Personal Hygiene and Training for Food Safety Quality Assurance

Info: 9057 words (36 pages) Dissertation

Published: 10th Dec 2019

Table of Contents

3.1. Key steps in a temperature control system.

3.2. Methods for safe storage of food.

3.3. Evaluate the importance of personal hygiene in the control of food contamination.

3.4. Evaluate cleaning and disinfection as a process supporting safe food production.

3.5. Assess the problems associated with pest control in food premises

3.6. Justify the need for hygienic design and construction of food premises.

3.7. Justify the importance of training as a quality assurance mechanism

4.1. Produce a food hazard risk assessment

4.2. Complete a food safety control system

4.3. Develop a food safety guide for legislation compliance.

1.0 Introduction

The food service provider has a responsibility to provide safe food to the consumer. Any establishment serving food to the public has an obligation on behalf of the authorities to make sure that they do so in accordance to the regulation, and compliance thereto is monitored. Deliberate contamination of food can be prevented with the help of Food Safety Management systems such as HACCP. These systems are widely used in the food industry for the prevention of accidental contamination. They are thus cost-effective and an attractive way to deal with deliberate contamination.

Food safety is how food can be handled, prepared, and stored to avoid foodborne illness. This comprises the routines to be followed to avoid likely health hazards. Food safety often overlaps with food defence in this way to avert harm to consumers. There are requirements for a food management system where an organisation in the food chain needs to demonstrate its ability to control food safety hazards to ensure that food is safe at the time of human consumption specified in ISO 22000:2005.

The paper aims at giving an insight into the prevention and control systems of food safety management.

3.1. Key steps in a temperature control system.

Temperature is used as one of the key control for food safety. To minimize deterioration of food, temperature is controlled appropriately during transportation, handling, and storage of the product. The growth of food poisoning bacteria can be prevented, destroyed, or retarded by the correct use of heat, chillers, and freezers, and therefore protect consumers. Temperature controls will have to be used in some way to preserve food and protect consumers by almost all food businesses. Restaurants will use hobs, ovens, grills, fryers, chillers and freezers, retail shops will use chillers to hold pre-made sandwiches, milk, meat and produce, to realize safe temperatures.

Maintain the appropriate storage conditions. Primary and secondary freezer stores should be maintained at between -20 degrees centigrade to -28 degrees centigrade. Frozen product temperatures also need to be maintained at less than 18 degrees centigrade. Chill stores should be maintained at between 0 degrees centigrade and 8 degrees centigrade. Chilled products that spoil rapidly must be maintained at between -1degree centigrade and +2 degrees centigrade. Microbiological susceptible product should be maintained at between 0 degree centigrade and +5 degrees centigrade. Temperature variations in cold stores must be minimized. Optimum stacking patterns in storage regimes should be ensured. Air temperatures in warmest part of the storage facility must be monitored and recorded and alarms to indicate temperature abuse should be provided.

Distribution of chilled and frozen foods. Temperatures for primary frozen distribution is between -12 degrees centigrade and – 18 degrees centigrade. The temperature for local frozen distribution is from -12 degrees centigrade to -15 degrees centigrade. In respect of temperatures control for chilled food, ensure Category 1 (-1 degree centigrade to +2 degrees centigrade): poultry, fresh meat, comminute meats, offal, smoked fish, fish and shellfish. Category 2 (0 degree centigrade to 5 degrees centigrade): cured meats, pre-cooked foods, pasteurised milk/cream sandwiches. Category3(0 degrees centigrade to 8 degrees centigrade): fermented meats, fruit and vegetables, bakery product, hard cheese, spread butter/margarine.

Ensure appropriate conditions for retailing/foodservice. Incoming food should be inspected and measured for temperature control. In-house cold store facilities must be monitored. Retail display cabinets should be operated using manufacturer’s guidance. Ensure a minimum reheating operation of 70 degrees centigrade for 2 minutes is achieved for cook-freeze and cook-chill products. For food service food temperatures should be maintained above 63 degrees centigrade.

Cooking and Reheating Food. Properly cooked food will destroy any harmful bacteria. Food poisoning could result if you eat food that is not properly cooked. Insert a small knife into food to check if the food is steaming hot in the middle, to test if the food has been properly cooked. Temperature probes or cooking thermometers can be used to check if food is cooked properly especially for very large dish. When cooking sausage, burger, or a portion of chicken or pork, check there is no pink meat left by cutting into the middle. Reheat food to reach a temperature of 70 degrees C for more than 2 minutes or should be steaming hot all the way through. You should only reheat food once and discard any leftovers.

3.2. Methods for safe storage of food.

Food quality is maintained with proper food storage. It also helps in retaining flavour, colour, texture, and nutrients, while reducing the chance of contracting a foodborne illness. We can classify food into three groups. Group one, perishable foods, include, fish, eggs, meat, milk, poultry, fish, vegetables, and raw fruits. Cooked foods are perishable foods. Perishable foods need to be held at refrigerator or freezer temperatures to store them for any length of time. Perishable foods should be used within several days if refrigerated. The second group, semi- perishable foods, may remain unspoiled for six months to about one year if properly stored and handled. Semi-perishable food include flour, grain products, dried fruits, and dry mixes. Group three is non-perishable or staple food for example sugar, canned goods, spices, dried beans. If handled carefully, they do not spoil. If stored over a long time however, these foods will lose quality, even if stored under ideal conditions. How long a food will maintain quality and be safe to eat cannot be determined, as various conditions affect quality. Factors affecting storage life of foods include, the temperature of your food storage areas, the length of time and the temperature at which it was held before purchase, the humidity level in your food storage areas, the freshness of the food when it reached the grocery store, the characteristics of the food item, and the type of storage container or packaging the food is stored in.

Refrigerated storage

Refrigerator should be maintained between 34degrees Fahrenheit and 40 degrees Fahrenheit. Thermometers of refrigerators are available to help monitor the temperature inside the appliance.Pathogenic or spoilage microorganisms are not destroyed by refrigerator temperature. The growth of microorganisms already in the food is slowed by the lower temperature. Perishable food will worsen, because of oxidation, enzymes, and spoilage microorganisms. Temperature and time remain significant influences in food quality. Food should be used quickly and cannot be expected to remain good for a very long time. Items that are partially used and opened generally deteriorate more rapidly than unopened packages. There is the need to keep food in the fridge to prevent the growth of bacteria on it, for example cooked food and ready to eat food like cooked meats and desserts, food with a ‘use by’ date. Food should be covered to protect it from contamination physical objects and raw food. Cooked food should be stored above raw meat in the refrigerator at all time to prevent contamination from blood through spillage and bacteria. The refrigerator should not be overstock because airflow around the food will be affected. Avoid putting hot food into the refrigerator because the internal temperature of the refrigerator will increase as this will affect other foods due to poor temperature control. Ensure the doors of refrigerator/freezer are always tightly closed. Avoid opening freezer/refrigerator doors often and close them immediately.

Freezers and thawing food

Food can be safely preserved in the freezer if it remains frozen all the time. Food texture and taste changes when frozen for too long. The instructions in the freezer’s handbook or on food labels should be checked however to see how long food should be frozen. Freezer temperature should be kept at 0 degrees Fahrenheit or below to maintain the quality of frozen foods. A lot of foods will sustain longer excellent quality if the temperature of the freezer is -10 to -20 degrees Fahrenheit. Food deteriorates more rapidly at temperature between 0 and 32 degrees Fahrenheit. Fluctuating temperatures may damage food quality, like those in self-defrosting freezers. Frozen foods should not be stored for the maximum recommended period if 0 degrees temperatures cannot be maintained by your freezer. Properly stored food will lose texture, nutritional quality, colour, and flavour, but foodborne illness will not occur. Food should never be thawed at room temperature, the risk of bacterial and fungal growth is increase by this and consequently the risk of food poisoning. Never refroze used food once thawed, it should be used. The following methods should be used to thaw frozen food they are, Microwave oven, in cold water, in the refrigerator, during cooking. Foods that have been warmer than 40 degrees Fahrenheit 4 degrees centigrade for more than 2 hours should be thrown out. Throw out the food if in doubt of the length of time it has been defrosted at room temperature.

Cupboard/Pantry Storage

Keep cupboard or pantries clean, cool dark, and dry. Dry and canned items best temperature range is 50-70-degree Fahrenheit. Canned food may deteriorate and lose quality with temperatures over 100 degrees Fahrenheit. Rotation system, First In, First Out should be used to prevent food from spoiling. This approach allows the usage of older dried and canned food items before newly purchased items. The rotation system will be maintained when the date of purchase is written on food items. Canned items must be checked often for any indication of spoilage. Foods that spurt liquid when opened or those from cracked, bulging or leaking cans, should not be used. These foods should not be tasted to ascertain how safe they are, the cans should be discarded immediately.

3.3. Evaluate the importance of personal hygiene in the control of food contamination.

According to the (General Food Hygiene) Regulations 1995, ‘Every person working in a food handling area shall maintain a high degree personal cleanliness and shall wear suitable, clean protective clothing where appropriate.’ Food handlers should make sure that their personal practices and habits while working, do not cause contamination. Food companies have the responsibility to ensure that these practices are complied with. Personal hygiene refers to a situation whereby food handlers develop clean habits and adhere to lofty standards of personal cleanliness to aid in lessening contamination risk. There are several ways that the food handler can contaminate food it is therefore imperative to have some high personal standards of hygiene. Food handlers are a cause of likely contamination, from the lips, mouth, ears, nose, hands, skin, hair, abrasions, cuts, bowel, the gut and sores. The rules on good practice should be followed by all food handlers while at work. Keep hair clean and tied back and if necessary covered, cover all cuts and wounds with a waterproof dressing, wash hands properly and frequently, keep hands clean, wash hands (before handling cooked food, before starting work, after handling rubbish and waste, after going to the toilet, after blowing your nose, sneezing, coughing, after smoking or touching your hair) and after any cleaning activity.

Food handlers should not, taste food with fingers, bite nails, wear nail vanish or false nails, cough and sneeze over food, pick or scratch nose, lick fingers when picking up wrapping materials, touch hair or scratch head while handling food, blow into bags to open them.

According to published scientific literature reviewed for the period 1975 -1998 by Guzewich and Ross (1999), food workers, who are ill could be source of infection in food poisoning outbreaks. Also, hand contact with food was a mode of contamination. Greig et al, (2007) reiterated the data on food worker- associated disease outbreaks evaluated by the Committee of the Control of Foodborne Illness of the Association for Food Protection. A total of 816 reports with 80,682 between 1972 and 2006 were found. 14 agents including norovirus or probable norovirus (338), hepatitis A virus (84), Salmonella enterica (151), Staphylococcus aureus (53), Streptococcus (17) Shigella spp. (33) and the parasites Cryptosporidium, Giardia and Cyclospora (23) caused outbreaks. Multi-component foods and multiple foods were recognized most commonly with outbreaks, maybe because of more regular hand contact throughout preparation and serving. Todd et al (2007) also indicated workers involvement in food poisoning outbreaks with the infection of majority of food workers. Bare hand contact with the food is the most frequently reported factor associated with the involvement of the infected worker, then failure to wash hands properly, poor cleaning of preparation or processing utensils or equipment, (for bacterial pathogens) temperature abuse and cross-contamination of ready-to eat foods by contaminated raw ingredients.

3.4. Evaluate cleaning and disinfection as a process supporting safe food production.

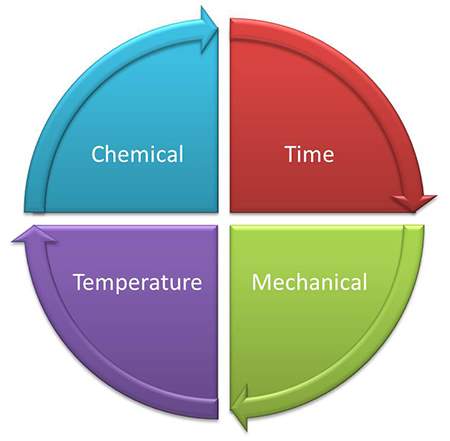

Cleaning and disinfection is an important part of any manufacturing process and especially so for the food industry. Effective cleaning gets rid of bacteria on hands, equipment, and surfaces. So, it helps to stop harmful bacteria from spreading onto food. Check product labels for these codes: BS EN 1276 or BS EN 13697, finally do not let food waste build up. Cleaning in the food industry is not an easy task. Nevertheless, it is a step that is critical in food production meanwhile it is vital to sustain and assure food safety. Cleaning and disinfection are two steps in the cleaning procedure. Cleaning involves comprehensive removal of soil and residues from surfaces, making them to be clean an effective resultant disinfection. Lack of effective cleaning will compromise disinfection. Soil is remove from a surface with the use of detergents are used to remove soil. The soil comprises bacteria and food waste attached to the surface of walls, floors, and processing equipment. The detergent solution acts to suspend this bacteria and soil mixture away from the surface and let it rinse off to the drain. Nevertheless, many soils are in the food industry with different detergent and cleaning procedure applied to accomplish the anticipated detergent action for each soil. Carbohydrates like cellulose, starch, sugar, are the most common soil easiest to be removed. Proteins such as eggs, meat, milk are quite difficult as changes in PH and heat change the protein structure, bind it other molecules, increasing their persistence and frequently making them insoluble. While milk is soluble in water for example, if a pan of milk is overboiled, the resultant milk soil will be tough to get rid of from the pan. Fatty soils pose a greater challenge than carbohydrates because they are not water-soluble. Here, alkaline cleaners are necessary to be used. Temperatures should be elevated above the melting point of the fat to achieve an efficient clean. Mineral salt (inorganic food soils) cause formation of scale on equipment. You require acid cleaners to remove the scale efficiently. There are four variables in the process of cleaning that can influence its proficiency to remove soil they are Concentration/Detergents, Temperature, Time, and Physical Action.

Fig 1 Sinner’s Circle

Source: www.foodsafetymagazine.com

Fig.1 was developed by Dr Herbert Sinner. The model demonstrates that if one of the four factors is reduced increasing another can compensate for it. For instance, the temperature can be increased to allow the use of chemical concentration that is lower. Disinfection is the process by which microorganisms are killed so that their numbers are reduced to a level which is neither harmful to health nor to the quality of perishable goods. Consequent upon cleaning, though microorganisms may remain surfaces will be free from soil. Microorganism levels is reduced to the required level for food production after the use of validated disinfectants on surfaces, following the instruction and contact times. The way disinfectants kill microorganism (mode of action) contrasts with the active ingredient. Some of the key activities and their mode is shown in the above figure. Some considerations need to be made when choosing a disinfectant. They are application, which include impact of water hardness, compatibility with materials found in the area being disinfected, required concentration, temperature required, leftover residues, toxicity. Principally, the consents for each disinfectant must be well thought-out in selection, for instance if you a product is being used in chilled environment, you should prove that the disinfectant will work at the intended temperature it is to be applied. Cleaning and disinfection is done for the following reasons including avoiding microbial contamination, the prevention of transfer of products/ingredients, improve plant efficiency, impact financial implication, to ensure disinfectant efficiency, boost stakeholder confidence, minimise legal ramifications. boost stakeholder confidence and improve safety.

3.5. Assess the problems associated with pest control in food premises

Pests constitute health risk. They carry disease-causing organism and contaminate food with foreign matter like dead bodies, hair, droppings/ urine, fur, and eggs. Ideal conditions are provided by food premises for pests to live and reproduce such as water, food, protection, and shelter. Unsatisfactory control can cause infestation of pests which can affect the health of the consumer. It is vital to employ pest control measures. A common cause of closure of food premises by local authorities is pest infestation. Pests like cockroaches, flies, mice, rats, ants, and birds, are main causes of contamination. Windows and doors that open to the outside in a food preparation area must be screened or closed to avert contact of pests. The existence of pests’ in food premises is improper. Pests constitute a lot of risks like damage to property, contamination of work surfaces and foodstuffs, poor staff relations, adverse public opinion and loss of reputation, prosecution, and closure. Difficulties connected with pest control in food premises comprise risk to food safety which affects those engaged in the production, storage, transport, processing, and sale of food, risk to public health due to activities of pests because they carry a range of pathogens which can be transferred to humans either through contaminated food or their presence in the environment. Such risks are, damage to packaging or product, introduction of microorganisms. We also have risk to the environment and public safety. The inaccurate or irresponsible usage of pesticides may be hazardous to members of the public, site staff and technicians in addition to the environment via water contamination, the effect on non-target species of animals and damage to plant. Rodents such as mice, rat need to be controlled to eliminate or reduce contamination of products, damage to food stock and property, the spread of disease. Food intended for humans, can be damaged by rodents by contamination with faeces and urine, consumption, other microbiological and physical contaminants. Grey squirrels are physically larger and stronger than rats and mice and can break through poor fitted proofing materials. They can cause considerable damage to food premises with their powerful jaws and sharp incisor teeth. Cockroaches taint materials with their characteristic smell, regurgitate food, foul their environment with faeces. Discard food containing ants to avoid selling or serving contaminated products. There is a risk that food may become contaminated by ant bodies. Ants presence in packaging prevent the sale food product. Waste food disposal causes rodent infestations. The adverse publicity from product recalls will lead to damage to the company’s reputation, financial loss, stopped production and prosecution by environment health department. Jobs may be lost due to closed premises.

3.6. Justify the need for hygienic design and construction of food premises.

A considerable amount of thought must always be given to the design and construction of food premises to ensure a cost effective and hygienic operation. All food premises must be suitable for the types of food involved and the preparation and processes being carried out. There are lots of different types of designs with the minimum requirements. Key premises and equipment considerations must include provision of good safe waste disposal area, good work flow, provide facilities for personal hygiene, ensure that staff have adequate facilities for cleaning, installing door and window screens, prevent pest infestation by pest proofing the building, provide chilling equipment that is out of direct sunlight, implement a pest control schedule. Chilled. Constant supply of fresh mains water, or potable water should be available. Suitable drainage that can remove food debris and waste water quickly should be ensured. Principles to consider when designing premises include avoid cross contamination- to have separate raw and cooked preparation areas, to have separate clean and dirty area, to have separate rubbish area, to have separate washing up area. There should be logical work flow so that clean and dirty procedures are in an order. Personal hygiene facilities such as toilets, hand basins, hot and cold water should be provided. Also, adequate temperature control like fridges, freezers, cooking and cooling facilities and holding facilities. There should be easy cleaning, wooden surfaces should be avoided, preferably use stainless steel and modern plastics. Pest control should be available, ensure access is denied through good construction and good housekeeping. Staff facilities such as lockers and changing rooms for outdoor clothing. The premises should also have adequate drainage to prevent potential problems. The food premises should also have ventilation. The best form is mechanical, stop pests, dust from entering also reduces condensation. There should also be adequate lighting. The construction details should be such that the ceilings need to be smooth and impervious, fire resistant and light coloured and easy to clean. Walls need to be smooth, impervious, easy to clean and have no cavities or joint that might harbour pests. Floors need to be smooth, impervious, non-slip, no cracks, easy to clean and drain. Finally waste disposal and storage should be sufficient and suitable containers should be provided. Dustbins should have tight lids so as not to attract pests and bacteria.

Rising demand for fresh food by the consumer resulted in the development of preservation and processing methods with little effect on sensory or nutritional properties of foods. Foods that are freshly produced have less sugar, additive, salt, preservatives, and acid. Hygienic process environment and a hygienic processing equipment are desired to stop chemical, physical, and microbial contaminants from touching these products while avoiding exposure of product filth caused by pest, dust. Integrating hygienic design to food processing facility averts development of microbiological and pest niches; evade contamination of product with chemicals and particles; enable sanitation and cleaning and hygienic conditions is preserved during maintenance. Providing barriers to food contamination is a generally applied concept to control food safety. Outside premises, such as fencing, to prevent unauthorised access to the facility is the first barrier. There is the need to control and monitor the access of personnel, domestic and non-domestic animals and transport vehicles with raw materials and end-products. Storm water collection and factory site drainage must be adequate; a 10-cm thick concrete curtain wall around the factory foundation at 60 cm below ground discourages rodents from entering the building; keep areas within 3-m perimeter of the factor free from vegetation to prevent the breeding of pest and harbourage sites; site effluent treatment plants and waste disposal units to prevent prevailing wind blowing dust and microbial aerosols into work areas. Closing of factory buildings is the second barrier. Entrances and exits must be designed to flow or exit of personnel, control over access, air, raw and finished food products, process aids, waste utilities and pests. Screen food drain to avert rats entering the food plant via sewers; Screen ventilator openings, to thwart roof rats and birds’ entry; Close gaps at the entrances of utility piping, electrical conduits, convenient for roof rats. The segregation of restricted areas in the plant, each of which have different hygienic requirements and controlled access is the third barrier. The last barrier is the process equipment with suitable hygienic design and closed to keep the food product from external contamination.

3.7. Justify the importance of training as a quality assurance mechanism

Quality assurance (QA) describes the evaluation, control, and audit of the food processing system. It provides confidence for management and the ultimate customer. The customer preferences are the basis for building label requirement and product specification. Much of the education and training takes place on the job in a food manufacturing company not in the classroom. One task of QA is to encourage supervisors and management to include quality in their training efforts. Education and training should focus on the culture and traditions of the organisation, fundamentals of quality, quality improvement, concepts of processes, technical topics, statistical concepts, management and supervisory practices, and quality leadership. A company must have a mechanism for providing this required education and training. It must also have a mechanism for keeping personnel informed about quality developments that are pertinent to their work and to the organisation. QA management and education concepts constitute a massive effort and might require temporary assistance from outside consultants to cope with the workload.

Procedures for quality food safety are not only for legal requirement and customer wellbeing, they enhance profitability and business success. Irrespective of the system in place within a food business, its depends on how well trained and competent the team to implement and maintain it are and management fully equipped to monitor the system effectively and consistently. Ensuring food handlers are trained to at least level 2 in a reputable food safety qualification, aids businesses achieve their obligation to ensure staff training to level appropriate with their job roles.

Your restaurant is saved time and money, coupled with increased profitability with a well-trained workforce. Ensure that every member of staff receives continuous and solid training to stand out in the vastly competitive industry. Ensure you work with trainers that are reputable and professional for a required outcome. The employees should understand proper food-handling practices to guarantee safety of food. A well-trained staff for instance would understand the need to wash their hands before engaging in the cooking process, or know how to store certain foods at their required temperatures. Employees with good knowledge of food safety practices can prevent waste due to contamination, food spoilage or cases of food poisoning. They would ensure all food-safety codes are met by your restaurant. The art of service should be mastered by your employees to ensure your customer return, and recommend you to families and friends. A core factor of customer satisfaction is proper customer service. A well-trained waiter, for instance, goes out of his way to provide customers with a special service or speak to customers courteously. Such customers will make repeat visits due to the fond memories of the event. Well-coordinated and smooth operations, are an asset to your restaurant. Training programmes facilitate a harmonious relationship between employees, and provide your workers with accurate specifications of their responsibilities thereby enhancing good team spirit. A good training programme in a restaurant covers quality standards.

4.1. Produce a food hazard risk assessment

‘A risk assessment is a systematic examination of a task, job or process that you carry out at work for identifying the significant hazard, the risk of someone being harmed and deciding what further control measures you must take to reduce the risk to an acceptable level’.

Food businesses are legally bound to ensure their activities are carried out in a manner that is safe and hygienic. Each step in the food production must therefore be considered, and decide about a potential for the food to be made unhealthy to eat by any microbiological, chemical, physical hazards. Then they must have a control in place to eliminate that hazard. This is a process called hazard analysis, which can be easily carried out.

Risk Assessment for The Dorchester Hotel London. Date: 30/10/17

|

Electrical |

Knives |

Gas appliances |

Contact with hot water, steam, and hot surface |

Fire |

Slips and trips |

Manual handling |

Hazards |

|

Serious/fatal injuries could be suffered by staff due to electric shock. |

Staff that prepare and serve food could be cut. |

Customers and staff could suffer fatal/serious injuries because of gas explosion or release |

Staff may suffer burns or scalding injuries |

Customers and staff could suffer fatal or serious injuries from smoke or burns inhalation |

Customers and staff may sustain injury if they slip on spillages or trip over objects. |

Staff may suffer strains, muscle pull and bruises due to lifting heavy objects |

Who harmed and how |

|

|

|

|

|

|

|

What are you already doing |

|

|

|

|

|

|

|

Further action |

|

High |

Medium |

Medium |

Medium Medium Medium |

Medium Medium Medium |

Medium High Medium |

Risk level |

|

|

Manager |

Manager |

Manager |

Manager Manager Manager |

Manager Manager Manager |

Manager Manager Manager |

Action by who |

|

|

30/11/17 |

30/11/17 |

30/11/17 |

30/11/17 30/11/17 30/11/17 |

30/11/17 30/11/17 30/11/17 |

30/11/17 30/11/17 30/11/17 |

Action date |

|

|

Low |

Low |

Low |

Low Low Low |

Low Low Low |

Low Low Low |

Residual risk |

4.2. Complete a food safety control system

Food safety is a term that refers to hazards, that may make food harmful to the consumer’s health and not negotiable.

Food control is defined as “a mandatory activity of enforcement by national or local authorities to provide consumer protection and ensure that all foods during production, handling, storage, processing, and distribution are safe, wholesome and fit for human consumption; conform to safety and quality requirements; and are honestly labelled as prescribed by law.”

Food safety control and environmental hygiene has several systems designed for it. Many food businesses have adopted the following four systems. They are Hazard Analysis and Critical Control Points (HACCP). System, the Assured Safe Catering (ASC) system. The Good Manufacturing Practices (GMPs).

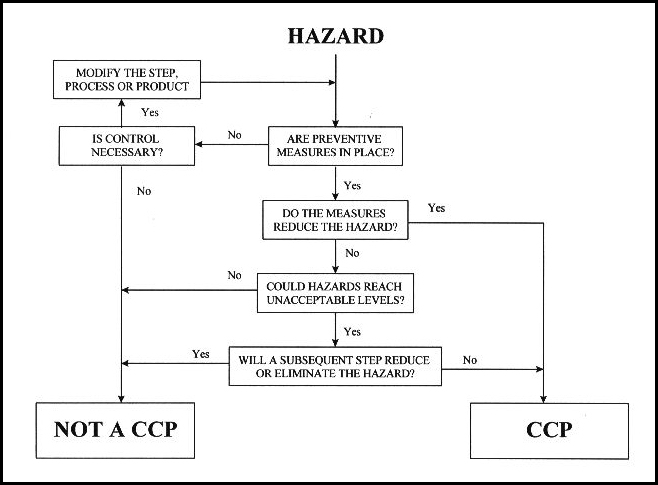

Hazard Analysis and Critical Control Points (HACCP)

HACCP is an internationally recognised system for reducing the risk of safety hazards in food. It is a methodical precautionary method to food safety from chemical, physical, and biological hazards in the processes of production that can cause the unsafe finished product to It designs measurements to reduce these risks to a safe level. HACCP in this manner, tries to prevent hazards instead of trying to check finished products for the effects of those hazard. The HACCP system is useable at every stage of a food chain. From food production and preparation processes including packaging and distribution. It is a system that helps food business operators look at how they handle food and introduces procedures to make sure the food produced is safe to eat. HACCP is in use because of an increasing awareness of food-borne illness. Concern throughout the industry is driving the use of HACCP and HACCP based certification programmes.

Sample HACCP Plan.

Source: https://uk.images.search.yahoo.com

Assured Safe Catering (ASC) was developed from HACCP. This system was developed for and with caterers to control food safety problems. It was born out of the difficulties encountered during the implementation of HACCP as it is a modified approach to HACCP (HMSO, 1993). It involves looking at the catering operation step by step from the selection of ingredients right through to the service of the food to the customer. ASC is a simpler system compared to HACCP in making sure food is safe (Forsythe & Hayes, 2012). It provides a framework for the proprietor of a QSR to assess, control and monitor hygiene standards. It involves looking at the catering operations in sequence from the selection of ingredients right through to the service of food to the customer.

Good Manufacturing Practice (GMP).

A general definition of “good manufacturing practices” can be found in EC Directive 2003/94/ec Article 2.6 “good manufacturing practice means the part of the quality assurance which ensures that products are consistently produced and controlled in accordance with the quality standard to their intended use.” GMP regulations require a quality approach to manufacturing that enables companie to minimize or eliminate instances of contamination, mix-ups and errors. This in turn protects the consumer from purchasing a product that is impure, misrepresented in label or even dangerous. GMP is a term that describes regulations and procedures designed to ensure the maintenance of sanitation in food manufacture

The basic requirements of good manufacturing practice are that:

- All manufacturing processes are clealy defined, and known to be capable of acahieving the desired end:

- All necessary resources and facilities are provided, including:

- Appropriately trained personnel

- Adequate premises and space

- Suitable equipment and services

- Correct materials, containers and labels

- Approved procedures (including cleaning procedures

- Suitable storage and transport

- Operators are trained to carry out the procedures correctly

4.3. Develop a food safety guide for legislation compliance.

Food safety is vital to consumers and therefore a priority for food businesses. A consumer wants an assurance about the food they buy and eat. That it is what it is labelled to be (i.e. doesn’t contain pork if its labelled as beef) and will not harm them once eaten. For public protection, several laws regulate retailers of food. They are, The General Food Law Regulation (Regulation EC 178/2002), The Food Safety Act 1990, General Food Regulations 2004, EC Regulation 852/2004, Food Hygiene Regulation 2006, Food Safety, and Hygiene (England) Regulations 2013. This legislation applies to anyone working with food, at the stages of production, processing, storage, or sales. The Food Safety Act 1990 provides the framework.

The European Union (EU) adopted the General Food Law Regulation (Regulation EC 178/2002), that created new laws on food safety; traceability; withdrawal and recall of products. The General Food Regulations 2004 created criminal offences for breaches of certain articles in Regulation EC 178/2002 in Great Britain. Food Hygiene Regulations 2006 covers food law which deals with hygiene requirements for businesses.

Food Safety law enforcement

The enforcement officers primary concern is the prevention of food-related illness and dangers. This is best achieved by encouraging effective management of food safety by those who create the risks. Enforcement officers seek to help businesses improve their management of food safety by giving guidance on safe food handling. They are a source of help on how best to maintain good standards in conformity with the law, and their guidance is usually followed. Enforcement officers should exercise considerable discretion when approaching individual proprietors.

5.0 Conclusion

Development of the profit-oriented food enterprises, growing consumers expectations and concerns about food quality and safety, as well as increasing requirements of food chain actors, forced many companies to improve safety and quality of their products through implementation of the quality and safety assurance and management systems. This research report into control and prevention systems of food safety management. It discussed the key steps in a temperature control, and summarised methods of safe storage of food. The paper further evaluated the importance of personal hygiene in the control of food contamination. An evaluation of cleaning and disinfection as a process to support safe food production was also done. The report also investigated the problems associated with pest control in food premises. It also justified the need for hygienic design of food premises. The importance of training as a quality assurance mechanism was justified in the research. Finally, the report also produced food hazard risk assessment, food safety control system and a brief guide for compliance with food safety legislation

Bibliography

Albrecht, J.A. (2007) Food Storage. University of Nebraska Lincoln Extension. Online available at extensionpublications.unl.edu/assets/pdf/ec446.pdf. Accessed on 12 November 2017

Assuring Food Safety and Quality: Guidelines for Strengthening National Food Control Systems. Joint FAO/WHO Publication. Online Available at www.wpro.who.int/foodsafety/documents/docs/English_Guidelines_Food_Control.pdf Access on 22 November 2017

Carey, J. (2017) The Importance of Training in a Restaurant. Online Available at smallbusiness.chron.com/importance-training-restaurant-75676.html. Access on 20 November 2017

(2012). Cleaning and Pest Control in Food Preparation Areas. Food Safety Series (NO.9). Online Available at www.unicen.cam.ac.uk/files/9_cleaning_and_pest_control_0.pdf

Day, G (2011). Storage of Food. WARWICK Health and Safety Department. Online available at https://www.warwick.ac.uk/services/healthsafetywellbeing/guidance/foodhygieneandsafety/storageoffood Accessed on 12 November 2017

Day, G (2011). Cooking and Re-heating Food. WARWICK Health and Safety Department. Online available at https://warwick.ac.uk/services/healthsafetywellbeing/guidance/foodhygieneandsafety/cookingandreheatingfood/ Accessed on 5December 2017

(2014) Design and Construction of Food Premises. Food Safety Level2. Meallmore Ltd. Online Available at community.learnprouk.com/ScormContent/11443_2014 Access on 20 November 2017

Diversey Care (2015). Cleaning and Disinfection: Improving Food Safety and Operational Efficiency in Food Processing. Online available at https://www.foodsafetymagazine.com/signature-series/cleaning-and -disinfection-improving-food-safety-and operational-Efficiency-in-Food-Processing/

Accessed on 15 November 2017

(2008) Food Safety Act 1990- A Guide for Food Businesses. Food Standards Agency. Online available at https://www.reading.ac.uk/foodlaw/pdf/uk-08016-food-safty-act-guide-draft.pdf Accessed on 22 November 2017.

Food safety: HACCP awareness and legislation. Online available at www.sajcn.co.za/index.php/SAJCN/article/viewFile/176/169 Accessed on 16 November 2017

Food safety enforcement. Tendering District Council. Online Available at https://www.tendringdc.gov.uk/business/licensing-legislation/food/food-safety-enforcement Accessed 23 November 2017

Food Standards Agency. Food hygiene for businesses. Online available at https://www.food.gov.uk/business-industry/food-hygiene Access on 20 November 2017

Food Supplements Europe (2014). Good Manufacturing Practice for Manufacturers of Food Supplements. Online available at www.foodsupplementseurope.org/sites/0023/uploads/content/publications/good-manufacturing-practice-for-manufacturers-of-food-supplements.pdf?1407341246

Goue, A.F., Gavriel, D (2016). Optimizing the Effectiveness of HACCP In AgriFood SMEs. European Scientific Journal, Vol. 12 No 24 pp 18-32

Greig, J.D., Todd, E.C.D., Bartleson, C.A. and Michaels, B.S. (2007), Outbreaks where food workers have been implicated in the spread of foodborne disease. Part 1. Description of the problem, methods and agents involved. Journal of Food Protection, Vol. 70 No 7 pp 1752-1761.

Guzewich, J and Ross, M.P. (1999) White paper, section 1. A literature review pertaining to foodborne disease: outbreaks caused by food workers, 1975-1998. Food and Drug Administration, Centre for Food Safety, and Applied Nutrition.

Hazard analysis. What is hazard analysis. Brighton & Hove City Council. Online available at https://www.broighton-hove.gov.uk/contect/business-and-trade/food-safety/hazard-analysis. Accessed on 22 November 2017

HACCP. Food Standard Agency. Online. Available at https://www.food.gov.uk/business-industry/food-hygiene/haccp Accessed on 22 November 2017

(2013). The importance of food safety management and training in restaurants. Cena HOSPITALITY CONSULTING. Online available at www.cenahospitality.com/articles/improtance-food-safety-management-training-restaurants

ISO 22000:2005 Food safety management systems— Requirements for any organisation in the food chain. Online available at https://www.iso.org/standard/35466.html Accessed on 16 November 2017

Managing the cold chain for quality and safety. Online available at Seafood.oregonstate.edu/pdf%20Links/Managing-the-Cold-Chain-for Quality-and-Safety.pdf Accessed on 16 November 2017

MAF (2011), Guidance for Developing Good Operating Practice Procedures: Pest Control. Online Available at www.foodsafety.govt.nz/elibrary/industry/Guidance_Developing_Good_Operating_Practice_Procedures_Pest-Provides_Their.pdf Accessed on 16 November 2017

Moerman, F. (2010). Hygienic Design of Food Processing Facilities. FoodSafety

0magazine. Online available at https://www.foodsafetymagazine.com/magazine-achive1/octobernovember-2010/hygienic-design-of-food-processing-facilities Accessed on 20 November 2017

Personal Hygiene (2017). Personal Hygiene requirement for catering staff. British Event Catering. Online https://britisheventcatering.co.uk Accessed on 20 November 2017

(2009). Pest control procedures in the food industry. Chartered Institute of Environmental Health. Online Available at www.cieh.org/uploadFiles/Core/Policy/Publications_and_information_services/Policy_publications/Publications/Pest_control_food Accessed on 16 November, 2017

Smith, M (2010). The Contribution of Food Safety Management Systems to Prevention of Deliberate Food Contamination. Food Chain Security, NATO Science for Peace, and Security Series: Environmental Security, Vol 00. Springer Science p.23

Taylor, A (2017). Food Safety and the Law. Safe Workers. Online available at www.safeworkers.co.uk/food-safety-law.html Access on 22 November 2017.

Todd, E.C.D., Greig, J.D., Bartleson, C.A. and Michaels, B.S. (2007). Outbreaks where food workers have been implicated in the spread of foodborne disease. Part 3. Factors contributing to outbreaks and description of outbreaks categories. Journal of Food Protection, Vol 70 No 9, 2199-2217.

(2013). The importance of food safety management and training in restaurants. Cena HOSPITALITY CONSULTING. Online available at www.cenahospitality.com/articles/improtance-food-safety-management-training-restaurants

Accessed on 20 November 2017

Vasconcellos, J.A (2005). Quality Assurance for the Food Industry. A Practical Approach. Taylor & Francis e-Library.

What is a Risk Assessment? HS Direct Health and Safety Experts. Online available at https: www.hsdirect.co.uk/free-info/risk-assessment.html. Accessed on 22 November 2017.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Food and Nutrition"

Food and Nutrition studies deal with the food necessary for health and growth, the different components of food, and interpreting how nutrients and other food substances affect health and wellbeing.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: