Investigating Fuel Delivery Regulations and Safety in Ireland

Info: 16288 words (65 pages) Dissertation

Published: 20th Feb 2025

Tagged: International StudiesEnergy

Abstract

The aim of my project is to investigate the regulations, and safety concerns surrounding the delivery and storage of fuel in Ireland. Because of the hazards, involved, strict guidelines, and regulations are in place governing the transportation and delivery of fuel. I developed an interest in this topic, during my work experience, in South Coast Transport. During my placement, South Coast were busily preparing for the first deliveries of new fuel tankers, which they purchased in Germany. These new tankers were bought, after the company secured the contract for the delivery of fuel, to a number of Topaz outlets. It was here I witnessed a sample the huge amount of planning and organisation, which had to be gone through, before the first delivery of fuel could be made. Now in this report I want to, build on that experience, and gain a more in-depth knowledge, of the regulation, and safety requirements, involved in the storage and distribution of fuel. I will, get my information, from both primary and secondary sources. My primary sources will be an interview with an experienced fuel retailer, and with an experienced transport planner. My secondary sources were mostly from reputable internet websites. On completion, of this project, I hope to have a greater insight, into the transportation of dangerous goods.

Contents Year 42016-2017AbstractDeclarationIntroductionChapter 1Haulage Operator1:1 Operators Licence1:2 Premises1:3 Companies Registration1: 4 Transport Manager1: 5 Fleet Management1:6 Dangerous Goods Safety Advisor ( DGSA)1:7 Irish Fuel Operators1:7 Irish Fuel OperatorsChapter 2Fuel Tankers2:1 ADRVehicle Testing2:2 CVRT2:3 Petrol Tankers2:4 Tanker Types2:5 Tanker Safety ConcernsChapter 3Petrol Forecourt3:1 Site Operators3:2 Petrol Forecourt Licensing3:3 Hazardous area Zoning:3:4 Auto Fuel Traders Licence3:5 Monthly Return of Oil Movements (ROM1)Chapter 4Storage Tanks4:1 Underground Storage Tanks4:2 Protection4:3 Bund:4:4 Size of TankChapter 5Tank Testing5:1 Pressure Testing5:2 Other Methods of testing include5:3 Automatic Tank Gauging SystemsChapter 6Tanker Drivers6:1 ADR DRIVER TRAINING AND HAZCHEM CERTIFICATION6:2 Petroleum Drivers Passport6:3 TREM Card6:4 Drivers Hours6:5 Fuel Deliveries6:6 Petrol Deliveries6:6 American Petroleum Institute (A.P.I)Chapter 7Refining and Reserves7:1Refining7:2 NORAChapter 8Fuel Quality8:1 Contaminated Fuel8:2 Petrol Stretching8:3 Diesel Laundering8:4 Lost Revenue8:5 Toxic Waste8:6 Fuel TestingChapter 9Wetstock Management9:1 Wetstock Management System.9:2 Dipstick Readings9:3 Overfill and Spill Prevention9:4 Petrol Interceptor / Oil Separator9:5 Vapour RecoveryConclusionsWorks CitedBibliographyAppendixInterview 1Interview 2

Table of Figures

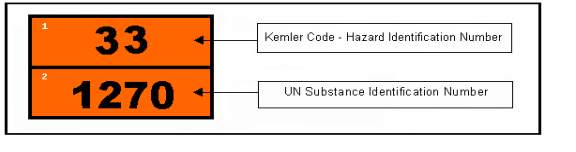

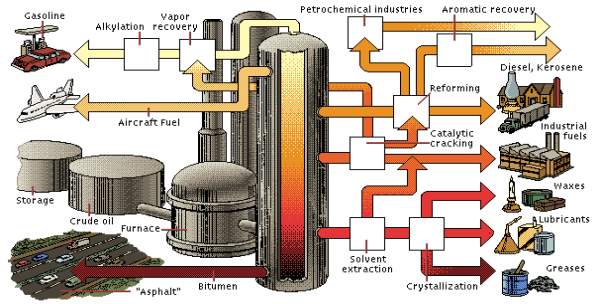

Figure 1 Zoned AreasFigure 2 Hazard PlateFigure 3 Trem CardFigure 4 Vehicle EquipmentFigure 5 Refining ProcessIntroduction

The aim of my project is to investigate, the regulations and obligations of those involved in the transportation, dispensing and storage of fuel in Ireland. My intention is to particularly look at the role of the, haulage contractor, tanker driver, and forecourt operator, and the obligations each of these have, so that the public and the environment are safe from fire, explosions, or fuel spillage. Naturally, there are strict, rules governing the movements and storage of fuel because of the risks and hazards involved. Also over the last number of years, there has been a lot of criminal activity surrounding the laundering and stretching of fuel. So therefore, I will also look at what measures have been taken to counteract this. Technology nowadays plays a huge part in monitoring our fuel supplies, giving a far more accurate picture of our national stock at any giving time. I will look at how this information, is of benefit to both Revenue and NORA. Overall, the objective of my investigation is gain a greater understanding of the hazards and regulations, involved in the storage and transportation of fuel, so that; I would be in a better position to pursue a career, in this industry either as a planner or as a Dangerous Goods Safety Advisor.Chapter 1

Haulage Operator

1:1 Operators Licence

If a person wants to open a road haulage business in Ireland, It Will have to enquire, about the need for, and the conditions of getting an operator's licence. There are very strict guidelines, which must be adhered to before the issuing of licences. Moreover, for the carriage of certain goods, you do not need a permit. The general rule is that if you are transporting goods for hire or reward in a vehicle of 3.5 tonnes or more, you will need an operator's licence. However you will not need a licence if the goods are you are transporting are your own, or you are delivering goods to customers who have purchased them from you. Also, there is a licence exemption for people who are transporting any of the following within the state, Cattle, Sheep, Pigs, Turf, Milk to the creamery, or freshly harvested oat wheat and barley between Aug 1st and Nov 30th. However, if you are carrying any of these outside the state, you will have to have an operators licence and a Community Licence.To obtain an operator's licence, and keep it valid for the 5-year duration, applicants must fulfil certain criteria, this include- Be of good repute Must declare if they have any previous convictions, and complete a Garda Vetting Form

- Have business premises in the state ( Suitable parking for vehicles)

- Healthy Financial Standing-- Financial Resources of €9,000 for the first vehicle and €5,000 for any additional vehicles, must also hold a tax clearance certificate, and an up to date accountants or auditors report or a bank guarantee.

- Professional Competence --- The operator or his Transport Manager must hold a CPC cert. There must be a least one person in the organisation that holds a CPC licence.

- National Licence €69.84 plus €95.83 for ever vehicle on the licence

- International Licence €69.84 plus €228.55 for every vehicle

1:2 Premises

Regardless of the size of the company or organisation, you will need sufficient space to operate and park up your vehicles securely.The premises will also require some form of office, workshop and employee facilities.When planning to purchase or rent a suitable site, it is important to consider the prospect of future expansion, of course, all of this is going to cost money, so it is of vital importance that you work on a good business plan, and get some sound financial advice, before making any major decisions. Also if you are planning to equip out a workshop, it can be initially quite expensive, having just a basic layout of lifts/truck pits, jacks, axle stands, tools, sockets, and a small stock of tyres, and oil could cost in the region of anything up to €30,000. Depending on the location of the premises, the amount of commercial rates will vary. The council has a formula for working this out this charge The council on their website have a link to, commercial properties valuation map, the council puts a valuation rate on each property depending on size, and location, the site I have chosen is rated at 20, and this is multiplied by the Annual Rate of Valuation. Rateable Valuation 20 x Annual Rate of Valuation 74.75 = €1495 per annum. (, Cork County Council, 2016) (, Cork County Council, 2016)1:3 Companies Registration

If starting up a new business, in Ireland, you can either operate as a sole trader or a limited company. Some businesses enter into a partnership, with somebody else, Being a sole trader, you can trade under your own name or a business name, if you choose a business name this must be registered at the Companies Registration Office. Sole traders are responsible for 100% liability, and they can't take advantage of the 12.5% corporation tax rate. They are taxed at the 20% or 40% personal income tax rates. Partnerships are where two or more people go into business together, they stand somewhere in between sole traders and limited liability companies. Like sole traders, partnerships also have 100% liability (and one partner can end up being pursued,for the debts of the other), As for limited liability companies, the liability of the business owner is limited (to the business assets). Also being a limited company, it can take advantage of the lower tax rate of 12.5%. (Companies Registration Office, 2016)1: 4 Transport Manager

A Transport Manager is a competent person who holds a Certificate of Professional Competence (CPC cert) he must be of good repute and be over 18 years of age, he must be continually engaged or employed to manage the fleet, and his details must be notified in writing to the Minister. However a Transport Manager may work for up to four companies at any given time, as long as the total number of vehicles, he is managing does not exceed 50. The function of the fleet manager is to oversee and coordinate all aspects related to the smooth operation of the transport system, which they are charged with. Be it the transportation of people or goods the scheduling of these services require great organisational skills; it is the Transport Manager who is ultimately responsible for the successful day-to-day planning and scheduling of all vehicle movements, be it for delivery or pick-up. (Gubbins, 2003)1: 5 Fleet Management

The function of the fleet manager is to oversee and look after all the vehicles and their drivers. It is the manager's responsibility to ensure that the vehicles and their drivers comply with all the regulation and legislation. He must make sure that the vehicles are well maintained and in a roadworthy condition capable of returning a profit for the company. It is he who will decide when the vehicle should be replaced and newer ones purchased, also he will have to monitor the driver's level of skill behind the wheel, to see if his driving behaviour can be improved in order to improve fuel efficiency and road safety. He must also ensure that all maintenance of the vehicles is carried out in a cost-effective manner so that the company can remain profitable and viable. As companies develop and grow the demand for extra staff and facilities will increase, this could lead to the establishment of various departments within the organisation, who would specialise in their own area. These departments are they parts, maintenance, sales, planning or accountancy would be all linked together, and supervised independently, but accountable to the general manager. Over the last number of years with the advances in computer, satellite and internet technology, software and telecommunication systems have been developed which have made the running of transport organisations much easier. Most transport and fleet operation companies will nowadays have some form of a telematic device fitted to their vehicles. This allows the planning department to keep in contact, with both vehicle and drivers constantly; they can monitor the position, speed, mileage, and fuel consumption, and start and stops times, of all their vehicles. This enables, companies, to become more efficient, and provide for safer drivers and vehicles on the road. It also helps, for the better, scheduling, of vehicles, which in turn, will provide a better overall customer service. For companies to maximise the benefits, and savings long term, they will have to, be able to bring their driver along with them, in the implementing, of any necessary changes, in work practices. Usually, the introduction, of some form of reward, or bonus, system, is used to encourage staff to reach targets. (LOWE, 2015)1:6 Dangerous Goods Safety Advisor ( DGSA)

Accordind to the regulations any company involved in the transport of hazardous goods by road, should appoint a Dangerous Goods Safety Adviser (DGSA). These companies are those who:- consign dangerous goods for transport

- are involved in,the loading, packing, filling or unloading

- Ensuring compliance and providing advice to the company

- Selecting, purchasing and approving vehicles

- Advising on, procedures with regards to the checking of safety equipment and transport equipment

- Overseeing training of personnel and the retention and maintenance of appropriate training records

- Monitoring the implementation of written emergency procedures, in the event of an accident or incident during the carriage of dangerous goods by road

- Accident and Incident Investigation

1:7 Irish Fuel Operators

The lists for Northern Ireland and the Republic of Ireland are based on tanker fleet size. Figures, January/February 2016. The Republic of Ireland| Rank | Company | Location | Number of tankers 2016 |

| 1 | Topaz | Dublin | 303 |

| 2 | East Cork Oil Co | Midleton, County Cork | 159 |

| 3 | TOP Oil | Dublin | 120 |

| 4 | Corrib Oil | Parkmore, Galway | 110 |

| 5 | Valero Marketing Ireland | Quarryvale, County Dublin | 53 |

| 6 | Jones Oil | Dublin | 40 |

| 7 | EMO ROI | Portlaoise, County Laois | 37 |

| 8 | Campus Oil | Bray, County Wicklow | 27 |

| 9= | M&J Kelleher | Macroom, County Cork | 16 |

| 9= | Ultima Oil | Kilpedder, County Wicklow | 16 |

| 9= | Glen Fuel Services | Kilmacanogue, County Wicklow | 16 |

| Rank | Company | Location | Number of tankers 2016 |

| 1 | LCC Oil | Cookstown, County Tyrone | 72 |

| 2 | EMO Oil (NI) | Belfast | 56 |

| 3 | Carlisle Fuels | Ballynahinch, County Down | 30 |

| 4 | Bangor Fuels | Bangor, County Down | 28 |

| 5 | TOP Kelly Fuels | Belfast | 24 |

| 6 | Topaz Energy (NI) | Belfast | 21 |

| 7 | Thompson Fuels | Tandragee, County Armagh | 15 |

| 8= | AH Fuel Oils | Cookstown, County Tyrone | 14 |

| 8= | Morrow Fuels | Lisburn, County Antrim | 14 |

| 8= | Patterson Oil | Craigavon, County Down | 14 |

Chapter 2

Fuel Tankers

2:1 ADR

ADR is the European agreement governing the safe transportation of dangerous goods, by road. This agreement sets the standards, or best practice, for the packaging, handling, driver training, and vehicle requirements, which the regulations are based on. Firstly, the various types of dangerous goods, are placed into different classifications and given an individual UN number. This number which is displayed on the vehicle shows the authorities, ie the Gardai and emergency crews, exactly what type of cargo is being transported, so in the event of an accident they know what action should be taken. There are nine,separate classes of Dangerous Goods, and these classes are sub-divided further to give the products an individual UN number. The nine classes are- Explosives

- Gases

- Flammable Liquids

- Flammable Solids

- Oxidizing Substances

- Toxic & Infectious Substances

- Radioactive Material

- Corrosives

- Miscellaneous Dangerous Goods

Vehicle Testing

Any vehicle, which transports dangerous goods is required by law to be certified and pass an ADR test annually. The test will only be carried out on vehicles which transport dangerous goods, and which hold a valid CVRT cert. Certificates are renewed annually, and are non-transferrable. Therefore if you purchase a vehicle with a valid cert,you must go and reapply to have it issued in your own name. The cost of a certificate is € 185 this fee is split almost 50/50 between the RSA and the test centre.2:2 CVRT

CVRT stands for a Commercial Vehicle Roadworthiness Test; this test is carried out annually on all commercial vehicles, over 3.5 GVW which are over one year old. Ambulances and buses, which can carry over eight passengers, must also be tested, accordingly. Testing is one part of a series of road safety measures, which have been introduced over the last number of years. Operators are now also obliged to keep a maintenance record, of all their vehicles. In addition, the driver is also required to carry out, a daily 10min walk about, visual check of his vehicle, to ensure its roadworthiness. There are two types of test LCV (Light Commercial Vehiclesof 3,500 kg or less GVW) HCV Heavy Commercial Vehicles The test covers all other commercial vehicles including:- goods vehicles over 3,500 kg GVW

- goods trailers over 3,500 kg GVW

- buses with more than eight passenger seats

- ambulances

- Brakes

- Lights and markings

- Wheels and tyres

- Steering and suspension

- Chassis and underbody

- Tachograph

- Speed limiter

- Exhaust emissions

- Electrical systems

- Glass and mirrors

2:3 Petrol Tankers

Typically road petrol tankers used in Ireland for the delivery of fuel to petrol forecourts are six-axle articulated vehicles. These vehicles have a capacity, to carry up 42, 0000 litres of fuel when full. The tanks themselves are bulkheads, with the larger ones, having up to six separate compartments each carrying 7, 0000 litres. These compartments can either be filled with the same or different types of fuel. The design of the tank can be either circular or elliptical. The elliptical tank has a lower centre of gravity, thus providing for better stability; also this tank will have a greater capacity than a circular tank with similar diameter. The materials used to construct these tanks are stainless steel, aluminium, FRP (fibreglass reinforced plastic) and carbon steel. These tanks can also be insulated and pressurised. They are insulated in order to minimise fuel temperature increases inside the tank, and in turn reduce fuel losses due to evaporation.2:4 Tanker Types

There are three major types of tanker used in road transport systems. These are- Bulkheads

- Baffles

- Smoothbores

2:5 Tanker Safety Concerns

A report carried out, in the UK by the Transport Research Lab for THE Dept of Transport showed worrying concerns in relation to tankers which had undergone testing for ADR certification. A number of these tankers were inspected afterwards by the research team, who radiographed the welding joints in the tanks. In a number of cases the joints around the circumference of the tank were found to be lacking fusion, and as a result it is feared that in the event of a roll-over, that the welds might completely rupture, leading to a major spillage, and possible fire or explosion. Even though rollovers are considered very rare, the consequences of having a rollover with spillage could be catastrophic. So it's for this reason that the findings are so concerning. Many of the 220 tankers in question, which were incorrectly certified, were manufactured outside the EU, mostly in South Africa. The research team then decided to construct and carry out a topple test on these tankers, in order to quantify the damage that would be caused, and it was proved that leakage would occur. The results were brought to the attention of the Health and Safety Executive, who notified the Govt, their response was to have any of these tankers repaired or withdrawn, and giving them a lifespan of 12 years. (Laboratory, 2014)Chapter 3

Petrol Forecourt

3:1 Site Operators

The site operator is responsible for carrying out a risk assessment, and providing the necessary measures to ensure that the site is as safe as is reasonably practicable. Under Irish and EU legislation, the employer has a duty of care to his employees, customers and visitors to his premises. To carry out this assessment effectively, a thorough examination of the site layout, equipment and work practices must take place by a competent person, who will compile a list of any potential hazards, their severity and the risk involved. A hazard is defined as, being something that has the potential to cause harm, e.g. fire and electricity, chemicals, working up a ladder, excessive noise, prolonged keyboard use, bullying, stress, etc. A risk is a likelihood, of a hazard causing somebody harm. In order to fully complete the assessment, it must also include what measures are recommended to address these hazards and in what time frame. This assessment must be written out clearly, updated, and reviewed periodically, at least on an annual basis. It also must be made available to inspectors from the Health and Safety Authority, and a copy should be left somewhere in the workplace that employees can easily access it to read its contents. After the risk assessment is completed, the employer needs to write up a Safety Statement in which he outlines his commitment to implementing the required changes which will reduce hazards and decrease the risk of injury,or illness in the workplace. This document also informs the employee of his or her responsibility in the prevention of accidents and of the importance of reporting accidents and near misses. The objective is to get everybody on board by making them conscious of the importance of a safer working environment. Accidents have significant costs, be it in reduced production, compensation claims, increased premium costs, broken machinery or possibly even the closure of the business, it is therefore in everybody's interest to seek to prevent them. ( Health and Safety Authority, 2017)3:2 Petrol Forecourt Licensing

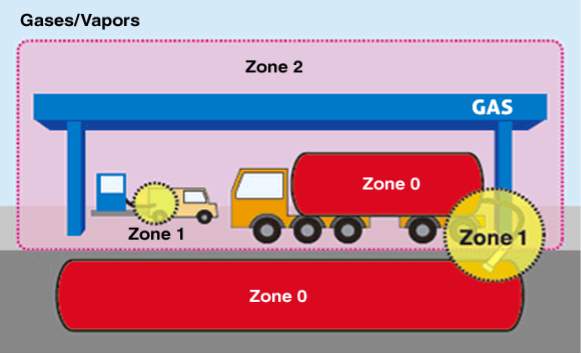

Great care has to be taken in the operation and design of petrol forecourts so that major accidents can be prevented. In order to obtain a licence for the operation of a Retail and Private Petroleum Store, you must satisfy the conditions which are set down in the legislation governing the storage of Dangerous Substances. The drawings or plans (blueprint) of the site, showing the layout of the buildings and the size and positioning of the storage tanks, petrol pumps and the tanker delivery area must be submitted to the Local Authority for inspection. Before any licence is granted, you must receive the approval of the Chief Fire Officer who will assess the risks of a fire or an explosion occurring and of any danger that may be posed to the public. The granting of a licence is discretionary so therefore the authority will be very interested in seeing how serious and committed you are in relation to issues of health and safety. An up to date safety statement and risk assessment should be available for inspection with records of any accidents and near misses that occurred in or around the forecourt, it should also highlight what measures you have taken to prevent a reoccurrence of these incidents. One of the main reasons why licences are still granted on a discrestionary basis is because many of our petrol stations pre-date 1979 and are known as Kerbside dispensers. In a lot of cases because of their location it would be far too costly for to re-design the site, replace underground storage tanks and install modern venting systems that fully comply with modern regulations. In order to reduce the risk of a fire or explosion occurring, all service stations are zoned into three different categories' according to the frequency and duration of the presence of petrol vapour. (Council, Limerick County Council, 2016)3:3 Hazardous area Zoning:

Hazardous area Zoning: The three zones are- Zone 0: An area in which explosive gas vapour,is present for long periods;

- Zone 1: an area which explosive gas vapour is likely to occur in normal operation;

- Zone 2: An area in which gas vapour is not likely to occur in normal operation, and, if does it will only exist for a short time.

Figure 1 Zoned Areas

Figure 1 Zoned Areas

3:4 Auto Fuel Traders Licence

As a means of combatting the sale of laundered diesel and contaminated petrol, the Irish Revenue Commission with the assistance of the Irish Petrol Retailers Association came up with a set of proposals which were introduced in October 2012. The measures included the introduction of a new licensing system for fuel traders. The new system requires retailers who wish to sell petrol or diesel for road vehicles to obtain an Auto Fuel Traders Licence and if they want to also sell agricultural diesel they must hold an additional Marked-Fuel Trader's Licence. Revenue have introduced certain conditions that all applicants must adhere to before a Licence can be issued, they are:- The premises which the person holds a Marked-Fuel Trader's Licence must be secure and suitable for the sale, delivery of the mineral oil to the satisfaction of Revenue.

- The Fuel Trader shall provide safe and secure means of access for inspection by Revenue Officers

- All fuel sold at the premises, must be dispensed using fuel pumps that accurately measure and record the volume of fuel dispensed.

3:5 Monthly Return of Oil Movements (ROM1)

This is another system, which was put in place in January 2013 by Revenue to monitor the movement of fuel in and out of retail outlets. Traders are now obliged to submit monthly records of the sales, deliveries and quantities of fuel they have on their premises. All these figures can be collected and submitted electronically. Initially traders were disgruntled at the prospect of being required to pay additional licensing fees and having to send their fuel sales data on to revenue. But when they finally began to realise the full impact of contaminated fuel on their industry and to their profit margins they soon became supportive of the new requirements. All fuel transfers and quantities stored in petrol retail outlets are monitored in what is known as a Wetstock Management System. It is these figures as well as the numbers they get from the refinery and other terminals that import fuel that Revenue depend on to monitor the consumption and movement of all fuel in the state. These data are very useful as if Revenue detect any unusual deliveries or sales of larger quantities of fuel then they can be able to examine it quite easily. ( Inland Revenue, 2013)Chapter 4

Storage Tanks

4:1 Underground Storage Tanks

Retail fuel outlets in Ireland store their fuel in underground storage tanks; these tanks have the capacity to hold anything between 40,000 and 50,000 litres of fuel. The larger petrol stations could have three or four of these tanks on site, so therefore it's essential that the highest possible safety standards are observed. The major hazards associated with these tanks are the risk of explosion and leakage; if leakage occurs as a result of corrosion or damaged fittings, the fuel will contaminate the immediate surrounding soil, and also pose a greater risk to our health and the environment if it enters the water table. Also the flammable vapours from the saturated soil will eventually make their way to the surface, and then could possible enter buildings through drainage systems, where it could be easily ignited. There are some practical precautionary measures that the Local Authority will take into consideration before granting planning permission for the construction of new petrol retail outlets. These include the location of the site and suitable access and exit points for vehicles, and also in the event of leakage or spillage that the tanks are not positioned too close to a river or a stream. Older tanks tended to be made from mild steel, but over time these were very prone to corrosion from rust so therefore additional measures have to be taken which will help combat this, and minimise the damaged that would be caused by any leakage occurring. ( The Texas Commission on Environmental Quality, 2009)4:2 Protection

Some of the methods of protection used are:- Prior to installation of the tank, it is coated with a rust inhibitor

- Doubled skin tanks are used instead of single skin

- Tank is placed within a bund

- Cathodic Protection

- Installation of a non-corrodible material like plastic or fibreglass tanks

4:3 Bund:

A bund is an enclosure that is build around a tank. It consists of four walls and a base that will contain any fluid in the event of a leak occurring. The bund is generally constructed from either reinforced mass concrete or concrete blocks. Block constructions tend to be less effective because cracks and weakness are likely to occur in the joints over time. For bunds to be effective, they must be capable of retaining certain volumes of liquid, in the case of a one tank system the bund must be able to hold 110% of the tanks volume. If the system has two or more tanks in the bund, then the rule is the bund must have the capacity to hold 110% of the largest tank or 25% of the total tank volumes whichever is the greatest.(Efficiency, 2016)4:4 Size of Tank

With the rise of modern technology, nowadays petrol storage tanks can be made to order and fit the customer's specific requirements. Depending on the size of the outlet, market conditions i.e. sales of diesel and petrol cars, fluctuating fuel costand supply uncertainties. All of these conditions will impact on the operator's decision of the volume and types of fuel he requires. He will also have to have the capacity to be able to hold a certain amount of backup or reserve fuel on site. Modern tanks can be made in a variety of sizes to order also the tank can be divided into different compartments, so that different fuel types and grades can be stored in the one tank. Some tanks hold up to 80,000 litres of fuel. (U.S. Environmental Protection Agency, 1996)Chapter 5

Tank Testing

5:1 Pressure Testing

Regardless of what type of anti-corrosion measures that are taken, underground storage tanks have to be continuously monitored and tested for any signs of and leaks All tanks and fittings over 20 years old must be pressure tested prior to being granted a licence and and tanks over 30 years old must be tested by a specialist annually. To perform a pressure test, the tank must be sealed off and taken out of use, it is then pressurised to a low psi and the pressure is monitored over a 24 hour period. A drop in pressure indicates the presence of a leak. Some tank manufacturers don't recommend this type of testing procedure, while some operator owners will also avoid it for fears the test will prematurely burst a tank which is about to fail. This is debatable because the pressure being used for the test is significantly lower than the tank is subjected to during operation and deliveries. The main advantage of this method is that it is simple to perform, and also it can check the condition of any connectors or pipework in the system.5:2 Other Methods of testing include

- Soil Testing

- Electronic Testing

- Ultrasound Scanning

- Water Testing

- Filter Testing

- Visual Inspection

5:3 Automatic Tank Gauging Systems

It is only over the last two decades that the public and the authorities have started to take environmental pollution issues seriously. Prior to this, the only concern an operator had if his tank was leaking was the financial loss of his stock. Nowadays with tighter regulation in place the operator is responsible for the clean up of any pollution occurs because of his negligence. He is liable for the cost of the removal and repair of any damaged tanks and also the expense of having the contaminated soil excavated and send away for decontamination. Also as a result of pollution the operator might have difficulty in getting his licence renewed and and this ultimately could lead to the closure of his business. These new tougher regulations have also given rise to the development of new industries which specialise in the monitoring of leak detection systems. Most modern tanks in use today are fitted with some form of a electronic Automatic Tank Gauging System that has sensors mounted on the tank and can send signals to a nearby easily accessible control panel. The information being sent indicates any changes in pressure, temperature or volume of stock and triggers an alarm if the readings suddenly change. ( Californa Enviromental Protection Agency) Regardless of what action or precautions are taken, accidents will still happen. However, if all operators follow the correct procedures and abide by the regulations, we lessen the risks of accidents occurring. It is essential that all accidents and leaks are treated straight away so as to minimise the amount of damage that could be caused. These accidents should be fully recorded and reported to the local authority so that they can be fully investigated. Additionally, appropriate measures should put in place to prevent similar occurrences in the future.Chapter 6

Tanker Drivers

6:1 ADR DRIVER TRAINING AND HAZCHEM CERTIFICATION

Under EU law any driver involved in the transportation of chemicals, or other dangerous goods, must be ADR/HazChem certified. In order to become certified the driver must, pass an exam, after completing a 5-day training course. Three of the days, will be spent, doing basic training, and an additional two days, will be devoted to tanker training. Once passed the certification, is valid for 5 years, and recognised throughout Europe. Certification can be extended, if the driver takes a refresher course in the final year. The whole purpose of the training is to educate the driver on the proper, proven procedures involved in transporting dangerous goods, and also that the standard is the same right across Europe. In Ireland the regulations are administered by the HSA, and the driver exams are facilitated by The Chartered Institute of Logistics and Transport.6:2 Petroleum Drivers Passport

The Petroleum Drivers Passport (PDP) is a certificate of competency that was initially set up by the UK petroleum industry in order to improve fuel handling at terminals and refineries. The initiative which had gained the backing of the UK government has now become a mandatory requirement for petrol tanker drivers to hold since January 2017. In order for a driver to obtain a passport he must undergo a training course and pass both a written and practical assessment, the purpose of this is to ensure that all drivers engaging in the transportation, uploading and delivery of fuel will have all reached a certain level of safety standards. It also provides the terminal operators with a system of proof that the drivers entering the terminal or refinery are all competent and fully trained. The PDP is valid for 5 years but in order to maintain their PDP, drivers must undergo an annual refresher course and a practical assessment. This is an entirely separate certificate from CPC or ADR and while it has not become mandatory in Ireland as of yet, the HAS are seriously considering it and and the refinery under its new owners like to see drivers who have it. The passport or PDP applies to drivers carrying the following products- UN 1202 — Gas oil or diesel fuel or heating oil, light

- UN 1203 — Gasoline or petrol or motor spirit

- UN 1223 — Kerosene

- UN 1863 — Fuel, aviation, turbine engines (Authority, Scottish Qualifications Authority, 2017)

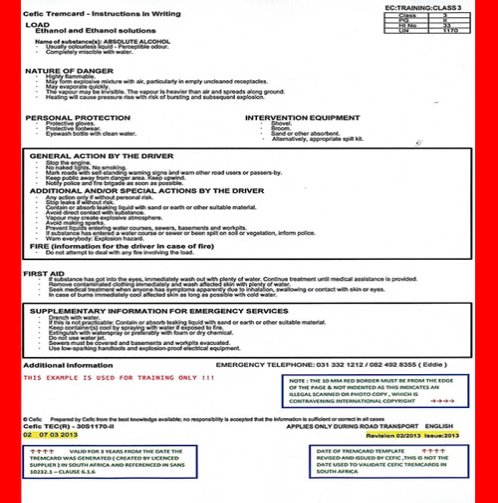

6:3 TREM Card

A Tremcard or a Transport Emergency Card is used when transporting dangerous goods. The card contains information about the vehicles load. In an emergency, this information is vital to the emergancy services,in order to treat the load correctly. If the vehicle is transporting multiple types of dangerous goods, then a seperate Tremcard will be required for each item.A Tremcard is an A4 sized document, with a thick red border. This is,so that it can be identified quickly, in an emergency situation. It should be located in the cab of the vehicle when it is carrying a dangerous load. Figure 3 Trem Card (Hazchemwize, 2016)

Figure 3 Trem Card (Hazchemwize, 2016)

6:4 Drivers Hours

In order to improve and maintain safety on our roads, the government, under the direction of the EU introduced legislation, governing the number of hours a HGV driver can safely work on a daily and weekly basis. The hours are as follows Daily driving is not to exceed 9 hours, but it can be extended twice a week to 10 hours. Maximum of 56 driving hours weekly, and no more than 90 hours in a fortnight hour. A driver must have a daily rest period of at least 11 hours, on exception this can be reduced to 9 hrs but no more than three times, in any given week. The daily rest can be split into a 3 hour and a 9 hour period. Must be a weekly rest period of 45 continuous hours,to be taken after six days of working, this can be reduced every second week to 24 hours. A 45 minutes break should be taken after 4 ½ hours driving. (Road Safety Authority, 2015)6:6 Petrol Deliveries

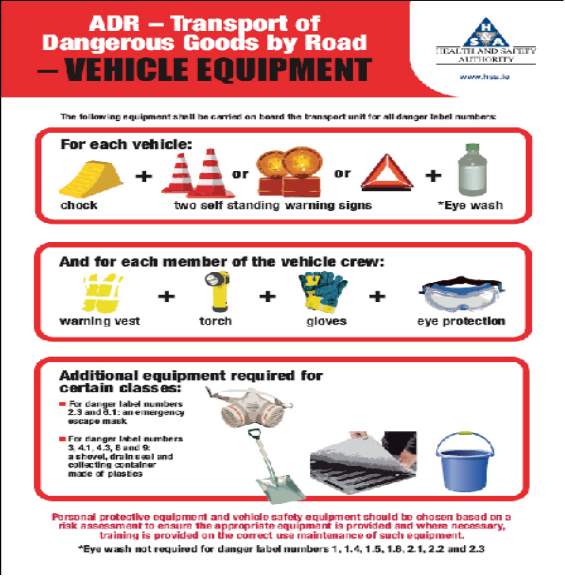

The delivery, dispensing and storage of petrol in filling stations pose a very serious threat of fire and explosion in the forecourt which could result in severe injury and damage unless safety procedures and guidelines are strictly followed. There is necessarily a lot of regulation and legislation surrounding this area because of the potential hazards and risks involved. Petrol is highly flammable; it can be ignited if it is exposed to even the slightest spark from any electrical source, be it a light switch or even a mobile phone. It can also ignite if the petrol vapour comes into contact with direct heat sources such as cigarettes or matches. Petrol vapour can create significant problems: it is heavier than air and because of this, it travels along very close to the ground and could easily fill up and ignite in basements, or travel down drains to contaminate our environment, or indeed pollute our water supply. Therefore, spills, leaks, and ignition are the three major safety concerns, which one must consider and prevent in the unloading of petrol from petrol tankers. For this reason, it is crucial that suppliers, drivers and site operators co-operate together to help reduce and eliminate the risk of serious accidents occurring.All fuel tanker drivers are highly skilled and well trained so they are very conscious of the hazards and what safety measures should be taken during the delivery process. If the delivery is being made to the petrol station during normal business hours they receive a message from the haulage company indicating an ETA (expected time of arrival) which allows the station ample time to prepare a safe area for the truck. Once arrived and parked up, the driver cordons off the delivery area, lifts up the manhole covers, identifies tanks, checks all hoses and connectors and verifies the ullage in each tank. Once the driver is satisfied, he can begin dispensing the fuel into the appropriate tanks. On completion the driver will be able to print out a delivery docket for the site operator, showing exactly the types of fuel and the quantities which were delivered. The main hazards associated with deliveries are the risks of spillage and overfilling. This is why the verification of ullage figures is so important. Ullage is defined as the difference between the maximum tank volume and the actual tank contents . Figure 4 Vehicle Equipment

. Figure 4 Vehicle Equipment

6:6 American Petroleum Institute (A.P.I)

Since 1924, the A. P. I have been establishing and maintaining standards for the oil and natural gas industry. With over 90 years experience, testing the equipment, and work practices used throughout the industry. The standards, they have set down are recognised worldwide as being best practice. In relation to fuel deliveries the institute has recommended the colour coding of delivery hoses and tank connections in order to eliminate the risk of cross contamination and the wrong fuel entering the tank. Also the A.P.I has tested, and set the standards, for the type of connector valves that are safe to use. These connections have been pressure and leak tested. (American Petroleum Institute, , 2017)Chapter 7

Refining and Reserves

7:1 Refining

The purpose of refining is to separate hydrocarbons. This can be achieved relatively easily with crude oil, because the molecules present, have different boiling points. Hydrocarbons that have different boiling points, also contain different chain lengths, and as a result have different properties, once treated they can either be solid, liquid or gas at room temperature.- Small hydrocarbons with only a few carbon atoms, have a low boiling point, and therefore are gases.

- Hydrocarbons with between 5 and 12 carbon atoms, are liquids.

- Large hydrocarbons with many carbon atoms, and have high boiling point, and are solids.

Figure 5 Refining Process So in order to separate the hydrocarbons, all we have to do is add heat to the oil, and allow it to evaporate. Because of the different boiling points of the hydrocarbons present, they will vaporise at various temperatures up a stack or a colum.There the vapours will cool and condense, at various levels and the hydrocarbons of similar size and properties will be drawn off together. The smaller lighter hydrocarbons will rise to the top, giving off products such as Butane and Propane gas. The heavier hydrocarbons, which are liquids, and give us products like petrol, diesel and paraffin are drawn off in the centre portion of the stack. The heaviest of the molecules that are drawn off at the bottom of the stack, have a very high viscosity, and give us products like asphalt, and shipping fuel. Below is a list of the products that come from crude oil

Figure 5 Refining Process So in order to separate the hydrocarbons, all we have to do is add heat to the oil, and allow it to evaporate. Because of the different boiling points of the hydrocarbons present, they will vaporise at various temperatures up a stack or a colum.There the vapours will cool and condense, at various levels and the hydrocarbons of similar size and properties will be drawn off together. The smaller lighter hydrocarbons will rise to the top, giving off products such as Butane and Propane gas. The heavier hydrocarbons, which are liquids, and give us products like petrol, diesel and paraffin are drawn off in the centre portion of the stack. The heaviest of the molecules that are drawn off at the bottom of the stack, have a very high viscosity, and give us products like asphalt, and shipping fuel. Below is a list of the products that come from crude oil

- Liquid Petroleum Gas (1-4 Carbon Atoms) Butane/Propane 20 C Boiling Point

- Naphtha Gas (5-9 Carbon Atoms) Further Processed 70 C Boiling Point

- Petrol (5-12 Carbon Atoms) Petrol 120 C Boiling Point

- Kerosene Gas (1-4 Carbon Atoms)Aviation/Heating 170 C Boiling Point

- Diesel (12 or more Carbon Atoms) Diesel Fuel 270 C Boiling Point

- Lubricating Oil (20-50 Carbon Atoms) Lubricating/Waxes/Polishes 290 C Boiling Point

- Heavy Fuel Oils Gas (20-70 Carbon Atoms) Ships/Power Stations 300 C Boiling Point

- Residual Gas (70 or more Carbon Atoms) Asphalt 350 C Boiling Point

7:2 NORA

NORA, which stands for the National Oil Reserves Agency, was set up in 1996, after a directive from the EU. Its function is to provide storage, and hold a 90 day supply, based on the previous year's imports, of the country's oil requirements in reserve stock. Stocks may be held in Ireland, or in countries with which Ireland has an Oil Stocks Agreement. NORA currently stores – Petrol, Diesel, Gas Oil, Kerosene, and Jet Fuel in oil storage depots in Dublin, Whitegate Refinery, Whiddy Island, Foynes, Tarbert, Galway, Derry, and Kilroot. Stocks held abroad are held in key locations in the UK, Denmark, Holland and Spain. Currently, NORA holds c.73% of its total oil stocks in Ireland, and the balance abroad.NORA is funded through a levy on the sale of fuel, currently this levy stands at 2 cents on every litre sold. All of Ireland's oil is imported,our dependency,in 2013 was the fourth highest in the EU. Imports of oil cost us an estimated €4.4 billion annualy. Prior to 2009 the majority of our crude oil came from the UK and Norway. Nowadays,we have significant imports from North and West Africa, reflecting the global nature of the international crude oil market. Over 70% of oil used in Ireland in 2014 was for transport. 97% of energy used in the transport sector was from oil based products. (NORA, 2017)Chapter 8

Fuel Quality

8:1 Contaminated Fuel

In Ireland a few years ago there was an upsurge in the incidence of reported cases of motor fuel being contaminated or tampered with, by criminals and rouge traders. The two types of contamination, which were occurring all over the country, but mostly in border regions, were petrol stretching and diesel laundering. Putting contaminated fuel into your vehicle can cause severe engine damage.8:2 Petrol Stretching

This is when, in order to increase the volume fuel, there are cheaper types of fuel blended with the petrol and sold off to the unsuspecting retailer and on to the customer as a genuine product. The fuel which is normally blended with the petrol is the heating oil kerosene, but illicit traders have also been known to add methanol, and ethanol which is essentially paint thinners. There can be up to 10% kerosene added to the mix. On a 10, 000 litre delivery of petrol traders can make an extra €700. In order to prevent this, drivers have to be vigilant and buy their fuel from a reputable retailer. The Irish Petrol Retailers Association (IPRA) members, in order to partake in the quality assurance scheme, have to sign up to and agree to the random testing of their supplies. Some of the warning signs of bad fuel are:- Lack of power,

- Engine misfiring,

- Engine knocking

- Check engine light on

- Fuel Varnish

8:3 Diesel Laundering

Diesel fuel falls into two separate tax rates. The lower of these rates applies to the sale of diesel for off road vehicles used in the agriculture, construction and the forestry industry. The higher rate of tax is imposed on diesel for all other road vehicles. Thus, in order to distinguish between the two fuels so that the appropriate tax could be imposed, a dye was added to the cheaper one. This fuel is commonly known as agricultural diesel and because of the huge difference in the pump price of the two fuels, the practice of removing the dye, either by using an acid or by passing it through filters, some as crude as cat litter or bread, from the cheaper agricultural fuel and then selling it off as a road fuel became known as diesel laundering or washing diesel. Over the years, an enormous criminal industry especially around the border counties was built up around the practice of diesel laundering. Like stretched petrol laundered diesel can cause severe damage to engine components, particularly to the fuel delivery system. Diesel is a lubricant and these lubrication properties are removed during the laundering process, so any parts in the high-pressure pump that normally would be lubricated will inevitably suffer and require a costly repair, which insurance companies are reluctant to cover and if they do you will lose your no claims bonus. The onus is on the motorist to be careful where he purchases his fuel from; he should always get it from a reputable and trusted source. If a person feels they have been sold contaminated fuel, then they should contact the retailer and let them know. If they don't get any satisfaction they can send a sample away for independent testing and if it returns positive i.e. it is contaminated, they should notify the Gardai and Revenue. The practice of fuel laundering and petrol stretching, used to impose significant costs on the state each year because of lost revenue and the clean-up costs associated with the disposal of the laundered waste material. However, great strides, have been made in recent years in reducing these excessive costs.8:4 Lost Revenue (The Irish Times, 2011)

In 2011, it was estimated that there were up to 150 petrol stations around the country selling illegal fuel. Indeed, one local politician in Co Meath reckoned 15 to 20 stations were operating in his constituency alone. This practice had a detrimental effect on legitimate businesses whose turnover diminished significantly. As soon as the authorities would shut down one operation, another one would reopen and takes its place. It became very difficult to stamp out these operations, partly because of the lack of co-operation and regulation at the time and because of the economic climate, which saw high levels of unemployment, which greatly increased the temptation of cheaper fuel to hard-hit consumers. The AA, at the time, estimated that up to 10% of the total diesel sold in Ireland was laundered and this could be costing the state up to €300 million annually in lost revenue. The laundered fuel used to be transported around the country to depots in concealed tankers; some of these were disguised as cattle trucks or lorries, that had separate tanks fitted to underneath false bottoms. The capacity of these tanks would be in the region of six to eight thousand litres. In February 2011 Customs and Revenue officers in Galway assisted by Gardai arrested two men who were delivering laundered diesel to a retail service station from a concealed tank hidden in a Northern Irish registered cattle truck.8:5 Toxic Waste

The disposal of the waste material associated with diesel laundering has cost local authorities a considerable amount over the last few years. Figures from the revenue commission said it cost in the region of €6.7 million between 2008 and 2015 to clean up the toxic sludge which was left behind, mostly in the Monaghan and Louth areas. Fuel laundering in Ireland has been going on for a number of years, but reached its height in 2012 when there was a massive increase in the amount of pop up service stations which were selling cheaper contaminated fuels. These fuels began to cause widespread damage to customer's vehicles and also to the profits of legitimate petrol retailers. Once the media became alerted, politicians had to sit up and take notice and it was then that the Revenue Commission set about tackling this problem for once and for all. Some of the measures taken are listed below:- Working more closely with the UK government in relation to cross border criminal activity

- New marker system which is more effective to be used in both countries

- Supply Chain controls, which allow Revenue to calculate the quantities of fuel that have been imported into the country and what has been sold at the pumps

- Licensing of Petrol Retailers which resulted in the closure of a number of pop up forecourts

- 2012 Auto Traders Fuel Licence introduced

- 2013, all fuel traders are required to make electronic returns to Revenue of their monthly fuel transactions. This makes it difficult for fuel criminals to source marked fuel for laundering.

8:6 Fuel Testing

As we have seen, motorists who purchase laundered diesel run the risk of causing serious damage to their engines and the use of this diesel is likely to make any warranty claims void. So, in the last few years we have seen a number of laboratories around the country becoming involved in testing both petrol and diesel for contaminants. The motorist themselves can purchase a kit to get their own samples tested, or the retailer can have a test carried out on the arrival of his deliveries. The IPRA (Irish Petroleum Retailers Association) has the requirement of testing as part of its criteria for membership. This gives the customer quality assurance guarantees, that if they use filling stations that display their logo then they know the fuel is safe to use. All tests are performed as per Institute of Petroleum guidelines and results compared to the EU, British and Irish Standards. ( Irish Petrol Retailer's Association, 2017). If consumers wish, to have their own fuel analysed independently, then there a number of laboratories, around the country, who will carry out sample tests. JHG Analytical Services Ltd in Co Waterford is one such company, have been in business for over 25 years. They carry out tests on a wide variety of products, but and are regarded as being, particulary very accurate and reliable in relation fuel analysis.Chapter 9

Wetstock Management

9:1 Wetstock Management System.

Petrol retailers are legally obliged to have up to date records of the quantities of wet stock (i.e. fuel) that they have stored on their premises. The two reasons for this legal requirement are firstly, to satisfy the local authority licensing criteria which see accurate wetstock controls as a vital indicator in the early detection of any fuel leaks from the tanks or delivery pipes into the surrounding soil and possible polluting of the water supply or becoming a vapour hazard. Secondly, the Revenue Commissioner needs the figures so they can monitor the transfer of fuel, both in and out of the station, to aid in their attempts to combat any illegal activity. Wetstock are not useful solely to fulfil legal obligations: the petrol retailer needs this information at his disposal so he can plan and make decisions according to what he has in stock. Wetstock or the quantities of fuel in a tank can be measured electronically, mechanically or manually. Most modern tanks and fuel dispensing systems nowadays have an electronic monitoring and leak detection system incorporated, which can give a very accurate reading of the total daily fuel sales. Accurate daily readings will give early indications of any losses. Losses can occur for a number of reasons:- Leakage

- Evaporation

- Theft

- Overfill

- Inaccurate pump calibration

- Spillages

9:2 Dipstick Readings

Both older and newer tanks can be read using a dipstick; however, some of the older tanks are solely dependent on this method of fuel monitoring which is not as accurate as the electronic system. In order to get the best possible results and be as accurate as possible, to detect early losses, it is important that the readings are taken at the same time every day, which is typically at the start and finish of trading. Any deliveries which have been made during trading hours must also be included in these records, so the retailer will be able to subtract the quantity of his end of day sales from his tank stock. If the readings don't correspond as they should do, then he knows there is a problem in the system which will require further investigation. In order to carry out a proper dipstick reading, the operator must ensure he is using the dipstick that is specific to that particular tank. The dipstick must be made from a non-sparking material, and if it is wooden, it should be varnished in order to prevent petrol creep, thus giving a false reading. The operator must also ensure that the stick is not damaged at the end or warped and the figures must be clearly marked. If the measurements are in imperial gallons, then they must be converted to litres by multiplying the total by 4.54. The dipstick should be lowered gently into the tank until it reaches the bottom. No additional or excessive force should be used as this would cause the stick to bend and therefore give an inaccurate reading. Once the reading is taken it should be recorded. Sometimes it is difficult to accurately read the stick but this can be overcome by applying a fuel finding paste to the dipstick before the test begins. This paste which is similar to water finding paste changes colour once it comes into contact with petroleum. Records must be kept permanently and the contents of each tank must be recorded separately. If a delivery is due on the day, then a reading should be taken before and after, however, it is important to realise, that in order to get an accurate post-delivery reading, a 5 minute waiting period should be allowed after the disconnection of the delivery hoses for the fuel in the tank to stabilise.Petroleum Classes

Petroleum classes are defined as follows

• Class I Petrol • Class II Kerosene/paraffin • Class III Diesel/DERV/Central Heating Oil (Authority, Health and Safety, 2017)9:3 Overfill and Spill Prevention

Other than ignition, the main hazards associated with deliveries are the risks of spillage and overfill. In order to prevent this happening, underground storage tanks are fitted with, overfill alarms, automatic shut off, and spill buckets. Overfill alarms, are used in conjunction with an automatic shut off or a flow restrictor that has been set to operate at 95% or more of tank volume. The alarm is triggered when the tank reaches a level of 90% of its volume. An automatic shut off operates by using a float and flapper principle. As the tank is being filled, a float which is attached to a flapper on the inlet tank connection will continue to rise, until it reaches a preset level and cuts off the supply. A spill bucket is located, where the filler hoses connect to the tank. These are specifically designed, to capture any leaks from poorly fitting connections, and also any drainage from the hoses when the tanker pumps are shut off. A spill bucket also contains a drain plug, which can be opened to allow the fuel to go back into the tank. These have to be inspected and cleaned regularly, and any debris and water should be removed before the delivery begins. Spill bucket vary in size, from 40 to 100 litre capacity, this has the potential to cause a considerable amount of damaged if it leaks into the soil, or if its water and seeps back into the tank so ongoing maintenance is vital. The cleanup costs associated with a fuel spillage could easily run into thousands, and if the groundwater was to become contaminated this could easily be hundredths of thousands, and possible close down the business. Another overfill prevention method is accurate ullage figures. Ullage is defined as the difference between the maximum tank volume, and the actual tank contents. Once the driver has verification of these figures, and with modern electronic metering systems overfilling should be eliminated. ( TEXAS COMMISSION ON ENVIRONMENTAL QUALITY, 2014)9:4 Petrol Interceptor / Oil Separator

A petrol Interceptor is an underground filtering tank, that has the ability to treat any surface rainwater that has run off a petrol forecourt.This water is very prone to contamination,because, there will always be a certain amount of spillage,on to the ground, as people top up their vehicles.When it rains this fuel will be washed away,but it cannot be allowed to enter the drains and on into the water supply,without being treated first. This is done by the water entering a specially designed underground tank which facilatates the separation of the harmful deposits in the water.The sludge or sediment will settle at the bottom of the tank,while any fuel will rise to the top, the water which is now separeted to the centre is allowed to drain off into the soil.An alarm indicates when the tank is full,and then the contaminated contents can be removed and taken away for proper disposal. (Martin Muckett, 2007)9:5 Vapour Recovery

Petrol gives off vapours, which can be extremely dangerous if ignited, these vapours are also cause of major concern to our environment, because they contain volatile organic compounds (V.O.C). These compounds are pollutants because there are known to cause damage to the ozone layer, and therefore contribute to climate change. The vapour also contains benzene, which is a carcinogen, and this is a serious risk to public health. Also over time the loss of these vapours, could also significantly impact on the profits of the retailer. So in order to limit these lossess,and eliminate our exposure to the health and environmental hazards, the legislation now requires that the delivery of fuel goes through a two stage process of vapour recovery. STAGE 1 Stage 1 vapour recovery (VR1) at petrol stations reduces the level VOC emissions, that occur during the unloading of petrol from a road tanker,into the storage tanks.During the transfer of petrol from the delivery tanker to the storage tank,there is a build up of pressure which displaces the vapour insdide the tank. This vapour is captured and returned to the delivery tanker by means of a seperate hose, called a vapour return pipe Stage 2 Stage 2 vapour recovery is the capturing of the vapours that occur, as a result of the motorist refuelling his tank. As the fuel enters the tank this displaces the vapours inside which try to escape out the filler pipe. These vapours are captured and returned to the storage tank,through a special channell or hose designed into the fuel pump delivery nozzell. (Association, 2015)Conclusions

The main aims and objectives of my report was to study the movements and storage of fuel here in Ireland. With an estimated 1250 fuel tankers operating throughout the country on a daily basis, the government imposes strict regulation, so that the risk to the public and the environment will be kept to a minimum. We have been fortunate here, because there has never been, a major incident involving the combustion of a road fuel tanker. However there has been some minor traffic incidents, throughout the years, with no serious consequences. Unfortunately, we did have a major catastrophe involving fuel in 1979 when the French registered oil tanker, Betelgeuse caught fire and exploded off Whiddy Island in Bantry Bay killing 50 people. If there, was an accident involving a fuel tanker on our roads, then the consequences could be far more serious. In order to prevent this type of scenario occurring, Ive learnt through my research, that there are strict regulations been applied to everyone involved in the delivery chain. In recent years the regulations have become even stricter, because of the tampering of fuel by criminals. Even before a haulage contractor will get an operator's licence, he must prove himself to be of good repute, and of a healthy financial standing. He must have all his vehicles checked periodically, to ensure that they are properly maintained and road worthy.He also has to keep a record of his drivers hours, and make sure he is suitable qualified to drive the vehicle he is in charge of. The Haulage company, must employ someone in procession of a CPC licence, and depending on their size and the type of goods there carrying a Dangerous Goods Safety Advisor. I also looked at the obligations and the requirements of both the driver and the petrol forecourt retailer. In relation to the driver, I learnt in addition to having a HGV licence, he will also have to obtain a ADR licence, and a drivers passport. The retailer will have to ensure that the storage tanks are secure and not leaking and that the site is safe and meets the requirements set down by the County Council in order to get a fuel traders licence. He is also obliged to return his fuel stock and sales figures, to revenue on a monthly basis, and have his tanks checked periodically for leaks. Since the introduction of closer monitoring of fuel stocks by revenue, there has been a significant reduction of the incidence of reported fuel tampering by criminals. Overall, my report shows the importance of having tight regulation, surrounding the movements, of this dangerous substance, so that the public, the environment and the consumer is protected in the best possible way. ReferencesWorks Cited

Californa Enviromental Protection Agency. (n.d.). Understanding Automatic Tank Gauging Systems - NWGLDE. Retrieved March 17th, 2017, from https://www.nwglde.org/downloads/CA_ATG_PDF.pdf European Commission. (2016). Dangerous goods - European Commission. Retrieved APRIL 3RD, 2017, from https://ec.europa.eu/transport/road_safety/topics/dangerous_goods_en Health and Safety Authority. (2017). Petrol Stations - Health and Safety Authority. Retrieved Feb 20th, 2017, from https://www.hsa.ie/eng/Your_Industry/Petrol_Stations/ Inland Revenue. (2013). New Monthly Return of Oil Movements (ROM1) - Revenue. Retrieved Jan 12th, 2017, from https://www.revenue.ie/en/tax/excise/mineral-oil-traders/rom1.html Inland Revenue. (2016). Auto-Fuel Trader's Licence - Revenue. Retrieved Jan 12th 2017, from https://www.revenue.ie/en/tax/excise/mineral-oil-traders/auto-fuel-traders-licence.html Irish Petrol Retailer's Association. (2017). IPRA. Retrieved Jan 9th, 2017, from https://www.ipra.ie/ TEXAS COMMISSION ON ENVIRONMENTAL QUALITY. (2014). Preventing Petroleum Storage Tank Spills and Overfills. Retrieved Jan 1st, 2017, from file:///C:/Users/PETER/Downloads/rg-475e-9.16%20(3).pdf The Texas Commission on Environmental Quality. (2009). Protecting Petroleum Storage Tanks Against Corrosion. TEXAS: The Texas Commission on Environmental Quality. United States Environmental Protection Agency. (2016). Leaking Underground Storage Tanks Corrective Action Resources. Retrieved March 10th 2017, from https://www.epa.gov/ust/leaking-underground-storage-tanks-corrective-action-resources US Energy Information Administration,. (June 2016). Refining Crude Oil - Energy Explained, Your Guide To Understanding ... Retrieved MARCH 17/3/17, 2017, from https://www.eia.gov/Energyexplained/index.cfm?page=oil_refining , Cork County Council. (2016). Rateable Valuation. Retrieved Dec 18, 2016, from https://www.corkcoco.ie/ .ie, T. J. (n.d.). Diesel Laundering · TheJournal.ie. Retrieved MARCH 5 th, 2017, from https://www.thejournal.ie/diesel-laundering/news/ Adams, A. (2006). Trucking: Tractor-Trailer Driver (3rd ed.). London: Thomson Delmar Learning. Agency, Minnesota Pollution Control Agency. (2013). Cathodic Protection Of Underground Storage Tank Systems. Retrieved JAN 24 th, 2017, from https://www.google.ie/webhp?sourceid=chrome-instant&ion=1&espv=2&ie=UTF-8#q=underground+storage+tank+protection+cathodic+protection&* Alan Rushton, P. C. (2017). The Handbook of Logistics and Distribution Management. In P. C. Alan Rushton, The Handbook of Logistics and Distribution Management (pp. 516, 516, 564, 567). Kogan Page Publishers. American Petroleum Institute, . (2017). API. Retrieved Feb 28th, 2017, from https://www.api.org/ Association, U. K. (2015). UKPIA - Refining Britain's Fuels - Vapour Recovery at Filling Stations. Retrieved Feb 14th, 2017, from https://www.ukpia.com/industry_issues/air-quality-climate-environment/vapour-recovery.aspx Authority, H. a. (2015). In Carriage of Dangerous Goods by Road, A Guide for Business. (pp. 65-68). Dublin: HSA. Authority, Health and Safety. (2017). Wetstock Reconciliation at Fuel Storage Facilities - Health and Safety ... Retrieved April 3rd, 2017, from https://www.hsa.ie/eng/Publications_and_Forms/Publications/Chemical_and_Hazardous_Substances/Wetstock_Reconciliation_at_Fuel_Storage_Facilities.pdf Authority, Scottish Qualifications Authority. (2017). Petroleum Driver Passport - Home. Retrieved MARCH 25th, 2017, from https://www.pdpassport.com/mini/30922.html Companies Registration Office. (2016). CRO Homepage. Retrieved Nov 09, 2016, from https://www.cro.ie/ Council, Limerick County Council. (2016). Petroleum Licensing | Limerick.ie. Retrieved Jan 10th, 2017, from https://www.limerick.ie/council/petroleum-licensing Curley, R. (2012). Energy Past Present and Future. In R. Curley (Ed.), Energy Past Present and Future (pp. 1-20). New York: Britannica. CVRT. (17). CVRT. Retrieved Feb 12th, 2017, from https://www.cvrt.ie/en/Pages/default.aspx Efficiency, E. (2016). What is a Bund? - Environmental Efficiency. Retrieved FEB 27th, 2017, from https://www.enviro-consult.com/faqs/what-is-a-bund/ EPA. (Jan 2017). Natural Gas Extraction - Hydraulic Fracturing | US EPA. Retrieved Feb 20/2/17, 2017, from https://www.epa.gov/hydraulicfracturing/process-hydraulic-fracturing Fuel Oil News. (2016). Top Fuel Oil Distributors and Logistics | Fuel Oil News. Retrieved April 5th, 2017, from https://fueloilnews.co.uk/top-fuel-oil-distributors/ Gubbins, E. J. (2003). Managing Transport Operations. In E. J. Gubbins, Managing Transport Operations (pp. 198-210). Kogan Page Publishers, 2003. Hazchemwize. (2016). TREMcards | Transport Emergency Card - Hazchemwize. Retrieved JAN 10th, 2017, from https://www.hazchemwize.co.za/compliance/tremcards/ Institute, E. (2016). Will the Corrib gas field reduce prices. Retrieved MARCH 10/3/17, 2017, from https://ireland2050.ie/questions/will-the-corrib-gas-field-reduce-prices/ Laboratory, T. R. (2014). Technical Assessment of Petroleum Road Fuel Tankers Summary Report. London: Dept of Transport. Retrieved from https://trl.co.uk/reports/PPR724 LOWE, D. (2015). Lowe's Transport Manager's and Operator's Handbook. In Transport Manager's and Operator's Handbook (p. 566). Kogan Page Ltd. Macharis, C. (2014). Sustainable Logistics. In Sustainable Logistics (pp. 46-50). Emerald Group. Martin Muckett, A. F. (2007). Introduction to Fire Safety Management. In Introduction to Fire Safety Management (p. 320). London: Butterworth-Heinemann. NaturalGas.org. (2013). Exploration NaturalGas.org. Retrieved MARCH 2, 2017, from https://naturalgas.org/naturalgas/exploration/ NORA. (2017). National Oil Reserves Agency. Retrieved MARCH 10, 2017, from https://www.nora.ie/ Pope, C. (2017). Rising oil prices may hit Irish consumers on many fronts. The Irish Times(Jan 30 2017). Regulation, C. f. (2016). Compressed Natural Gas Funding Request Decision Paper. Commission for Energy Regulation . Road Safety Authority. (2015). RSA.ie - Driver hours. Retrieved Jan 8th, 2017, from https://www.rsa.ie/en/RSA/Professional-Drivers/Driving-Safely/Driver-Hours/ sciencedirect. (2014). Life Cycle Assessment of Natural Gas-based Chemical Looping for Hydrogen Production. Science Direct. Technology, C. T. (2016). UST Testing - Compliance Testing & Technology. Retrieved JAN 15TH, 2017, from https://www.google.ie/webhp?sourceid=chrome-instant&ion=1&espv=2&ie=UTF-8#q=ust+pressure+testing&* The Irish Times. (2011). Now we're suckin' illegal diesel. The Irish Times. Retrieved from https://www.irishtimes.com/news/now-we-re-suckin-illegal-diesel-1.614526 Tourism, D. o. (2016). Transport Licensing Forms - Road Transport Operator Licensing. Retrieved Nov 11, 2016, from https://www.rtol.ie/rtol-online/forms;jsessionid=0C9mBnq50h3gz1SCVH-B+32p. U.S. Environmental Protection Agency. (1996). Underground Motor Fuel Storage Tanks. U.S. Environmental Protection Agency.Bibliography

Californa Enviromental Protection Agency. (n.d.). Understanding Automatic Tank Gauging Systems - NWGLDE. Retrieved March 17th, 2017, from https://www.nwglde.org/downloads/CA_ATG_PDF.pdf European Commission. (2016). Dangerous goods - European Commission. Retrieved APRIL 3RD, 2017, from https://ec.europa.eu/transport/road_safety/topics/dangerous_goods_en Health and Safety Authority. (2017). Petrol Stations - Health and Safety Authority. Retrieved Feb 20th, 2017, from https://www.hsa.ie/eng/Your_Industry/Petrol_Stations/ Inland Revenue. (2013). New Monthly Return of Oil Movements (ROM1) - Revenue. Retrieved Jan 12th, 2017, from https://www.revenue.ie/en/tax/excise/mineral-oil-traders/rom1.html Inland Revenue. (2016). Auto-Fuel Trader's Licence - Revenue. Retrieved Jan 12th 2017, from https://www.revenue.ie/en/tax/excise/mineral-oil-traders/auto-fuel-traders-licence.html Irish Petrol Retailer's Association. (2017). IPRA. Retrieved Jan 9th, 2017, from https://www.ipra.ie/ TEXAS COMMISSION ON ENVIRONMENTAL QUALITY. (2014). Preventing Petroleum Storage Tank Spills and Overfills. Retrieved Jan 1st, 2017, from file:///C:/Users/PETER/Downloads/rg-475e-9.16%20(3).pdf The Texas Commission on Environmental Quality. (2009). Protecting Petroleum Storage Tanks Against Corrosion. TEXAS: The Texas Commission on Environmental Quality. United States Environmental Protection Agency. (2016). Leaking Underground Storage Tanks Corrective Action Resources. Retrieved March 10th 2017, from https://www.epa.gov/ust/leaking-underground-storage-tanks-corrective-action-resources US Energy Information Administration,. (June 2016). Refining Crude Oil - Energy Explained, Your Guide To Understanding ... Retrieved MARCH 17/3/17, 2017, from https://www.eia.gov/Energyexplained/index.cfm?page=oil_refining , Cork County Council. (2016). Rateable Valuation. Retrieved Dec 18, 2016, from https://www.corkcoco.ie/ .ie, T. J. (n.d.). Diesel Laundering · TheJournal.ie. Retrieved MARCH 5 th, 2017, from https://www.thejournal.ie/diesel-laundering/news/ Adams, A. (2006). Trucking: Tractor-Trailer Driver (3rd ed.). London: Thomson Delmar Learning. Agency, Minnesota Pollution Control Agency. (2013). Cathodic Protection Of Underground Storage Tank Systems. Retrieved JAN 24 th, 2017, from https://www.google.ie/webhp?sourceid=chrome-instant&ion=1&espv=2&ie=UTF-8#q=underground+storage+tank+protection+cathodic+protection&* Alan Rushton, P. C. (2017). The Handbook of Logistics and Distribution Management. In P. C. Alan Rushton, The Handbook of Logistics and Distribution Management (pp. 516, 516, 564, 567). Kogan Page Publishers. American Petroleum Institute, . (2017). API. Retrieved Feb 28th, 2017, from https://www.api.org/ Association, U. K. (2015). UKPIA - Refining Britain's Fuels - Vapour Recovery at Filling Stations. Retrieved Feb 14th, 2017, from https://www.ukpia.com/industry_issues/air-quality-climate-environment/vapour-recovery.aspx Authority, H. a. (2015). In Carriage of Dangerous Goods by Road, A Guide for Business. (pp. 65-68). Dublin: HSA. Authority, Health and Safety. (2017). Wetstock Reconciliation at Fuel Storage Facilities - Health and Safety ... Retrieved April 3rd, 2017, from https://www.hsa.ie/eng/Publications_and_Forms/Publications/Chemical_and_Hazardous_Substances/Wetstock_Reconciliation_at_Fuel_Storage_Facilities.pdf Authority, Scottish Qualifications Authority. (2017). Petroleum Driver Passport - Home. Retrieved MARCH 25th, 2017, from https://www.pdpassport.com/mini/30922.html Companies Registration Office. (2016). CRO Homepage. Retrieved Nov 09, 2016, from https://www.cro.ie/ Council, Limerick County Council. (2016). Petroleum Licensing | Limerick.ie. Retrieved Jan 10th, 2017, from https://www.limerick.ie/council/petroleum-licensing Curley, R. (2012). Energy Past Present and Future. In R. Curley (Ed.), Energy Past Present and Future (pp. 1-20). New York: Britannica. CVRT. (17). CVRT. Retrieved Feb 12th, 2017, from https://www.cvrt.ie/en/Pages/default.aspx Efficiency, E. (2016). What is a Bund? - Environmental Efficiency. Retrieved FEB 27th, 2017, from https://www.enviro-consult.com/faqs/what-is-a-bund/ EPA. (Jan 2017). Natural Gas Extraction - Hydraulic Fracturing | US EPA. Retrieved Feb 20/2/17, 2017, from https://www.epa.gov/hydraulicfracturing/process-hydraulic-fracturing Fuel Oil News. (2016). Top Fuel Oil Distributors and Logistics | Fuel Oil News. Retrieved April 5th, 2017, from https://fueloilnews.co.uk/top-fuel-oil-distributors/ Gubbins, E. J. (2003). Managing Transport Operations. In E. J. Gubbins, Managing Transport Operations (pp. 198-210). Kogan Page Publishers, 2003. Hazchemwize. (2016). TREMcards | Transport Emergency Card - Hazchemwize. Retrieved JAN 10th, 2017, from https://www.hazchemwize.co.za/compliance/tremcards/ Institute, E. (2016). Will the Corrib gas field reduce prices. Retrieved MARCH 10/3/17, 2017, from https://ireland2050.ie/questions/will-the-corrib-gas-field-reduce-prices/ Laboratory, T. R. (2014). Technical Assessment of Petroleum Road Fuel Tankers Summary Report. London: Dept of Transport. Retrieved from https://trl.co.uk/reports/PPR724 LOWE, D. (2015). Lowe's Transport Manager's and Operator's Handbook. In Transport Manager's and Operator's Handbook (p. 566). Kogan Page Ltd. Macharis, C. (2014). Sustainable Logistics. In Sustainable Logistics (pp. 46-50). Emerald Group. Martin Muckett, A. F. (2007). Introduction to Fire Safety Management. In Introduction to Fire Safety Management (p. 320). London: Butterworth-Heinemann. NaturalGas.org. (2013). Exploration NaturalGas.org. Retrieved MARCH 2, 2017, from https://naturalgas.org/naturalgas/exploration/ NORA. (2017). National Oil Reserves Agency. Retrieved MARCH 10, 2017, from https://www.nora.ie/ Pope, C. (2017). Rising oil prices may hit Irish consumers on many fronts. The Irish Times(Jan 30 2017). Regulation, C. f. (2016). Compressed Natural Gas Funding Request Decision Paper. Commission for Energy Regulation . Road Safety Authority. (2015). RSA.ie - Driver hours. Retrieved Jan 8th, 2017, from https://www.rsa.ie/en/RSA/Professional-Drivers/Driving-Safely/Driver-Hours/ sciencedirect. (2014). Life Cycle Assessment of Natural Gas-based Chemical Looping for Hydrogen Production. Science Direct. Technology, C. T. (2016). UST Testing - Compliance Testing & Technology. Retrieved JAN 15TH, 2017, from https://www.google.ie/webhp?sourceid=chrome-instant&ion=1&espv=2&ie=UTF-8#q=ust+pressure+testing&* The Irish Times. (2011). Now we're suckin' illegal diesel. The Irish Times. Retrieved from https://www.irishtimes.com/news/now-we-re-suckin-illegal-diesel-1.614526 Tourism, D. o. (2016). Transport Licensing Forms - Road Transport Operator Licensing. Retrieved Nov 11, 2016, from https://www.rtol.ie/rtol-online/forms;jsessionid=0C9mBnq50h3gz1SCVH-B+32p. U.S. Environmental Protection Agency. (1996). Underground Motor Fuel Storage Tanks. U.S. Environmental Protection Agency.Appendix

Interview 1

Maxol Filling Station Donnybrook Douglas This filling station is in operation since 1999, and is located in the Douglas area of Cork. I would like to thank the proprietor, Mr Jerry Breen, for allowing me the opportunity, to visit the site, under the guidance, of Miceal Brennan a member of his staff. On the day of my visit, it was explained to me how the forecourt had recently gone through a safety audit. A consultancy firm who specialise in forecourt risk and safety assessment carried out, the audit. I was shown, a copy of the final report, and the areas in which the company had to make improvements. These were significant, but easily remedied problems. They included poor lightening in the delivery area, in the event of after dark deliveries. The parking of shop customer's vehicles, obstructing vehicles coming in for fuel, was also causing problems. In addition, the report said improvements could be made if a one-way traffic system was introduced, in and around the filling area. The three zoning areas, where there is a likelihood of vapours to be present, in various degrees, around the forecourt were also shown, and explained to me. I was also brought into the Wetstock control room, where the quantities of the amount of fuel on site is monitored. The daily sales and the fuel temperatures are continually recorded, and if there is, any abnormal activity the alarm will go off. The alarm going off will most likely will indicate a leaking tank, so therefore a lot of environmental damage could be prevented, by taking immediate action. The Vapour Recovery system was also highlighted to me. Again I would like to thank Mr Jerry Breen and staff for spending the time with me and showing me around the forecourt.Interview 2