Strategies for Hurricane Damage on Pavements

Info: 11732 words (47 pages) Dissertation

Published: 10th Dec 2019

Tagged: ConstructionCivil Engineering

CHAPTER-1: INTRODUCTION

- What is pavement:

Pavement in civil engineering is durable surfacing of a road, airstrip, or similar area. The primary function of a pavement is to transmit loads to the sub-base and base soil. These days flexible pavements consist of sand and gravel or crushed stone compacted with bituminous materials i.e. asphalt, tar, or asphaltic oil. Such that pavement has enough plasticity to absorb stock. Rigid pavements are made up of concrete, combined with coarse and fine aggregates and Portland cement, and usually reinforced with steel rod and mesh (Bhutia, 2015).

- Types of pavement:

They are two types of pavements, Flexible pavement and rigid pavement. These both are differentiated based on load distribution to sub-grade.

- Flexible pavement:

This can be characterized as the one comprising of a blend of asphaltic or bituminous material and aggregates put on a bed of compacted granular material of suitable quality in layers over the sub-grade. Water bound macadam roads and settled soil roads with or without asphaltic fixings are cases of flexible pavements.

The plan of flexible pavement depends on the rule that for a load of any magnitude, the intensity of load reduces as the load is transmitted downwards from the surface by temperance of spreading over an increasingly larger area, by conveying it sufficiently profound into the ground through progressive layers of granular material (Mishra, 2017).

Surface Course

Base Course

Subbase (Optional, usually treated subgrade)

Subgrade Existing Soil

Figure 1.1: Layers of Flexible pavement (Mishra, 2017)

In this way for flexible pavement, there can level materials utilized, the materials with high level of quality is utilized at or close to the surface. Hence the quality of sub-grade basically impacts the thickness of the flexible pavement.

- Rigid pavement:

A rigid pavement is developed from cement concrete or reinforced concrete slabs. Grouted concrete roads are in the category of semi-rigid pavements. The design of rigid pavement depends on giving a structural cement concrete slab of adequate quality to oppose the loads from movement. The rigid pavement has rigidity and high modulus of elasticity to disperse the load over a moderately wide region of soil (Mishra, 2017).

Tied rigid

shoulder

Longitudinal joint

Transverse joint

Concrete slab (jointed)

Base course (non-erosive)

Subbase course (if needed)

Figure 1.2: Layers of Rigid Pavement (Mishra, 2017)

Minor varieties in sub-grade quality have little effect on the structural capacity of a rigid pavement. In the plan of a rigid pavement, the flexural strength of concrete is the central point and not the strength of sub-grade. Because of this property of pavement, when the sub-grade redirects underneath the rigid pavement, the concrete slab can connect over the localized failures and territories of insufficient help from sub-grade because of slab action.

- Pavement Distress:

Pavement distress is splitting, rutting, bending or different sorts of surface decay which demonstrates a decrease in the pavements surface condition or auxiliary load-conveying limit. The major types of pavement distress are explained below (Brett Neal, 2017).

- Alligator Cracking:

Alligator cracking is an asphaltic concrete pavement trouble sort. Alligator cracking comprises of interconnecting cracks which outline little (under 1 foot by 1 foot), unusually formed squares which take after the examples found on a alligator skin. Alligator cracking extents from 0 to 100 percent of the wheel way length (Brett Neal, 2017).

Figure 1.3: Alligator Cracking (Kleenco Constructions, 2016)

Alligator cracking is a kind of trouble that is generally caused by lacking base support or delicate pavement surface. Since breaks empower surface water to enter the sub-grade and further annihilate the security of the sub-grade, fixing should be proficient when helpful. When cracking has advanced to the extent that mistake of the roadway surface is drawing nearer, repairs should be made at the earliest opportunity. The alligator crack surface material advancing toward frustration will frequently should be emptied and supplanted with asphalt settling material. Where the base is flimsy or wet the base material should be emptied, supplanted or balanced out.

- Block Cracking:

Block cracking is an asphaltic concrete pavement distress sort. Block cracking comprises of interconnecting cracks that separation the asphalt surface into roughly rectangular pieces, fluctuating in measure from 1 foot by 1 foot up to 10 feet by 10 feet. Block cracking extents from 0 to 100 percent of the lane area (Brett Neal, 2017).

Figure 1.4: Block Cracking (Applied Pavement Technology, 2016)

- Corrugation and Shoving:

Corrugations are deviations of the pavement surface from its unique cross segment which are for the most part caused by inordinate bitumen, improper aggregate gradation in the pavement, inadequate compaction of the mix or low antiparticle grinding to a degree that makes precarious asphalt with low resistance to traffic loads (Brett Neal, 2017).

Figure 1.5: Corrugation or Shoving (Seal-Tite of Arklahoma, 2015)

- Bleeding:

Bleeding alters to the upward development of asphalt in pavement, bringing about a film of black-top framing on the asphalt surface. It shows up in patches of dull smooth surface, as a rule in the wheel tracks. Draining usually happens in hot climate (Brett Neal, 2017).

Figure 1.6: Bleeding (Pavement Interactive, 2013)

- Longitudinal Cracking:

Longitudinal cracking is an asphaltic concrete pavement trouble sort in which cracks or breaks run around parallel to the asphalt centerline. Longitudinal cracking extents from 0 to 999 feet for every station (Brett Neal, 2017).

Figure 1.7: Longitudinal cracking (Paveman Pro, 2017)

- Patching:

Patching is an asphaltic concrete pavement distress sort. Patches are repairs made to asphalt trouble. The nearness of fixing demonstrates earlier support action and is in this way utilized as a general measure of maintenance cost. Fixing ranges from 0 to 100 percent of the lane area (Brett Neal, 2017).

Figure 1.8: Patching (Pavement Interactive, 2013)

- Scope:

Due to the occurrence of a natural disaster, infrastructure can be damaged. Particular to this project, pavement structures can be damaged with the end goal that response activities can be frustrated. Inside the context of this project, the term “response” is characterized as in NRF (2008) talked about in Chapter 1 as quick activity to save lives, secure property and the environment, and meet essential human needs. In light of data aggregated amid this project, damage to pavement structures can take many structures; from minor damage to add up to loss of the pavement structure.

With a specific end goal to fulfill the general goal and build up a protocol for assessing, organizing and repairing pavement systems for response activities, a critical exertion was exhausted on characterizing the sorts of pavement harm that could be experienced after a natural disaster. Exact characterizing of pavement harm is crucial to creating and using protocols for repairing the pavement structures to permit successful response activities.

CHAPTER-2: LITERATURE REVIEW

- Pavement History:

A short perspective of how pavement design, construction and performance has advanced should help give viewpoint on present and, possible, future practice. This short view into the past will begin with the Romans; at that point proceed onward to the Macadam and Telford time, at that point into the initial 150 years of asphalt and Portland cement pavement. The development of pavement design will stress the U.S.A. what’s more, the U.K. more than for different parts of the world (Pavia Systems, 2012).

2.1.1. Roman roads:

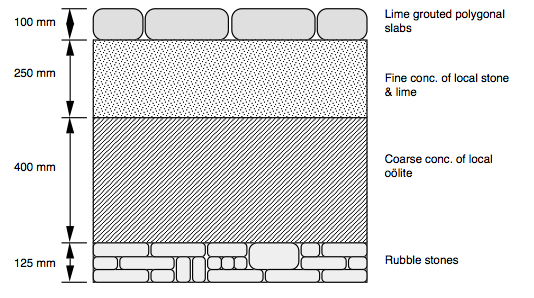

In fairness, the Carthaginians are generally credited with being the first to construct and maintain a road system (about 600 B.C.) according to Tillson (1900). The Romans eventually decided that their neighbors across the Mediterranean were a bit of a threat to the empire destroying Carthage in 146 B.C. The Carthage ruins are located in Tunisia (Northern Africa) next door to Algeria on the left and Libya on the right so to speak. It is suggested that the Romans took up the practice of a military road system from the Carthaginians. It is estimated that the Romans built about 87,000 km of roads within their empire about equal to the length of the U.S. Interstate system. The Roman outline for their essential U.K. roads for the most part comprised of four layers top to bottom as takes after (Collins and Hart, 1936): Summa Crusta surfacing: Smooth, polygonal squares slept with in fundamental layer. Core: A sort of base layer made out of rock and sand with lime cement. Rudus: The third layer was made out of rubble masonry and smaller stones likewise set in lime mortar. Statumen: Two or three courses of level stones set in lime mortar.

Figure 2.1: Layers of Roman Roads (Pavement Interactive, 2012)

2.1.2. Telford and Macadam:

Telford Thomas Telford served his apprenticeship as a building artisan. Along these lines, he stretched out his brick work learning to connect building. During lean circumstances, he cut grave-stones and other elaborate work. In the long run, Telford turned into the “Surveyor of Public Works” for the province of Salop, in this manner turning his consideration more to streets.

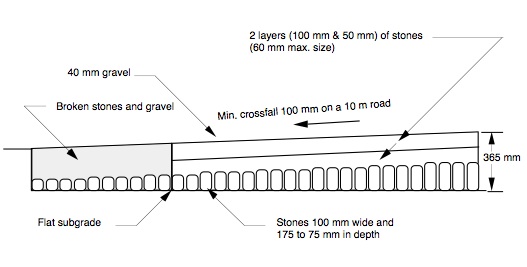

Telford endeavored, where conceivable, to fabricate streets on generally level levels close to 1 out of 30 with a specific end goal to lessen the quantity of stallions expected to pull load. Further, the pavement area was around 350 to 450 mm top to bottom and by and large indicated in three layers. The base layer was contained extensive stones 100 mm wide and 75 to 180 mm top to bottom (Collins and Hart, 1936). It is this particular layer which makes the Telford plan interesting (Baker, 1903). Over this were put two layers of stones of 65 mm most extreme size around 150 to 250 mm add up to thickness trailed by a wearing course of rock around 40 mm thick. It was assessed that this framework would bolster a heap comparing to 88 N/mm 500 lb for each in. of width.

Figure 2.2: Telford (Pavement Interactive 2012)

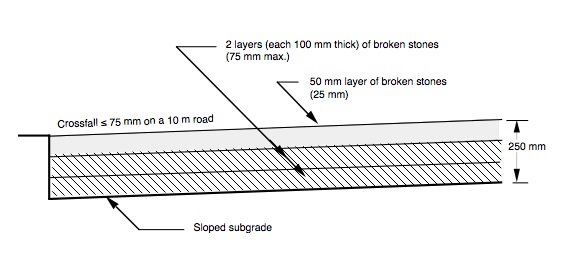

Macadam John Macadam watched that the majority of the “cleared” U.K. streets in mid-1800 were made out of adjusted rock. He realized that precise total over a very much compacted sub-grade would perform significantly better. He utilized an inclined sub-grade surface to enhance waste dissimilar to Telford who utilized a level sub-grade surface, on which he put precise total hand-broken, most extreme size 75 mm in two layers for an aggregate profundity of around 200 mm (Gillette, 1906). Over this, the wearing course was put around 50 mm thick with a most extreme total size of 25 mm (Collins, 1936). Macadam’s explanation behind the 25 mm most extreme total size was to give a “smooth” ride for wagon wheels. Along these lines, the aggregate profundity of ordinary Macadam asphalt was around 250 mm. An intriguing quote credited to Macadam about suitable greatest total sizes was that “no stone bigger than will enter a manmouth ought to go into a road” (Gillette, 1906). The biggest passable load for this kind of configuration was assessed to be 158 N/mm 900 lb for every in. width. The first macadam pavement in the U.S. was constructed in Maryland in 1823

Figure 2.3: Macadam (Pavement Interactive, 2012).

2.1.3 Early Bituminous Pavement:

Tar Macadam it creates the impression that the primary tar macadam pavement was put outside of Nottingham Lincoln Road in 1848 (Collins and Hart, 1936; Hubbard, 1910). Around then, such asphalts were viewed as reasonable just for light movement not for urban avenues. Coal tar the binder had been accessible in the U.K. from around 1800 as a deposit from coal-gas lighting. Potentially this was one of the most punctual endeavors to reuse squander materials into a pavement.

Sheet Asphalt sheet asphalt set on a concrete base foundation ended up noticeably well known amid the mid-1800 with the main such pavement of this sort being worked in Paris in 1858. The main such pavement set in the U.S. was in Newark, New Jersey, in 1870. Dough puncher 1903 portrays this pavement framework as a wearing course 40 to 50 mm thick made out of asphalt cement and sand, a fastener course around 40 mm thick made out of broken stone and asphalt cement, lastly, a base layer of water driven concrete or pavement rubble old rock pieces, blocks, and so on. By and large, the concrete layer was 100 mm thick for “light” movement and 150 mm thick for “substantial” activity (Baker, 1903). The last thickness depended on the heaviness of the activity, the quality of the concrete and the soil support.

Bitulithic pavements in 1901 and 1903, Frederick J. Warren was issued licenses for the early “hot mix” paving materials. A run of the mill blend contained around 6 percent “bituminous cement” and reviewed total proportioned for low air voids. Basically, the most extreme total size was 75 mm extending down to dust. The idea was to create a blend which could utilize a more “fluid” cover than utilized for sheet asphalt. This material wound up noticeably known as “Bitulithic.”

2.1.4 Early Portland Cement Concrete Pavements:

When the new century rolled over 1900, cements were classified as “characteristic” or “manufactured.” Natural cements were influenced specifically from particular to shake. artificial cement was produced using proportioned fixings and ended up plainly known as “Portland’s” named after the regular limestone shake found on the Portland Bill, which is a little projection of land into the English Channel close Weymouth on the southern U.K. drift. The principal genuine Portland cement was created in the U.K. around 1824 really Portland cement was licensed in 1824 by Joseph Aspdin, a bricklayer in Leeds, U.K. and in the U.S. around 1865 (Tillson, 1900).

Strangely, Portland cement concrete PCC was not utilized as a pavement wearing course much until after around 1910 Agg, 1940; in any case, it was routinely utilized as a “firm” base to help other wearing courses, for example, wooden pieces, blocks, cobble stones, and so forth. One likely purpose behind this was the absence of a reliable particular for the early cements. Tillson in 1900 abridged more than 109 separate particulars on Portland cement fineness. Add to this disarray the way that regular cements were generally utilized also around 60 percent of aggregate cement utilization in 1898. Further, PCC hand blending was as yet regular in 1900 which without a doubt confined efficiency and exact proportioning. By 1900 as announced by Tillson, it was basic to volumetrically extent PCC as a 1:2:4 or 1:2:5 cement: sand: coarse total.

- Materials:

A portion of the earliest recorded data about materials which could be and were utilized as a part of pavements concern hydraulic cement and the Romans; be that as it may, in reasonableness, the earliest known utilization of hydraulic lime was in Syria around 6,500 B.C. more than 6,000 years previously the Romans — plus or minus a couple of hundred years (Brown, 1987). The Romans “found” that pounding volcanic tuff with powdered hydraulic lime created hydraulic cement “hydraulic” in that it solidified within the sight of water. The hydraulic lime was created by warming limestone over 850 °C subsequently driving off CO2 and changing over the limestone to CaO. The main known utilization of hydraulic cement by the Romans happened at around 120 B.C. in Rome strangely. The “best” assortment of volcanic tuff was found close to the town of Pozzuoli close Naples on the southwestern shore of Italy and the material procured the name of Pozzolana. Further, the Romans took in somewhat about the utilization of different added substances, for example, blood, fat and drain. Evidently, blood hemoglobin really is a powerful air-entraining specialist and plasticizer given the mellow Mediterranean atmosphere the essential utilize was likely for workability. Concerning material testing, the year 1898 was huge: the American Society for Testing and Materials ASTM was built up.

A portion of the early clearing materials have been already talked about; be that as it may, it may enthusiasm to look at a couple of costs. For instance, refined Trinidad Lake black-top in 1893 cost about $27 to $36 per metric ton at the Port of New York. To change these expenses to contemporary costs one should increase by no less than a factor of ten. Consequently, a similar cost today would be about $270 to $360 per metric ton or about twice as much as a black-top cement cover today without the item refinements.

With respect to PCC compressive quality, Byrne revealed in 1896 that PCC air cured for a half year for a St. Louis-connect had a compressive quality of 8.3 MPa. Other compressive qualities he detailed (apparently pre-1890s) ran from 1.4 MPa (1 month age) to 9.7 MPa (1 year age). Contrast these outcomes with contemporary compressive qualities of 34.5 to 137.9 MPa. In this manner, in 100 years, PCC quality has expanded around 100 times (proportion of extraordinary low to outrageous high). “The bearing ratio test was formulated in 1929 trying to dispose of a portion of the complaints to handle stacking tests and to give a quick technique to looking at neighborhood base and sub-base materials.”

- A portion of the positive parts of the CBR research center test as recorded by Porter:

- Improvement over field static load tests which must beat “solidification disfigurement” since the CBR specimen is compacted to a thickness expected in the field. California’s endeavors to utilize static field bearing tests were judged as unsuccessful; subsequently, the accentuation on corresponding asphalt execution with a clear research facility test.

- The splashing of the research center examples with an additional charge (which speaks to the heaviness of the asphalt) allows the material to swell and achieve the unfavorable condition of dampness which can exist in the field.

- The entrance test decides the material’s protection from parallel relocation bringing about a consolidated measure of the impact of attachment and inside contact.

- The test gives a brisk technique for looking at base and sub-grade materials.

- By exploring and testing the related materials, an observational relationship can be set up between CBR esteems, asphalt thickness, and execution.

CHAPTER-3: DAMAGE TO PAVEMENT BY HURRICANES

On average, USA faces 10.1 named storms every season, with an average 5.9 will be hurricanes and 2.5 becoming major hurricanes (category 3 or greater). The most hurricanes caused in the year 2005 in which 28 tropical cyclones formed, of which 15 became hurricanes. Below are the lists of major hurricanes and their magnitudes in USA that are caused from 2016-1999.

States Affected and Category by States Affected: The impact of the hurricane on individual U.S. states based upon the Saffir-Simpson Scale (through the estimate of the maximum sustained surface winds at each state). (TX S-South Texas, TX C-Central Texas, TX N-North Texas, LA-Louisiana, MS-Mississippi, AL-Alabama, FL NW-Northwest Florida, FL SW-Southwest Florida, FL SE-Southeast Florida, FL NE-Northeast Florida, GA-Georgia, SC-South Carolina, NC-North Carolina, VA-Virginia, MD-Maryland, DE-Delaware, NJ-New Jersey, NY-New York, PA-Pennsylvania, CT-Connecticut, RI-Rhode Island, MA-Massachusetts, NH-New Hampshire, ME-Maine. In Texas, south refers to the area from the Mexican border to Corpus Christi; central spans from north of Corpus Christi to Matagorda Bay and north refers to the region from north of Matagorda Bay to the Louisiana border. In Florida, the north-south dividing line is from Cape Canaveral [28.45N] to Tarpon Springs [28.17N]. The dividing line between west-east Florida goes from 82.69W at the north Florida border with Georgia, to Lake Okeechobee and due south along longitude 80.85W.).

Table- 3.1: List of hurricanes and their magnitudes (Chris Landsea 2016)

| Hurricanes | Year | Main damage area | Category | Magnitude of hurricane |

| Matthew | 2016 | FL NE2,GA1,SC1,NC1 | 1 | 86 |

| Hermine | 2016 | FL NW1 | 1 | 80 |

| Arthur | 2014 | NC2 | 2 | 97 |

| Sandy | 2012 | NY1 | 1 | 80 |

| Isaac | 2012 | LA1 | 1 | 80 |

| Irene | 2011 | NC1 | 1 | 86 |

| Ike | 2008 | CTX2, LA1 | 2 | 109 |

| Gustav | 2008 | LA2 | 2 | 103 |

| Dolly | 2008 | ATX1 | 1 | 86 |

| Humberto | 2007 | CTX1, LA1 | 1 | 92 |

| Wilma | 2005 | FL SW3, SE1 | 3 | 120 |

| Rita | 2005 | TX NE3;LA, 2 | 3 | 115 |

| Katrina | 2005 | FL SE1;LA, 3;MS, 3;AL, 2 | 3 | 126 |

| Dennis | 2005 | FL NW3, AL, 2 | 3 | 120 |

| Cindy | 2005 | LA, 1 | 1 | 74 |

| Jeanne | 2004 | FL, SE3, SW1, NW1 | 3 | 120 |

| Ivan | 2004 | AL, 3; FL, NW3 | 3 | 120 |

| Frances | 2004 | FL, SE2, SW1 | 2 | 103 |

| Gaston | 2004 | SC, 1 | 1 | 74 |

| Charley | 2004 | FL, SW4, SE1, NE1; SC,1; NC,1 | 4 | 149 |

| Alex | 2004 | NC, 1 | 1 | 80 |

| Isabel | 2003 | NC, 2; VA, 1 | 2 | 103 |

| Claudette | 2003 | TX, C1 | 1 | 92 |

| Lili | 2002 | LA, 1 | 1 | 92 |

| Irene | 1999 | FL, SW1 | 1 | 80 |

The major damages caused due to hurricanes are human deaths and the infrastructure. In the below table the total fatalities and total cost damages are listed.

Table-3.2: list of damages caused due to hurricanes

| Hurricanes | Fatalities | Total cost damage | |

| direct | indirect | ||

| Matthew | 586 | 17 | $15.09 billion |

| Hermine | 4 | 1 | $550 million |

| Arthur | 1 | 1 | $22.7 million |

| Sandy | 233 | $75 million | |

| Isaac | 34 | 7 | $2.39 billion |

| Irene | 49 | 12 | $16.6 billion |

| Ike | 103 | 92 | $37.5 billion |

| Gustav | 112 | 41 | $6.61 billion |

| Dolly | 1 | 21 | $1.35 billion |

| Humberto | 1 | $50 million | |

| Wilma | 87 | $29.4 billion | |

| Rita | 97-125 | $12 billion | |

| Katrina | 1245-1836 | $108 billion | |

| Dennis | 76 | 12 | $3.71 billion |

| Cindy | 1 | 4 | $320 million |

| Jeanne | >3035 | $7.66 million | |

| Ivan | 92 | 32 | $23.3 billion |

| Frances | 7 | 43 | $9.8 billion |

| Gaston | 8 | 1 | $130 million |

| Charley | 15 | 20 | $16.3 billion |

| Alex | 33 | 18 | $1.89 billion |

| Isabel | 17 | 34 | $5.37 billion |

| Claudette | 1 | 2 | $181 million |

| Lili | 13 | 2 | $925 million |

| Irene | 3 | 15 | $800 million |

- Pavement damages due to hurricanes:

Pavement conditions can differ generally post natural disasters. Along these lines, the categorization of pavement damage is layered. They are four primary categories of pavement condition, Intact, Damaged-Passable, Damaged-Dangerously and Impassable (Isaac L. Howard, 2010).

- Intact Pavements:

An Intact pavement structure is one that was not damaged or has exceptionally negligible harm; however, activities may at present be required keeping in mind the end goal to complete reaction operations. Damage to Intact pavement may incorporate little potholes or scarring of the pavement surface because of garbage ignoring the pavement. In many cases, and conceivably most, pavement stay Intact aside from debris makes them impassable. debris can come as wood from harmed structures or utility poles, fallen trees, water crafts or scows, exteriors of structures, signs, and so forth. These events are outside the extent of this specific assignment however will require bulldozers or other material movers to clear. The capacity to get the material movers to the suitable area could be applicable to this undertaking if damaged pavements exist nearby.

Figure 3.1: Typical Debris Making Road Impassable (Isaac L. Howard, 2010).

Figure 3.2: Debris Making Road Near Impassable (Isaac L. Howard, 2010).

- Damaged-Passable Pavements:

The classification of Damaged-Passable incorporates pavements that have been damaged but response personnel can still travel to every part of the roadway once debris is cleared. Distresses inside the Damaged-Passable category could involve potholes or little territories in which the pavement substructure has been eroded. These troubles will for the most part be caused by wave activity before the death of the eye or because of the water streaming back toward the ocean, retreating after the passing of the eye (Douglas et al 2004). From a seriousness stance, pavements classified as Damaged-Passable can have fluctuating degrees of damage. Consequently, two seriousness levels have been created to improve the capacity for choosing the fitting pavement repair methodology and organizing courses. The main seriousness level is named Light Damage. The Light Damage seriousness level is characterized as asphalt zones in which the damaged zones are under 2 to 4 m2. These sorts of damaged regions may incorporate moderately little ranges of pavement that have washed away almost an asphalt edge because of the activities of waves or water retreating; little regions close scaffold projections or ducts that have washed away or little territories where the asphalt has been damaged because of debris passing over top of the asphalt. For the most part, damaged pavements that fall into the Light Damage seriousness level don’t broaden a whole path width and don’t prevent reaction exercises in different lanes; if accessible.

Figure 3.3: Typical Debris Making Road near Impassable (Isaac L. Howard, 2010).

The second seriousness level related with the Damaged-Passable class is Medium-Damage. Pavements that fall into this seriousness level are damaged no less than one path width leaving no less than one path width for travel. These sorts of damaged zones are by and large the aftereffect of scour caused by wave activity or water retreating toward the ocean

Figure 3.4: Medium-Damage Severity from Damaged-Passable Category (Isaac L. Howard, 2010).

- Damaged-Dangerous pavement:

The third type of pavement damage is Damaged-Dangerous. Damage related with this classification will for the most part be the aftereffect of wave activities or the retreating of water and incorporate the scouring endlessly of the basic pavement structure. In a few cases, damage might be as buckled concrete slabs caused by the washing ceaselessly of sub-grade soils close joints. Asphalt pavements may likewise break separated and seem like buckled concrete slabs as sub-grade soils are disintegrated away and the activities of waves reorient the broken pieces. Like the Damaged-Passable classification, the Damaged-Dangerous classification has two seriousness levels however they are named to connote the elevated requirement for repair: Medium-Damage and Severely-Damaged. The Medium-Damage seriousness level includes damage that is generally a single lane width. In many cases, the roadbed (or pavement substructure) has been disintegrated from underneath the pavement surface and the entry of reaction vehicles close to the edge of the damaged range could bring about extra pavement damage; henceforth the dangerous part of the classification.

Figure 3.5: Medium-Damage from Damaged-Dangerous Category (Isaac L. Howard, 2010).

The second seriousness level inside the Damaged-Dangerous class is Severely-Damaged. These pavements have been damaged over all travel lanes; be that as it may, response vehicles can ignore the pavements in extraordinary cases if off-road vehicles are used. Pavements that fall inside this seriousness level may incorporate full segments of roadway that have been broken separated and the broken pieces reoriented because of tidal surge.

Figure 3.6: Severely-Damaged from Damaged-Dangerous Category (Isaac L. Howard, 2010).

- Impassable Pavements:

The last type of pavement damage is Impassable. Pavements that fall into this classification have been completely demolished and cannot be traveled in vehicles. In many cases, these pavements have been eroded away absolutely by the activities of waves or the subsiding of water back to the ocean.

Figure 3.7: Impassable damage (Isaac L. Howard, 2010).

CHAPTER-4: WATER INFLUENCE IN PAVEMENTS

4.1 Different types of road structures versus affectability to water Road:

Pavements are multi-layer structures generally constituted of a surface course and at least one or more base layers, resting on a pavement foundation. Water permeability should increase from top of the pavement layer to bottom layer until 0.7 m depth. Generally, water may collect onto the low permeability layer and keep the upper layer wet and diminishing its bearing limit and administration life. In the event that the layers are bound together, solidify up of the gathered water may unbind the upper layer.

Thin asphalt layer asphalt or concrete layer

Thin asphalt layer asphalt or concrete layer

Base & sub-base sub-base

Soil improvement layer

Sub-grade sub-grade

Low volume higher volume

Figure 4.1: Typical pavement soil (Chris Landsea 2016)

The pavement foundation comprises of the natural ground (sub-grade), and regularly a topping layer, which part is to enhance the leveling, homogeneity and bearing limit of the sub-grade, and furthermore to guarantee frost protection.

The pavement base ordinarily comprises of two layers: the sub-base, surmounted by the road base. These layers can be constituted of treated materials (in high-activity pavements) or untreated in low movement pavements. These layers give the pavement the mechanical quality to withstands the heaps because of movement, and circulate these heaps on the pavement foundation.

The surface course (and conceivably a cover course beneath) is the top layer of the pavement, presented to the impacts of activity and atmosphere. It must oppose to movement wear and furthermore secure the basic layers, specifically against penetration of water.

- Pavement structures:

They are divided in to four groups.

- Thin bituminous pavements, which comprise of a generally thin bituminous surface course, resting one or more layers of unbound granular materials. Goal: low traffic level.

- Thick bituminous pavements comprising of a bituminous wearing course, more than maybe a couple bituminous layers (base and sub-base). Goal: high traffic level. They might be considered as adaptable; however they are significantly stiffer then the first ones.

- Semi-rigid pavements including a bituminous wearing course more than maybe a couple layers of materials treated with hydraulic binders. Goal: high traffic level.

- Cement solid pavements which comprise of a cement concrete slab (15 to 40 cm thick), conceivably secured with a thin bituminous wearing course, and laying on a sub-base (bound or unbound), or straightforwardly on the foundation. The concrete slab can be ceaseless with longitudinal reinforcement, or broken. Goal: high traffic level.

- Mechanical behavior:

These different pavements types introduce diverse types of mechanical behavior, and distinctive disintegration mechanism. In any case, for all structures, water plays a major part in pavement disintegration.

In thin bituminous pavements, high stresses are transmitted to the unbound granular layers and to the sub-grade; and prompt perpetual disfigurements of these layers. Since unbound layers and sub-grades are sensitive to dampness content, the execution of these pavements is unequivocally reliant on varieties of dampness conditions. This can lead, specifically to “edge failures”: water invades from the pavement shoulders, under the edge of the pavement, prompting subsidence at road edges. As these asphalts are extremely touchy to dampness, impermeability of the surface course and great seepage are critical for their execution.

In thick bituminous pavements, of much lower adaptability, with bituminous base layers, the anxieties transmitted to the dirt are much lower, and the danger of permanent deformations in the soil, and also the sensitivity to the dampness substance of the soil are lower. The primary component of disintegration of these pavements is breaking because of fatigue, caused by high tractable worries in the bound layers. Once the pavement is split, water penetration quickens the degradation, prompting debilitating of the sub-grade, wearing down at the lips of the breaks, material chipping without end, to frame potholes. Without support, decay can lead quickly to add up to destroy.

In pavements with layers treated with hydraulic binders, the principle crumbling process is by and large because of intelligent cracking. Warm withdrawal and shrinkage in the bond treated materials make transverse cracks. These makes for the most part rise laugh out loud through the wearing course and show up on the pavement surface at genuinely notwithstanding dividing (5 to 15 m). These breaks have a tendency to crumble and cracking under movement loads. On the other hand, water invasion is a noteworthy issue, prompting a decay of the holding between bound layers, a reduction of the bearing limit of the sub-grade in the broke region, in this manner diminishing burden exchange and supporting whittling down of the break lips. On these asphalts, insurance against water invasion, via fixing the shrinkage cracks, and by utilizing moderately thick surface courses is fundamental;

In concrete pavements, because of the high modulus of elasticity of concrete, just low burdens are transmitted to the foundation. Thermal breaking in concrete structures is for the most part controlled by transverse joints, or by the longitudinal reinforcement, delivering just fine miniaturized scale cracks. Two fundamental sorts of harm are watched:

- Cracking made by over the top malleable worries at the base of the sections, because of the blend of traffic loads and disfigurements of the chunks because of thermal inclinations.

- Evolution of bearing limit around joints and cracks, prompting pumping wonders. This development is basically because of the presence of water at the interface between the piece and the sub-base. Under stacking by vehicles, water in interface is locally exceedingly pressurized, high weight inclinations show up, actuating high water stream speeds which can dissolve the sub-base material (close asphalt edge), decrease the bearing limit of the help and lessen stack exchange between the sections. This is for the most part seen as edge or corner splitting.

For all pavements, solidifying and defrosting marvels are additionally a noteworthy wellspring of crumbling. In frost sensitive, fine grained soils, solidifying prompts a convergence of water close to the solidified zone (cryosuction). This prompt hurling of the pavement, and after that loss of bearing limit amid the defrost period. It ought to likewise be seen that in cool atmosphere, where winter tires with spikes are utilized, the wearing of pavement and the back to back re-pavement is regularly faster than weakness or deformation.

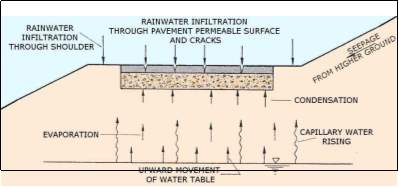

Changes in moisture content, particularly excess moisture, in pavement layers joined with traffic loads and solidifying and defrosting can essentially lessen pavement benefit life. Disappointments related with moisture are distinguished on low and high-volume roads everywhere throughout the Europe. To limit the negative impacts of moisture on pavement execution, first we need to distinguish the wellsprings of infiltration of water. There are a wide range of conceivable wellsprings of water infiltration in pavement framework. Mostly the nearness of water in pavement is because of infiltration of rainwater through the pavement surfaces through joints, splits and different deformities, particularly in more seasoned to some degree weakened pavements, and shoulders. Vital source is additionally movement of fluid water upwards to the solidifying front. Water may likewise leak upward from a high groundwater table because of slim suction or vapor developments, or it might stream along the side from the pavement edges and side trench.

The essentialness of the courses of infiltration relies upon the materials, atmosphere, and geography. Numerous pavement disappointments are immediate consequences of water entering the pavement courses and additionally the sub-grade. Water passage in the compacted unsaturated material will build water weight or diminishing suction, and thus lessen the powerful anxiety.

The quality and the versatile and plastic stiffness of the pavement material and the sub-grade. The rate of traffic-actuated decay of the street will increment amid this time. The loss of quality and solidness can lead, in extraordinary, to rutting and different types of surface distortion or, all the more usually, to pavement edge disappointments. The most exceedingly bad circumstance happens with ineffectively compacted granular material (shear quality decrease), with ice powerless soils or with durable swelling dirt (harming volume changes).

Water leaking through pavement can likewise transport soil particles and cause disintegration and filtering of most materials and pumping (i.e. transport) of fines. Moisture section can likewise influence the execution of the surface course by causing stripping of bitumen from total, layer partition between bound courses, and pothole development.

Harm in pavements related with water can be partitioned in moisture-caused and moisture-quickened troubles. Moisture-caused troubles are those that are principally prompted by moisture, while moisture-quickened are those that are started by various elements; however the rate of decay is quickened by nearness of water. Most generally watched harms because of the moisture are:

- Surface defects

- Surface deformations

- Cracking

For the most part, water debilitates the stability of soil and it is especially antagonistic to pavement structures since they are worked through territories of alterable moisture amounts.

It has been for the most part settled that the expanded sub-grade moisture content amid spring brings about expanded deformability, i.e. diminished bearing limit of the pavement. These adjustments in bearing limit are specifically evident for soil and clayey materials.

Set up moisture substance under adaptable pavements are impacted by sum and force of precipitation. Times of long precipitation of low power can be more extreme than concentrated times of high force, since the measure of moisture consumed by the dirt is most noteworthy under the previous conditions.

Additionally, consolidated impacts of precipitation and solidifying temperatures decide, to some degree, the degree of pavement harm.

Additionally, consolidated impacts of precipitation and solidifying temperatures decide, to some degree, the degree of pavement harm.

Figure 4.2: Water penetrate into the pavement structure in several ways (pavement interactive 2012)

CHAPTER 5 – REPAIR TECHNIQUES

5.1 Introduction

Many pavement repair techniques that are applicable to small and/or large areas. During the evaluation of each of the various techniques, there were several items deemed important. One item of interest for each of the evaluated repair techniques was shelf life. Techniques or products that have a long shelf life would allow for storage of materials for long periods of time. In other words, long shelf lives would allow for the stockpiling of materials prior to the occurrence of a natural disaster should an agency elect to do so. Another item of interest for each technology is construction. Each manufacturer of the various technologies has recommended construction methodologies. A quick overview of construction considerations is also provided. However, within the discussions on the various repair techniques, general comments are provided on the relative size of areas that the technique will repair. The final comment on the various repair techniques is on the expected performance life. In most cases, local DOT’s will be able to mobilize within a week after a large natural disaster. However, the DOT will have to prioritize pavement rehabilitation. For the purposes of this project, a performance life of up to 60 days was selected. This time should allow for the DOT to mobilize and conduct all pavement repairs.

Many damaged areas or areas that have been washed out can be made temporarily passable by placing a geotextile and a compacted dense-graded aggregate. This repair option is useful for medium to large areas of pavement damage. When selecting a geotextile for this repair technique, it is important to select a product that is designed for reinforcement (typically a high-density product). Some geotextiles are designed for other purposes and are 30 not desirable in reinforcement applications. The degree of compaction and aggregate stability will dictate what type and volume of traffic that can utilize this repair. AASHTO M 288 procedures should be followed if possible for material selection and construction guidance. General construction guidance is provided in Figure 16. Depending on the size of the repair, the geotextile should be pulled relatively tight and secured to the subgrade. Construction traffic should not be allowed to drive directly on the geotextile. Aggregate meeting local standards should be back-dumped onto the geotextile and advanced by a dozer or equivalent. In general, aggregate should be advanced on the outside edges ahead of the center in a U shape to tension the geosynthetic during compaction (15 to 20 cm lifts are typical). Equipment required includes haul trucks and a spreader to place the aggregate. The trucks hauling aggregates could possibly provide adequate compactive effort, but a compaction roller would be more efficient, effective, and consistent. This technique may also utilize repairs in the following sections as the aggregate may be a base layer topped by asphalt, rapid set concrete, precast concrete, or paving mats. The shelf life of the aggregate and geotextile is indefinite. Appendix A provides data for acceptable geotextiles.

Flowable asphalt is a bituminous based epoxy-like material. Generally, all components required to make flowable asphalt are supplied within a 19 L bucket. The components will be polymers and topping materials (sand). Flowable asphalt repair can be used to patch small areas of distress. Generally, the area of repair will range from 0.1 to 5 m2. The smaller areas would include pothole repairs and the larger areas would typically be resurfacing projects. This is a low skill repair option, as the repair team needs only follow the instruction on the repair kit. Construction with flowable asphalt includes mixing the material with a power drill, cleaning the area and spreading the material for thin lift applications. For pothole filling applications, all steps are the same except the flowable asphalt is poured directly into the pothole, where it will cure into a hard surface in about 1 hour. Suppliers of flowable asphalt indicate the approximate cost of the material is around $20 a square meter. Flowable asphalt has a shelf life of one year if kept indoors in a dry environment. For small repair areas, repairs made with flowable asphalt may be utilized as permanent repairs. Appendix B provides additional information about flowable asphalt.

5.4 Cold Patch Asphalt

Cold Patch Asphalt is a blend of aggregates and asphalt binder. The asphalt binder has additives which allow the cold patch asphalt to be compacted without heating. Cold Patch Asphalt repair can be used to repair small areas of distress. Generally the area will be 0.1 to 1 m2 . If the patched area is much larger it may take some time for the patch to cure so that it will not shove under loading. Larger areas can be repaired with cold patch asphalt, but the patched area may be unstable until the mixture can cure because of the lack of close confinement. Cold patch asphalt repair is a simple repair option and requires very little skill. The distressed area to be repaired needs to be moderately dry (no pooled water). The cold patch is then placed in the distressed area in lifts and compacted with a hand tamp or another suitable device. The cost of cold patch is around $75 a square meter (5 cm deep). The shelf life of most cold patch sealed in bags is 1-2 years. Stockpiled cold patch material can last 6 months to a year. Appendix C provides more information about cold patch asphalt.

5.5 Rapid Set Concrete

Rapid set concrete is a hydraulic cement based product that is specifically designed to set rapidly. The rapid set cement, when combined with aggregates, can provide a hard driving surface. Rapid Set Concrete can be used to repair small potholes to entire roadways. Conventional concrete could also be used if available. As the repair area increases in size, the equipment required will also increase. If used to fill potholes or smaller distress area, a small concrete mixer or even a wheelbarrow and a technician with a shovel could be utilized to mix the material and place into the repair area. A hand trowel or float would be necessary to smooth out the concrete surfaces. If the area to be repaired does not have a suitable construction platform. If filling a depressed area, the edges of the depression would act as confinement for the rapid set concrete. If an entire section of roadway requires repair, a form will have to be built, mixing will need to be accomplished in a concrete truck and larger finishing equipment will be required. The skill required for the repair also significantly increases as the area increases. Depending on the type of rapid set concrete used, the shelf life can range from 1 year to much more. The cementitious portions of the concrete will need to be stored in a dry location. Because of the wide range of areas that can be repaired with rapid set concrete, the approximate price varies significantly as well. Appendix D provides more information about rapid set concrete products.

There are several different types of paving mats available. Generally, these mats can be used to bridge a distress or replace a washed-out roadway. A paving mat can cover a wide range of areas (e.g. 1 to 17 m2 per mat). They can be connected to produce a repair of any desired area. Several options exist for paving mats including Pierced Steel Plank (PSP), small hardened steel (JR), Folded Fiberglass Mat (FFM), Fiber Reinforced Polymer, Wood, and Precast Concrete. No matter the type of mat used, a stable base on which to lay the mat will be required, though the stability required varies with mat type. This can be accomplished with stone, sand, or chemically stabilized soil. The remainder of this section describes paving mat options.

The PSP and JR mats are World War II surplus mats, but are generally available because of quantities produced during the war. These mats can be placed and connected by hand. They weigh approximately 30 kg per mat; therefore, heavy equipment would be required to move several of the mats at once. Costs for these mats could be on the order of $30 to $40 per m2. These mats can be stored outdoors indefinitely and can be reused. FFM mats are generally broken into panels on the order of 1.8 by 9.1 m. Each panel weighs on the order of 150 kg and can be placed by several workers. Again, multiple mats will require heavy equipment to haul these mats to the distressed area. These mats are often utilized by the military to repair airfields, so kits put together by the manufacturer provide all the necessary equipment to place FFMs. The construction of these mats is relatively simple, but prior training is required. FFMs can be stored indefinitely.

Precast concrete panels are available through a number of contractors that can make them to whatever size is deemed most beneficial. Typical sizes include 3 m by 3 m or 3.7 m by 3.7 m. Precast panels are typically the most durable of all the repair options and can often be left in place permanently, if the underlayment is properly prepared. Precast concrete panels, though, are also likely the costliest. Once the base for these panels is prepared, heavy equipment is required to transport the slabs to the site and a crane is required to place them. Short sections can be placed in a 5-hour span with experienced personnel. This is a 36 relatively high skill operation with specific equipment required for placement. The precast panels can be stored indefinitely. Wooden construction platforms are also a viable option for temporary applications such as emergency pavement repair. These mats are manufactured on a large scale by multiple companies. Conceptually, they are used in the same manner as the aforementioned matting types. Fiber reinforced polymer mats (and similar mats produced with modern materials) are available. The US Army Corps of Engineers (USACE) through its Engineer Research and Development Center (ERDC) conducted a sustained research effort referred to as the Joint Rapid Airfield Construction (JRAC) program beginning in 2002. The objectives of the program were fairly unique; one of the objectives was rapid mobilization of forces. The majority of the JRAC efforts were related to C-130 and C-17 aircraft, with some efforts devoted to items such as helipads. On the order of 30 projects were performed as part of the JRAC program. The information related to the use of matting systems has direct applicability to this research. ERDC also has tested matting systems in the presence of vehicular traffic for temporary applications. A summary of this research has been presented in Appendix E to demonstrate the viability of the technology.

5.7 Slab Jacking

Typically slab jacking is performed on intact sections of concrete pavement that have lost subgrade material because of rapid water movement in or around the subgrade and have consequently sunken from their original grade. Slab jacking should only be performed if the differential movement of the concrete pavement is only a few centimeters. This technology will vary in the square footage repaired, but generally the areas will be less than 20 square meters. Figure 21 provides general construction guidance for slab jacking. The standard process is to drill holes into the slab and inject expanding foam into the void below until the slab returns to its original elevation. Slab jacking with foam is a proprietary process that usually is performed by highly skilled workers with very specialized equipment. The cost of slab jacking is around $110 per square meter and the material can be stored for 1 to 3 years out of extreme temperatures.

5.8 Hot Mix Asphalt

Hot mix asphalt (HMA) is a blend of asphalt binder and aggregates that have been processed at temperatures around 150 C in an HMA production facility. Hot mix asphalt can be used to repair any size area, from very small to entire roadways. Generally, construction with hot mix asphalt will require a construction platform. This platform may be an aggregate base material or a compacted subgrade. During response operations, HMA will have to be trucked in, laid, and compacted. The skill level to place HMA is high, but many contractors are experienced with placing HMA. Specialized heavy equipment and a plant to produce the HMA are also required. This is typically readily available in a pre-natural disaster scenario. If nearby plants are damaged HMA can be trucked in from longer distances. If the distance is too great, warm mix asphalt (WMA) technologies should be considered. The cost of HMA repair varies significantly depending on the amount of work required before placement and the thickness of the asphalt. The components required to blend HMA in a plant can be stored for long periods of time.

Compacted Asphalt Warm Mix Asphalt (WMA) is similar to HMA but utilizes a process or asphalt binder additive that allows it to be compacted to proper density at lower temperatures. The benefit of this lower temperature compaction is that it can be trucked in from greater distances than HMA if the plants that are more local are damaged by the natural disaster and/or are without power. The major difference in WMA and HMA occurs at the plant where an additive or foam is added to the asphalt binder in order to ensure a compactable mixture at lower temperatures. Appendix G provides more information on different types of WMA technologies. Hot mix warm compacted asphalt would combine HMA and WMA. The mixing temperature is that of HMA but the WMA additives allow warm compaction extending the haul distance. This technology is relatively new, so many asphalt plants are not equipped to produce WMA. The cost for WMA could be higher than HMA. Appendix H provides the results of an extensive laboratory study conducted as part of Task 4 to evaluate hot mixed warm compacted asphalt with WMA additives for rapid pavement repair.

Based upon this research, hot mixed warm compacted asphalt can be placed successfully a number of hours after production, possibly up to six hours. This 39 finding is significant. Because of this extended time for being able to construct with the material, it can be hauled from greater distances. Also included on this map are circles having a radius of 80, 160, 240 and 320 km centered on Mobile, Alabama. The rings of various distances represent different haul times in which WMA could be transported. The 80 km ring represents an approximate 1 hour haul time and the 320 km ring represents an approximate 4 hour haul time. According to Appendix H, a 4 hour haul time would still allow approximately 2 hours of time to construct a pavement repair. This statement assumes the aging protocols match field conditions which have yet to be verified. Hot mixed warm compacted asphalt could be hauled to Mobile from as far as Birmingham, Alabama; Jackson, Mississippi; and Columbus, Georgia. These locations are far enough inland that HMA production facilities should be operational.

It should be noted that all WMA technologies are not equal. WMA produced with foaming technology generally cannot be compacted at temperatures as low as some of the WMA additives on the market. Also, the use of hot mixed warm compacted asphalt would not be possible with some additives due to maximum plant temperature requirements and similar.

CHAPTER-6: CONCLUSION

The protocols and methodologies provided in this project are new and innovative. The pavements are damaged due to hurricane flooding every year. So, the pavements should be repaired or reconstructed. In this report how to analyze the damaged pavement are explained. The damages caused to pavements by different hurricanes are identified.

The general damages caused to pavements by hurricanes are Intact, Damaged-Passable, Damaged-Dangerous and Impassable. And the water from floods enters in to base; sub-base layers in pavements and problems like surface defects, surface deformations and cracking are occurred. These are identified and repaired using different repair techniques.

The rapid repair techniques are used based on the different type of damages occurred. In the above the number of repair technologies that can be used post natural disasters. For every category and several levels of pavement damage, many repair techniques are provided. By using these techniques, the repairs for the pavement damages can be solved. This report is significant, and it allows the asphalt industries to respond to pavement damages caused due to hurricane disasters much more effectively.

REFERENCES

- J. Richard Capka, Acting Administrator, Federal Highway Administration. October 6, 2005. FHWA Response to Hurricane Katrina. https://www.transportation.gov/content/fhwa-response-hurricane-katrina

- Paul Pisano, Road Weather Management Program, FHWA, Office of Transportation Operations. Lynette C. Goodwin, Senior Transportation Engineer. Surface Transportation Weather Applications (2002). https://ops.fhwa.dot.gov/weather/resources/publications/fhwa/ite02surftranswxappl.pdf

- Gopal Mishra types of pavements-Flexible pavements and Rigid pavements (2017). https://theconstructor.org/transportation/types-of-pavement-flexible-and-rigid-pavement/9570/

- Isaac L. Howard, PhD SEERI project. RAPID PAVEMENT REPAIR GUIDANCE IN RESPONSE TO HURRICANE DAMAGE march 2010. www.cee.msstate.edu/assets/documents/(2010)%20SERRI%20Report%2070015-004%20(Pavements).pdf

- Chris Landsea Chronological list of all Hurricanes which affected the Continental United States 1851-2015(2014). www.aoml.noaa.gov/hrd/tcfaq/E23.html.

- Kevin Gaspard, Mark Martinez, Zhongjie Zhang, Zhong Wu, LTRC Pavement Research Group. Impact of Hurricane Katrina on Roadways in the New Orleans Area (March 2007). https://www.ltrc.lsu.edu/pdf/2007/07_2ta.pdf

- Hurricanes and tropical cyclones (1851-2006). https://www.wunderground.com/hurricane/usdeadly.asp

- Zhongjie Zhang, Zhong wu, Mark Martinez, Kevin Gaspard. Pavement structures Damage caused by hurricane Katrina Flooding May 2008. https://www.researchgate.net/publication/245294469_Pavement_Structures_Damage_Caused_by_Hurricane_Katrina_Flooding

- Mohamed Elshaer, Majib Ghayoomi & Jo Sias Daniel. Impact of subsurface water on structural performance of inundated flexible pavement April 2017. http://www.tandfonline.com/doi/full/10.1080/10298436.2017.1366767?src=recsys&

- Ian N. Robertson ; H. Ronald Riggs ; Solomon C. S. Yim ; and Yin Lu Young. Ian N. Robertson1 ; H. Ronald Riggs2 ; Solomon C. S. Yim3 ; and Yin Lu Young Decemeber 2007. http://web.engr.oregonstate.edu/~yims/publications/2007_11%20WW%20Robertson%20Riggs%20Yim%20Young.pdf

- Ning Lin, Kerry Emanuel, Michael Oppenheimer & Erik Vanmarcke. Physically based assessment of hurricane surge threat under climate change February 2012. https://www.nature.com/articles/nclimate1389?foxtrotcallback=true

- Pavement Interactive 2012. Pavement History. http://www.pavementinteractive.org/pavement-history/

- Robert Charlier, pierre Hornych, Mate Srsen & Primoz Pavsic. Wqater influence on Bearing capacity and pavement performance: field observations. In: Water in Road structures. https://www.researchgate.net/publication/226208915_Water_Influence_on_Bearing_Capacity_and_Pavement_Performance_Field_Observations_In_Water_in_Road_Structures

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Civil Engineering"

Civil Engineering is a branch of engineering that focuses on public works and facilities such as roads, bridges, dams, harbours etc. including their design, construction, and maintenance.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: