Reduce Embodied Carbon in Low-rise Office Buildings in the UK

Info: 10840 words (43 pages) Dissertation

Published: 9th Dec 2019

Tagged: ConstructionCivil Engineering

USE OF NATURAL BUILDING MATERIALS TO REDUCE EMBODIED CARBON IN LOW-RISE OFFICE BUILDINGS IN THE UK

- Background

Carbon Reduction from the built Environment (Importance and need, along with policies)

Over the last decades, there have been various evidences that show the climate is changing rapidly (Houghton JT et al., 2001) and the change will endure with time (Cabeza et al., 2014). Numerous researches associate human activities as the drivers of this current changing climate due to emissions of high amounts of greenhouse gases (GHG) into the atmosphere (IPCC 2017), this has become one of the major threats to our society. These GHG emissions are referred coherently as carbon emissions, which arises from the general practice of comparing the global warming potential of different GHG gases to that of carbon dioxide (CO2) using the measurement unit of carbon dioxide equivalent (CO2e). Among all the sectors, the building construction sector places the most pressure on the natural environment (Pomponi & Moncaster, 2016), while it provides for basic need of shelter requirement and infrastructure for civilisations, it also places various ecological threats. In the UK, it is responsible for about 40% of the total GHG emissions, further it also accounts for 45% of the final energy consumption, 50% of raw materials extraction and 32% of waste flows (Pomponi & Moncaster, 2016) (Chau, Leung, & Ng, 2015). Thus, inevitably the building sector becomes a key focus of efforts to tackle climate change and offer cost effective and significant improvements for sustainable environmental management (United Nations Environment Programme, 2009, p. 4). Various incentives have been taken in order to mitigate the effects of these emissions, crucial when the UK is bound to sustain its global commitment made in the Climate Change Act 2008 of reducing its target emissions to 80% by 2050 relative to the 1990 baseline (DECC, 2008).

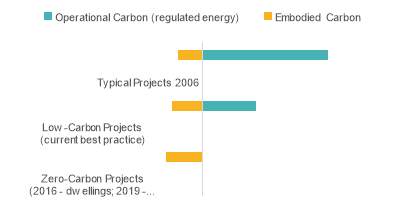

As a result of this commitment, many legislative policies and building regulations on low carbon building have been introduced, which till date (as in Building Regulations Part L) mainly concentrate on reducing the operational carbon emissions of the buildings. As operational carbon account for 40% of all UK carbon emissions while building construction accounts for 10% (Carbon Trust 2009; HM Government 2010), this may be the primary reason embodied carbon emissions are neglected from the legislative attention (Michele Victoria, 2016). Due to these policies, the operational carbon is relatively reducing, leading to increase in significance of embodied carbon. Thus, to decrease overall carbon whilst complying with the 80% reduction goal, both operational and embodied carbon of buildings need to be significantly reduced (Richardson, 2017). Increase in energy efficient buildings may reduce emissions in the coming years but without focusing on the parallel reductions in embodied emissions, the present savings that could be currently made are being compromised, often instead leading to short term impact (Pomponi, De Wolf, & Moncaster, 2018).

Arguments on importance of EC have slowly added up over the past few years and have led to its gained momentum in the field. Apart from growing number researches on the importance of EC (fig if possible of number of studies coming each year on EC), industrial consultancies have developed tools for its assessments and product manufacturers have incorporated the effects of GWP on various EC stages of the product life (Pomponi et al., 2018). However, there is still a widespread disparity in the current methods and knowledge regarding EC, thus there is a vital need for a coherent body to form regulatory policies which can induce real change in forming decisions regarding construction of our built environment. Otherwise there is a risk of getting cocooned in a pool of detached ideas.

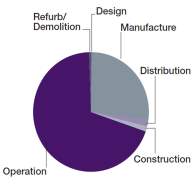

Hence to form coherent ideas and policies, it has become exceedingly crucial to first understand emissions and impact assessments related to embodied carbon. EC assessment focuses on global warming potential of the products and excludes emissions associated with combustion of fossil fuels required for building use, known as operational carbon. The embodied carbon of any building is defined as the CO2e emissions associated with extraction, manufacturing, transport, installation, maintenance and replacement, and subsequent demolition and disposal of materials used in construction (Anderson & Thornback, 2012). These processes can be divided into 3 categories, processes from extraction to installation of materials are termed as Initial EC, Recurring EC, includes the maintenance and repair or replacement and Demolition EC associated with end of life of the materials (fig if possible)(Michele Victoria, Srinath Perera, 2016). Another phase of recycling of materials after demolition can be accounted for in EC assessment, however many projects exclude this phase.

Fig – (Michele Victoria, Srinath Perera, 2016)

Raw Material

Extraction

Transport

Recycle

Demolition

In-use

Manufacturing

Construction

Not present in all projects

Growing Importance of EC in current scenario

The importance of embodied carbon along with operational carbon is evident and there is a growing understanding of the beneficial consequences of its reduction. Reasons attributed to its growing importance can be:

- The UK government have made recommendations in 2010 regarding implementation of a standard methodology to calculate embodied carbon in early design stage and in 2012 subsequently published TC350 standards for the same (Moncaster & Symons, 2013).

- After the inclusion of operation carbon reduction through Part L Building Regulation in 2006, the embodied carbon percent of the buildings kept rising from initially 10% of the total (Azzouz et al., 2017) to now 15-50% (Richardson, 2017)(RICS, 2012).

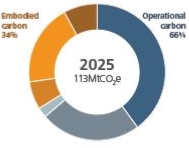

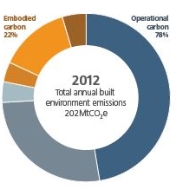

Figure: The ratio of embodied to operational carbon increases as Building Regulation are revised (RICS, 2012)

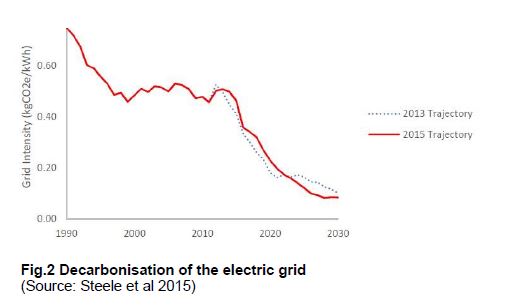

- The electricity sector is predicted to undergo complete decarbonisation (by 2050 there will be 95% reduction in carbon emission by a unit of electricity)(RICS, 2017), this will significantly reduce the operational carbon of any building. Hence, paving a way for improvements in embodied carbon reduction.

Figure 5: Greenhouse Gas intensity of UK electricity, 2010-2050 (RICS Professional Information, UK, 2012)

- According to IPCC, instead of focusing on 30 years later targets there is an urgent need of current reductions in yearly carbon emission. Reducing emissions from construction and demolition of present building stock can achieve this and embodied carbon reduction is a way to do so (Pomponi et al., 2018).

Current state of building’s embodied carbon in non-commercial buildings

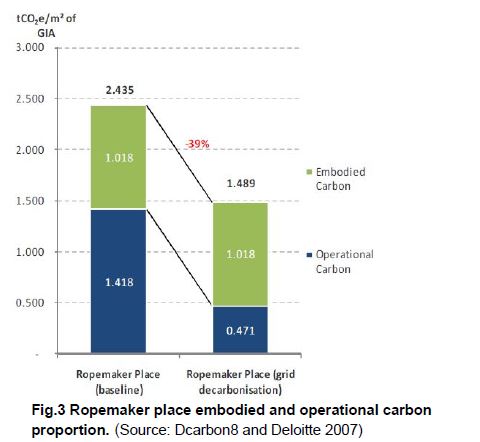

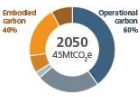

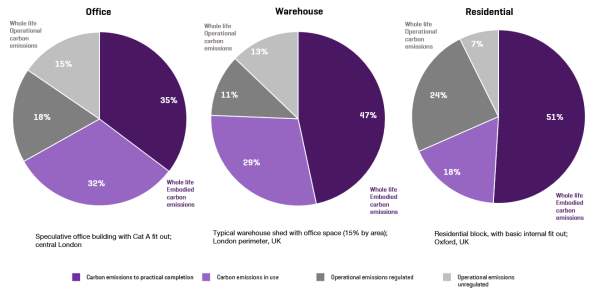

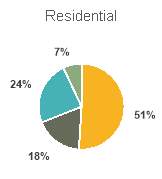

EC in buildings depend on the building typology and its use. As non-commercial buildings have high operational carbon (add fig or source), with grid decarbonisation the relative significance of their embodied carbon is bound to increase. The below figure shows assumed increase in fraction of EC of an office building after grid decarbonisation

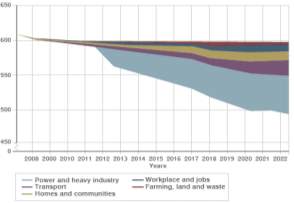

Fig 1 shows proposed emission reductions by each sector in the UK. We see that by 2022, the carbon reductions in non-commercial buildings are supposed to drop significantly, for workplace and jobs sector it is assumed to be reduced till approximately 580 mtCO2e. The current emissions from offices are ————— . This means there is still much need for reductions in offices. For a typical new developed office, the current EC accounts for 40-50% of the total (Candau, 2016). This is a high fraction and there is a much need for improvement.

Figure 1: Proposed emission reductions per UK sector by 2025 (Adapted from DECC)

Influence of initial planning (materials) on building embodied carbon

An emission reduction target route map was developed in 2013 (GCB, 2013) which manifested the way for future reductions, though recent updates show that the mitigation strategies adopted to date are insufficient to deliver these targets (Steele et al., 2015). This gap arises due to increased embodied carbon in new assets and will keep increasing if grid decarbonisation does not accelerate or if carbon storage strategies in new construction are not adopted and these technologies remain unviable to material manufacturers (Giesekam & Pomponi, 2017). Therefore, construction materials can play a vital role in future path of overcoming the gap between predicted and actual emission reductions. Early implementation of low carbon strategies in building designs, focusing on appropriate material selection for carbon storage, can prove to be highly beneficial.

or

Early implementation of low carbon strategies in building designs prove to be beneficial (Pomponi & Moncaster, 2016) . Like selection of appropriate materials which store carbon throughout the building life, can play a vital role in overcoming the gap between predicted and actual emission reductions targets.

There are various other informed decisions and strategies that can be undertaken during early stage design which can mitigate embodied emissions throughout building life (Lupíšek et al. 2016; Pomponi and Moncaster, 2016). Some of these corresponding to building materials can be:

- Using alternate building materials (Cabeza et al., 2013; Giesekam et al., 2014;Giesekam et al., 2016c) – substituting alternate low carbon building materials can reduce the EC in a building by 17-30% of its initial value (Candau, 2016).

- Using Life cycle carbon analysis in material manufacturing: The assessment of life cycle carbon help the companies to identify emission reduction opportunities throughout the process of material manufacturing (Shi & Meier, 2012). This will result in efficient emission reduction throughout the UK and increased number of usage of low carbon materials (Basbagill et al., 2013).

- Reuse and Recycle of building materials: adopting the circular economy approach encourages reuse of building components and structure, which will reduce life cycle carbon emissions (Giesekam & Pomponi, 2017) (Pomponi & Moncaster, 2016).

- Use of biogenic materials – along with having very low emissions, these materials also store carbon, which in turn benefits in reducing GHG from the environment (Giesekam & Pomponi, 2017).

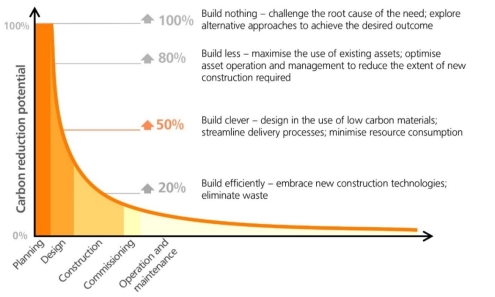

Figure 2: Tackle Carbon early – more opportunities for reductions exist earlier in the construction process

RICS (2017) suggests, embodied carbon reduction potential is high during early design stages and continues to decrease as design develops. There is less room for flexibility and change and more carbon is committed in the project. This can be contradicted as many design variables at initial stages are temporary and only a few parameters are fixed, while assessment methods require high amount of very specific data to undergo complex calculations (Gerva´sio et al. 2014). Therefore it is a relatively new path (RICS, 2017) and there are limitations to current standards and researches, to aid in early decision making. This study discusses in detail one such early design decision of using biogenic building materials to reduce building embodied carbon.

(total words till here – 1550)

CHAPTER 2

Literature Review

2.1 What is Life Cycle Carbon?

LCA and Embodied carbon as its Component

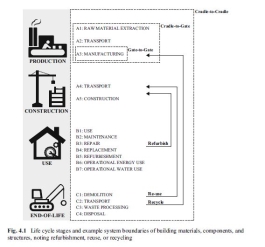

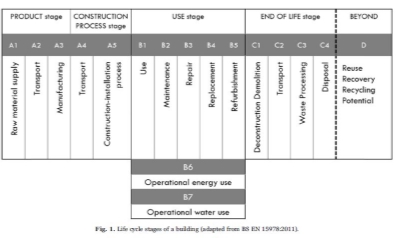

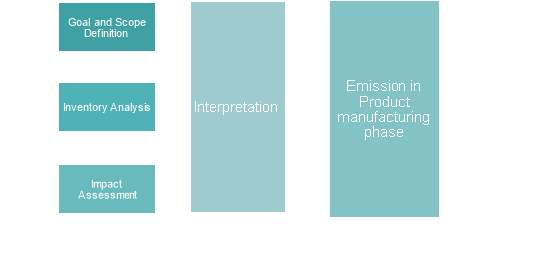

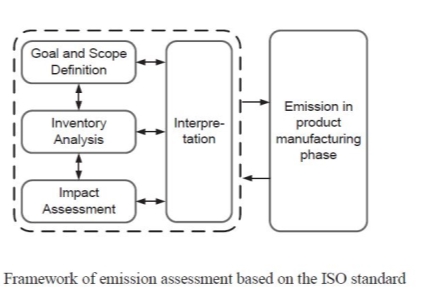

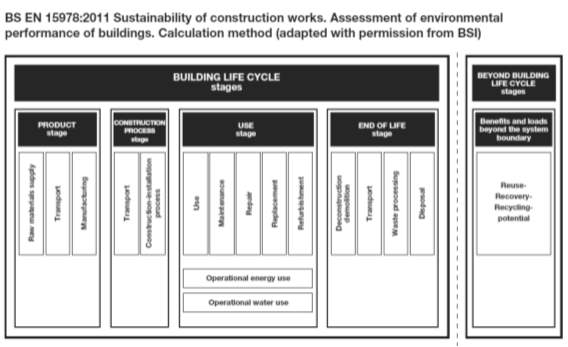

Life cycle assessment is a standardized method of assessing the environmental impacts associated with the life stages of a building or a product. It quantifies the total carbon emitted by a building throughout its life (Pomponi et al., 2018). The different stages involved in LCA calculations are represented below in the (fig). As the need to reduce GHG gases from the atmosphere rises, the need to present quantified emissions from buildings or products also increase. Thus, LCA study is crucial to understand the overall performance of a building (Pomponi et al., 2018) and its environmental impact. The standalone numeric output values of its emissions are not so relevant by itself unless when comparisons are to be made and a better option is to be selected without any risks. Also, there still lies large amount of disparities in methods to calculate LCA, this can become a constraint for making comparisons.

LCA was studied extensively in the past to understand impact from all stages (Pomponi et al., 2018), though in general practice it is seldom that each and every stage is considered, and researchers or manufacturers tend to take into account only the stages which are the most relevant and are considered to make the most impact on whole life cycle.

Some of the useful terminologies to understand LCA are:

- Various environmental impact are quantified in LCA studies such a GWP (Global warming potential), ozone depletion, eutrophication, non – renewable energy use and land acidification (US Green Building Council 2013). The GWP calculations are most utilised in studies and correspond to use of product and its production activity (Moncaster & Symons, 2013)

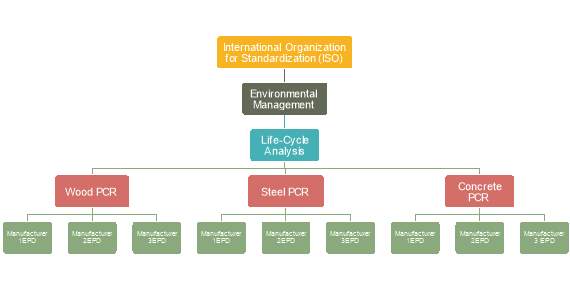

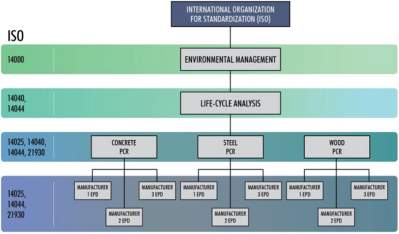

- EPD – Environmental product Declaration. Environmental impact of a product over its whole life, specified by the manufacturers and must comply with ISO 14025 and 21930 standards (Pomponi et al., 2018)

- PCR – Product Category Rules. Guidelines for measurement used by the industry to specify a product’s EPD (Carbon Leadership Forum 2015).

Embodied carbon assessments are a sub part of LCA assessments as shown in fig, although there can be differences in their methodological assessments as shown in table

Figure 2-1: How embodied carbon assessment fits into the wider scheme of LCA (Richardson, 2017)

Major difference between LCA and embodied carbon assessment:

| LCA Assessments | EC Assessments |

| Multiple impact categories assessed | Single impact category – GWP assessed |

| Includes all stages ( A-D) | Includes all (A-D) except operational use (B6, B7) |

| Rarely all categories are used for building emission assessment | GWP extensively used for building emission assessment |

| All categories specified for product/ material emissions | Rarely specified alone in product/ material emissions |

| Mostly used by PCR to form EPD’s | Used to calculate building’s embodied carbon |

Fig. 6.1 Relationships between ISO Standards, LCA, PCRs, and EPDs

Embodied carbon assessment methods

There are three primary methods known for LCA and subsequently embodied carbon assessment:

• Process based analysis (SETAC-EPA approach)

• Environmentally extended input-output analysis (EEIO)

• Hybrid analysis (combination of process analysis and EEIO)

| Process based Analysis | EEIO | Hybrid Analysis |

| Focuses on environmental impact from individual stages of product | Studies macro – economic data for assessing impact of a product | Combination of both process and EEIO techniques |

| Focuses on product system and product boundaries needs to be defined (Richardson, 2017) | Focuses on larger monetary and sectoral exchanges of national/regional economy (Richardson, 2017) | Assesses entire supply chain of a product |

| All input- output between product and environment calculated | Economic output from a sector is calculated as a result of inputs from all other sectors, thus all

input output economic transitions calculated |

Consists of process data wherever available and the gaps filled by input-output data |

| Environmental impact of each of input – output category calculated | Environmental impact from each sector’s economic flow calculated to get output of any sector | – |

| A bottom to up method | A top to down method | A combined approach |

| Traditional method | Relatively recent method | New approach of calculation |

| Widely used for assessing embodied carbon of a building | Rarely assessed for smaller scale such as an individual building | Rarely assessed for an individual building |

| Complies with ISO 14040 and 14044 British Standards | – | – |

Data sources to calculate EC

All the methods used for embodied carbon assessment require rigorous data collection, time and efforts (Pomponi et al., 2018). The accuracy of the results depend on the data availability and authenticity. There are two major data sets required for assessments (RICS, 2017), these are:

- Input to and output data of a building –process analysis requires physical quantities of building material or energy at each stage while EEIO requires economic transitions from each sector (RICS, 2017).

- Carbon factors associated with each input / output process (environmental impact data) – required to assess the overall emissions of GHG of a product or building by calculating environmental impacts (commonly GWP) associated with each stage (RICS, 2017). For materials these are expressed in mass or volume terms with units either as kgCO2e/kg or kgCO2e/m3 (Hammond & Jones, 2011). Some of the common sources for these are:

- Compiled from literature reviews – like ICE database by (Hammond & Jones, 2011)

- Industry data – directly from industrial source, not published as formal EPD

- EPD’s – Environmental declarations by manufacturers, compliant with standards

- Government data – carbon factors provided by national government like Defra, 2015

- Commercial database – Software such as GaBi or Ecoinvent

- PAS 2050 standards

As researchers use different scope and boundaries for assessment (Pomponi et al., 2018), their data sets also vary and so it is difficult to make comparisons. Thus, highlighting the lack of standardization in assessment methods. It can be noted that though there are variety of sources available, there is still a dearth of credible data for construction materials, as it tends to be difficult to find or its quality is uncertain. Thus, it becomes crucial to understand these data gaps and find solutions to mitigate them, some mitigation strategies applied in literatures, result in high uncertainties (Heijungs and Huijbregts 2004). Therefore, the quality of data must be clearly reported (Pomponi et al., 2018) and its quality should be checked prior to its release to obtain better results.

Challenges in Assessment

Some of the challenges in EC assessments are:

- Geographical Limitations

- It takes no account of the location or environment of an emission (Finnveden et al. 2009)

- It excluded the characteristics of source of emission

- These are unimportant when overall impact of the emissions like climate change is considered but are significant if the result of environmental impact of those individual emissions are to be considered (Richardson, 2017) (e.g. how much average temperature will rise with those emissions)

- Boundary Limitations

- System boundaries are essential for analytical simplifications (Wiedmann & Minx, 2007), although they can lead to incompleteness of assessment (Treloar, 1997).

- System boundaries are set due to lack of data or insufficient time or exclusions of stages which are considered to be insignificant (Kofoworola & Gheewala, 2009).

- Data Availability and Quality Limitations

- As discussed in the previous section, it is hard to find exact data as per requirement and even harder to assess its quality.

- This may lead to consideration of proxy data. These are parameters considered to be analogous to the required data (Funtowicz & Ravetz, 1990). In some cases they might closely relate, while in others it can be difficult to find links of these with the data actually required (Risbey, Sluijs, & Ravetz, 2006).

Limitations to LCA

| Advantages of LCA | Limitations to LCA |

| Helps quantify global emissions from product or a building and in turn can aid in reducing global warming | Lack of standardization to use LCA principles and data. UKGBC has also not provided guidance of on how to use LCA within their standards |

| Help in making educated decisions relating to performance of a building or product | Data inconsistent or inaccessible |

| Aid in making comparisons within various stages or within buildings or products to judge performances | Tedious process to evaluate the data (Pomponi et al., 2018) |

| Led to the recognition of importance

that embodied carbon play in buildings (Heinonen et al. 2011) |

All GHG emissions follow different metrics, therefore difficult to compare |

| Operational emissions used to be the most dominant, but through LCA it is revealed in newer evidences (Pomponi and Moncaster 2017) that embodied carbon of all stages are almost equal to operational carbon | Data for material production are complex and subjective and therefore often based on averages. |

| Defines clear stages from raw material manufacture to end of life of a product or building | There is a risk for process overlapping and double counting |

| Extensively used by both academic researchers and manufacturing industry | Series of assumptions required for later life stages |

| More assumptions lead to more uncertainties (Richardson, 2017) | |

| EC reduction potential is highest in early stage design when nature of material inputs are uncertain. | |

| Uncertainty calculations within LCA are often ignored |

(Total words till here – 1445)

Current Standards for embodied carbon

2.3 Laws on embodied carbon or (LCA?)

There are currently a number of International as well as European standards (developed from European Technical committee (CEN)) which address LCA and subsequently EC assessment of a building or a product. These Include:

- ISO 14000 series – These environmental management standards give the outline of LCA assessments and mention the principles to be used. These can be formulated and used in manufacturing assessments (Shi & Meier, 2012). These are:

- ISO 14040:2006 – defines LCA principles and frameworks

- ISO 14025:2006 – defines principles and procedures for environmental declarations

- ISO 14044:2006 – defines LCA requirements and guidelines. Gives four phases for assessment as shown in fig

- TC350 Standards – they regulate EC assessments and reporting (Giesekam & Pomponi, 2017) and provide cradle – grave environmental impact of a product or building (Moncaster & Symons, 2013).

- These standards guide the calculation methods for assessing building environmental performance (as per BS EN 15978:2011 (BSI , 2012)) and PCR’s for generating EPD’s of construction materials (as per BS EN 15804:2012+A1:2013 (BSI, 2014))

- They define the main framework for LCA, specify common LCA stages and provide guidelines for EC assessment (Giesekam & Pomponi, 2017). However, they fail to acknowledge system boundaries and leave it up to the will of the practitioners. This hinder result comparisons to be made as approaches and interpretations tend to differ.

- PAS 20180:2016 – defines framework for carbon management in infrastructure. Focuses on management of CO2 emissions rather than measuring it. Though provides insights on CO2 benchmarking and reporting (Giesekam & Pomponi, 2017).

Some of the standards useful for EC Assessment of biogenic products are:

- EN 16449:2014 – defines calculations for carbon sequestration in wood and wood based products.

- EN 16760:2015 – defines LCA for bio based products

- EN 16908 :2017 – defines PCR for calculation of EPD of cement and lime products

These standards provide an intricate methodology, though generally fail to define system boundaries which leads to disparities in results generated. Hammond and Jones, 2011, argue that as many later stages of life cycle assessment require building specific assumptions to be made, therefore it is difficult to provide standardised dataset for these boundaries. Thus, harmony in EC assessment methods remain difficult to achieve. Often modelled and actual embodied carbon impacts differ, this may be due to the fact that uncertainty corresponding to life cycle assumptions remain ignored. This performance gap can act as a catalyst for future researches, consequently leading to formulation of more accurate standards.

EC in non-commercial buildings (especially offices, explain why offices, overview of offices and carbon emissions in offices)

As there is increasing demand of office buildings in the UK and there are a number of office buildings coming up each year, it is necessary to reduce the embodied carbon of these buildings to achieve the desired targets. Embodied Carbon of a typical house is estimated to be approximately 500 kg CO2 per m2 while that of a typical office building is approximately 500-1,000 kg CO2 per m2, which is 20-35% of the whole life carbon. Fig 9 shows the distribution of embodied carbon in non-domestic sector emissions in an office building. We can see the highest is operational emission but as they will reduce in future scenario, the main source of emission would be manufacturing of materials. Figure 6 shows Emissions by Offices.

Figure 7, shows the percentage of embodied carbon in non-domestic buildings and their rising importance in the future scenario where operation carbon is assumed to be reduced. Thus, embodied carbon is crucial for calculation and should be reduced for better building performance.

2012 Total Annual built environment emissions 202 MtCO2e

2025 113 MtCO2e

2050 45 MtCO2e

UK regulatory drivers to manage EC/drivers for target reduction

Various initiatives were taken by the UK government over the years, to outline a number of actions addressing embodied carbon or life cycle carbon of buildings (HM Government 2010). These include:

- Promoting early stage planning to reduce embodied carbon in buildings by promoting tools which measure embodied carbon impact during design stage (HM Government 2011) like? (Name of tools).

- Building construction associations such as the “The Embodied Carbon Task Force” have argued to add embodied carbon reduction in UK Building Regulations as a solution to achieve zero carbon domestic buildings (Embodied Carbon Industry Task Force 2014) (Hawkins, 2016), though the “allowable solution” scheme (by?) was seized in 2015.

- The inclusion of Basic Works Requirement (BRW 7) in EU construction project regulations suggesting sustainable use of natural resources and BR3 suggesting reducing life cycle impacts of GHG. If the UK Building Regulations chooses to follow these suggestions, the proposed regulations should have to comply with the EN 15978:2011 and EN 15804:2011(Hawkins, 2016). Although this would be a tedious process as the data sources used for LCA will also have to comply with EPD standards, which aren’t readily available.

- The UK Planning Policy Framework (DCLG 2012), promotes sustainable use of resources. It is ambiguous as it does not directly suggest reduction in embodied energy or carbon.

- The heritage lottery fund in 2012, made a compulsion to calculate carbon footprint of heritage projects pursuing more than £2m funding.

- The Brighton and Hove Council incorporated a tool for calculating embodied carbon of residential projects in their sustainable planning matrix. The tool approximately estimates the embodied carbon of the project based on its materials and compares it with the benchmark to assess its compliance (Brighton and Hove Council 2012).

(Total words till here – 2290)

EC reduction through natural materials

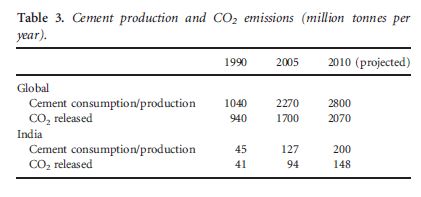

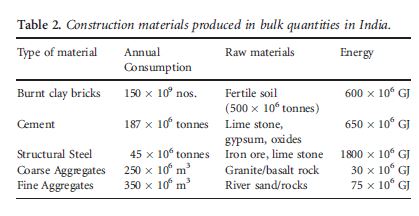

(Venkatarama Reddy, 2009) Like this above table try to find the production/ consumption of typical materials and their carbon emissions

| Type of material | Annual production/consumption | CO2 emissions in 1990 | CO2 emissions in 2017 |

| Cement | |||

| Structural steel | |||

| Aggregates | |||

| Sand | |||

| Burnt Bricks |

After completing the table – write about the increased carbon emissions from conventional materials and need for alternative materials.

Basbagill et al. (2013), introduced a method of calculating embodied carbon emissions in early stage design to highlight the importance of materials used and their dimensioning choices on overall emissions. Also, after the publication of 2011-12 European TC350 standards defining the ‘cradle to grave’ impact of buildings, there has been growing interest in the construction industry to compare the embodied carbon of variety of materials (Monahan & Powell, 2011). Thus, selection of materials play an important role in deciding the environmental impact of the building. J. Monahan et al. (2011) suggested that emissions from cement manufacturing were responsible for 75% of total carbon emissions from construction industry since pre – industrial time. Thus, to reduce such impacts, alternative materials with lesser environmental impacts can be adopted for construction. Using natural materials can be one such viable option as they usually undergo few manufacturing operations (Melia P., 2014) responsible for almost one third of total EC emissions of a building (as in fig) (RICS, 2017). UKGBC (2016), has also suggested selection of materials with low carbon intensities, reusability and recyclability and usage of locally available materials as measures to reduce embodied carbon emissions in buildings (UKGBC, 2016).

It is predicted that to deliver the target emission reductions of 80% by 2050 from 1990 baseline (DECC, 2015), all new construction will have to be carbon negative or carbon neutral by 2030 (Rockström et al., 2017). Construction of new assets with biogenic materials will have to rise in future scenarios, as these materials also absorb carbon along with having low emissions (Giesekam & Pomponi, 2017), thus leading to a pathway of carbon negative buildings.

Identification of low embodied carbon materials or products can help decision – making building professionals to make environmentally sustainable choices (Dixit et al., 2012). Unfortunately, there is a lack of qualitative data and studies related to embodied carbon in natural materials. This leads to high amount of uncertainty related to EC assessment of these materials and thus industry professionals are unwilling to use them. Also there are economic, practical and technical barriers to explore natural materials for construction compared to typical building materials.

Provision of set of standardized data and methodology related to emissions by natural materials, could help increase their use for carbon reduction in buildings. Effective use of EC assessment to compare natural material building emissions with typical building emissions can overcome the knowledge gaps hindering their use.

(Total words till here – 2700)

Data for table: in extras sheet

CARBON SEQUESTRARTION

Trees absorb CO2 from the atmosphere during photosynthesis. Therefore, natural building materials like timber and wood based products have carbon stored in them until their end of life (EoL)(RICS, 2017). This process of absorbing CO2 from atmosphere and storing it within the material is known as carbon sequestration. This must be taken into account in embodied carbon calculations when:

- The impact of end of life stage of the material is considered

- The timber is originated from sustainably managed forests or sources (certified by FSC, PEFC or equivalent) (RICS, 2017).

- Sustainably managed forests ensure that any tree fell are substituted with same number of trees planted. It therefore maintains the carbon absorption from the forests and do not contribute to deforestation.

Carbon storage proves beneficial for reducing carbon from the atmosphere and combating climate change, since carbon remains locked up in buildings through its life. Though it is argued that the stored carbon is released back in atmosphere after timber decomposition and releases methane along with carbon, which has GWP 28 times more than that of carbon (IPCC). It is therefore crucial to take into account EoL impacts of timber (RICS, 2017). Though it can be managed by responsible sourcing of construction material waste. The below table shows amount of carbon stored by biogenic materials throughout their life, thus highlights the advantages of using these materials.

| Research | Typology | Material Used | Carbon Storage (kgCO2) |

| Harris (2009) | Residential House | Timber Frame | 4000 kgCO2 |

| Berge (2009) | Residential House – 120m2 | Timber Frame | 32000 kgCO2 |

| Boutin et al. (2006) | 26 cm Wall | Hemp Crete | 35 kgCO2 |

| Marcom et al. (2008) | 30 cm Wall | Earth & Straw | 52 kgCO2 |

| Bath Lecture (find) | 30 cm Wall | Hemp lime | 33 kgCO2 |

| Bath Lecture | 49 cm wall | Straw Bale | 70 kgCO2 |

Despite of the uncertainties associated with taking into account carbon sequestration like specific details of sources and management of forests (Hammond & Jones, 2011), many standards and database still use it. Much used current Database like Ecoinvent (2009) and PAS 2050 standards by British Standards Institutes take into account carbon sequestration. Natural GHG emissions combined with natural carbon sequestration overshadows emissions from human activities, but it is this small contribution of human activities that causes climate change (IPCC, 2007 Fig. 7.4).

(Total words till here – 3050)

Add Table and summary

CHAPTER 3

Research Methods

The literature review showed the growing importance of embodied carbon and how there is still a need to regulate it, in turn to regulate the environmental performance associated with the construction sector to achieve the target emission reductions by 2050. And use of natural materials in building construction can be one such solution to achieve it. Thus, this chapter sets the aim for proving the above hypothesis and provides the objectives and research methods set to prove its validity.

3.1 Aim

This research aims to propose reduction in embodied carbon in office buildings in UK by the usage of low carbon natural materials and understand carbon sequestration associated with them and concurrently study the difference in embodied carbon of standard construction materials with natural materials.

It further aims to examine the effectiveness of using these materials in the future and their impact over the whole life cycle of the building.

3.2 Objectives

| Objectives | Description | Research methods |

| 1. Understand the growing importance of embodied carbon in future scenario | Study the decarbonisation of grid and its impact on future carbon emissions by the buildings | Desk based study of peer reviewed journals and literature.

|

| 2. Review standards and data sources used for embodied carbon assessment | Examine the Standards and different data sources used (ICE dataset, EPD’s of materials) and methods for embodied carbon assessment in the UK | Desk based study of peer reviewed journals and literature.

|

| 3. Assess the embodied carbon of office buildings built with natural materials in the UK

|

Undertake the methodology for assessment of embodied carbon specified in RICS relating to EN 15978; by using ICE database and EPD’s as data sources

|

Case study of buildings and computer based calculations of emissions on excel |

| 4. Compare embodied carbon of natural material buildings with conventional offices

|

Assess the comparative performance of the building elements built with natural material and those built with conventional materials in typical office buildings. | Desk based systematic analysis of peer reviewed journals, literature and results of the case studies |

| 5. Identify natural materials for use in construction of offices | Evaluate performance of materials for construction based on their low carbon intensities, carbon sequestration, reusability and recyclability and lower transport related emissions

|

Desk based systematic analysis of peer reviewed journals, literature and results of the case studies |

| 6. Appraise the life cycle performance of natural building material | Evaluate the potential of building with natural materials

|

Final analysis of results |

3.3 RESEARCH METHODS

DESK BASED STUDIES:

Literature review of emerging research methods: The review included understanding the current methods specified for embodied carbon assessment and appropriate methods to calculate the carbon sequestration of natural materials. The literature research was carried out undertaking the following criteria:

- Peer reviwed papers were assessed to understand the possible methods for calculation of embodied carbon and LCA.

- The journals reviwed should have assessment of impact related to GWP of materials.

- Only the journals specifying the detailed methodology and ones published after 2010 were reviwed.

Based on these and the data available for case studies provided by the project architects, relevant method was adopted. The approach selected is specified by RICS (2017). It gives the methodology of carrying out EC assessment as per EN 15978 following the Process based Analysis approach of calculating embodied carbon in a bulding. Methodology for calculation of carbon sequestration was adopted from EN 16449. It gives out a formula for calculation of stored carbon in the building, if it is not already specified by the manufacturer. This formula was used to calculate the sequestration from all FSC certified wood based products.

Computer modeling:

Systematic Literature Review (Chapter 2)

Steps (Chapter 4):

- Make an inventory of all materials used in case studies in excel.

- Calculate the quantities of all materials from the provided plan and sections.

- Develop excel based embodied carbon assessment tool

- Select and model all three case studies based on this tool

Results

- Embodied carbon for all these case study buildings

Discussion (Chapter 5):

Critically analysis and assess the implications of the result

Limitation and Boundaries

The most ideal method for calculating the embodied carbon in the building, is to calculate its carbon footprint from its Cradle to grave or cradle to cradle. But this research will be limited to calculating the embodied carbon of a material from its cradle to gate and then finally making a comparison of different materials by analysing their environmental impact and associated emissions assuming the building will live for 60 years.

LCA BOUNDARIES:

The material manufacturing process is one of the most crucial step to calculate embodied carbon in a building, it involves processes like material extraction and manufacturing, both of which are responsible for high amounts of GHG emissions into the atmosphere (Shi & Meier, 2012). The manufacturing process is alone responsible for 33% of total building emissions. According to Brett and Pba (2013), carbon emissions associated with the materials can be responsible for as much as 50% of the total building emissions.

To meet the requirements of low carbon thinking and reduce the direct and indirect emissions in the process of manufacturing, it is important to study the cradle to gate emissions of the materials involved in construction. As it has the highest percentage of building associated embodied carbon emissions (excluding operational carbon) thus, this study only considers cradle to gate stage for assessment. Also, cradle to gate stage involve less uncertainties associated with assessment as the data related to it are direct, for all other stages a lot of assumptions are to be made. Due to the lack of data present for making the assumptions for this study, other stages are omitted. The exclusion of all other stages may affect the total embodied carbon of the building but as majority of emissions are influenced by the materials manufacturing it will give a broad idea of benefits of using natural materials.

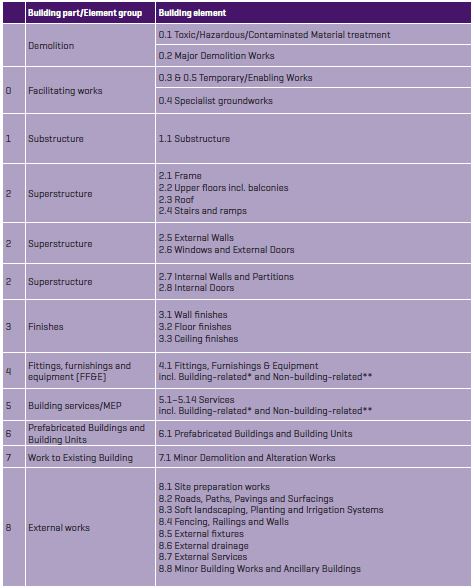

Element Boundaries

RICS (2017) specifies the elements of building taken in account for EC assessment based on the New Rules of Measurement (fig). Generally the elements which are responsible for the highest emissions in the building are called building hotspots. In general the substructure, frame, floors, roof and finishes are considered to be the building hotspots. For this study, the same hotspot elements are selected for assessment:

An overall diagram:

CHAPTER 4

Building Case Study Results

This chapter involves case study of 3 office buildings, as there are only less than 5 present in the entre UK, out of which one is in the process of construction

CASE STUDY 1

Building Introduction:

The PYC office is a small low – rise office building with its adjacent factory, located in Welshpool and is one of the few offices in the UK to use natural materials for its construction. The majority of construction is carried out with wood – based materials from sustainably managed forests and FSC certified products. Warmcell insulation, along with timber framing forms the core loadbearing structure of the office building. It is a fairly new construction and is built according to the standards of Passivhaus.

Building details:

| PYC Office, Welshpool | |

| Key Facts | |

| Location | Welshpool, Wales |

| Building Type | Office |

| Year of Completion | 2018 |

| Gross Internal Floor Area | 290 m2 |

| No. of Storeys | 2 |

| Avg. Storey Height | 3m |

| Frame Type | Masonite – Timber Frame Structure |

Scope of Assessment/ Reason for Building selection:

The building aims to achieve Passivhaus certification and is therefore energy efficient with low operational energy, thus it is crucial to understand its embodied energy performance and it will become more significant in the future. The building also uses wide variety of wood based materials for its frame, flooring, insulation, roof and finishes, which means the structure also sequesters high amount of carbon within itself and so would have lower embodied carbon.

The scope of study lies within calculating the embodied carbon from cradle to gate and analysing the sequestered and emitted carbon of the structure separately.

Embodied Carbon of Key Elements –

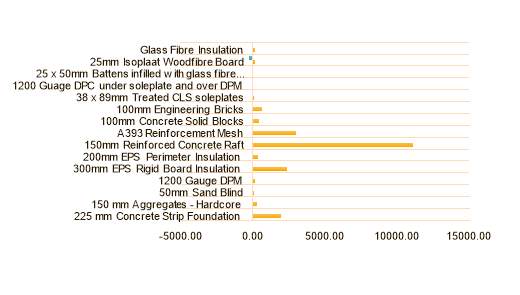

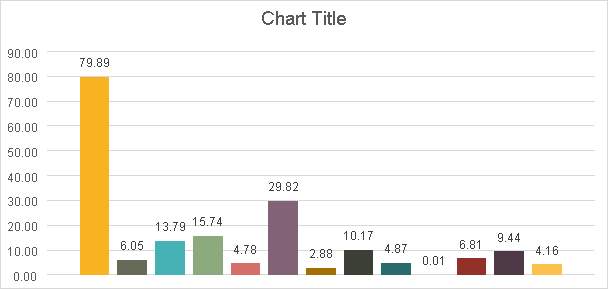

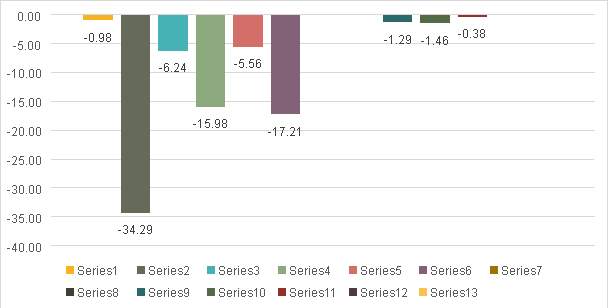

- Substructure:

The substructure of the building is the highest emitter of carbon in the structure. This may be due to the reason that it uses large amount of concrete and steel in its raft foundation. It also uses a thick layer of EPS polyethylene insulation as its bed and perimeter insulation. The GWP of the EPS insulation is the highest among the all the materials (fig), which means it releases the most GHG during its manufacturing, but as its total mass used in the structure is low, thus its overall impact is just 9% of the whole building emissions. Whereas for that of the concrete raft is 36% of the total emissions (fig), therefore solutions to reduce the emissions from concrete should be prioritised in the building. The building replaces 50% of the commonly used Portland cement in the concrete by GGBS, this reduces the overall emissions from it by 20%. Thus, such solutions can be applied to minimise the environmental impact of the overall foundation. However, the design of the foundation mainly depends on the ground conditions and the materials and strength of concrete used mainly relies on it. There is minimal sequestration, 1 % of the total in the foundation through wood fibre board. However. In comparison to the emissions, its effect is negligible.

The overall emissions associated with the foundation of the Office is:

| Type – | Substructure |

| % of total emissions | 39.84% |

| % of total sequestration | -1.18% |

| Net value for E or S per m2 | 70.89 |

- Frame:

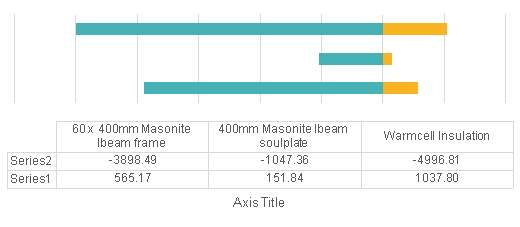

The building uses FSC certified Masonite timber as its main structural frame. The Masonite I-beam used provides for good construction efficiency and allow minimal thermal bridging, thus these I – beams are very well suited for Passivhaus constructions. These beams claim to use 65% lesser raw material per m3, for manufacturing as it needs smaller dimensions to provide the same strength as compared to other timber structures (Masonite manufacturers). It is said to use approximately 65% less raw materials per m3 than other timber. These I- beams are used as beams and when filled with thick insulation inside, provide for load bearing walls of the structure. The insulation used in the structure is Warmcell cellulose fibre insulation made with recycled paper. Being plant – based products, both Masonite timber and Warmcell insulation store carbon within them till the end of life of the structure. Thus the total carbon stored in the frame is the highest among other elements.

| Type – | Frame |

| % of total emissions | 3.35% |

| % of total sequestration | -41.12% |

| Net value for E or S per m2 | -28.24 |

- Floor:

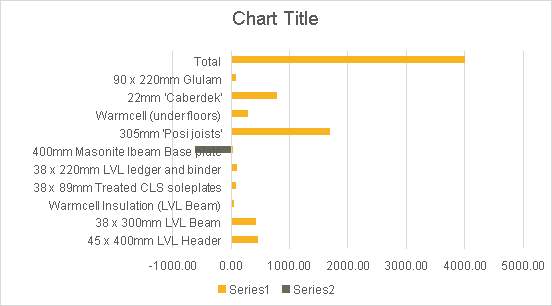

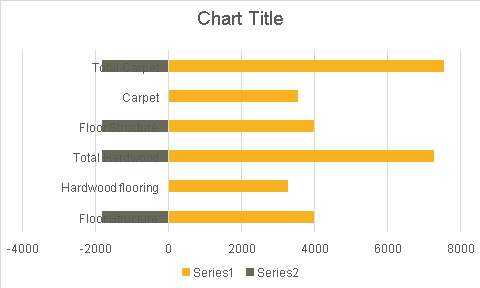

The laminated veneer lumbers (LVL) box beams, along with Masonite I – beams filled with insulation are used to support the floor. Posi – joists form the structure of the upper floor and are filled with Warmcell insulation. They are spanning beams which combine the lightness of timber and strength of steel. Steel is used as a bracing between hollow timber joists, providing for long spans. These joists are quick to install, therefore save the emissions associated with their construction. Also they use lesser raw materials than completely filled joists. These floors are finished with hardwood or carpet finish.

The total emissions from the floors far overpowers the small amount of sequestration from Masonite I – beams and Warmcell insulation. Only the FSC certified wood products are considered to store carbon as these come from sustainably managed forests, in which any tree fell or cut is replaced by planting another tree. Thus, maintaining the carbon absorption from the atmosphere. In this flooring system, the posi – joists are responsible for the maximum emissions, as it contains steel. Although this product is useful in the long run as the steel used is 98% recyclable, therefore beneficial for the end of life stage.

| Type – | Floor |

| % of total emissions | 7.64% |

| % of total sequestration | -7.48% |

| Net value for E or S per m2 | 7.55 |

Floor structure with floor finish:

Carpet and Harwood are the two main floor finished used throughout the building. The environmental impact performance are almost the same for both, slightly higher of the nylon carpet. The carpet also requires replacement after every 7 years whereas the hardwood flooring can survive for much more time. Although for sound absorption in any office, the carpet flooring is preferred. Therefore a use of such wooden flooring system which can reduce embodied carbon by sequestration along with and having decent sound absorption would be ideal for EC reductions from floor finishes.

| Type – | Floor Finishes |

| % of total emissions | 5.23% |

| % of total sequestration | 0% |

| Net value for E or S per m2 | 9.44 |

- Roof type – 1:

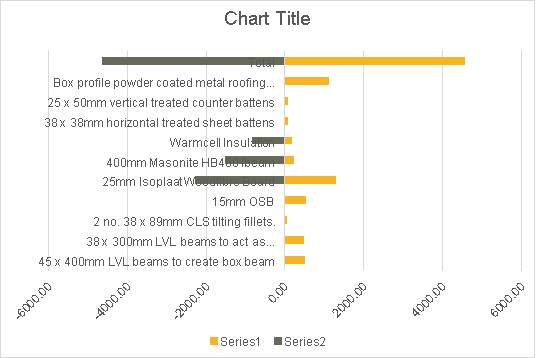

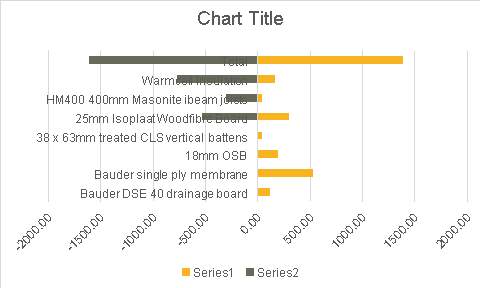

A variety of beams, joists and battens are used in the structural framework of the roof. The sloping roof consists of Masonite I – beams filled with Warmcell insulation forming the truss. It is mounted with wood fibre board for airtightness while CLS battens form the ventilated cavity above, the roof is mounted with box profile metal roofing. Apart from the box metal roof finish, the roof structure has a very low net embodied carbon. The wood fibre board and the Masonite frame with Warmcell, absorb the maximum carbon. The flat roof is similar in structure but differs in finish. It uses plywood and sedum plant roofing as its finishes. It is finished with plasterboard from the inside.The emissions from the roof are almost equal to its sequestration, therefore has very low embodied carbon.

| Type – | |

| % of total emissions | |

| % of total sequestration | |

| Net value for E or S per m2 |

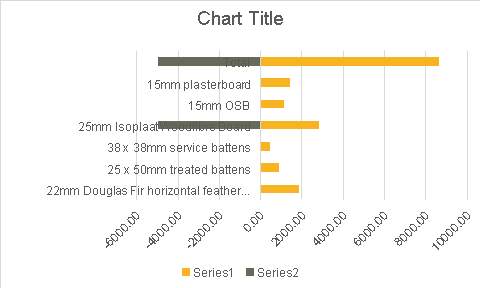

- External Wall Cladding:

The external side of the wall comprises of wood fibre board attached to Masonite frame, this board provide the required airtightness to the structure to comply with the standards of Passivhaus. Apart from the 400mm thick structural wall, these cladding materials further add to the thickness and the result is a bulk 550mm wall, but it adds thermal mass to the structure and also stores high amount of carbon within it. Thus, using natural materials can have a drawback for increasing wall thickness of the structure to provide desirable conditionals for successful operation of the building. OSB and Plasterboard are attached the internal side of the frame. For all the locally sourced materials such as OSB (specified by project architect), only emissions related to fossil fuels are considered and those related to bio fuels are ignored (ICE Database). The GWP of the wood fibre board is obtained from the manufacturer’s EPD and is FSC certified, thus considers sequestration. The overall emissions overpower the sequestration from the structure.

| Type – | External Wall |

| % of total emissions | 16.53% |

| % of total sequestration | -20.64% |

| Net value for E or S per m2 | 12.61 |

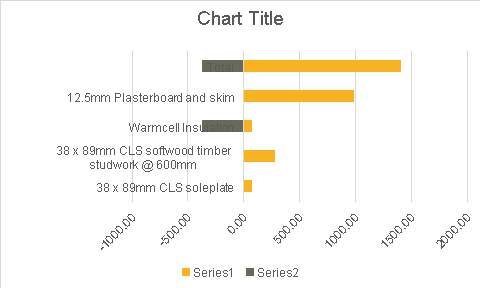

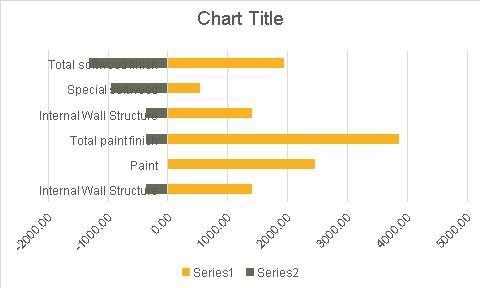

- Internal Walls:

The internal walls are standard studwork walls filled with Warmcell and finished with plasterboard or softwood finish.

| Type – | Internal Wall |

| % of total emissions | 2.70% |

| % of total sequestration | -1.54% |

| Net value for E or S per m2 | 3.58 |

Internal Wall and finishes:

The paint finish to the internal walls are responsible for high amount of emissions, therefore this can be easily minimised in the structure. Use of natural paints can also be beneficial in reducing the embodied carbon of the finishes. In this office, the softwood finish to the walls are a better option than painting the walls.

- Embodied Carbon of Overall Building:

The emissions associated with

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Civil Engineering"

Civil Engineering is a branch of engineering that focuses on public works and facilities such as roads, bridges, dams, harbours etc. including their design, construction, and maintenance.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: