Analysis of Fleet Operations at Eddie Stobart

Info: 6396 words (26 pages) Dissertation

Published: 9th Dec 2019

Tagged: TransportationBusiness Strategy

Contents

Overview of Relevant Manufactures Specifications

Volvos new improved automatic gear box (I-Shift):

What are Eddie Stobart doing to stay Green?

Fleet Maintenance options and Considerations

Fleet Operations Documentation and Legal Requirements

Introduction

The company I chose to do my assignment on was Eddie Stobart a large Transport company of freight, ambient and chilled goods.

When completing this assignment I had many resources available to me that were more than sufficient they included the Library, IT open access and my lectures knowledge of the industry.

Abstract

With the EU enforcing such strict regulations on the Transport industry it is getting harder and harder for companies to operate at a profit as the margins are so fine in this present moment. As well as this fleets need to be up to date with both vehicles and management systems to achieve peak efficiency and operate at a profit.

As a result companies like Eddie Stobart an industry leader must have the most reliable and up to date equipment to maintain their high level of customer satisfaction.

Objectives

The following are objectives I hope to achieve throughout this assignment:

- Work carried out by Eddie Stobart

- Analysis Operations

- The environmental impact Stobart is having and how they try to counter act this

- Vehicles used, Trailers used

- Analyses the other vehicles technologies

- Consider upgrading the fleet/ how would it be financed

- Look at fleet maintenance options

Eddie Stobart

Eddie Stobart is a leading logistics and supply chain group based in the UK. It was founded in 1970 by Edward Stobart, it went on to become one of the largest companies in operation in the UK. Eddie Stobart is a great and well respected name in the industry.

From its HQ in Warrington, there are approximately 2,200 vehicles and 3,800 trailers along with this mass volume of vehicles it has 24 depots throughout the UK and Europe. One of Eddie Stobart’s main reason for such a vast successes is loyalty to its customers many contracts have been running for ten or more years. One unique solution Eddie Stobart offers is its Pay-as-you-go scheme, this enables a shared user network which in turn gets the most out of fleet and warehouse use. This flexibility allows Stobart’s to deliver an above average level of 86% utilisation compared to the industry average of just 71%. Stobart’s main focuses have been E-Commerce, Manufacturing, Industrial & Bulk, Retail and Consumer.

(Eddie Stobart , 2018)

Company Procedure & Policies

Company procedures and policies establish the boundaries for employers and employees within an organisation. They are both in place to protect workers’ rights and the employer’s best business interests. The content contained in these policies establish rules regarding items such as attendance, dress code, employee conduct, privacy and other sections of the terms and conditions of the employment.

Employee Conduct

An employee conduct policy clearly lays out the responsibilities and duties each employee must abide by as stated in the conditions of employment policy. Policies such as these are in place as to use as a guide for appropriate employee behaviour. Policies have now branched off to include the use of computers, internet and use of data. Policies may also act as a code of conduct for employers when some of the terms are broke by an employee such as suspension or work discipline.

Equal Opportunity

Equal opportunity laws are included in the company policy and are rules that promote fair treatment in the workplace. Bigger organisations mostly introduce equal opportunity policies to show their stance against work place discrimination. In these policies they discourage any discrimination on gender, age, race and religious beliefs.

(Scott, 2018)

The Health and Safety at Work Act (1974), supporting regulations, approved codes of practice, guidance notes and standards govern the work activities within Eddie Stobart.

To abide by this legislative ruling, Eddie Stobart as a company must develop their own specialised health and safety policies which all staff members must read and understand before signing. These health and safety polices are reviewed by the company regularly and any new risks will be assessed by the responsible director.

A summarised version of the health and safety policy is as follows:

- Identify hazards, assess risks, establish and maintain procedures and safe systems of work in order to ensure as far as is reasonably practicable the health, safety and welfare of employees and those affected by the company’s work activities

- Monitor plant, equipment, materials, substances and processes to ensure that adequate arrangements are made for their safe use

- Set and maintain standards for employee selection, training and development to ensure that staff are competent for the tasks they are required to undertake

- Consult with employees on matters of health and safety

- Establish and maintain a system of auditing and monitoring and provide adequate resources to ensure that the safe working procedures and systems are continuously improved and reflect current legislative requirements

- Prepare and implement emergency plans and test their effectiveness by regular exercises

- Conduct accident and incident investigations to establish the root causes of such events to prevent recurrence

- Liaise with organisations on whose premises Eddie Stobart staff may be required to work to ensure that they are not exposed to undue risk at such places where Eddie Stobart operating companies are not the controlling authority of the site

(Eddie Stobart , 2018)

(Best Fact.net, 2018)

Overview of Relevant Manufactures Specifications

Eddie Stobart’s strong fleet of approximately 2,200 vehicles is made up of mainly Scania articulated lorries. Scania is a Swedish based truck manufacture and is resounded for its reliability but also its expensive purchase price. Scania was founded in 1911 but has since grown to be one of the biggest manufactures in the world with 49,000 employees and importing more than 90,777 to the UK and Irish markets. In most recent years however, Scania has changed ownership and is now owned by the VW group. The main make and model used by Eddie Stobart to make up his fleet is the Scania R 450 this is a very reliable truck with a great track record. It has the perfect balance between pulling power and efficiency.

(Scania, 2018)

Next Generation Scania P- Series trucks:

As a result of the introduction of Euro 6 regulations, engines displacement and relatively low power output run a certain risk of after treatment issues due to the engine not producing the adequate excess heat to maintain the high temperature in the after treatment system. A quick solution to this problem could be to burn extra fuel however, this obviously results in a higher fuel consumption which would just undo the many years of hard work and investment of capital.

Scania has however came up with a solution, it is based on the 1950s technology of the Miller cycle. This operates using a unique designed camshaft, the camshaft allows the intake valves to stay open longer than normal during the compression phase as to release excess air in then combustion chamber. As a result less air is pumped through the engine this contributes to the rise of temperature and a smoother running SCR system this is all achieved without using extra fuel for the sake of temperature alone. Scania claim it contributes to fuel savings of 4% compared to previous generations.

(Scania, 2018)

The R-Series

As one of the most appreciated truck manufactures in the world it does have a top product a crown jewel if you please for example Audi with its A8 well the Scania equivalent would be the R-series. This truck is designed by Scania to carry massive payloads with low cost fuel consumption and max safety in long haul journeys. The R series competitors would consist of the Mercedes Actros, the Volvo FH, Daf XF and the Renault Magnum. The R series when it was overhauled in the style and technology departments was named international truck of the year. This truck is available with a day cab model and a top-line high sleeper cab for those long-haul journeys.

As one of the most appreciated truck manufactures in the world it does have a top product a crown jewel if you please for example Audi with its A8 well the Scania equivalent would be the R-series. This truck is designed by Scania to carry massive payloads with low cost fuel consumption and max safety in long haul journeys. The R series competitors would consist of the Mercedes Actros, the Volvo FH, Daf XF and the Renault Magnum. The R series when it was overhauled in the style and technology departments was named international truck of the year. This truck is available with a day cab model and a top-line high sleeper cab for those long-haul journeys.

(Seafirm, 2018)

The P-Series

In this day and age with such advancements in technology and efficiency cut to the very smallest of margins only two other truck companies can really rival Scania in these departments they come in the forms of Volvo and Mercedes. However Scania has the edge in the form of its engine and the technologies that co inside above everything in logistics reliability is the one principle that must never fail a transport company. Scania have and continue to build some of the very best engines in the world with using quality parts and in genius engineering this translates into some of the most reliable engines out there. The P-series is essentially the younger brother of the Scania R and G series. This truck was designed mainly for short delivery transportations and light construction sites.

In this day and age with such advancements in technology and efficiency cut to the very smallest of margins only two other truck companies can really rival Scania in these departments they come in the forms of Volvo and Mercedes. However Scania has the edge in the form of its engine and the technologies that co inside above everything in logistics reliability is the one principle that must never fail a transport company. Scania have and continue to build some of the very best engines in the world with using quality parts and in genius engineering this translates into some of the most reliable engines out there. The P-series is essentially the younger brother of the Scania R and G series. This truck was designed mainly for short delivery transportations and light construction sites.

(Seafirm, 2018)

The G-Series

The G-Series

The Scania G series is the perfect mix between the smaller P series and the Bigger R series. This truck has the same reliability as any other Scania whilst also having the same modern features and slick aesthetics. This model can be purchased with a 13-litre or a 9-litre inline engine. This particular vehicle is available in 4×2, 6×2, 6×4 and 8×4 configurations all with the option of a sleeper cab which is essential for long haul trips in both the UK and Europe.

(Seafirm , 2018)

Volvo FH16

Improvements to Volvos new engine technology works (Euro 6):

- Engine – gas flow is improved due to new components in the engine. These components ensure the exhausts reach the after treatment system at the optimum temperature.

- Seventh Injector – A special diesel injector is used for heat management of the diesel oxidation catalyst (DOC) and secures the continuous optimum efficiency of the DPF and good SCR functionality.

- DOC (Diesel Oxidation Catalyst) – The DOC produces the NO2 necessary for the DPF to efficiently burn the particles. In cold conditions it has an added function of providing heat needed for regeneration.

- DPF (Diesel Particulate Filter) – The filter collects and stores particulate matter until it is disposed of through burning methods during regeneration. This action happens automatically.

- SCR (Selective Catalytic Reduction) – In the mixing area the exhausts are sprayed with Ad Blue. As a result, when they reach the catalyst the NO2s are transformed into harmless gasses (Nitrogen & H20) in the most efficient way possible.

- Ammonia Slip Catalyst (ASC) – This process is the last step before the gases reach the exit of the tail pipe it is to catch any remaining (NH3) ammonia left in the exhaust gases before it enters the atmosphere.

(Volvo , 2018)

Volvos new improved automatic gear box (I-Shift):

Volvo claims that I-Shift makes driving safer, easier and more comfortable. It has no clutch and there is no gear stick to wrestle with especially in times of urgency. Every gear change is perfectly timed to improve efficiency and comfort. The simplicity of the system reduces driver fatigue, helping the driver to focus on the road and the traffic in their surroundings. And if you do want to change gear manually, the button on the gearstick gives you direct control of the shift to overwrite the system.

This new I-Shift gear box is designed to save fuel. The internal energy losses are lower than on manual gearboxes, but it’s the electronics that really make the difference. Every gear change is timed to precision by the system as it uses the information in which the vehicle is sending it thus selecting the optimum gear. This ensures that the engine works at its most efficient rpm, whether in economy or performance mode. Additionally, when you’re travelling downhill, I-Roll disengages the engine – maximising the truck’s momentum and saving up to an additional 2% of fuel. 2% may not sound like a lot but when it is put into perspective in a company like Stobart’s this saving could be Hundreds of Thousands. This is hugely beneficial to a company in this industry as profit margins are very tight.

How I-Shift works is based on a “classic” unsynchronised manual gearbox, hence its compact design and low internal losses. The special component in all this mechanism is the electronic control unit that manages the clutch and shifts. By evaluating information about speed, weight, road grade and torque demand, it applies extreme precision to every shift. The system also communicates with the engine, allowing it to adjust the revs and brakes for optimum performance. This all contributes to the cost saving.

(Volvo Trucks , 2018)

Financing/ Payment Options

Scania

Scania has 3 different options of leases and payment plans:

Scania Financial Lease – You are the soul owner of the vehicle for the agreed duration of time however you take responsibility for maintenance, tax and insurance during this period. You pay lease instalments on the agreed price and monthly time period. At the end of the lease you will have the option to purchase the vehicle for a favourable residual value. Benefits include: interest only payable on the outstanding value, tax and VAT benefits and vehicle appears as an asset on balance sheet.

Scania Operating Lease – Scania financial services is the owner of the vehicle. The business pays a fixed rate monthly returning the vehicle when the contract expires. With this lease a service contact is attached. You take responsibility for maintenance, tax and insurance. Benefits include: No residual value, predictable cash flow and cash flow benefits due to the fixed cost, paid out of operating income so offset against taxable profits, off- balance sheet financing.

Scania Loan Agreement – Under this agreement you own the vehicle from day one. You use the vehicle as security against the loan you take out and pay it back monthly in instalments. The loan is reimbursed through an agreed payment plan and time period. Benefits include: Tax depreciation on customers books and can only pay interest on the outstanding value.

(Scania , 2018)

Volvo

For payment options Volvo offers a multitude of finance specials that are suited to you and your business needs. Some adjustments can be made after the deal has been made also to get the debt off your hands quicker. Some of these options include, down payments to reduce monthly payments, quicker payments and fixed and floating interest rates for enhanced finance control. Also with an added care by Volvo they will look at your industry cycle and make changes to the finance payment deadlines they’ll look at straight, balloon and seasonal amortizations in your business cycle. It is in the best interests of the business if it is making a large enough order to cut out the middle man (dealership) and buy/leasing directly from the manufacture. Eddi Stobart’s is large enough to do this.

(Volvo, 2018)

Fleet Requirements and Mix

Some of the work carried out by Eddie Stobart would include

- Ambient

- Refrigeration

- Containers.

The ambient department of Eddie Stobart offers a highly efficient, cost- effective and temperature controlled solutions for transportation of ambient goods. Along with this is a chain of warehouses strategically placed throughout Britain and Europe. These warehouses are designed specifically for fast moving consumer goods (FMCG). This is to facilitate special demands by our customers, the big manufacturing and retail giants.

The refrigeration department operates very similarly to the ambient just that the products are different and need to be cooled at all times to keep the produce fresh. For this task thermos king refrigeration trailers were chosen for the task. These trailers allow the products to be cooled even during transportation.

The container logistics department specialises in transportation and storage of shipping containers throughout the UK, Ireland and Europe. Eddie Stobart offers the service of serving every major port in the UK and Ireland. (Eddie Stobart , 2018)

For this type of operation attention to detail is essential. The right fleet must have the right operation system in place as well as the right vehicles and trailers with the appropriate equipment. Some equipment Eddie Stobart uses most frequently would include:

- The Scania R450 articulated tractor unit

- For ambient foods or packaged goods Stobart’s use a 3 axle SDC box trailer

- For chilled/frozen goods they use chilled box SDC box trailer however it is chilled by a diesel ran refrigerator Thermo King positioned at the front of the trailer.

- For containers they use a 3-axel slider trailer.

The best way in which to manage a fleet of this magnitude would be to divide it into different sectors first of all you have the 3 different sectors ambient, chilled/frozen and containers. When you have a fleet of 2,200 it would be impossible to have one team look after them, all wires would get crossed and it wouldn’t work. By dividing it into sectors it becomes much easier to manage the fleet, if you then divide each sector again into a 100 trucks per transport manager it becomes even better way of managing and becomes much more efficient.

It is essential to have a well operating telematics program in place in a company as vast as Eddie Stobart`s. a telematics system will help keep track of vehicles and their positions in the country as well as give feed back on driver times, previous journeys and driver behaviour. This is all essential to guarantee the most efficient way in which to operate a logistics business so great as Eddie Stobart`s.

As Eddie Stobart is such a big company they have many of there own dedicated depos throughout the UK. This is a huge benefit to the fleet as it gives them time to carry out work in between deliveries if the customer is not quite ready to take a delivery it can be stored and a trailer can be freed up.

Stobart use SDC box trailers for the moving of ambient and packaging goods. They use this trailer for mainly transportation of goods for one of there main contracts in the UK, TESCOS. Eddie Stobart uses these trailers as they are reliable, light weight and have a max amount of space available in a single story 3 axel trailer. These trailers cost around £15000 + VAT.

For chilled and frozen goods Stobart’s use a 3-axeled box trailer with a refrigerator attached to the front. This refrigerator is responsible for the temperature in the back and keeping the goods frozen. For this job they selected the Thermo King technologies refrigeration unit. This unit the S-600 specifically sets the standard in refrigeration technology. It is certified by CARB evergreen as well as having the most advanced technology out there the company can wreak rewards of double-digit fuel savings. As it is the latest technology it offers all this with remote temperature control and variable cooling sections within the trailer itself. Benefits of this system include: No DPF, superior temperature control, big fuel savings and real time recording and monitoring.

Another sector in which needs special requirements would be the container department. All though all 3 departments use the same vehicles the trailers are all different and the containers are no different. The special trailers they use are SDC 3 axle slider trailers. As there are 3 types of container sizes 20ft 40ft 45ft there are different requirements needed to be facilitated by the trailer in ways of load distribution on the trailer as well as dimensions for the locks. These slider trailers help solve this issue instead of needing 2 different types of trailers, the one slider trailer will cover all 3 as it can be extended and shortened depending on the container. As well with this if it is a 20 ft container it would not need the 3 axels so the trailer may now be able to have a lift axel to save the tyres.

(SDC, 2018) (Thermo King, 2018) (Eddie Stobart , 2018) (Scania , 2018)

Environmental considerations

When running a transport company, you could be side tracked very easy by just number and profit margins however as part of Europe it is vital to show you are making the effort to lessen your carbon footprint and meeting strict EU regulations. In the logistics industry two main factors of damaging the environment would be air and noise pollution. It is essential to maintain a high standard of environmental protection to play your part as a business.

Air Pollution

The main issue with air pollution within the haulage industry is the harmful gasses emitted from the vehicles themselves. Any fossil fuel powered vehicle will amit harmful gases in to the atmosphere. The gases that are admitted are Carbon Monoxide, Hydrocarbons, Nitrogen Oxides and Particulate Matter. These gases are all causes of the green house effect which leads to global warming. To try and counter act this Stobart have a fleet of vehicles to the latest euro 6 standards this means the exhaust gases being emitted from the vehicles are virtually harmless due to the after-treatment systems. Ad blue also plays a role in diluting these gases.

(Air- Quaility , 2018)

Noise Pollution

When transporting and on the move trucks can be hugely responsible for noise pollution. If you are transporting goods through a quiet urban area disturbing the peace it will not only affect the environment but it could damage the reputation of the company. For this reason, it is important to have the correct standard of vehicles on the road and replace the older less modern trucks and replace them with the newer quieter vehicles as to not disturb the peace. It would also help to teach the drivers not to use their horns unless absolutely necessary.

(EPA, 2018)

What are Eddie Stobart doing to stay Green?

As Stobart introduced Stobart rail where they can to transport bulk loads it saves 33.8 million road miles travelled by trucks which results in 22,400 fewer tonnes of emissions. Back in 2009 they opened a new service (chilled) between south Spain and the UK this will run 3 times per week resulting in the saving of 17.76 million road miles and 16,506 fewer tonnes of emissions.

Efficiency Through Shared Use Driven Stobart`s shared user model, Stobart has achieved a 10% annual reduction in empty running over the last 5 years they have a rule that a driver must not travel more than 50 miles empty unless instructed to do so. For every 1% of increased utilisation, carbon emissions are reduced by 1,107 tonnes.

Better Driving Practices Stobart’s intensive SAFED driver training programme, coupled with advanced in-cab electronic monitoring of driving technique has resulted in better driving practices. As a result Stobart will achieve one of the best 44 tonne gross fuel consumption records in the industry.

Innovative Environmental Trailer Stobart has proposed a unique solution to significantly reducing pollution, whilst cutting the number of haulage vehicles on the road. The trailer can carry up to 8% more pallets and 13% more caged goods. The design has been exclusively tested for Stobart by MIRA, confirming it is fully compliant with current legislation.

Investing in Fuel of the Future Use of Biomass is a key element in the EUs strategy to increase power generation using cleaner renewable energy sources and is targeted to satisfy up to 25% of the UK’s total energy needs by 2020.

Positive about Recycling Strong emphasis on recycling in all of our operations. The 5 truck washes, keeping Stobart`s fleet immaculate throughout the UK, use recycled water.

(Butcher, 2018)

Fleet Maintenance options and Considerations

As a result of the research I have gathered on Eddie Stobart I have found that a new order of 1,500 trucks (mainly G-450) had been placed on order directly from Scania in 2015. This order had been made by Stobart and had been a record order for Scania from a single customer. Scania controls nearly 20% of the HGV truck market in the UK. These vehicles were purchased on a hire lease agreement of 36 – Months. The previous over haul of the fleet was in 2012 where it was 1,000 trucks and previously 2010 another 1,000 trucks. (Scania Group, 2018)

When upgrading the fleet I would stick with Scania as there has been a clear long lasting relationship between Stobart and Scania thus resulting in the best value for money for new vehicles. Scania is also a leading manufacture in the industry and has very reliable vehicles that meet the Euro 6 standards. Volvo is making a good case for themselves also so to purchase a handful of roughly 3 HGV vehicles to compare their performance against the operation of the Scania would be a good strategy for the business. Stobart has facilities for servicing in house but any major works would be outsourced to the local Scania dealer.

The way I would implement the change is I would introduce the R-450 highline as the truck of choice. This truck would provide the highest form of efficiency and safety in my fleet. I would replace the fleet by 2,500 over 3 years.

- Year 1 (2019) – 500 in the first 6 months, July would consist of another 500 introduced.

- Year 2 (2020) – 250 in the first 6 months, July would consist of another 250 being introduced.

- Year 3 (2021) – 500 in the first 6 months, July would consist of another 500 introduced.

All these vehicles will consist of a 36 month hire lease agreement as this has worked well in the past. The reason I would change the vehicles in such vast numbers is that it is important to keep the most modern vehicles on the road for reliability and efficiency but also the company has proved it has the resources to make these changes in vast quantities in the past.

Advantages of upgrading

- Costs can be predicted due to agreed monthly payments on vehicles

- Outsourcing maintenance helps relieve stress on managers

- By buying new vehicles you have a more reliable fleet as well as as having a good company image.

- With new vehicles also comes a manufactures warranty.

- Euro 6 graded vehicles good trade in value if traded in against new vehicles

Disadvantages of upgrading

- If the company purchases the vehicle the company is solely responsible for the maintenance

- If the company purchases the vehicle outright they may take a hit on resale value after (market dependant)

- Can prove more costly when paying finance (rate depending)

- If the company changes make and model could involve unfamiliar systems and a mixed fleet.

Maintenance of the fleet

In Eddie Stobart’s agreement with Scania they have agreed to get the leased vehicles maintained by the Scania group of dealerships throughout the UK this translates as Eddie Stobart’s “outsourcing” maintenance. It is essential to keep these vehicles on the road and not take part in any breakdowns. By outsourcing the work it guarantees the work to be done to manufactures specifications.

Advantages

- Costs can be monitored easier

- No headaches of an onsite workshop

- Any work carried out has to be stood over by Scania

Disadvantages

- Can be much more costly

- You may have to join a que no prioritising

Fleet Operations Documentation and Legal Requirements

To have the adequate documentation is essential for any transport company when transporting and delivering goods both in the UK and the EU. It is vital the driver has the correct documentation for the vehicle and the load this is the duty of the transport manager. If the driver is pulled in by the relevant authorities and does not have the correct documentation this could lead to big fines for the company.

Documentation that must be on the vehicle

- The CVRT (Commercial Vehicle Roadworthiness Test), this disc must be in date and displayed on the front windscreen of the vehicle for both the tractor unit and the trailer behind.

- A vehicle tax disc must also be in date and displayed on the windscreen

- Insurance documentation for the vehicle and the driver.

- Road Haulage Operators Licence (RHOL)

Documents for the load

- Proof of delivery document

- Planned journey

- Origin of load and destination

- What the load is

- Hazcam documentation if the goods are hazardous

Documentation for the driver

- Up to date Driver CPC

- Relevant licence for the vehicle

- Tachograph card

(Chartered Institute of Logistics and Transport , 2018)

Conclusion

I have learnt a lot of information about Eddie Stobart’s as a company whilst completing this assignment. It is evident to see how they are such a dominating player in the transport industry due to their dedication to high quality service and logistics efficiency. I have discovered their reasoning behind some of their decisions as a business to keep them on top of their game.

I discovered that as a company deep with history there has been relationships built up which is good for business as loyalty usually repays in savings in the business world. Changing the fleet to improve the efficiency and reliability of the company as well as upgrading the vehicles to Euro 6 technologies. This as a result reflects in the great name of Eddie Stobart being associated with reliability and a gold standard of service in the logistics industry where it matters most.

References

Bibliography

Air- Quaility . (2018, 10 21). Air Quaility . Retrieved from http://air-quality.org.uk/26.php

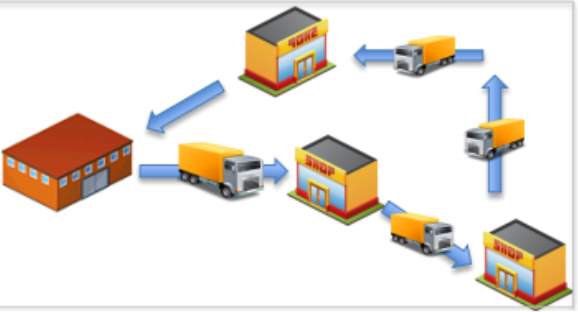

Best Fact.net. (2018, 10 22). Retrieved from https://www.google.ie/search?hl=en&authuser=0&biw=1920&bih=1073&tbm=isch&sa=1&ei=JSPOW77nA6KWgAbq8pqoAg&q=transport+warehousing++distribution+diagram&oq=transport+warehousing++distribution+diagram&gs_l=img.3…51853.54972.0.55152.13.13.0.0.0.0.64.658.13.1

Butcher, M. R. (2018, 10 22). Imperial Collage London. Retrieved from https://www.imperial.ac.uk/media/imperial-college/research-centres-and-groups/centre-for-transport-studies/seminars/2010/Stobart-Group-Delivering-sustainable-multimodal-logistics-solutions.pdf

Chartered Institute of Logistics and Transport . (2018). The Chartered Institute of Logistics and Transport . The Chartered Institute of Logistics and Transport.

Eddie Stobart . (2018, 10 18). Eddie Stobart . Retrieved from http://eddiestobart.com/our-operations/contract-logistics/health-safety

Eddie Stobart . (2018, 10 22). Eddie Stobart . Retrieved from http://eddiestobart.com/our-operations/

EPA. (2018, 10 21). EPA.nsw. Retrieved from https://www.epa.nsw.gov.au/your-environment/noise/vehicle-noise

Scania . (2018, 12 21). Scania Global . Retrieved from https://www.scania.com/global/en/home/products-and-services/finance-and-insurance/finance.html

Scania. (2018, 10 19). Scania.co.uk. Retrieved from https://www.scania.com/uk/en/home/experience-scania/news-and-events/news/2017/06/6-new-egnines.html

Scania. (2018, 10 21). Scania.com. Retrieved from https://www.scania.com/ie/en/home.html

Scania Group. (2018, 10 22). Scania News . Retrieved from https://www.scania.com/group/en/scania-wins-record-truck-order/

Scott, S. (2018, 10 18). Smallbuisness.chron . Retrieved from https://smallbusiness.chron.com/examples-company-policies-procedures-10995.html

SDC. (2018, 10 21). SDC.com. Retrieved from http://www.sdctrailers.com/

Seafirm . (2018, 10 21). Topspeed.com. Retrieved from https://www.topspeed.com/trucks/truck-reviews/scania/2010-scania-g-series-ar128980.html

Seafirm. (2018, 10 21). topspeed.com . Retrieved from https://www.topspeed.com/trucks/truck-reviews/scania/2010-scania-r-series-ar125821.html

Seafirm. (2018, 10 21). topspeed.com . Retrieved from https://www.topspeed.com/trucks/truck-reviews/scania/2010-scania-p-series-ar126354.html

Thermo King. (2018, 10 21). Thermo King . Retrieved from https://www.thermoking.com/na/en/road/trailers/single-temperature-controlled-units.html

Volvo . (2018, 10 18). Volvo. Retrieved from https://www.volvotrucks.co.uk/en-gb/trucks/volvo-fh16/features/diesel-engines.html

Volvo. (2018, 10 21). Volvo.com. Retrieved from https://www.volvotrucks.com/en-en/services/financing.html

Volvo Trucks . (2018, 10 18). Volvo Trucks. Retrieved from https://www.volvotrucks.co.uk/en-gb/trucks/volvo-fh16/features/i-shift.html

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Business Strategy"

Business strategy is a set of guidelines that sets out how a business should operate and how decisions should be made with regards to achieving its goals. A business strategy should help to guide management and employees in their decision making.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: