A Review on Quality Preservation and Energy Efficiency in Refractance Window Drying

Info: 4498 words (18 pages) Dissertation

Published: 16th Dec 2019

A Review on Quality Preservation and Energy Efficiency in Refractance Window Drying: A Conductive Hydro-Drying Technique

Abstract

Thermal drying consume up to 25% of the industrial energy consumption in the developed countries. Refractance Window (RW) is a relatively new film drying method that it is characterized by maintaining a relatively low temperature inside the food and by short drying times. The cost of the RW equipment is about one-third of the cost of a freeze-dryer, whereas the energy consumption of RW is less than half of the energy consumption for a freeze-dryer. RW drying system uses circulating hot water as a means to convey thermal energy to materials to be dehydrated. RW dryer can produce high-quality products with heat sensitive vitamins, phytochemicals content, color and antioxidant activity comparable to those of the freeze-dried products.

Early understandings heat transfer mechanism in RW drying have concluded that thermal radiation from hot water transfers to the moist material by the use of a thin plastic sheet that allows creates a “window” for transfer of infrared (IR) radiation. This “window” gradually closes as the material dries out cutting off radiation. Recently a conjugate heat and mass transfer model showed that a major portion of thermal energy is transferred via conduction and the relatively low sample temperature is attributed to the development of a thermally resistive layer at the base of the product or development of air spaces between the product and the plastic sheet which reduces the heat flux from the hot water; therefore, quality of the dried product is preserved. Another important parameter in RW drying is air convection. Forced air convection causes lower product temperature and higher moisture loss in comparison with natural convection.

Keywords: Refractance Window, drying, energy efficiency, product quality, infrared radiation, thermal conduction.

Introduction

Dried vegetables, fruits and other food ingredients are widely used in prepared foods. Conservation of quality attributes such as aroma, color and nutrients has always been a challenge in dehydration of heat sensitive fruits and vegetables. Consumer demand for high quality dehydrated foods continually inspires efforts toward development of improved and innovative drying methods (Baeghbali, Niakosari, & Kiani, 2010; C. I. Nindo, Feng, Shen, Tang, & Kang, 2003).

Thermal drying consumes 10–25% of the industrial energy in the developed countries. Drying energy consumption in the United States, United Kingdom and France were 1600×109, 128×109, 168×109 MJ/year, respectively. With rapid industrialization of emerging global economies, the energy consumed for thermal dehydration and the resulting adverse environmental impact of the greenhouse gases will unavoidably increase over time (Law & Mujumdar, 2012).

Refractance Window Drying

Refractance Window (RW) is a new film drying method and it is characterized by maintaining a relatively low temperature inside the food and by requiring shorter process times (C. I. Nindo, Sun, Wang, Tang, & Powers, 2003). To dry a similar amount of product, the cost of the RW equipment is about one-third of the cost of a freeze-dryer (FD); while energy consumption of RW is less than half of the energy consumption for a FD (C. I. Nindo & Tang, 2007).

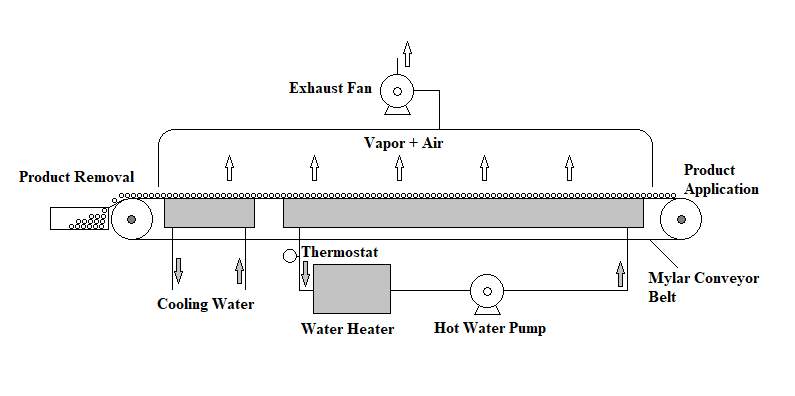

RW drying system uses circulating water at 90 to 95°C as a means to convey thermal energy to materials to be dehydrated (figure 1). As the product does not have direct contact with the heat transfer medium during RW drying, no cross-contamination occurs (Moses, Norton, Alagusundaram, & Tiwari, 2014). Evaporation capacity up to 10 kg m−2 h−1 shows that RW is a very efficient drying process (Zotarelli, Carciofi, & Laurindo, 2015).

Figure 1. Schematic of a continuous RW dryer (Baeghbali, Niakousari, & Farahnaky, 2016).

RW dryer can preserve color (Castoldi, Zotarelli, Durigon, Carciofi, & Laurindo, 2014), heat sensitive vitamins and phytochemicals that some of them will be discussed in the following section.

Preservation of heat sensitive vitamins and phytochemicals

Ascorbic Acid Retention

Ascorbic acid is an important vitamin and an essential nutrient for humans and some animal species. It is found in many fruits and vegetables but it is very sensitive to heat and oxidation (Burdurlu, Koca, & Karadeniz, 2006). Several studies have shown that RW drying can preserve ascorbic acid content in the products. Ascorbic acid retention of the strawberry purees (94.0%) after RW drying was comparable to 93.6% in FD (Abonyi et al., 2002). Another study also showed that Ascorbic acid retention in strawberry purees dried with RW system (93%) was comparable to FD products (94%) (Sablani, 2006). In dried asparagus using heated air, RW, and microwave assisted spouted bed, RW drying resulted in highest retention of total ascorbic acid (Santos & Silva, 2008).

Anthocyanin Retention

Anthocyanins are valuable and nutritional phytochemicals, which are present in various plants. They are susceptible to drying processes (Tonon, Brabet, & Hubinger, 2010). Researches have shown that RW drying results in low anthocyanin losses. In a study 45, 41 and 23% losses in total anthocyanins content were observed in colored potato flakes after FD, drum drying and RW drying, respectively (Nayak, Berrios, Powers, Tang, & Ji, 2011). Haskap berry puree was dried using an RW dryer and more than 92% of anthocyanins was retained (Celli, Khattab, Ghanem, & Brooks, 2016). RW dryer produced high-quality pomegranate juice powder with anthocyanins content, anthocyanins color and antioxidant activity equal or greater than those of the freeze dried and spray dried samples (Baeghbali et al., 2016).

Carotene Retention

Carotenes are colored pigments found many fruits and vegetables. β-carotene is the most common form of carotene in plants. It can be used as a food coloring and it is a precursor to vitamin A. Carotenes are also susceptible to heat and oxidation (Pénicaud, Achir, Dhuique-Mayer, Dornier, & Bohuon, 2011) and their retention in dried products is imperative to achieve a high quality products. A study on quality retention of dried carrot puree showed that RW drying is a much better method than drum drying to dry carrot puree (Table 1). The color of the RW-dried carrot purees was comparable to fresh puree (Abonyi et al., 2002). Another research on RW drying of carrots have also demonstrated similar results (Hernández-Santos et al., 2016).

Table 1. Carotene losses in carrots samples dried by drum, freeze, and Refractance Window drying methods.

| Dryer / Carotene Loss | Total carotene | α-carotene | β-carotene |

| Drum Dryer | 56.0% | 55.0% | 57.1% |

| RW Dryer | 8.7% | 7.4% | 9.9% |

| Freeze Dryer | 4.0% | 2.4% | 5.4% |

Vitamin B retention

In a recent study Nemzer et al, studied phytochemical and physical properties retention in blueberries, tart cherries, strawberries, and cranberries as affected by FD, RW and hot air drying methods and their results showed that RW dried cranberry and strawberry samples had higher total vitamin B retention than FD and hot air dried products (Nemzer, Vargas, Xia, Sintara, & Feng, 2018).

Microbial Reduction

Although RW drying is comparable with freeze drying and other low temperature drying methods in terms of physiochemical quality retention, it can also reduce microbial load in its dried products. In a study on RW drying of pumpkin puree from 80% to 5% moisture content (wb) which was completed in about 5 minutes (with water at 95ºC). RW drying of inoculated pumpkin purees resulted in 4.6, 6.1, 6.0, and 5.5 log reductions of total aerobic plate counts (APC), coliforms, Escherichia coli, and Listeria innocua, respectively. The RW dryer in this study demonstrated up to 70% energy efficiency (C. I. Nindo, Feng, et al., 2003).

Case studies of drying fruits and vegetables

Green Asparagus

In a study on drying of green asparagus using different methods, microwave assisted spouted bed (MWSB) drying was the fastest and resulted in highest retention of total antioxidant activity (TAA) among the methods where heated air was used. TAA of asparagus was improved after RW and freeze-drying, with the TAA values being significantly higher than for heated air-drying methods. The highest amount of ascorbic acid was retained in the product after RW drying, followed by freeze-drying, MWSB and spouted bed drying (C. I. Nindo, Sun, et al., 2003).

Paprika

Refractance Window drying (RWD) method was used to dry paprika and the quality of the dried product was compared with paprika samples dried using freeze drying, hot-air oven drying, and natural convective drying methods. The freeze-dried and RWD-dried paprika exhibited better reflected color characteristics. There was no significant difference in browning index between freeze-died and RW-died samples (A. Topuz, Dincer, Ozdemir, Feng, & Kushad, 2011; Ayhan Topuz, Feng, & Kushad, 2009).

Mango

Drying process of mango was carried out using RW drying, freeze drying, drum drying, and spray drying. Results showed that the color of RW-dried mango powder and reconstituted mango puree were comparable to the freeze dried products, but were significantly different from drum dried (darker), and spray dried (lighter) counterparts. The bulk densities of drum dried and RW-dried mango powders were higher than freeze dried and spray dried powders. There were no significant differences between RW and freeze dried powders in terms of solubility and hygroscopicity. The microstructure of RW-dried mango powder was smooth and flaky with uniform thickness (Caparino, Sablani, Tang, Syamaladevi, & Nindo, 2013; Caparino et al., 2012; Ochoa-Martínez, Quintero, Ayala, & Ortiz, 2012).

Aloe-vera

Aloe-vera extract was dried using spray drying, freeze drying, and RW drying methods. Solutions prepared from spray dried aloe-vera had the lowest viscosity, while freeze dried and RW‐dried counterparts had higher and nearly similar consistency. The activation energy for network formation of solutions reconstituted from spray dried powder was 23.9±0.1 kJ mol‐1, which was slightly lower than the 24.6±0.3 and 24.7±0.4 kJ mol‐1 acquired from freeze dried and RW dried samples, respectively (C. Nindo, Powers, & Tang, 2011). Another study on RW drying of aloe-vera gel also showed that RW and freeze dried products are comparable (Minjares-Fuentes et al., 2016).

Strawberry Puree

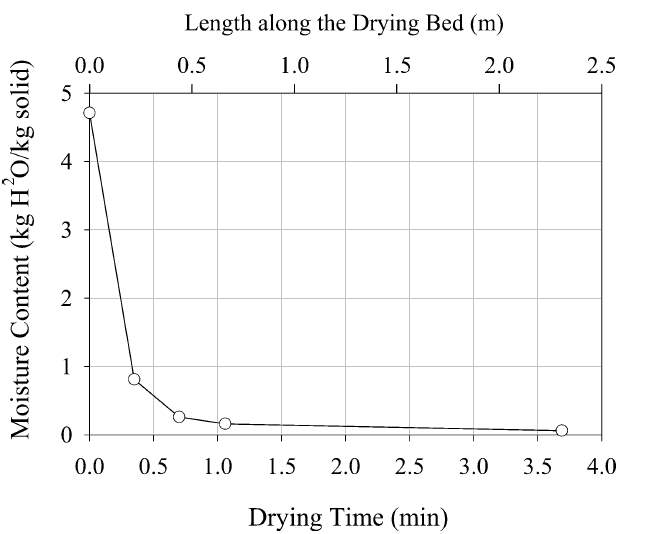

RW-dried strawberries demonstrated color values close to that measured in freeze-dried samples. In case of aromatic compounds, sample analysis showed that RW-dried strawberry purees had less esters and alcohols and more heat-induced ketones and aldehydes. Total drying time was about 4 minutes (figure 2).

Figure 2. Moisture content as compared with drying time for strawberry puree with carrier dried with the RW drying (Abonyi et al., 2002).

Energy Efficiency

Different studies on energy consumption and energy efficiency of RW drying have concluded that in comparison with different conventional drying methods, RW drying is a very energy efficient choice (Table 2,3).

Table 2. Comparison of energy consumption of RW with other selected dryers (C. I. Nindo & Tang, 2007).

| Dryer type | Typical product temperature (ºC) | Thermal efficiency (%) |

| Rotary dryer | About 175 | 50-25 |

| Spray dryer | 80-120 | 51-20 |

| Drum dryer | 120-130 | 78-35 |

| RW Dryer | 60-70 | 77-52 |

Table 3. Overall energy efficiency of spray, freeze and RW dryers (Baeghbali et al., 2016).

| Overall energy efficiency (%) | Energy consumption for drying 1kg sample (kWh) | Calculated energy needed for drying 1kg sample (kWh) | Dryer |

| 1.12 | 130.65 | 1.46 | Freeze dryer |

| 31.56 | 4.31 | 1.36 | RW dryer |

| 12.92 | 11.01 | 1.42 | Spray dryer |

Heat Transfer Mechanism

In the RW drying process, the actual product temperature is usually less than 70ºC. The hot water is recycled and reused, thereby improving the thermal efficiency of the system. The use of hot water as the heat transfer medium and at temperatures just below boiling is a design feature that is unique to this drying method. First mechanism which was proposed for RW drying suggested that in this type of dryer, thermal energy from circulating hot water is transported to the wet product via a plastic interface which is relatively transparent to infrared radiation. During RW drying, the three modes of heat transfer are active which include conduction (qcond), convection (qconv), and radiation (qrad) (C. I. Nindo & Tang, 2007).

Since the plastic conveyor is very thin, it reaches the temperature of hot water flowing beneath it almost instantly. Thermal energy from the hot water is transmitted through the plastic conveyor by conduction and radiation. Thin Mylar conveyor with infrared transmission in the wavelength range that matches the absorption spectrum for water all work together to facilitate quick drying. Water has high absorption for infrared with wavelengths of 3.0, 4.7, 6.0, and 15.3 µm. The infrared transmission is stronger when the plastic interface is in contact with water on one side and a moisture-laden material on the other side (C. I. Nindo & Tang, 2007).

In a recent study, a conjugate heat and mass transfer model was developed to simulate the RW drying of pumpkin slices. Computed results indicated that there was a 5% increase in transmission of IR radiation through the plastic sheet between a dry and wet product. A major portion of thermal energy was transferred via conduction through the plastic sheet. It was concluded that the relatively low sample temperature observed for RW drying of thin samples was attributed to the development of a dried, thermally resistive layer at the base which prevented heat transfer from the plastic sheet during the later portions of the drying process; for thick-sized samples, the low sample temperature was a result of development of air spaces between the product and the plastic sheet, which reduced the heat flux from the hot water. As a consequence, quality of the RW dried product is preserved when compared with other drying techniques (Monica Jimena Ortiz-Jerez, Gulati, Datta, & Ochoa-Martínez, 2015).

In another research, time–temperature evolution of drying mango pulp surface was determined by thermography during the RW process performed with 2 mm-thick pulp and water at 95 °C. After spreading, pulp temperatures quickly increased up to 70 °C and remained almost steady during the constant drying rate period. From10 to 15 min after the RW process started the temperature began to increase in some areas, owing to their low moisture content (Zotarelli et al., 2015).

Effect of Air Convection

Effects of natural convection and forced convection of air in RW dryer was studied by Ortiz-Jerez & Ochoa-Martínez (2015). Pumpkin slices were dried in this study and temperatures were measured at three levels (bottom, middle and top) during drying. Average temperatures measured at the three point of sample thickness were higher in the runs with natural convection and lower in those with forced convection, which was highly similar to the results of the drying curves. The lowest moisture kinetics were obtained in samples dried with natural-convection, while the samples dried with forced-convection showed the highest moisture loss values (M. J. Ortiz-Jerez & Ochoa-Martínez, 2015).

Future Trends

- Modeling of drying process in RW dryer and investigating the role of different parameters and heat transfer mechanisms in the process.

- Optimization of Refractance Window drying in terms of energy consumption and process design.

- Investigating dehydration of different food materials including microorganisms (yeast, probiotics), leaf vegetables, meat and marine products.

- Investigating the effect of RW drying on starch granules.

Summary

Refractance Window is a relatively new film drying technique and it is characterized by high-quality products, short drying times, low cost, high energy efficiency and high evaporation capacity. RW dryer can retain product quality in terms of heat sensitive vitamins, phytochemicals content, color and antioxidant activity equal or greater than those of the freeze-dried products.

Firstly, it was assumed that the main heat transfer mechanism of RW drying system was thermal radiation via the plastic sheet through a transparent window which was created by the contact of wet material on the surface of the sheet. Recently, a conjugate heat and mass transfer model developed to simulate the RW drying process showed that a major portion of thermal energy is transferred via conduction and development of a dried, thermally resistive layer at the base or development of air spaces between the product and the plastic sheet reduces the heat flux from the hot water therefore reducing thermal damage and preserving the quality of the product. Another important parameter in RW drying is air convection. Forced air convection in RW dryer causes lower product temperature during the process and higher moisture loss values in comparison with natural convection.

Although many different drying experiments have been conducted on RW drying system, optimization of RW drying in terms of energy consumption and process design and investigating the effect of RW drying on starch granules and dehydration of microorganisms (yeast, probiotics), leaf vegetables, meat and marine products should be of interest to researchers.

Selected References:

Abonyi, B. I., Feng, H., Tang, J., Edwards, C. G., Chew, B. P., Mattinson, D. S., & Fellman, J. K. (2002). Quality Retention in Strawberry and Carrot Purees Dried with Refractance WindowTM System. Journal of Food Science, 67(3), 1051-1056. doi:10.1111/j.1365-2621.2002.tb09452.x

Baeghbali, V., Niakosari, M., & Kiani, M. (2010). Design, manufacture and investigating functionality of a new batch Refractance Window system. Paper presented at the 5th International Conference on Innovations in Food and Bioprocess Technology, Pathumthani, Thailand.

Baeghbali, V., Niakousari, M., & Farahnaky, A. (2016). Refractance Window drying of pomegranate juice: Quality retention and energy efficiency. LWT – Food Science and Technology, 66, 34-40. doi:10.1016/j.lwt.2015.10.017

Burdurlu, H. S., Koca, N., & Karadeniz, F. (2006). Degradation of vitamin C in citrus juice concentrates during storage. Journal of Food Engineering, 74(2), 211-216. doi:10.1016/j.jfoodeng.2005.03.026

Caparino, O. A., Sablani, S. S., Tang, J., Syamaladevi, R. M., & Nindo, C. I. (2013). Water Sorption, Glass Transition, and Microstructures of Refractance Window– and Freeze-Dried Mango (Philippine “Carabao” Var.) Powder. Drying Technology, 31(16), 1969-1978. doi:10.1080/07373937.2013.805143

Caparino, O. A., Tang, J., Nindo, C. I., Sablani, S. S., Powers, J. R., & Fellman, J. K. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135-148. doi:10.1016/j.jfoodeng.2012.01.010

Castoldi, M., Zotarelli, M. F., Durigon, A., Carciofi, B. A. M., & Laurindo, J. B. (2014). Production of Tomato Powder by Refractance Window Drying. Drying Technology, 33(12), 1463-1473. doi:10.1080/07373937.2014.989327

Celli, G. B., Khattab, R., Ghanem, A., & Brooks, M. S. (2016). Refractance Window drying of haskap berry – Preliminary results on anthocyanin retention and physicochemical properties. Food Chem, 194, 218-221. doi:10.1016/j.foodchem.2015.08.012

Hernández-Santos, B., Martínez-Sánchez, C. E., Torruco-Uco, J. G., Rodríguez-Miranda, J., Ruiz-López, I. I., Vajando-Anaya, E. S., . . . Herman-Lara, E. (2016). Evaluation of physical and chemical properties of carrots dried by Refractance Window drying. Drying Technology, 34(12), 1414-1422. doi:10.1080/07373937.2015.1118705

Law, C. L., & Mujumdar, A. S. (2012). Energy Saving In Drying Processes. In D. C. Y. Foo, M. M. El-Halwagi, & R. R. Tan (Eds.), Recent Advances in Sustainable Process Design and Optimization (Vol. 3, pp. 577-591). Singapore: World Scientific Publishing Co. Pte. Ltd.

Minjares-Fuentes, R., Femenia, A., Comas-Serra, F., Rosselló, C., Rodríguez-González, V. M., González-Laredo, R. F., . . . Medina-Torres, L. (2016). Effect of different drying procedures on physicochemical properties and flow behavior of Aloe vera (Aloe barbadensis Miller) gel. LWT – Food Science and Technology, 74, 378-386. doi:10.1016/j.lwt.2016.07.060

Moses, J. A., Norton, T., Alagusundaram, K., & Tiwari, B. K. (2014). Novel Drying Techniques for the Food Industry. Food Engineering Reviews, 6(3), 43-55. doi:10.1007/s12393-014-9078-7

Nayak, B., Berrios, J. D. J., Powers, J. R., Tang, J., & Ji, Y. (2011). Colored Potatoes (Solanum Tuberosum L.) Dried for Antioxidant-Rich Value-Added Foods. Journal of Food Processing and Preservation, 35(5), 571-580. doi:10.1111/j.1745-4549.2010.00502.x

Nemzer, B., Vargas, L., Xia, X., Sintara, M., & Feng, H. (2018). Phytochemical and physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chem, 262, 242-250. doi:10.1016/j.foodchem.2018.04.047

Nindo, C., Powers, J., & Tang, J. (2011). Thermal properties of Aloe vera powder and rheology of reconstituted gels. Transactions of the ASABE, 53(4), 1193-1200.

Nindo, C. I., Feng, H., Shen, G. Q., Tang, J., & Kang, D. H. (2003). Energy Utilization and Microbial Reduction in a New Film Drying System. Journal of Food Processing and Preservation, 27(2), 117-136. doi:10.1111/j.1745-4549.2003.tb00506.x

Nindo, C. I., Sun, T., Wang, S. W., Tang, J., & Powers, J. R. (2003). Evaluation of drying technologies for retention of physical quality and antioxidants in asparagus (Asparagus officinalis, L.). LWT – Food Science and Technology, 36(5), 507-516. doi:10.1016/S0023-6438(03)00046-X

Nindo, C. I., & Tang, J. (2007). Refractance Window Dehydration Technology: A Novel Contact Drying Method. Drying Technology, 25(1), 37-48. doi:10.1080/07373930601152673

Ochoa-Martínez, C. I., Quintero, P. T., Ayala, A. A., & Ortiz, M. J. (2012). Drying characteristics of mango slices using the Refractance Window™ technique. Journal of Food Engineering, 109(1), 69-75. doi:10.1016/j.jfoodeng.2011.09.032

Ortiz-Jerez, M. J., Gulati, T., Datta, A. K., & Ochoa-Martínez, C. I. (2015). Quantitative understanding of Refractance Window™ drying. Food and Bioproducts Processing, 95, 237-253. doi:10.1016/j.fbp.2015.05.010

Ortiz-Jerez, M. J., & Ochoa-Martínez, C. I. (2015). Heat Transfer Mechanisms in Conductive Hydro-Drying of Pumpkin (Cucurbita maxima) Pieces. Drying Technology, 33(8), 965-972. doi:10.1080/07373937.2015.1009538

Pénicaud, C., Achir, N., Dhuique-Mayer, C., Dornier, M., & Bohuon, P. (2011). Degradation of β-carotene during fruit and vegetable processing or storage: reaction mechanisms and kinetic aspects: a review. Fruits, 66(6), 417-440. doi:10.1051/fruits/2011058

Sablani, S. S. (2006). Drying of Fruits and Vegetables: Retention of Nutritional/Functional Quality. Drying Technology, 24(2), 123-135. doi:10.1080/07373930600558904

Santos, P. H. S., & Silva, M. A. (2008). Retention of Vitamin C in Drying Processes of Fruits and Vegetables—A Review. Drying Technology, 26(12), 1421-1437. doi:10.1080/07373930802458911

Tonon, R. V., Brabet, C., & Hubinger, M. D. (2010). Anthocyanin stability and antioxidant activity of spray-dried açai (Euterpe oleracea Mart.) juice produced with different carrier agents. Food Research International, 43(3), 907-914. doi:10.1016/j.foodres.2009.12.013

Topuz, A., Dincer, C., Ozdemir, K. S., Feng, H., & Kushad, M. (2011). Influence of different drying methods on carotenoids and capsaicinoids of paprika (Cv., Jalapeno). Food Chem, 129(3), 860-865. doi:10.1016/j.foodchem.2011.05.035

Topuz, A., Feng, H., & Kushad, M. (2009). The effect of drying method and storage on color characteristics of paprika. LWT – Food Science and Technology, 42(10), 1667-1673. doi:10.1016/j.lwt.2009.05.014

Zotarelli, M. F., Carciofi, B. A. M., & Laurindo, J. B. (2015). Effect of process variables on the drying rate of mango pulp by Refractance Window. Food Research International, 69, 410-417. doi:10.1016/j.foodres.2015.01.013

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Energy"

Energy regards the power derived from a fuel source such as electricity or gas that can do work such as provide light or heat. Energy sources can be non-renewable such as fossil fuels or nuclear, or renewable such as solar, wind, hydro or geothermal. Renewable energies are also known as green energy with reference to the environmental benefits they provide.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: