gasoline even further. Last year alone the global oil consumption grew by almost 2 million barrels per day, which was considerably more than the 1.1 million barrels used in 2014. [2]

An essential stride is in effort, to take care of the issue to replace the fossil fuel energy with biofuels. Fossil fuels and greenhouse emission can be greatly reduced due to the usage of biofuels in the transportation sector. [3] In the transportation sector you would present the idea of introducing transportation vehicles, which can run on biofuels or use biofuels which have a certain amount of gasoline to run the vehicles. The two possibilities presented are not totally unrelated. In any case, mixing biofuels with gasoline based fuels for the current transportation vehicles has benefits that even the usage of low mixture of biofuel with gasoline, will bring about considerable volumes of fuel being substituted by biofuels. [4]

Biomass is a renewable energy which can be produced by certain types of crops such as sugar cane, sorghum and corn starch. It is made of many complex carbohydrates which were recently living organisms that cannot be used for food or feedstock’s and hence are called lignocellulosic biomass. To break down the mixture of complex carbohydrates which are cellulose, hemicellulose and lignin and produce ethanol from them, a pre-treatment is needed to reduce the size of the biomass. This ensures that the hemicellulose is broken down into sugars which at that point causes the structure of the cellulose component to be opened up. The portion which has just been opened up is hydrolysed by protein enzymes and thus causing the fermentation into ethanol. Similarly, the hemicellulose is also fermented into ethanol. The remaining waste which is the lignin is consequently burned to produce fuel which in turn powers the entire process. [5]

Likewise, another form of source which biomass can be created from is forest residues such as dead trees or fallen branches. These pieces of organic waste, would be either burnt in forest fires or dumped which can be used to optimise in the manufacture of biomass energy. [6]

Sugarcane is a multipurpose harvest whose segments might be utilized in aiding sugar generation, for different energy bearers or finished results (power, fluid biofuels and heat) which upgrades its financial potential. For a long time, plant reproducers and agronomists have concentrated on expanding sucrose yields per hectare and mill operators on expanding recoverable sucrose per ton of sugarcane in sugar factories. Therefore, to fully capitalise on the energy potential of sugarcane you would need to go for more general approach concentrating of different production methods [7].

Chapter 2: Literature review

Throughout this report we will be looking at the costs and investments required to produce the two and consider the revenues generated from each stream to find out what combination of the output should be used to maximise profit for business in Brazil. We will also be looking at when biofuel becomes a viable output instead of sugar production. However, USA will be widely used for comparison because of its similarity in size and production methods. The reason why Brazil was chosen for this report is discussed below.

There are multiple countries where ethanol is widely produced. The United states of America is one of the main producers of ethanol and their ethanol production has eclipsed all other nations. They also have highly extensive amount of resources which enable to produce so much ethanol. As of 2015, the amount of fuel ethanol produced in USA peaked at approximately 14,800 (million gallons). the nearest country which produced the most fuel ethanol was brazil and it had produced less than half of what USA produced at 7,090 (million gallons). [8 FIGURES???] In the USA the main feedstock product used to produce ethanol is corn. Producing ethanol from corn is much more difficult than using a sugar based feedstock such as sugar cane. This is because converting the sugar to ethanol involves only a fermentation stage whilst on the other hand corn requires the addition of several different enzymes and needs more cooking to convert it into ethanol.

One of the main reasons why the USA produces corn based ethanol is because corn production plays a big part in the USA’s economy. This is a very significant since both countries are quite similar in size. The amount of arable land available in USA could play a big part of why more ethanol is produced in USA than Brazil as they are roughly the same size. The United States of America has approximately 3 times as much arable land as Brazil around 1,650,00 km2 whilst brazil is only around 586,000 km2. [9 NEED TO REMEMBER WHERE FIGURES CAME FROM]

On the other hand, Brazil is a nation which over the years in which their ethanol production has increased consistently for the last ten years. This meant that Brazil became the number two country in the world in terms of ethanol production. There are many favourable conditions which make Brazil a country where ethanol is produced such as tradition on culturing sugarcane, also sugar cane being the most efficient raw material required for the ethanol production and finally the climate. There are several reason why Brazil initially decided to produce Ethanol to begin with. The first reason would be that in the 1970s, 1 litre of ethanol was worth three time more than a litre of gasoline which meant that most countries didn’t think about investing in biofuel production. This is all changed for Brazil when they decided to produce ethanol from sugar cane. This was because of the low cost of the sugar at the time and the ability of the countries familiarity with the feedstock. [10]

The second reason was that in the year 1979 an oil crisis occurred globally which further made Brazil go into producing a gasoline substitute which was ethanol. A national alcohol program which was known as PROALCOOL was made which aimed at reducing the countries reliance on important oil or even oil-based automotive fuel. [11] A number of factors helped enable the governments influence to start producing ethanol which the main point would be that at that time, ethanol’s price was lower than gasolines. Also, because that gas stations would be obliged to sell ethanol as oil the oil crisis continued. The main aim of the PROALCOOL was to increase the production of sugar based ethanol from sugar cane. This guaranteed purchases by the governments to farmers for growing the sugar cane. Another key point which was embedded in the PROALCOOL was that the ethanol produced would sell for a price of just 59% of gasoline at the gas station. [12]

This also helped the producers of sugar acne as the they were guaranteed to be paid for the growth and cultivation of the feedstock.

There are still a number of countries which could be taken into consideration. For instance, China which recently started to consistently produce ethanol could be one. The reason for them producing ethanol came from a plan which was put into place by the Chinese government called the 12th five-year plan. Some of the targets of the plan include reducing fossil fuel consumption and to also promoting low-carbon energy sources. [13] There are a number of concerns for china in terms of hazardous air pollutions and some concerns about the impacts of climate change. Therefore, there a number of efforts on the sustainability development of the country. However, as there was a quick growth of the number of feedstock’s being used for ethanol production there were a number of concerns raised. The one major concern was that the possible issues of food shortages which had swept China in many regions where ethanol production was occurring. [14]

Another set of countries where ethanol production is slowly on the increase is the continent of Europe. In 2014, the production capacity of Europe was close to 7.8 billion litres which was over 90% of the total production capacity which stood at 8.8 billion litres. However, the actual production rate was at 6.6 billion litres of ethanol compared to 2013 which was an increase of approximately 13% in production. [15] The feedstock used to produce ethanol in Europe is corn which is similar to USA as they primarily use the same feedstock. However, Europe has suffered due to the fact that European producers are under growing pressure from a mixture low market prices and also the volatility in the Europe’s biofuel policy.

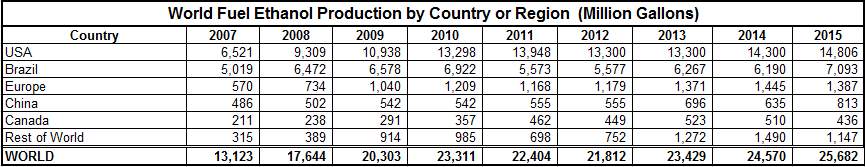

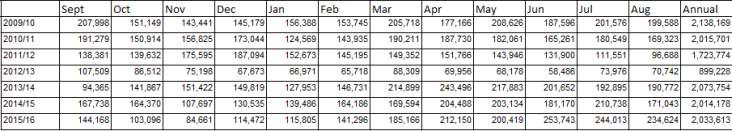

Figure 1: World Ethanol Production [16 EXCEL FILE GOT THAT SAVED]

http://www.ethanolrfa.org/resources/industry/statistics/#1454098996479-8715d404-e546

This table shows the world fuel ethanol production worldwide but only in the main countries associated with ethanol production. From the table, USA is the leading country in ethanol production and it also shows that the quantity of the ethanol produced never decreases as the years go by. Brazil on the other hand is also increasing as the years go by but during the years 2011 and 2012 it began to decrease. This was due to the face that brazil had a poor harvest of sugar cane during them years which led them to importing more ethanol. However, sugar cane is the primary feedstock in ethanol production in brazil and it’s the reason why brazil was the country of choice for this project.

https://www.eia.gov/todayinenergy/detail.php?id=5270

https://apps.fas.usda.gov/psdonline/circulars/sugar.pdf

http://econet.ca/pdf/usdrymillethanolindustry.pdf

http://www.ethanolrfa.org/wp-content/uploads/2015/09/c5088b8e8e6b427bb3_cwm626ws2.pdf

https://www2.gwu.edu/~ibi/minerva/Spring2008/Final%20Paper%20-%20Karla.pdf

http://www.sciencedirect.com/science/article/pii/S096014811100382X

Ethanol production process

Brazil is the world’s largest sugarcane ethanol producer and a world pioneer in using ethanol as a motor fuel. Within the year 2015/2016 the production of ethanol was approximately 30.23 billion litres. This ethanol is sold in the market as either pure fuel or combined with gasoline. In Brazil alone the gasoline has a blend percentage between 18 to 28 percent ethanol. [17] The total sugar cane production in Brazil was 666,824 (thousand tons) in the 2015/2016 harvest season, compared to the 30,232 (thousand m3) produced. This value is very high almost double compared to the harvest which occurred the year before which only produced 17,636 (thousand m3).

There are 3 main stages which make up the production process of ethanol. These are

- conversion of biomass to fermentable sugars;

- fermentation of sugars to ethanol; and

- separation and purification of the ethanol

Fermentation

Two noteworthy parts of plants, starch and cellulose, are both comprised of sugars, and can on a basic level be changed over to sugars for fermentation. The first step would be the breakdown of complex carbohydrates into simpler ones. Ethanol is created by microbial maturation of the sugar. Microbial maturation will right now just work straightforwardly with sugars. The aging is exothermic; in this manner, cooling is expected to hold the response under maturation conditions. Yeast is included alongside supplements (nitrogen and trace elements) to keep yeast developing. Maturation can occur in both group and persistent reactors; however, Brazil essentially utilises consistent reactors. [18]

Ethanol can be delivered from biomass by the hydrolysis and sugar maturation forms. To deliver sugars from the biomass, the biomass is pre-treated with acids or proteins so as to diminish the measure of the feedstock and to open up the plant structure. The cellulose and the hemi cellulose parts are separated (hydrolysed) by catalysts or weakened acids into sucrose sugar so that it is then aged into ethanol. The lignin which is additionally present in the biomass is ordinarily utilized as a fuel for the ethanol creation plants boilers. Before the fermentation stage certain crops need saccharification. Saccharification enzymes aid in the breakdown of the complex carbohydrates such as starch into plain sugars.

Ethanol can either be produced using a dry mill process or a wet mill process. It’s usually produced by means of a fermentation process which uses glucose resulting from sugar based food stocks such as sugar cane, molasses or sugar beet. The fermentation can also occur without using sugar based food stocks and instead using either starch based food stocks or cellulose based food stocks.

https://www.e-education.psu.edu/egee439/node/647

http://sugarcane.org/resource-library/studies/BNDES%20-%20Chapter%203.pdf

https://www.e-education.psu.edu/egee439/node/647

http://biofuelsassociation.com.au/biofuels/ethanol/how-is-ethanol-made/

http://www.icminc.com/innovation/ethanol/ethanol-production-process.html

http://www.afdc.energy.gov/data/

http://www.unicadata.com.br/historico-de-producao-e-moagem.php?idMn=32&tipoHistorico=4&acao=visualizar&idTabela=1805&safra=2015%2F2016&estado=RS%2CSC%2CPR%2CSP%2CRJ%2CMG%2CES%2CMS%2CMT%2CGO%2CDF%2CBA%2CSE%2CAL%2CPE%2CPB%2CRN%2CCE%2CPI%2CMA%2CTO%2CPA%2CAP%2CRO%2CAM%2CAC%2CRR

http://www.ethanolrfa.org/how-ethanol-is-made/

https://www.glbrc.org/research/technologies/P09305US02

http://www.sucden.com/statistics/11_u-s-ethanol-market

https://www.sugar.org/images/docs/refining-and-processing-sugar.pdf

http://powo.science.kew.org/taxon/urn:lsid:ipni.org:names:419977-1

http://www.sugarcanecrops.com/108/

Timeline of Ethanol

American inventor Samuel Morey was the first man to develop an engine which could be run using ethanol in 1826. He first noticed its efficiency when fuel lamps which were originally powered by oils such as vegetable oil ended up becoming too expensive to purchase. Morey received a patent for an internal combustion engine which was his first ever. Some 35 years later, another inventor who went by the name of Nikolaus Otto who was of German decent, was fascinated in work by Morey and therefore dedicated his life to it. He built the first ever four stroke engine which is more commonly known as four cycle. The four cycle is an internal-combustion engine in which the piston completes four different stroke while turning a crankshaft.

https://en.wikipedia.org/wiki/Four-stroke_engine

https://www.britannica.com/biography/Samuel-Morey

http://www.icminc.com/innovation/ethanol/ethanol-timeline.html

http://www.biography.com/people/nikolaus-otto-9430652

In the year 1896 the first ever automobile was built which was completely powered by 100% ethanol. American industrialist Henry Ford, who was the founder of the Ford Motor company, used biofuels to power his first vehicle which was the Quadricycle. Up until modern times Ford Motor company still produces Flexible-Fuel vehicles (FFVs). 12 years later in the year 1908, Ford developed their first ever commercially produced flexible-fuel vehicle. The car named Model-T had an adjustable carburettor, low compression engine and also a spark advance. This enabled it for the car to switch forth and back from ethanol to gasoline. In recent times the company has modified two of their most popular models – the Ford Focus and the Ford C-MAX and modified in a way in which they are able to run on biofuel.

https://www.theguardian.com/fordflexifuel/story/0,,2139914,00.html

http://www.icminc.com/innovation/ethanol/ethanol-timeline.html

One thing in history which had a major effect on ethanol production was World War 1. The fuel consumption increased in the US to almost 60 million gallons per year. During this period not only did the use of ethanol increase but it was also used to for war purposes as well. They did by adding a denaturant to the ethanol to make it poisonous for human consumption. In the year 1919, Prohibition was bought in to effect. This was a movement driven by religious groups which considered alcohol a threat to the nation. The 18th Amendment prohibited the transportation, manufacturing the sale of intoxicating liquors. However, Prohibition proved very difficult to implement as it led to an increase in organised crime which dedicated itself to produce and smuggling of alcohol.

http://www.clover.okstate.edu/fourh/aitc/lessons/upper/biofuel3.pdf

http://www.history.com/topics/18th-and-21st-amendments

https://www.thoughtco.com/what-is-denatured-alcohol-p2-603999

Having started out by lighting fuel lamps to eventually powering Quadricycles to finally being able to power aeroplanes. Pilot Chuck Yeager was the first pilot to have exceeded the speed of sound at Mach 1.07 over the Mojave Desert in California. The aircraft which was a Bell X-1 airplane contained a blend of ethanol and liquid oxygen as fuel which amounted to almost 600 gallons. A major crisis occurred in 1964 at the Indianapolis 500 race when more than 150 gallons of gasoline was set ablaze which claimed the lives of several drivers. This prompted the organisation to ban gasoline powered cars and switch to methanol.

Towards the end of world war 2 and many years after that, there was a reduced demand for fuel and therefore the price of fuel dropped. This subsequently led to ethanol being cast aside for a period of time since people didn’t need to depend on ethanol anymore. During the 1980s the united states of America produced the Energy Security Act, this helped give loans out to producers of ethanol so that the production levels could rival the level it was at the time period of 1950-1970.

https://www.eia.gov/kids/energy.cfm?page=tl_ethanol

http://www.icminc.com/innovation/ethanol/ethanol-timeline.html

A phenomenon known as engine knock occurs in a vehicle when the fuel used is at a low octane level at which the car can operate on. A type of lead known as tetraethyl lead was added to vehicles so that it would help reduce the knocking effect which occurs in the engine. It also helps increase the octane ratings of the fuel so that the knocking effect doesn’t take place. Nevertheless, this type of lead was ultimately removed from the fuel due numerous health reasons. One of the crucial reasons being that the inhalation of the lead particles from the exhaust lead to the impairment of the nervous system of children. This type of lead in the fuel could also lower a child’s intelligence level and cause brain damage in not only children but also in adults.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2263033/

http://www.worstpolluted.org/projects_reports/display/66

http://www.todayifoundout.com/index.php/2011/11/why-lead-used-to-be-added-to-gasoline/

Biofuels

A biofuel is a type of renewable fuel which can be attained through a procedure called biological carbon fixation. This process occurs when inorganic carbon is converted into organic compounds. As a matter a fact any hydrocarbon fuel which takes anything from a period of time whether it be a couple of days, weeks or even months and was originally produced from organic matter is considered a biofuel. There are three main categories in which biofuels fall under. They are first generation biofuels, second generation biofuels and third generation biofuels. First generation biofuels are when biofuels are produced directly from the food crop source. This could either be sugar cane or corn as these are two of the world’s primary source for ethanol fuel. The first generation fuel has an advantage over the other two generation fuels as they have the benefit of reducing the overall greenhouse gas emissions. This because the carbon absorbed by the plants during their growth equates with the carbon which is released into the atmosphere when the biofuels are burned.

Advantages of corn

- Able to use the entire stalk to produce ethanol

- Simple to convert it from corn starch to ethanol

- No extra lands cost due to farming corn

Disadvantages of corn

- Energy yield only produces about 20% net yield

- The production rate of corn is very low as it only produces around about 350 gallons of fuel per acre

http://biofuel.org.uk/first-generation-biofuel.html

The second generation biofuels are when the feedstock which is needed to serve as the food source doesn’t really have to be food crops. It deals with the microbial fermentation of non-food crops. They are usually waste material such as used vegetable oil. When the vegetable oil has served its food purpose and it is no longer fit for human ingesting then it would be used as a food source for the second generation biofuels. For it to qualify as a second generation biofuel food source it must not qualify for human consumption. Common types of secondary generation feedstock’s include switch grass, wheat straw and waste vegetable oil (WVO).

Advantages of grasses

- Very high energy yield of around 540%

- Very low fertilizer is needed for it to grow

- Grow very fast and can be harvested multiple types during the year

Disadvantages of grasses

- They don’t grow on unfertile land

- Needs a lot of processing for it to be converted into ethanol

Advantages of waste vegetable oil

- It does not affect the food chain

- Usually readily available for it to be converted into ethanol

Disadvantages of waste vegetable oil

- It can have an effect in the engine if it is nog properly refined

http://biofuel.org.uk/second-generation-biofuels.html

The last type is third generation biofuels and this is when biofuels are solely derived from algae. Algae is also in the second generation biofuel category but since it has higher yields with lower resource inputs than the other feedstock’s mentioned in the second generation category. This was the reason it was moved into its own category and therefore was made into a third generation biofuel. Algae is able to produce an oil which can be refined into different components of fuel. It also can be genetically modified to produce different biofuels such as ethanol and butanol.

List of fuels that can be made using algae

- Ethanol

- Butanol

- Biodiesel

- Jet fuel

http://biofuel.org.uk/third-generation-biofuels.html

Use of ethanol

Regulations

Initially when the oil crisis occurred in the 1970s which was due to a number of problems that was occurring in the middle east. This caused the price of oil to spark and thus triggered the 1970s oil crisis. To overcome this, the idea of producing gasoline which contained a small percentage of ethanol was introduced. Most popular blends of this fuel was E10 or E20 which contained 10% or 20% ethanol respectively.

At first methanol was viewed as the original alcohol to be added to the gasoline. This was because methanol can be created by gas at no extraordinary cost and the face that it is very simple to mix with gas and therefore was the most viable option. In any case when utilising methanol as a part of practice it turned out that there were safety measures which must be grasped when taking care of it, and that methanol has a hostile reaction to some of the plastic segments and even to some of the metals in the fuel framework. What we can take from this is that different materials which were new must be utilized as a part of the fuel arrangement of the vehicles and also in the circulation framework. This brought the interests for delivering a substitute fuel based on biomass has also been a major factor in the early choice between methanol and ethanol. [4]

On the 13th of October 2010 the Environmental Protection Agency which is based in the US established the E10 rule dictates that the maximum mixture for ethanol is 10% with the remainder being gasoline. However, this lead to many problems with car manufacturers because they have had to recall cars. Toyota being one of the car manufactures to have done so have recalled 2.9 million vehicles worldwide, with 72,885 vehicles in the UK alone. However, some of the reasons for is that the engines were at risk of corroding due to the imbalance of the ethanol mixed fuel. Another possible reason was the vehicles are usually equipped with an evaporative fuel emissions control unit which is known as a canister. There were problems with the canister such possible cracks developing which after some time grows bigger and, in the long run fuel may spill from these cracks which ultimately leads to loss of fuel. The evaporative fuel emissions control unit is an important system which is designed to store get rid of fuel vapours before they can into the atmosphere. Since Toyota vehicles had possible cracks in this unit it leads to evaporative emissions. Not only does the emissions have an impact on the environment due to greenhouse gases released, it also has an impact on personal health. One major impact on health is that it affects breathing capabilities and lung capacity as it blocks the amount of oxygen that red blood cells are able to transport around the body.

http://publications.jrc.ec.europa.eu/repository/bitstream/JRC77061/final_evap_report_online_version.pdf

[http://media.toyota.co.uk/2016/06/toyota-and-lexus-announces-vehicle-recalls/] [http://search.proquest.com.proxy.library.dmu.ac.uk/docview/860007841/fulltextPDF/4D1AE0A8A441493APQ/1?accountid=10472]

https://www.dieselnet.com/tech/env_top.php

The new rule of E10 gasoline which was passed by the Environmental Protection Agency (US), has a number of advantages and disadvantages. Arguably one of the main advantage is that E10 was designed to reduce the amount of harmful emissions which get released to the atmosphere. This rule can reduce harmful emissions by up to 30%. The American medical association (AMA) believes that there is hard evidence supporting the facts that by adding ethanol to petrol and biodiesel to diesel than there is a good chance of reducing the deaths and illnesses caused by the emissions released into the atmosphere as a result of the combustion of those fuels. Another main advantage of the E10 fuel is that farmers benefit from this blend as the ethanol produced comes from the food crops that farmers grow. This would have a positive effect globally on countries which produce ethanol by adding value to agricultural crops. Another effect this would have is bring employment opportunities to the region in which the crops are produced in.

http://e10thegoodfuel.com.au/benefits-of-e10/

Costs

When considering biofuel costs there are many different processes to bear in mind. Costs of producing biofuels primarily depends on lands costs and labour, feedstock and how the oil market fares. Another thing it depends on the agricultural subsidies which a government aid that is usually paid to farmers. The amount of money which is paid to these farmers depend on the market prices and affects crops such as wheat, sugar cane, soy beans and rice.

One of the first things to bear in mind is the initial cost to plant the sugar cane. This depends on how big the land used to plant the food crop stretches out for. Also another cost aspect to be taken into consideration is if the land is fertile enough for the sugar cane to grow on. If this is not the case, then cultivation of the land would need to take place which adds to the cost.

When at this stage and the initial costs are stated, you are enter the conversion steps. This is the necessary steps needed to convert the sugar cane into ethanol. This proces

https://assets.publishing.service.gov.uk/media/57a08a03e5274a31e000039a/130520_ENV_BraEthPro_BRIEF4.pdf

http://www.worldometers.info/world-population/brazil-population/

Advantages of Bioethanol

Biofuels are unlike their energy counterpart’s fossil fuels as they a renewable energy source.

Since they are acquired from products that are reaped annually or in the case of algae which is acquired monthly, the resources needed to make the biofuels are unrestricted. Fossil fuels on the other hand is considered non-renewable as they take millions of years. Biofuels are considered cost effective as the price in the oil market is similar to that in fuel. This means it takes less money for them to make it compared to standard fuel which is obtained via crude oil. They are also considered much cleaner fuels as they have very less carbon emissions which get released to the atmosphere compared to their fossil fuel counterparts. Another fact which could be argued is that the amount of carbon dioxide which is absorbed by the plants in the first place during the process of photosynthesis, equals roughly the same amount of carbon dioxide which is released during the production process.

It impacts the economy in a positive way since the need to acquire fuel from foreign countries is greatly reduced. By doing so, you also create a positive impact of the society as a number of different citizen within that country benefit from this venture. Starting at the farmer who grows the crops to the companies which are involved in transporting and extracting the sugar from the cane to the companies who buy the sugar in its raw form to be sold to food companies. Everyone along the line benefits from this and also bring stability within the country. Another thing which it has an impact on is the environment. This is because if there was an oil spillage and had an effect on the land, the effects of this spillage would not be long last since the ethanol is straightforwardly biodegradable.

http://www.conserve-energy-future.com/advantages-and-disadvantages-of-biofuels.php

https://www.sciencedaily.com/releases/2016/03/160317151305.htm

http://biofuel.org.uk/advantages-of-biofuels.html

http://bioethanol-np.blogspot.co.uk/p/advantages-of-bioethanol.html

Disadvantages of Bioethanol

On the other hand, ethanol does have a number of disadvantages which some of them are similar to the shortcomings of fossil fuels. This can be argued by saying that the carbon emissions are similar to that of fossil fuels but they add up at different points. For fossil fuels the carbon emission is at the highest when it is burnt, however, for ethanol fuel this is not the case. Things which need to be taken into consideration are the amount of emissions that are released when the land needed for the crop to grow on is changed, and also when the transportation of the sugar cane to the milling site. And also how much emissions go into the atmosphere from this site. Another point which is extensively argued is deforestation. The amazon rainforest has a very bio-diverse range of inhabitants and this natural habitat is continuously threatened since a large amount of farmable land is required to grow crops.

As of 20th April 2017 the population of Brazil stood at approximately 210,900.000 and the total land area is roughly 8,349,00 km2. This means the argument which would erupt in this situation since the population is growing progressively is the food vs fuel argument. This when feedstock’s which are used to produce the ethanol are used for biofuel production instead of food. Also using the land for biofuel purposes instead of food

http://bioethanol-np.blogspot.co.uk/p/advantages-of-bioethanol.html

http://www.worldometers.info/world-population/brazil-population/

https://www.worldwildlife.org/threats/deforestation

http://www.biofuelstp.eu/food-vs-fuel.html

http://www.sciencedirect.com/science/article/pii/S0961953407002310

History of sugar cane

Sugar cane is a crop that is widely farmed across the world and amounts to approximately 70% of the world’s sugar. It goes by the scientific name of Saccharum Officinarum and was first found in the 14th century and it came from New guinea. Major expansion first began when Arab people were invading Persia and found sugar cane being produced and it was there how they learnt how to make sugar. Sugar is a general term for a great number of carbohydrates which distinctively has a sweet taste. The key sugar, glucose, is present in all plants and it is a by-product of the photosynthesis.

http://www.kew.org/science-conservation/plants-fungi/saccharum-officinarum-sugar-cane

http://www.sciencedirect.com/science/article/pii/S2211464515000147

Sugar Cane Production process

In the sugar cane production process there are many steps involved which are all vital in its development. Since sugar cane is a sub-tropical food crop it requires a lot of sunlight and water for its growth. However, this shouldn’t mean that the roots be exposed to too much water. The plant needs enough air to breathe so when the roots are too wet it limits the amount of air pockets. This causes the roots to be prone to diseases which is detrimental to its growth. It usually takes around about 9-12 months for the plant to grow in Brazil but this time varies across different places in the world.

https://www.provenwinners.com/learn/wait-plant-drowning

http://www.sucrose.com/lcane.html

The second step in sugar cane production is the harvesting of the plant. This can be done in a number of ways but it depends on the region or how big the field is where the sugar cane is growing. The main method of harvesting which is done globally is by using self-propelled harvesting machines. Either the farmer would already own the vehicle or they would hire machine owners to harvest their fields for them. Harvesting can be done manually by hand or by machine. Doing the job manually requires lot of manpower and it is an unclean job. When doing this job by hand the sugar cane would have to be cut from the stems and leave the roots alone. This ensures that the roots redevelop in time for the following yield. Another way which Is a hazard to the environment is burning the dead foliage which is around the sugar cane and also burn the waxy coating. The fire would scorch at a really high temperature but it would be done quickly so it doesn’t affect the sugar content or harm the stalk. The reason it is a hazard to the environment is because of the carbon content which is released when it burns. However local farmers argue that there little to nothing environmental impact since the C02 which is released is nothing compared the C02 needed for photosynthesis to occur in the first place.

After the harvesting stage is complete comes the extraction method. This involves several crucial aspects which flows into many different streams such as the efficiency of the extraction. This in the long run shows the profitability of the entire operation. After the sugar cane is harvested the sugar needs to be extracted immediately so that sugar is not lost. The sugar cane is crushed as soon as possible and thus with this crushing process creates syrup. The sugar cane is drowned in warm water in conveyor belts while strong water jets forcefully remove any debris from rocks or mud. This is put through many heavy duty rollers which are designed to squash the remaining pieces of sugar cane and thus extract the juice from its pulp.

http://www.sucrose.com/harvest.html

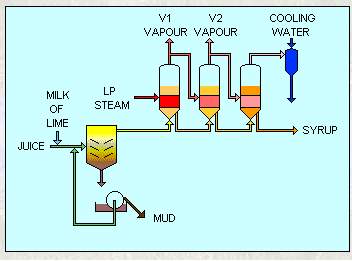

Subsequently when this process is finished, its once again placed in water but this time the water is boiling. In addition, lime is thrown into the mixture which aids in purification of the sugars. This mixture of adding heat and lime to the process helps remove any small particles to improve filterability. The sugar purification stage is also aided to form sugar crystals since the physical chemistry of the product helps it to only attach itself to other sugar crystals whilst rejecting the non-sugar and therefore ends up forming pure sucrose. The boiling step which occurs at this stage to signal the start of the process which is responsible for removing any small particles from the mixture. Once that stage is complete comes the evaporation stage. There a 3 vacuum pans in which the pulp of the sugar cane passes through. Initially it enters through vacuum A (V1) and this is where the boiling takes place. It is then put through vacuum B (V2) where at this stage, the crystal sugars are separated from the raw thick liquid which is known as Massecuite. Finally, it comes into vacuum C (V3) where it comes out as molasses.

http://www.sucrose.com/evaprate.html

http://vcampus.uom.ac.mu/sugar/education/processing/crystallisation.htm

http://www.sucrose.com/boiling.html

The ethanol which is produced form different feedstock’s such as corn or the sugar beet which is grown in Europe are alike. They still have the same chemical properties and its virtually the same type of fuel which is produced. However, sugar cane has many advantages over its fellow feedstock’s such as being the one with highest yield per hectare of land for production. For this this size sugar cane is able to produced 7500 litres of ethanol which is quite high in comparison to its fellow counterparts. In comparison, corn in the United States would only produce 3800 litres of ethanol per hectare which is just above half of the quantity ethanol from sugar cane is produced at. As for sugar beet which is predominately produced in Europe due to having a colder climate than its counterpart has a yield of roughly 5500 litres of ethanol per hectare of land.

A really efficient by product of sugar cane is called bagasse. This waste product the is the fibre which remains after the extraction of sugar cane happens. Traditionally, bagasse was burnt was burnt in fields since it’s use was fairly limited and the emissions which came from burning aiding pollution, However, now there are many uses for this once thought waste product such as burning it in factories for steam production or for producing electricity. By burning it in the mills, the factories become self-sufficient and therefore are able to control their own energy input. Another thing which helps the creation of this electricity, is that the harvest season of the sugar cane over laps the driest period of the year, and so this aids the countries hydro-electricity as it isn’t able to produce as much as electricity.

Another use for bagasse is feeding it to cattle as an emergency feed. Bagasse can also be moulded into products which can be used for food services such as bowl and plates. The strength of these products are generally 50% stronger than their usual as well as have more durability and flexibility due to the starch component involved in the production process. One environmental benefit of bagasse is that it limits the amount of trees cut down to produce paper.

http://sugarcane.org/media-center/faqs

http://www.ecokloud.com/what-is-bagasse.html

http://www.fao.org/docrep/005/X4988E/x4988e01.htm

climate

Sugar cane is a sub-tropical feedstock which requires plenty of sun and water for it to grow. Amongst this there are a further 3 requirements which aid in the growth and development of sugar cane. The 3 main requirements for utilising sugar from sugar cane are; air temperature, the amount of sun light and the final one being the right amount of rainfall to fall on the land. Sugar cane in its principle is a C4 plant and thus has the means to carry out higher photosynthesis rates which causes the stalk growth to be affected.

http://www.sugarcanecrops.com/climate/

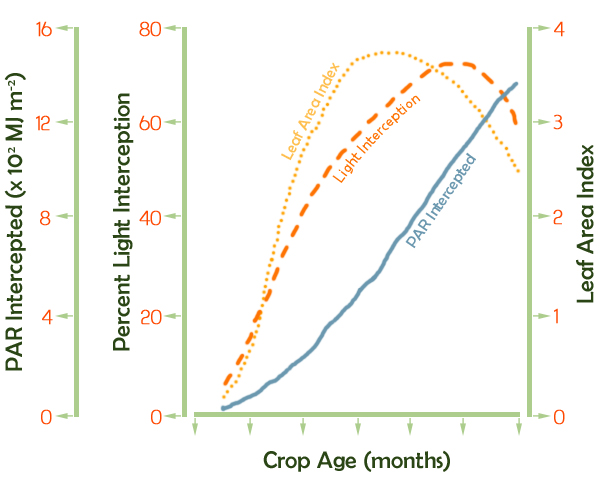

This graphs shows that the longer the hours of the sun shines on the crop, the quicker the sugar cane growth at. The second main requirement of sugarcane which aids in its growth and development is rainfall. The most preferable amount of rain required for its growth is in the region of 1100 and 1500 mm. This helps cause rapid cane growth as well as the lengthening of the plant. However, too much water can also be harmful to the plant especially in the course of ripening. The ripening of the plant is usually determined largely by the reducing sugars, the levels of sucrose of the plant and the stalk humidity during the harvest season. The sucrose in turn are usually at its highest during the last stages of sugarcane cycle which occurs during the end of December as the plant has low growth rate during this period.

The last factor for optimum growth is the temperature of air which has direct effect on the ripening of the plant as well as the growth of the sugarcane. The rate at which photosynthesis occurs changes when the temperature of air is reduced therefore a sugar which is made by photosynthesis is converted into sucrose. During the last 3 months before the harvest period the air temperature plays a big role in the ripening since there is a drop in temperature. This decrease in the temperature during the last few months is more favourable for the conditions required for optimal ripening. Another thing this helps with is the amount of sugar produced in the plant.

http://www.scielo.br/scielo.php?script=sci_arttext&pid=S0103-90162013000600011

http://www.sucrose.com/harvest.html

need this http://www.sugarcanecrops.com/climate/

https://www.foodelphi.com/production-process-in-sugar-industry/

http://www.sourcewatch.org/index.php/Sugarcane_Production_in_Brazil

Sugar cane requires sub-tropical temperatures

http://www.sugarcanecrops.com/climate/

http://www.kew.org/science-conservation/plants-fungi/saccharum-officinarum-sugar-cane

https://www.slideshare.net/mustafeex/steps-involved-in-sugar-production

http://www.sucrose.com/learn.html

http://www.madehow.com/Volume-1/Sugar.html

https://www.sugar.org/images/docs/refining-and-processing-sugar.pdf

http://genomicscience.energy.gov/biofuels/2005workshop/2005low_sugar.pdf

Trade – off

To first establish a direct link between the trade-off between sugar and ethanol productions are number of things need to be taken into consideration. The first point to be considered is the utilisation of the land. Another important factor which needs to be considered is the amount of sugar cane and ethanol is produced. Brazil as a nation has the strongest economy in Latin America as well as being the world’s largest coffee producer. It also sits on 850 million hectares of land and is the fifth most populous country in the world in terms of size and inhabitants. Its coffee sector utilises more than 5 million individuals and contributes up to 40% of the entire world’s coffee supply. http://www.ecf-coffee.org/about-coffee/coffee-facts https://www2.gwu.edu/~ibi/minerva/Spring2008/Final%20Paper%20-%20Karla.pdf

Despite all of this, the problem with utilising the land needed to grow the feedstock which in this case is sugar cane, is that they use up the land which could have been used for food. This could pose a problem for Brazil since poverty is widespread in some regions of the country and this could be down to the inequality of land tenure. In the early 1960s, a military dictatorship brought about a distinctive change to the country. Because of this millions of rural natives moved to the big cities for work due to the rapid industrialisations and mechanisations of agriculture. However, an Agrarian reform in 1990s enabled up to four million farms in Brazil to be given back to the citizen. Nevertheless, these farms were in size relatively small and this small scale type of farming was called family farming and it accounted for up 70% of the countries food production.

http://www.ruralpovertyportal.org/country/home/tags/brazil

http://www.sciencedirect.com/science/article/pii/S0305750X09000497

http://www.mstbrazil.org/content/need-basis-agrarian-reform

Another point which needs to be taken into consideration is the amount of sugar and ethanol is produced. During the harvest season of 2015-2016, the total amount of sugar cane produced was in the region of 666.824 (thousand tons) however this figure doesn’t represent the amount turned into sugar or into ethanol. The bulk of the amount of sugar cane produced came from the South-Central region of Brazil which produced 617,709 (thousand tons) which nearly 96% whilst the rest of the amount was contributed by the North-Northeast region of Brazil which produced 49,115 (thousand tons). The total amount sugar cane produced was split into two categories; one was the sugar produced from it and the other factor was the amount of ethanol produced. The total sugar produced in Brazil from sugar cane came to 33,837(thousand tons) where once again this figure was majorly dominated by the South-Central region. The North-Northeast region only contributed a little over 7% at 2616(thousand tons).

The total amount of Ethanol produced was also split into two different kinds of Ethanol. The first type of Ethanol produced was Hydrous Ethanol at 17,581 (thousand m3). This type of ethanol is at its highest concentration without having to distil it even further. In addition, this fuel which is added to Ethanol and by doing so it lowers the operating temperatures of the engine because of the absorption of more water than its counterpart (Anhydrous). It also increases the octane level of the fuel and reduces the risk of knocking, in doing so, it further improves the thermodynamic efficiency of the engine whilst also improving fuel efficiency. On the contrary, the amount of Anhydrous Ethanol produced is lower at a figure of 11,661(thousand m3). In this form, Ethanol is at highest level of purity since all traces of water are removed with its purity at 99.5%. Over 50% of Anhydrous Ethanol is produced in the Sao Paulo which is situated in the Southern region of Brazil.

https://fieldtopump.wordpress.com/2009/04/22/anhydrous-ethanol-vs-hydrous-ethanol-in-gasoline-blending/

http://www.sciencedirect.com/science/article/pii/S1364032110000705

The last and most key point which needs to be looked at before establishing a link between the trade-off of sugar and ethanol production is prices of sugar and Ethanol in Brazil.

(NEED TO FIND PRICES OF SUGAR AND PRICES OF ETHANOL IN BRAZIL)

Show trade-off in America

The United States of America is the biggest producer of Ethanol in the world. During the year 2015 it produced a record 30,983 (thousand tons) this was a rise of 2.9% increase from the previous year. Most of the biofuel produced in this country comes from corn which is the primarily the feedstock used. Corn is the main feedstock which grown by farmers amounting for around 95% of the total feed grain which is produced. The amount of land in which corn is produced in the united states is approximately 90 million acres of land.

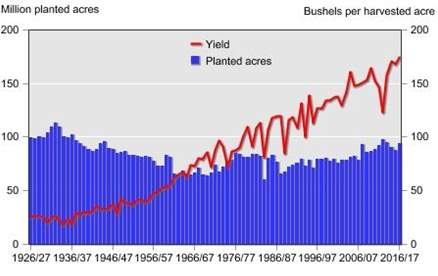

Figure: Corn yield and acreage

Over the years the graph shows that the amount of farmable lands being used for corn has been decreasing very slowly as well as some years increasing very slowly once again. Although the amount of acres used to produce the corn roughly the same amount of land that was used 10 years ago (2006/2007), the amount of yield produced is greatly higher. This is due to the fact that in recent years there has been a strong demand for ethanol as fuel and therefore farmers have adapted to creating initiative methods to getting more corn out of lands which was not previously suitable for farming. The way they have done this is by introducing different types of seed varieties to maximise growth of the crop and by also introducing a number of different fertilisers and pesticides to avoid the crops getting spoiled. The farmers have also decided to mainly focusing on corn as there is a huge demand and by doing so crops such as soybeans have seen a decline in their production.

https://www.ers.usda.gov/topics/crops/corn/background.aspx

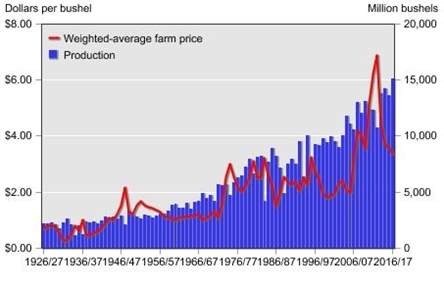

As shown in the figure above, it can be seen as production rate increases so does the average weighted farm price. The price increase over the years could be seen as an incentive to farmers who grow the feedstock and make it more profitable for them. Also other factors which could have affected the trend is the availability of the feedstock. Another cause for the price increase could be that the if the demand for ethanol is increased so does the feedstock which required to produce the fuel. https://www.ers.usda.gov/topics/crops/corn/background.aspx

As shown in the figure above, it can be seen as production rate increases so does the average weighted farm price. The price increase over the years could be seen as an incentive to farmers who grow the feedstock and make it more profitable for them. Also other factors which could have affected the trend is the availability of the feedstock. Another cause for the price increase could be that the if the demand for ethanol is increased so does the feedstock which required to produce the fuel. https://www.ers.usda.gov/topics/crops/corn/background.aspx

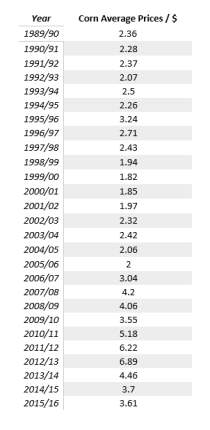

From Table.., during the market year of 1989/90 the average Corn price was at 2.36(US Dollars) and this was for per bushel of Corn. In the next decade or so the prices for corn went either up or down, and in the market year of 1999/00 the price was at 1.82 us dollars per bushel corn which resulted in a decrease of almost 30%. The market year following that which was 2000/01 at 1.82 (us dollars) and it reached its highest recorded price during the market time period of 2012/13. The reason for this really high price which was almost an increase of 192% from the year 1989/90 was due to the fact there was a severe drought which hit parts of the USA and therefore due to limited crop demand increased. Also another effect which the drought had was that the amount of corn exported by the US decreased leading to an increase in price. So in 27 years from 1989 to 2016 the average price of corn saw an increase of approximately 53%.

https://www.ers.usda.gov/topics/crops/corn/trade/

http://www.farmdoc.illinois.edu/manage/uspricehistory/USPrice.asp

Table: Corn Average prices in US (Per Bushel)

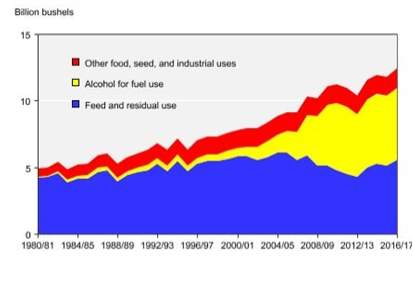

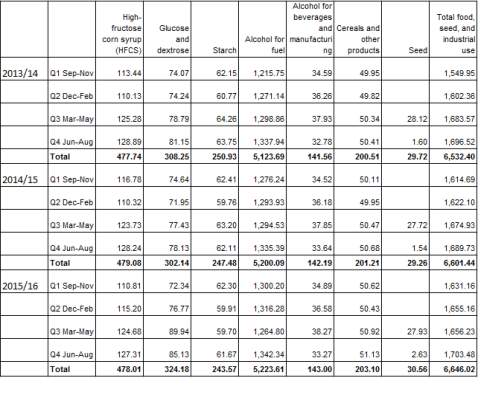

When corn was first planted in USA it was initially a produce which would provide as food source for human and animals. However, over the years when it was discovered to be a feedstock for producing Ethanol and the many industrial uses it has, the consumption in that sector has grown. The amount of corn used every year for feed and residual use has remained steady but there was a slight dip in the year 2012/13 as previously explained earlier that this was due to drought that occurred during that period which had an impact on the data. One thing which had a large increase in the past decade was the amount of corn which was produced and was used to produce alcohol for the purposes of using as a fuel. Also another thing which can be seen from the figure above is that corn which was produced for the food sector has been increasing. A reason for this could be the US’s adopted methods from Latin America which utilises corn for various foods and snack such as; tacos, enchiladas and tortillas.

https://www.ers.usda.gov/topics/crops/corn/background.aspx

Figure: US Corn Exports (1000 Bushels)

https://www.ers.usda.gov/data-products/feed-grains- database/feed-grains-yearbook-tables.aspx

As shown in the table above, the export rates always been in the region of 2 million (1000 bushels) until the harvest year of 2011/2012 where export rates dropped slightly. However, the biggest difference could be seen in the year 2012/2013 where the export rate decreases by over 50%. This dramatic loss was due to the climate as drought heavily affected the growth of the crops. Because of these reasons the prices of the corn increased which subsequently increased export and import prices and this is why the export amount is lower than the previous years. The graph also shows that once the harvest year ended and the new harvest year started the number of corn exported returned to its normal position. https://www.bls.gov/opub/btn/volume-1/pdf/impact-of-the-drought-on-corn-exports-paying-the-price.pdf

Fuel Consumption

In figure 1 and 2, the difference in the consumption of the two charts is pretty clear. As shown above the Hydrous blend of Ethanol fuel is more used. Hydrous which mean more wet is more widely used since it is has strong concentration level that Anhydrous Ethanol. The reason for this is that since Hydrous Ethanol is more wet and so that the water particles have strong hydrogen bonds and when it comes into contact with the oxygen and hydrogen bonds within the Ethanol, the hydrogen molecules bridge over and therefore create strong molecular forces. Since the molecular forces have become strengthened it leads to the reduction of Nitrogen emissions which are emitted from the vehicle. A number of positive impacts are listed below:

- Compression rate of the engine is increased due to ethanol

- Overcomes knocking effect in the engine

- More efficient than its Anhydrous counterpart

- Octane level is increased and therefore efficiency of engine at its highest

This shows what corn is used for in the US and its purposes. Firstly, in the 3 years shown in the data there were steady increase in the amount of uses corn production had such as the conversion of corn for alcohol for fuel purposes. Another contribution corn had was the manufacturing of alcohol but this time for beverages, this also an increase over the years presented. One by-product of corn which is produced by the wet milling process to ultimately create ethanol is a product called High-fructose corn syrup or in short HFCS. This syrup in recent years has replaced sugar to become the main sweetener due to the fact that it is simply cheaper than sugar.

https://www.ers.usda.gov/topics/crops/sugar-sweeteners/background/

Sites to use

http://sugarcane.org/resource-library/studies/Wageningen.pdf

https://en.wikipedia.org/wiki/Ethanol_fuel_in_Brazil

https://web.extension.illinois.edu/ethanol/

http://www.cropenergies.com/en/Bioethanol/Produktionsverfahren/

http://www.afdc.energy.gov/fuels/ethanol_e85.html

https://en.wikipedia.org/wiki/Common_ethanol_fuel_mixtures

http://www.eia.gov/energyexplained/

https://www.newscientist.com/search/?q=FORGET%20BIOFUELS

http://bioethanol-np.blogspot.co.uk/p/case-study-in-brazil.html

http://bioenergyconnection.org/article/sweetening-biofuel-sector-history-sugarcane-ethanol-brazil

http://auto.howstuffworks.com/fuel-efficiency/biofuels/biofuel-fossil-fuel1.htm

References

[3] http://growthenergy.org/images/reports/avl_ethanol_sparkignition.pdf

[4] http://growthenergy.org/images/reports/avl_ethanol_sparkignition.pdf 25/12/16

[5] http://sugarcane.org/sugarcane-products/ethanol 25/12/16

6 http://www.reenergyholdings.com/renewable-energy/what-is-biomass/

[8] http://www.esru.strath.ac.uk/EandE/Web_sites/02-03/biofuels/what_bioethanol.htm#bio_production

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Energy"

Energy regards the power derived from a fuel source such as electricity or gas that can do work such as provide light or heat. Energy sources can be non-renewable such as fossil fuels or nuclear, or renewable such as solar, wind, hydro or geothermal. Renewable energies are also known as green energy with reference to the environmental benefits they provide.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: