Microbial Fuel Cell with Biosensors

Info: 6037 words (24 pages) Dissertation

Published: 9th Dec 2019

Tagged: Biology

MICROBIAL FUEL CELL WITH BIOSENSORS

ABSTRACT

For a consistent growth in economy and human progress, the energy and water are inevitable. The population explosion and industrialization led to high energy and water consumption and created a massive demand. There is a need to implement alternate energy production methods because the fossils fuels are dangerous to the Earth and that is the highest contributor to the total global energy generation at present. Though there are other methods available in the industry, the Microbial Fuel Cell (MFC) technology is more productive and efficient because of its dual purpose of producing both energy and water. The MFC is also known as Biological fuel cell which is a bio-electrochemical system (BES) that uses the micro-organisms to oxidize the organic and inorganic substances in the wastewater and generates bioelectricity. The MFC based Biosensors are the next generation innovative technology which aims to monitor the Biochemical Oxygen Demand (BOD) and the toxicity in wastewater. This project report aims to provide insights on the basic configuration of MFC and its design. The first part of the report discusses the recent advancements in MFC technology and the working principle of Biosensors & MFC. Finally, the challenges faced by MFC process and its future scopes are reported. On completion of the report, it is evident that the internal resistance is the main cause for low performance of MFC.

1 INTRODUCTION

The depletion of fossil fuel resources and its negative impact on the environment is the main cause for a shift towards sustainable energy solutions. The non-renewable energy resources produce carbon dioxide and that increases the global temperature. The percentage of fresh water is declining rapidly due to over population and exploitation of natural water sources by human beings. The regions which lack proper maintenance of utilities and infrastructure contributed to the mixture of sewage water with the ground water. This is an alarming concern, and which can be addressed only by recycling the wastewater into potable water. The recycling process consumes immense energy and so a technology which can give solution to both energy and water demand is essential. Although, there are many other technologies that can produce bioelectricity, the recent development is MFC and the researchers predict that this could contribute 30% to the global energy demand in environmentally-safe way (Gujral, 2017).

The MFC is a device that generates bioelectricity through biodegradation of organic waste substances in wastewater. A typical MFC consists of cathode and anode chambers which is separated by a cation or anion exchange membrane. MFC can treat municipal wastewater, industrial wastewater, biowaste and synthetic wastewater that has substantial organic content and, also produces bioelectricity simultaneously (Sevda et al., 2018)

The MFC’s employ bacteria to draw the electrons from the organic and inorganic substances and transport from anode to cathode where they join with the proton and oxygen to produce pure water. The power produced is dependent completely on the efficiency of conversion, rate of loading and the biodegradability of substrate (Logan). At present, MFC produces low power output in comparison with other conventional energy production methods. To enhance the power production and to use its efficiency in appropriate way, this research is mandatory to establish the factors that affects the MFC performance. Over the years, various prototypes of MFC are proposed and the configuration of each MFC differs from one another. This report aims to propose the best MFC design which is feasible for power generation. Additionally, the report tends to provide an overview of the application of bio sensors in MFC such as detection of pollutant, BOD, DNA without the use of any electrical device.

The main objective of this report is to find the answers for my research questions which are, what are the limiting factors for reduced power production and how the biosensors are operated to effectively track the toxicity and quality of wastewater. Along with this, the best configuration of MFC which can produce maximum power density is identified.

1.1 MFC configurations and designs

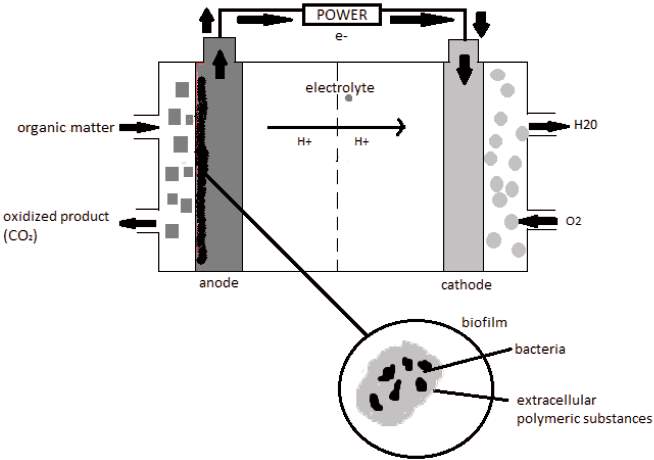

The MFC possess massive potential to produce pure energy and water and it can reduce the carbon in atmosphere. In 1911, the researchers first determined that the bacteria possess electric potential. Then, in 1991, it was recognized that the MFC can produce power even in the absence of chemical mediators and this invention took the research to the next stage (Patil et al., 2014). There are three main MFC designs which are single-chamber, Dual-chamber and Tubular MFC. The single-chamber MFC is the simplest design which has only one compartment because the cathode chamber is not included in the design and the cathode is directly exposed to the air. It consists of rectangular shaped anode chamber which is connected to the air cathode. The most common type is cube bioreactor that is made up of Perspex plastic and the protons moved from the anolyte solution to air cathode. The most often used MFC configuration is double chambered MFC which consists of cathode, anode and separated by Proton Exchange Membrane (PEM). The anode chamber is generally in anaerobic condition for the breakdown process to occur. Since there are separate compartments for

Figure 1 Dual Chambered MFC

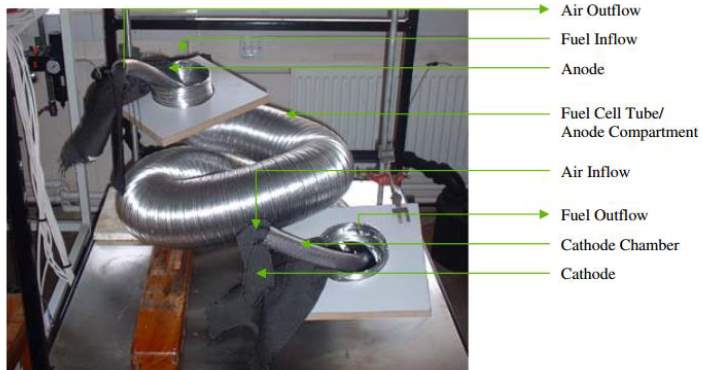

anode and cathode, this design can accommodate various electrode designs such as plane, brush or granular. The figure 1 shows the basic schematic diagram of dual chambered MFC process (Z. Du, Sep. 2007.). The tubular MFC utilizes as granular graphite matrix as anode to generate high power. This configuration produced effective results but Chemical Oxygen Demand (COD) concentration changed and the current density decreased. This type is highly suitable for commercial because it generates high power with low cost materials (K. Scott, 2007). The Figure 2 shows the tubular MFC configuration.

Figure 2 Tubular MFC(K. Scott, 2007)

1.2 Electrode materials

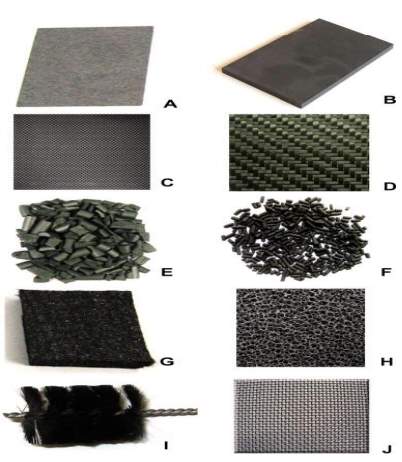

The performance of MFC is affected by the electrode material, electrode configuration, membranes and catalysts. Though there are several factors, the electrode material affects the MFC performance significantly than other factors. Because of the oscillation of electron transfer between electrode and microbes can reduce the power production (Bai L, 2016). The electrode material selection is vital because the inappropriate material can cause corrosion which affects the MFC electricity generation directly. Copper offers high power density when employed as an electrode material. But, the copper ions possess antibacterial quality.

Figure 3 Base material of electrodes

The mostly used base materials for all the electrodes are shown in the figure 3. In the figure 3, A is carbon paper, B is graphite plate, C is carbon cloth, D is carbon mesh, E is granular graphite, F is granular activated carbon, G is carbon felt, H is reticulated vitrified carbon, I is carbon brush and J is stainless steel brush.

In the anode, the bio-electrochemical reactions tend to take place and hence it affects the efficiency of MFC. It is essential to give importance to the anode material and the anodic parameters which can impact the MFC performance are longevity, surface area and electrical conductivity (Malik D, 2014). A lot of research has been made to improve the MFC performance by analyzing low cost materials of electrode under various conditions. One of the methods is the treatment of carbon cloth anodes with phosphate buffer and ammonia gas. This method resulted in positive output by showing considerable development in MFC performance and increased the conductivity of solution. This method increased the overall power production by 48% when compared to the MFC without electrode (E, 2007)

1.3 Advancement in MFC technology

The MFC technology is continuously assessed based on the performance of anode, limitations of cathode, substrates used in MFC and recent technological improvements. Microbial Electrolysis Cell (MEC) is the recent advancement which incorporates anoxic cathode with high external potential at cathode. Great progress in MFC process of electricity generation is witnessed when phototrophic and solar powered MFC are attempted (Cho Y K, 2008).

Recently, MFC was started to operate in electrolysis mode to get bioproducts in the tests conducted in laboratory. The maximum power density of MFC is significantly increased in the last decade and various types of wastes are treated. At present, MFC’s are able to power only small devices and hence advancement is needed to increase the power generation. Uncomplicated and strong MFC with membrane-less system is needed to reduce the overall operational cost. This system needs highly productive biofilms and to produce these biofilms, the latest development of conductive cell aggregates, transfer of electrons through hyperpilation and other improvements in bioengineering improves the chances (Zhou et al., 2013).

2 WORKING PRINCIPLE

- Microbial Fuel cell

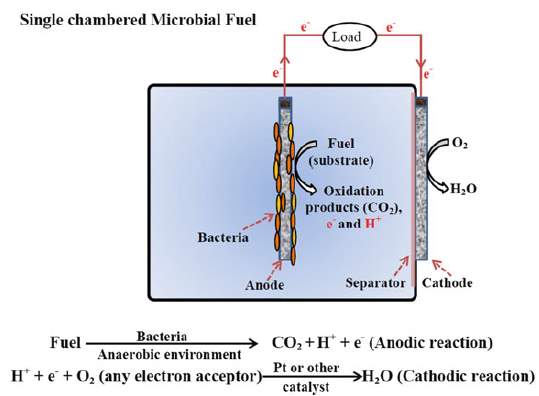

The MFC is a bio-electrochemical system which is comprised of anaerobic anode chamber and aerobic cathode chamber detached by Anion Exchange Membrane (AEM). In a classic MFC prototype, microorganisms are employed for oxidizing the organic and inorganic substances in the anode chamber. Next, the electrons which are released from the microbes are transferred to the cathode through external wire connection. The anode chamber incorporates bacteria as catalyst and the electrode as anode which is nourished with wastewater. The required protons and electrons are extricated when the bacterial substrate catabolism integrated with the oxygen to produce water in cathode.

Figure 3 Schematic diagram of principle of single chambered MFC (Venkata Mohan S, 2014)

Normally the electrons tend to flow to the cathode through a conductive material which possess external resistance. The protons which transfer through membrane are decreased by acquiring electrons and electron acceptor at cathode alike to chemical fuel cell (Venkata Mohan S, 2014). The figure 3 shows the schematic diagram of the working principle of single chamber MFC.

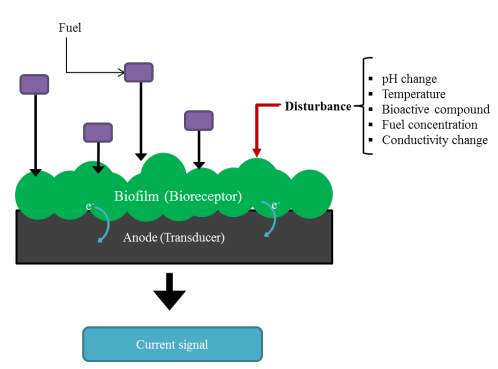

2.2 Biosensors

The microbial biosensors are designed to identify substances in the wastewater by using the biological response of microbes. A biosensor is constructed based on the information obtained from the specific analyte. The critical step involved in the biosensor is the connection of analyte information with the quantitative data. Based on the type of transducer, the biosensors are classified into MFC, Optical and electrochemical biosensors. By using e-coli, the fluorescence biosensors are developed. A biosensor can be defined as the analytical device which can provide quantitative information utilizing the biosensing element connected with transducer.

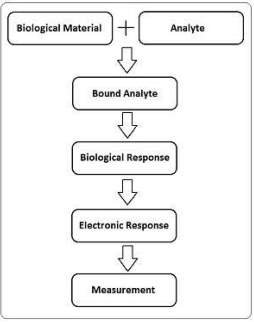

The biosensor construction involved three steps they are, selection of biological selection element, selection of transducer and biological component which is the detection element (Xu X., 2011). The biorecognition elements can be enzymes, microbes, animal cell, plant cells and cell receptors. The working principle of biosensors involves immobilization of biological material such as enzymes by conventional methods. The immobilized biological material is in connection with the transducer. The analyte sticks to the enzyme to form a bound analyte that produces electrical response which can be measured. The analytes may be transformed into a product that is related with the heat, gas or electrons release. The transducer can change the product associated into electrical responses which can be magnified and measured(Malhotra et al., 2017). The Figure 4 gives the working flow of the biosensors.

Fig 4. Work flow of biosensors [11]

- MICROBIAL BIOSENSORS

- Configuration of Biosensor

Depending on the signal transducers, there are optical, electrochemical and microbial fuel cells. When the microbial analyte contact occurs, the electrochemical transducers utilize the changes of electrical conductivity, potential and current. Additionally, electrochemical transducers are again classified into potentiometric, conductometric and amperometric biosensors. The amperometric biosensors tend to work at predetermined potential and the current produced is because of the oxidation or reduction of electroactive organisms at the electrode surface (Xu X., 2011). The potentiometric transducers use the selective ion electrodes to change the biological signal into an electrical signal. But these transducers are not highly sensitive, produces high relative error and has a bad linear relationship existing between the signal and concentration of analyte (Xu X., 2011). The changes in the conductivity of media is detected by the conductometric biosensors. Though the measurements are highly sensitive, the solution conductance detection is not specific (Xu X., 2011).

- MFC as BOD sensor

The organic substances in wastewater is used as a source for generating electricity and when the concentration of that source is reduced, it directly affects the output generated. To be specific, the steady current output is in connection with the concentration of organic substances while the charge output is in connection with the total amount of organic substances present (Kim and 2003). Hence, we can relate the output generated with the fluctuating organic substances in wastewater. Enormous research has been done on designing the MFC based biosensors to evaluate the BOD concentration of wastewater. Mostly, the systems are designed depending upon the dual chamber MFC, in which the anaerobic anodic chamber is the detection component. The time provided for anodic biofilms to enrich is 3-8 weeks because of the provision of several activated sludges (Peixoto and Angelidaki, 2011). Once the anode biofilm formation is completed, the analyte is fed into anodic chamber and the output is observed with devices and that is the output of biosensor. The power produced is based on the concentration of substrate in Monod’s equation. Normally, the concentration of BOD is linked with the maximum power output or total charge output. In case of maximum power output, the linear relationship is generally monitored only at the low levels of BOD while the broad BOD concentration is monitored via total charge output.

The electric current produced from MFC is directly proportional to the concentration of wastewater and that allows the system to utilize it as BOD sensor. Nevertheless, when effort has been made to improve the efficiency of power output, the evaluation of BOD concentration persists as a severe problem because the oxygen spreads via the cation exchange membrane and resulting in low power generation (Kim and 2003). For observation of wastewater treatment processes like anaerobic digestion, the Volatile Fatty Acids (VFA) is used as a parameter (Kim and R. M. & Guwy, 2010). A good interrelationship is established between the concentration of VFA and the total charge output obtained from MFC. Mainly, the MFC based biosensors are built to monitor the individual VFA’s such as propionate, acetate or butyrate in the wastewater (Kaur and Premier, 2013).

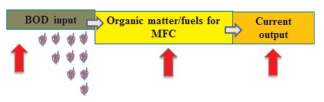

Figure 5 Mechanism of MFC based BOD monitoring(Kim and 2003)

The figure 5 shows the Mechanism of MFC based BOD monitoring where the increased BOD output enables more organic matter for MFC which ends up producing high current output.

- MFC sensor for toxicity monitoring

Toxicity is a vital parameter to be monitored in wastewater treatment process because it can cause significant health diseases to all living species. The detection of toxicity is inevitable in treatment of wastewater, drinking water and environmental monitoring (Davila). The metabolism of bacteria is the main reason for the conversion of chemical energy into electrical energy and so the MFC efficiency is depending on the bacterial activity. If the bacterial activity is restrained for some reason, it directly affects the MFC power output. The MFC output is decreased when the bacterial activity is hindered due to the exposure of bacteria to toxic elements (Stein, 2010). In the conventional dual chambered MFC, when it is used as a toxicity biosensor, the anodic chamber is the detection component. Generally, the anodic chamber is run by feeding wastewater and the online monitoring is done (Stein, 2012).

- MFC sensor for water quality early warning

The evolution of biosensors in the last few years has helped to enable low cost biosensors for water quality monitoring. In the biosensors, a device which can identify the biological elements combined with a transducer is set-up for converting the biological response into a response that is dependent on the concentration of analyte (Chaubey, 2002). The biosensors are very flexible because they are cost-effective, compact and expendable. It saves cost allowing online monitoring the eliminates the need for collecting samples, transporting and testing (Eggins, 1997.).

Most of the sensors are operated in electrochemical method which means they have the benefit of selectivity towards the analyte. Due to leaching, the biosensors are affected by short life period, high cost purification of enzyme and bad stability (Lagarde, 2011). The biosensors are adaptable to various analytes because the cell possess consortium of enzymes (Lagarde, 2011). Predominantly, the microbial biosensors are used for monitoring the water quality but recently, its been used as water toxicity monitoring device (Lei, 2006). The micro-organisms which can tolerate the high temperature, high alkalinity, high acidity and high salt content allows several aspects for monitoring of industrial wastewater (D’Souza, 2001). Nevertheless, the microbial biosensors for water quality monitoring has some drawbacks such as low detection rates, low selectivity and high risk of mixing with other microbes (D’Souza, 2001).

Figure 6 MFC for water quality monitoring (D’Souza, 2001)

4 MFC biosensor for detecting heavy metals

The heavy metals in wastewater can damage the organs and tissues. The chromium (Cr6+) is a strong cancer-causing agent and for detecting such toxic metals, the MFC biosensor is highly beneficial. By dual-chamber MFC, Hg2+ and Pb2+ can be detected (Kim, 2007). But, this research helped to detect only small amount of concentration of heavy metals. The MFC based biosensors are also used to find the impacts of Cu2+ on microbes in soil. The electric signals obtained from the soil is used to calculate the toxic level of Cu2+ (Deng, 2015).

5 Limiting-factor of low MFC performance

The main reason for low power output is the internal resistance and over potential. The power production is affected by the electron transfer from microbe to anode. Theoretically, the maximum voltage can be produced by MFC is 1.1 v but however, when measured, the voltage is significantly less due to some losses. The other losses involved are

Ohmic loss – This loss includes the resistance of electrons to flow to the electrodes and resistance of ion to flow towards anode and cathode electrolytes. This loss can be decreased by reducing the spacing between electrodes, by increasing the conductivity of solution and employing the membrane with low resistivity.

Activation loss – The activation energy is required for redox reactions during electron transfer at surface of electrode. This loss show increase at low currents and constant rise when the current density is increased. The activation loss can be reduced by increasing the surface area of electrode, increasing the temperature and enhancing the electrode catalysis.

Concentration loss– This loss happens when the mass transfer of species rate hinders the power production. The concentration loss likely to occur at high current density because of less mass transfer to surface of electrode.

Bacterial – Metabolic loss– The metabolic energy is generated by the transportation of electrons from a substrate at a lower potential to a substrate at a higher potential. As far as MFC is concerned, the anode is the final electron accepting component and its strength influences the energy obtained by microbes. When the difference between redox potential and anode potential of substrate is significantly high, then the metabolic bacterial energy is also high. To increase the voltage, it is essential to maintain the anode potential at lower level.

The MFC sensors enables tracking of water quality faster and, also efficiently. But, the efficiency of the sensors is limited to detect the contaminants less than 0.063 mg L−1 (Moon, 2005). The MFC sensors are affected by potential contaminants present in the wastewater to some extent.

6.1 Factors affecting the Performance of MFC sensors

The MFC sensors are widely affected by the Extracellular Electron Transfer (EET). When the mediators are not present, the anode biofilm can increase the EET process (Yong, 2013). When the carbon mesh is pretreated, it has a significant impact on the MFC performance. And the treatment of carbon mesh with ammonia gas increased the power output by 51 W m−3 (Choudhury, 2017). The type of anode can also directly affect the power production of MFC.

7 Challenges and Future Perspectives of Microbial Fuel cell

It is mandatory to discuss about the low power generation of MFC and how to optimize the existing prototypes. Some losses are occurred due to unwanted reactions such as the oxidation of fuel by oxygen diffusion into anode chamber which is not an advantage to the project, should be focused to improve the process. Contrastingly, the increment of volumetric capacity of system should be made possible irrespective of the internal energy loss. Additionally, the tubular MFC and other prototypes need to be explored. At present, researchers are working towards better electron transfer mechanisms between the electrode and biocatalyst by making some changes in the electrode surface and also, the active catalyst is coated on the surface of electrode (BRUCE E. LOGAN et al., 2006)

Conclusion

This journal discusses broadly about the configuration of MFC and biosensors. Along with this, the biosensors and its operation are described elaborately with appropriate content. The factors which are the reasons behind the reduced MFC performance and the solutions to reduce the losses are clearly identified. MFC potential is still unraveled to the world, and the challenges and the future scope of MFC is added. To conclude, this paper is an overall representation of MFC along with microbial biosensors and their operating procedure in real work environment.

BAI L, Z. M. A. G. C. (2016). Advanced nanomaterials for the design and construction of anode for microbial fuel cells Advanced Electrode Materials, 457-83

Logan,E.B, Hamelers,B, Aelterman,P, Schroder,U, KellerJ, Freguia,S.. 2006. Microbial Fuel Cells: Methodology and Technology. ENVIRONMENTAL SCIENCE & TECHNOLOGY 40, 5181-5190.

CHAUBEY, A. M., B.D., 2002. Mediated biosensors. Biosens. Bioelectron. 17.

CHO Y K, D. T. J., TEJEDOR I, ANDERSON M A, MCMAHON K, D & NOGUERA D R 2008. Development of a solar-powered Microbial duel cell. J Appl Microbiol, 104, 640-650.

CHOUDHURY, P. P. U., U.S.; BANDYOPADHYAY, T.K.; RAY, R.N.; BHUNIA, B. 2017. Performance improvement of microbial fuel cell (MFC) using suitable electrode and Bioengineered organisms: A review. Bioengineered, 1–17.

D’SOUZA, S. F. 2001. Microbial biosensors. Biosens. Bioelectron., 16, 337–353.

DAVILA, D., ESQUIVEL, J. P., SABATE, N. & MAS, J Silicon-based microfabricated microbial fuel cell toxicity sensor. Biosensors & Bioelectronics 26, 2426–2430.

DENG, H. J., Y.; ZHOU, Y.; SHEN, K.; ZHONG, W. 2015. Using electrical signals of microbial fuel cells to detect copper stress on soil microorganisms. Eur. J. Soil Sci. , 66, 369–377. .

E, C. S. A. L. B. 2007. Ammonia treatment of carbon cloth anodes to enhance power generation of microbial fuel cells. Electrochem Commun, 9, 492–96. .

EGGINS, B. B. 1997. Biosensors: An Introduction. Wiley: Hoboken, NJ, USA,.

GUJRAL, I. 2017. A Review of Microbial Fuel Cells for Bioelectricity Generation. Conference Proceedings.

K. SCOTT, C. M., AND G. RIMBU 2007. A tubular microbial fuel cell. 37, 1063-1068.

KAUR, A., KIM, J. R., MICHIE, I., DINSDALE, R. M., GUWY, A. J., & PREMIER, G. C. C., S. E. R 2013. Microbial fuel cell type biosensor for specific volatile fatty acids using acclimated bacterial communities. Biosensors & Bioelectronics, 47, 50–55.

KIM, B. H., CHANG, I. S., GIL, G. C., PARK, H. S. & KIM, H. J & 2003. Novel BOD (biological oxygen demand) sensor using mediator-less microbial fuel cell. Biotechnology Letters, 25, 541–545.

KIM, J. R., PREMIER, G. C., HAWKES, F. R., RODRIGUEZ, J., DINSDALE, & R. M. & GUWY, A. J. 2010. Modular tubular microbial fuel cells for energy recovery during sucrose wastewater treatment at low organic loading rate. . MBioresource Technology, 101, 1190–1198.

KIM, M. S. H., M.; GADD, G.M.; JOO KIM, H. 2007. A novel biomonitoring system using microbial fuel cells. J. Environ. Monit. , 9, 1323–1328.

LAGARDE, F. 2011. Cell-based electrochemical biosensors for water quality assessment. affrezic-Renault, N.. Anal. Bioanal. Chem. , 400, 947–964.

LEI, Y. C., W.; MULCHANDANI, 2006. A. Microbial biosensors. Anal. Chim. Acta, 568, 200–210.

LOGAN, B. E. Exoelectrogenic bacteria that power microbial fuel cells.

MALHOTRA, S., , A. V., , N. T. & , V. K. 2017. BIOSENSORS: PRINCIPLE, TYPES AND APPLICATIONS. 3

MALIK D, T. J., SINGH S, SINGH R K, KAPUR A, KAUR A, NIJHAWAN S AND KUMAR 2014. A Nanocomposite electrode microbial fuel cell: a promising technology for enhanced power generation from yamuna water. IJSR, 3, 641-46.

MOON, H. C., I.S.; JANG, J.K.; KIM, K.S.; LEE, J.; LOVITT, R.W.; KIM, B.H. 2005. On-line monitoring of low biochemical oxygen demand through continuous operation of a mediator-less microbial fuel cell. . Microbiol. Biotechnol. , 15, 192–196.

PATIL, S., HÄGERHÄLL, C. & GORTON, L. 2014. Electron transfer mechanisms between microorganisms and electrodes in bioelectrochemical systems.

PEIXOTO, L., MIN, B., MARTINS, G., BRITO, A. G., KROFF, P., PARPOT, P., & ANGELIDAKI, I. N., R. 2011. In situ microbial fuel cell-based biosensor for organic carbon. . Bioelectrochemistry, 81, 99–103.

SEVDA, S., SARMA, P., MOHANTY, K., R. SREEKRISHNAN, T. & PANT, D. 2018. Microbial Fuel Cell Technology for Bioelectricity Generation from Wastewaters.

STEIN, N. E., HAMELERS, H. V. M. & BUISMAN, C. N. J. 2010. Stabilizing the baseline current of a microbial fuel cell-based biosensor through overpotential control under non-toxic conditions. Bioelectrochemistry, 78, 87–91.

STEIN, N. E., HAMELERS, H. V. M. & BUISMAN, C. N. J. 2012. Influence of membrane type, current and potential on the response to chemical toxicants of a microbial fuel cell based biosensor. . Sensors and Actuators B (Chemical) 163, 1–7.

VENKATA MOHAN S, V. G., ANNIE MODESTRA J, SRIKANTH S 2014. Microbial fuel cell: Critical factors regulating bio-catalyzed electrochemical process and recent advancements. Sustain Energy Rev, 40, 779–797.

XU X., Y. Y. 2011. Microbial Biosensors for Environmental Monitoring and Food Analysis. Food Reviews International, 27, 300-329.

YONG, Y. C. C., Z.; YU, Y.Y.; CHEN, P.; JIANG, R.; CAO, B.; SUN, J.Z.; WANG, J.Y.; SONG, H. 2013. Increase of riboflavin biosynthesis underlies enhancement of extracellular electron transfer of Shewanella in alkaline microbial fuel cells. Bioresour. Technol., 130, 763–768.

Z. DU, H. L., AND T. GU Sep. 2007. A state of the art review on microbial fuel cells: A promising technology for wastewater treatment and bioenergy. Biotechnol. Adv, 25, 464–482.

ZHOU, M., WANG, H., HASSETT, D. & GU, T. 2013. Recent advances in microbial fuel cells (MFCs) and microbial electrolysis cells (MECs) for wastewater treatment, bioenergy and bioproducts.

BAI L, Z. M. A. G. C. 2016. Advanced nanomaterials for the design and construction of anode for microbial fuel cells Advanced Electrode Materials, 457-83

BRUCE E. LOGAN, BERT HAMELERS, , RENEÄ ROZENDAL, | UWE SCHRO¨ DER, ⊥ J U¨ RG KELLER, , STEFANO FREGUIA, P. A. & WILLY VERSTRAETE, A. K. R. 2006. Microbial Fuel Cells: Methodology and Technology. ENVIRONMENTAL SCIENCE & TECHNOLOGY 40, 5181-5190.

CHAUBEY, A. M., B.D., 2002. Mediated biosensors. . Biosens. Bioelectron. , 17.

CHO Y K, D. T. J., TEJEDOR I, ANDERSON M A, MCMAHON K, D & NOGUERA D R 2008. Development of a solar-powered Microbial duel cell. J Appl Microbiol, 104, 640-650.

CHOUDHURY, P. P. U., U.S.; BANDYOPADHYAY, T.K.; RAY, R.N.; BHUNIA, B. . 2017. Performance improvement of microbial fuel cell (MFC) using suitable electrode and Bioengineered organisms: A review. Bioengineered, 1–17.

D’SOUZA, S. F. 2001. Microbial biosensors. Biosens. Bioelectron., 16, 337–353.

DAVILA, D., ESQUIVEL, J. P., SABATE, N. & MAS, J Silicon-based microfabricated microbial fuel cell toxicity sensor. Biosensors & Bioelectronics 26, 2426–2430.

DENG, H. J., Y.; ZHOU, Y.; SHEN, K.; ZHONG, W. 2015. Using electrical signals of microbial fuel cells to detect copper stress on soil microorganisms. Eur. J. Soil Sci. , 66, 369–377. .

E, C. S. A. L. B. 2007. Ammonia treatment of carbon cloth anodes to enhance power generation of microbial fuel cells. Electrochem Commun, 9, 492–96. .

EGGINS, B. B. 1997. Biosensors: An Introduction. Wiley: Hoboken, NJ, USA,.

GUJRAL, I. 2017. A Review of Microbial Fuel Cells for Bioelectricity Generation. Conference Proceedings.

K. SCOTT, C. M., AND G. RIMBU 2007. A tubular microbial fuel cell. 37, 1063-1068.

KAUR, A., KIM, J. R., MICHIE, I., DINSDALE, R. M., GUWY, A. J., & PREMIER, G. C. C., S. E. R 2013. Microbial fuel cell type biosensor for specific volatile fatty acids using acclimated bacterial communities. Biosensors & Bioelectronics, 47, 50–55.

KIM, B. H., CHANG, I. S., GIL, G. C., PARK, H. S. & KIM, H. J & 2003. Novel BOD (biological oxygen demand) sensor using mediator-less microbial fuel cell. Biotechnology Letters, 25, 541–545.

KIM, J. R., PREMIER, G. C., HAWKES, F. R., RODRIGUEZ, J., DINSDALE, & R. M. & GUWY, A. J. 2010. Modular tubular microbial fuel cells for energy recovery during sucrose wastewater treatment at low organic loading rate. . MBioresource Technology, 101, 1190–1198.

KIM, M. S. H., M.; GADD, G.M.; JOO KIM, H. 2007. A novel biomonitoring system using microbial fuel cells. J. Environ. Monit. , 9, 1323–1328.

LAGARDE, F. 2011. Cell-based electrochemical biosensors for water quality assessment. affrezic-Renault, N.. Anal. Bioanal. Chem. , 400, 947–964.

LEI, Y. C., W.; MULCHANDANI, 2006. A. Microbial biosensors. Anal. Chim. Acta, 568, 200–210.

LOGAN, B. E. Exoelectrogenic bacteria that power microbial fuel cells.

MALHOTRA, S., , A. V., , N. T. & , V. K. 2017. BIOSENSORS: PRINCIPLE, TYPES AND APPLICATIONS. 3

MALIK D, T. J., SINGH S, SINGH R K, KAPUR A, KAUR A, NIJHAWAN S AND KUMAR 2014. A Nanocomposite electrode microbial fuel cell: a promising technology for enhanced power generation from yamuna water. IJSR, 3, 641-46.

MOON, H. C., I.S.; JANG, J.K.; KIM, K.S.; LEE, J.; LOVITT, R.W.; KIM, B.H. 2005. On-line monitoring of low biochemical oxygen demand through continuous operation of a mediator-less microbial fuel cell. . Microbiol. Biotechnol. , 15, 192–196.

PATIL, S., HÄGERHÄLL, C. & GORTON, L. 2014. Electron transfer mechanisms between microorganisms and electrodes in bioelectrochemical systems.

PEIXOTO, L., MIN, B., MARTINS, G., BRITO, A. G., KROFF, P., PARPOT, P., & ANGELIDAKI, I. N., R. 2011. In situ microbial fuel cell-based biosensor for organic carbon. . Bioelectrochemistry, 81, 99–103.

SEVDA, S., SARMA, P., MOHANTY, K., R. SREEKRISHNAN, T. & PANT, D. 2018. Microbial Fuel Cell Technology for Bioelectricity Generation from Wastewaters.

STEIN, N. E., HAMELERS, H. V. M. & BUISMAN, C. N. J. 2010. Stabilizing the baseline current of a microbial fuel cell-based biosensor through overpotential control under non-toxic conditions. Bioelectrochemistry, 78, 87–91.

STEIN, N. E., HAMELERS, H. V. M. & BUISMAN, C. N. J. 2012. Influence of membrane type, current and potential on the response to chemical toxicants of a microbial fuel cell based biosensor. . Sensors and Actuators B (Chemical) 163, 1–7.

VENKATA MOHAN S, V. G., ANNIE MODESTRA J, SRIKANTH S 2014. Microbial fuel cell: Critical factors regulating bio-catalyzed electrochemical process and recent advancements. Sustain Energy Rev, 40, 779–797.

XU X., Y. Y. 2011. Microbial Biosensors for Environmental Monitoring and Food Analysis. Food Reviews International, 27, 300-329.

YONG, Y. C. C., Z.; YU, Y.Y.; CHEN, P.; JIANG, R.; CAO, B.; SUN, J.Z.; WANG, J.Y.; SONG, H. 2013. Increase of riboflavin biosynthesis underlies enhancement of extracellular electron transfer of Shewanella in alkaline microbial fuel cells. Bioresour. Technol., 130, 763–768.

Z. DU, H. L., AND T. GU Sep. 2007. A state of the art review on microbial fuel cells: A promising technology for wastewater treatment and bioenergy. Biotechnol. Adv, 25, 464–482.

ZHOU, M., WANG, H., HASSETT, D. & GU, T. 2013. Recent advances in microbial fuel cells (MFCs) and microbial electrolysis cells (MECs) for wastewater treatment, bioenergy and bioproducts.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Biology"

Biology is the scientific study of the natural processes of living organisms or life in all its forms. including origin, growth, reproduction, structure, and behaviour and encompasses numerous fields such as botany, zoology, mycology, and microbiology.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: