Incorporating Silica Nanoparticles into Fiber Sizing

Info: 4244 words (17 pages) Dissertation

Published: 3rd Feb 2022

Tagged: ChemistryOrganic Chemistry

Incorporating silica nanoparticles into fiber sizing to improve the properties of corn fiber reinforced polylactide composites

Abstract

Nanofiller-modified interfaces in man-made carbon and glass fibers reinforced composites have been investigated, while no such investigation was reported for natural fibers. In this work, we report a novel strategy of improving the interfacial nature in corn fiber/polylactide (CRF/PLA) composites by directly applying a sizing containing silica nanoparticles on the surface of corn fibers. This results in enhanced mechanical properties of the CRF/PLA composites. These improvements are mainly due to the presence of silica nanoparticles on corn fiber-PLA interfaces, which act to resist the crack propagation. The increased surface roughness of corn fibers from incorporated silica nanoparticles may also contribute to the enhanced mechanical properties. This simple methodology can be easily scaled up and thus shows great promise in industrial applications.

1. Introduction

It is well accepted that the fiber/matrix interface in composites controls not only the mechanical properties, but also physical properties [1-4]. Generally, a strong interfacial bonding helps to achieve high stiffness and strength, while a relatively weak interfacial bonding improves the energy absorbing performance under impact conditions [1, 2]. The manipulation of fiber/matrix interface is mainly achieved through surface treatment of fibers. In fact, all reinforcing fibers, particularly carbon and glass fibers, used as the reinforcements of polymer composites are surface treated [2]. After surface treatment, a polymer coating (typically epoxy), referred to as a “sizing”, is applied to protect the carbon and glass fibers during handling and improve the processability of fiber yarns [5, 6].

In recent years, apart from glass and carbon fibers, the development of green composites made from natural fibers has been a hot topic all over the world. The major motivation of using natural fibers is their lower cost (priced at one-third or less of the cost of glass fibers), weight reduction (half the weight of glass fibers), and easy recycling. There are thousands of different natural fibers in the world but only few of these fibers have been studied. Among the most popular natural fibers, flax, jute, hemp, sisal, ramie, and kenaf fibers are extensively researched and employed in different applications. Besides those natural fibers, corn fibers are also gaining interest due to their lower cost and more abundance than other natural fibers as they are waste of farms. It is believed that the use of fibers from agricultural waste as reinforcements in green composites offers a low cost and environmentally friendly solution to waste disposal and a possibility for farmers to gain a profit from waste [7-12].

Unlike glass and carbon fibers, natural fibers possess very different properties. They are composed of bundles of elementary fibers, contain voids and defects, their cross-section is irregular, and their surface nature is hydrophilic. The hydrophilicity of natural fibers translates to incompatibility with hydrophobic polymer matrices. Similar to man-made glass and carbon fibers, to improve the fiber/matrix adhesion in natural fibers reinforced composites, surface treatments are also mandatory. Up to date, many methods have been reported [2, 13]. In general, surface treatments can be classified into two categories, physical and chemical methods [14-17].

Compared to physical methods, chemical methods are more effective and stable [18, 19]. A vast range of chemical treatments (alkaline, bleaching, coupling with silanes, acylation, grafting by monomers etc.) have been developed to improve the interfacial adhesion [13]. Unlike the alkaline treatment which is the most widely applied, surface sizings of natural fibers are still in their infancy [2]. However, the advantages of surface sizing such as improving handling properties of fibers, enhancing fiber wetting by the matrix and in particular improving fiber/matrix adhesion [20-22] make it a very promising route [2]. Interestingly, recent studies have demonstrated that adding nanofillers into sizing formulations can improve interfacial bonding and is thus gaining more and more attention [2, 6].

The reported nanofillers in sizing formulations include halloysite nanotubes [23], carbon nanotube (CNT) [24-26], graphene [27], graphene oxide [28-30], and silica (SiO2) nanoparticles [6, 31-34]. For example, to improve the interfacial properties in carbon fiber/epoxy composites, Zhang et al. [28] directly introduced graphene oxide (GO) sheets dispersed in the fiber sizing onto the surface of individual carbon fibers and significant enhancements of interfacial shear strength, interlaminar shear strength, and tensile properties were achieved in the composites when 5 wt. % of GO nanosheets were introduced in the fiber sizing. Godara and co-workers [35] directly dispersed CNTs in a fiber sizing formulation of E-glass fibers. They compared the fiber sizing method to other two ways of incorporating CNTs to the matrix and incorporating CNTs in the fiber sizing and matrix simultaneously. They declared the improvements of interfacial shear strength in all three cases while the maximum improvement is achieved in the composite where CNTs are introduced solely in the fiber sizing. Yang et al. [31] applied a sizing containing pre-treated silica nanoparticles on the surface of carbon fibers, and significantly improved interfacial shear strength was obtained. Unfortunately, there is no report in literature regarding the nanofillers-contained sizing for the surface treatment of natural fibers, not to mention corn fibers.

In this work, a facile method to adjust the interface properties between corn fibers and polylactide (PLA) has been developed by adding nanofillers to the sizing solutions of corn fibers. Silica nanoparticles were selected as the model nanofillers since they are much cheaper than CNT, graphene, and /graphene oxide. The silica nanoparticles were dispersed in the fiber sizing and then directly coated on the surface of corn fibers. The surface-treated corn fibers (denoted as SiO2@CRF) were used to reinforce PLA. The purpose of this work was to prepare PLA composites reinforced by SiO2@CRF and to analyze the effect of incorporating silica nanoparticles in sizing solutions on the mechanical properties of the as-prepared SiO2@CRF/PLA composites.

2. Experimental

2.1. Materials

The silica nanoparticles (model W-200, average diameter = 60 nm, purity ≥99.9%) used in this work were purchased from Shouguang Baote Chemical Co., Ltd., Weifang, China. The matrix material (provided by Shenzhen Guanghua Weiye Industrial Co. Ltd., China) was an AI-0001 PLA with the basic parameters of Mn = (8-10) × 105 and melt index = 512 g/10 min. The corn stalks were obtained from a farm in Hebei province, China. NaOH, analytical grade, was provided by Tianjin Chemical Reagent Co. Ltd, Tianjin, China. The KH550 silane coupling agent (g-aminopropyl triethoxysilane, molecular formula H2NCH2CH2CH2Si(OC2H5)3, a colorless to slightly yellowish low-viscosity liquid) was purchased from Nanjing Chemical Industry Group, China.

2.2. Preparation of corn fibers

The preparation process of corn fibers was similar to that reported in our previous work [7, 8]. Briefly, corn stalks were thoroughly cleaned and dried, followed by separation of straw skins using a skin separator (PRFII-0.2, Jilin Fenghe Botanical Development, China). The resultant skins were smashed to pieces using a JWF-250 Cutting Mill (Hongle Machinery Plant, Xingyang, Henan, China). Finally, a 40-mesh sieve was used to remove corn husks and debris and corn fibers with a length of ca. 3 mm were obtained.

2.3. Preparation of sizing solutions containing silica nanoparticles

First, silica dispersion was prepared by adding silica nanoparticles to the solution of sodium dodecyl sulfate (SDS, dispersant) under ultrasonication for 2 h. The ratio of silica nanoparticles to SDS was 1 : 2. Meanwhile, a sizing solution was prepared by hydrolyzing silane coupling agent KH550 in an ethanol aqueous solution (deionized water to ethanol ratio = 3 : 1 by weight) for 20 min at room temperature. The sizing material was added to the solution of KH550 with stirring at a rate of 250 rpm until a homogeneous solution was formed. The concentration of sizing agent was 12 wt.%, in the final sizing solution. The above-mentioned silica dispersion was mixed with the sizing solution, leading to four silica modified sizing solutions containing 0.5, 1.0, 1.5, and 2.0 wt.% silica nanoparticles, respectively. As a control, the unmodified blank sizing solution without silica nanoparticles was also prepared.

2.4. Surface treatment of corn fibers with silica nanoparticles-contained sizing solutions

Prior to sizing treatment, corn fibers were treated with alkali. The process of alkali treatment was described in our previous work [7]. The alkali-treated corn fibers were dried at 95 °C in an oven followed by immersion in various sizing solutions containing silica nanoparticles under vigorous stirring for 30 min. Subsequently, the sizing-treated corn fibers were taken out of the solutions and dried in an oven at 80 °C for 12 h.

2.5. Preparation of SiO2@CRF/PLA composites

PLA and corn fibers with varying sizings were blended at ambient temperature for 8 min at 60 rpm using a SLH-0.01 internal mixer (Shanghai Dongqiu Mixing Machine Co. Ltd., Shanghai, China). The mixed materials were then dried at 100 °C for 4 h. Finally, test specimens were injection molded at a temperature of 180 °C and an injection pressure of 70 MPa. The mass content of fiber in composite samples prepared in this work varied from 5 to 20%, unless otherwise indicated. The designation of all composite samples prepared in this work is listed in Table 1.

Table 1 The designation of the composites prepared in this work.

| Designation | Fiber content

(wt.%) |

Content of silica nanoparticles in sizing solution (wt.%) |

| SiO2@CRF10/PLA-0 | 10 | 0.0 |

| SiO2@CRF10/PLA-5 | 10 | 0.5 |

| SiO2@CRF10/PLA-10 | 10 | 1.0 |

| SiO2@CRF10/PLA-15 | 10 | 1.5 |

| SiO2@CRF10/PLA-20 | 10 | 2.0 |

| SiO2@CRF5/PLA-10 | 5 | 1.0 |

| SiO2@CRF20/PLA-10 | 20 | 1.0 |

2.6. Mechanical testing

The tensile and flexural properties of SiO2@CRF/PLA composites were tested as per ISO 527-1 and ISO 178, respectively, using a CMT-4304 universal testing machine (Shenzhen Suns Co. Ltd., China). The crosshead speed for tensile and flexural tests was 5 and 1.4 mm/min, respectively. Notched Izod impact tests were conducted in accordance with ISO 179-1:2010 using a XCJD-50 impact tester (Chengde Puhui Testing Instrument Co. Ltd, Hebei, China). Heat deflection temperature (HDT) measurement was conducted on a HDT analyzer (Chengde Jinjian Testing Instrument, Hebei, China) at a bending force of 1.82 MPa following ISO 75-2:2004. The heating rate was 2 °C/min and data was collected from 25 to 120 °C. All mechanical tests were performed in triplicate.

3. Results and discussion

3.1. Preparation and morphology of corn fibers and composites

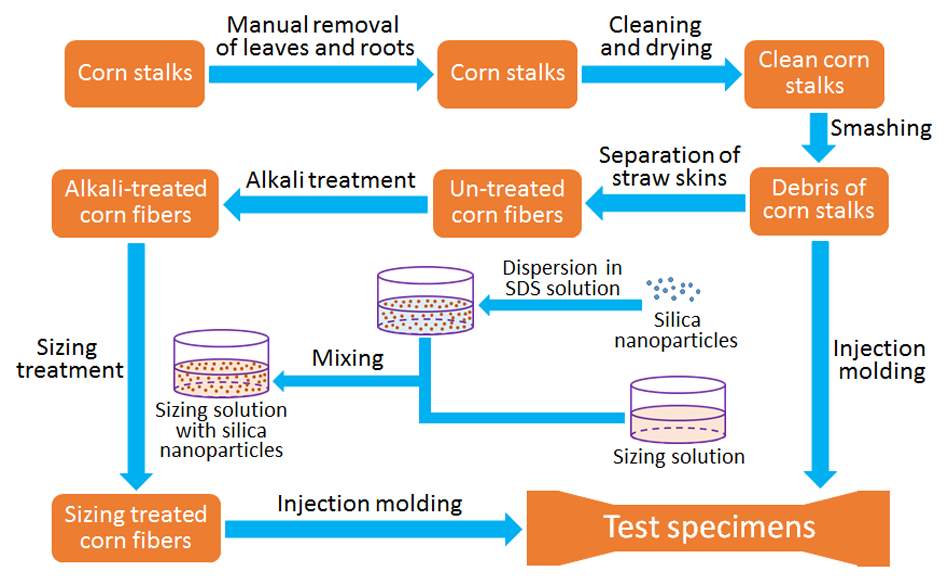

The preparation process of SiO2@CRF/PLA composites is illustrated in Fig. 1. The procedure starts with skin separation followed by smashing, sieving, alkali treatment, sizing treatment and injection molding. Obviously, the preparation process of the SiO2@CRF/PLA composites is versatile and can be easily scaled up from research laboratory to industrial applications, which makes the SiO2@CRF/PLA composites very competitive in the market.

Fig. 1. Preparation process of the SiO2@CRF/PLA composites.

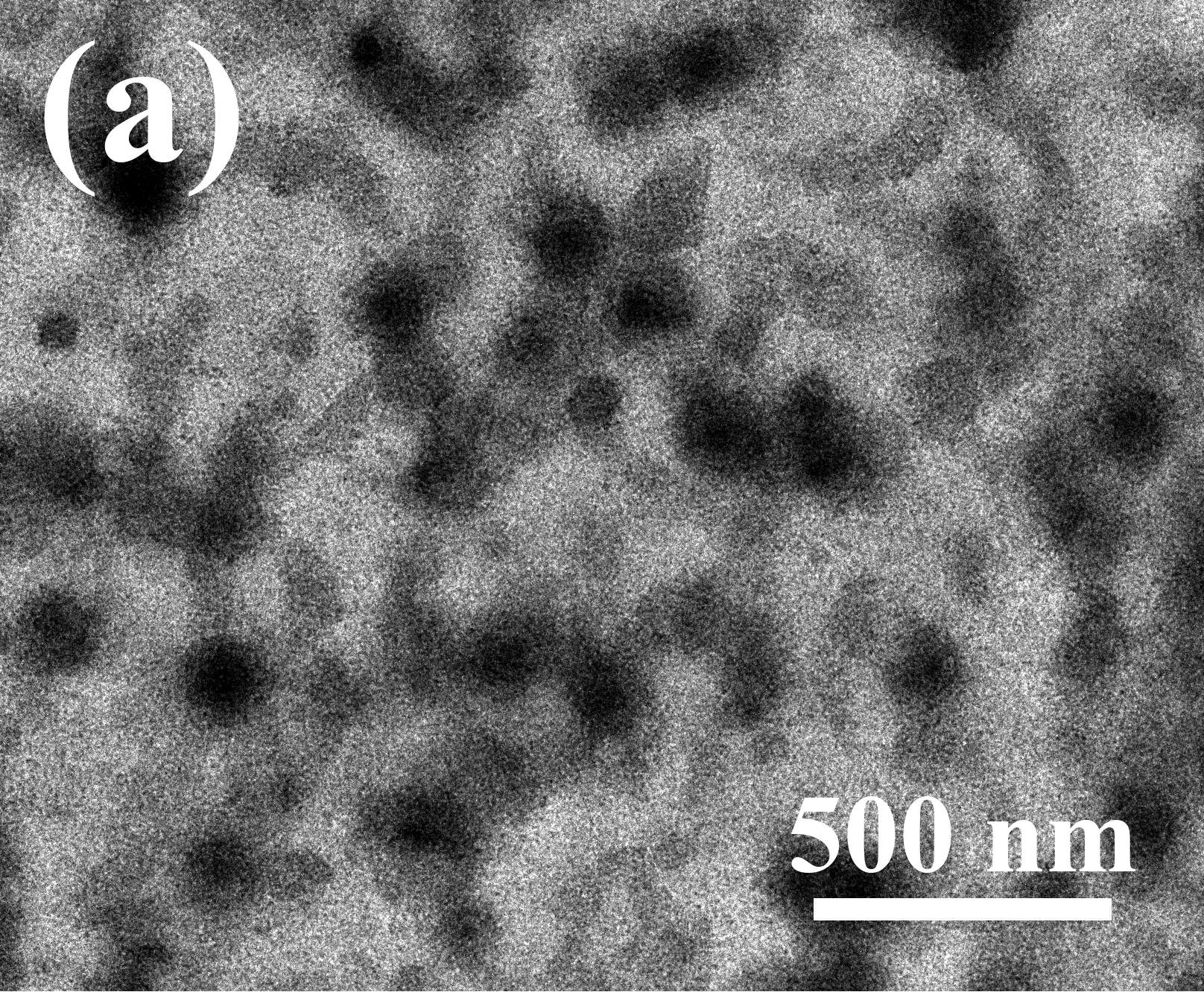

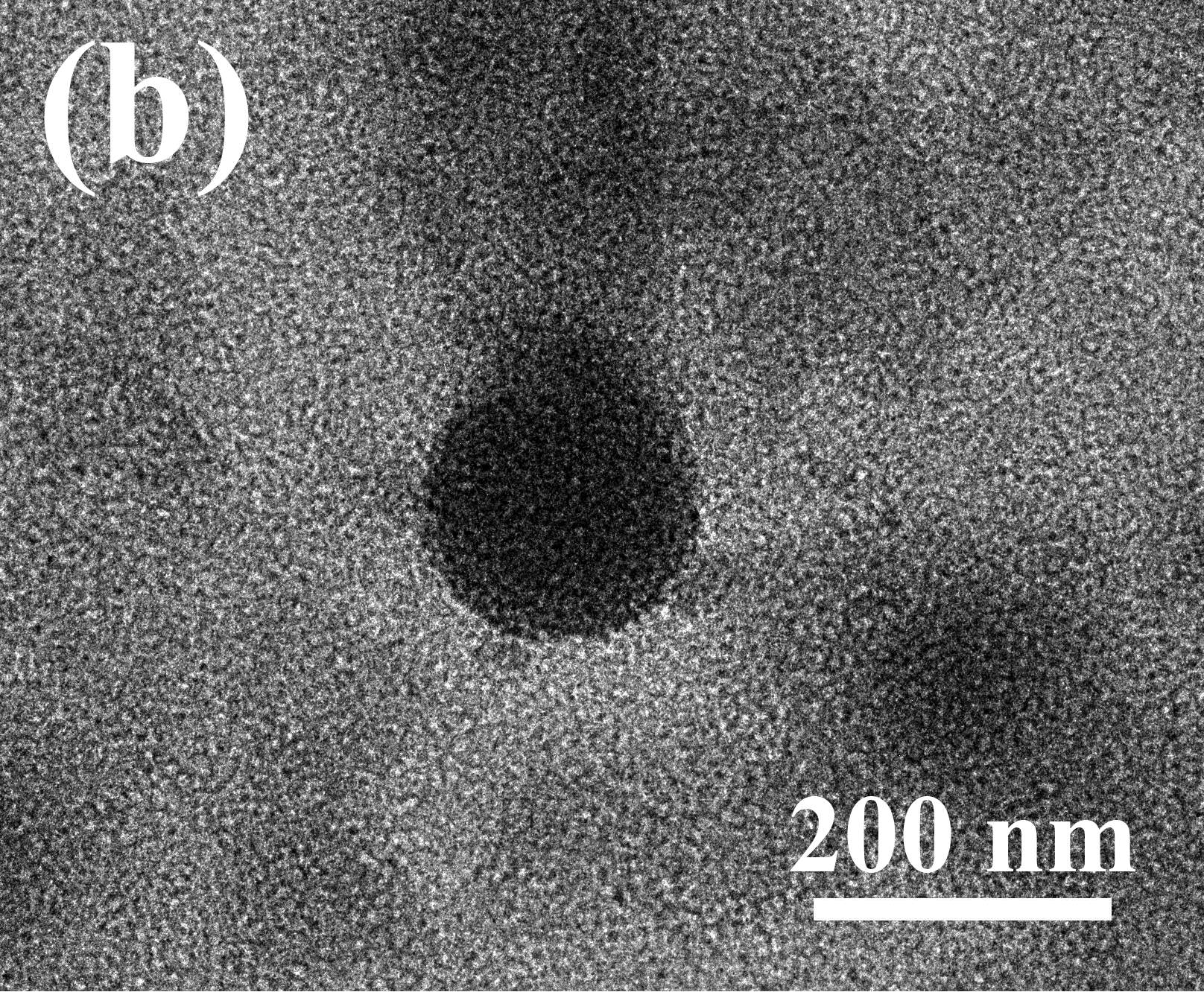

The dispersion of silica nanoparticles in the sizing solutions was examined using TEM. Fig. 2a demonstrates highly dispersed silica nanoparticles in the sizing solution and Fig. 2b shows that the size of silica nanoparticles is around 60 nm, in line with the data specified by the provider, further confirming the separation of each single silica nanoparticle.

Fig. 2. TEM images of silica nanoparticles in sizing agent at (a) low and (b) high magnifications.

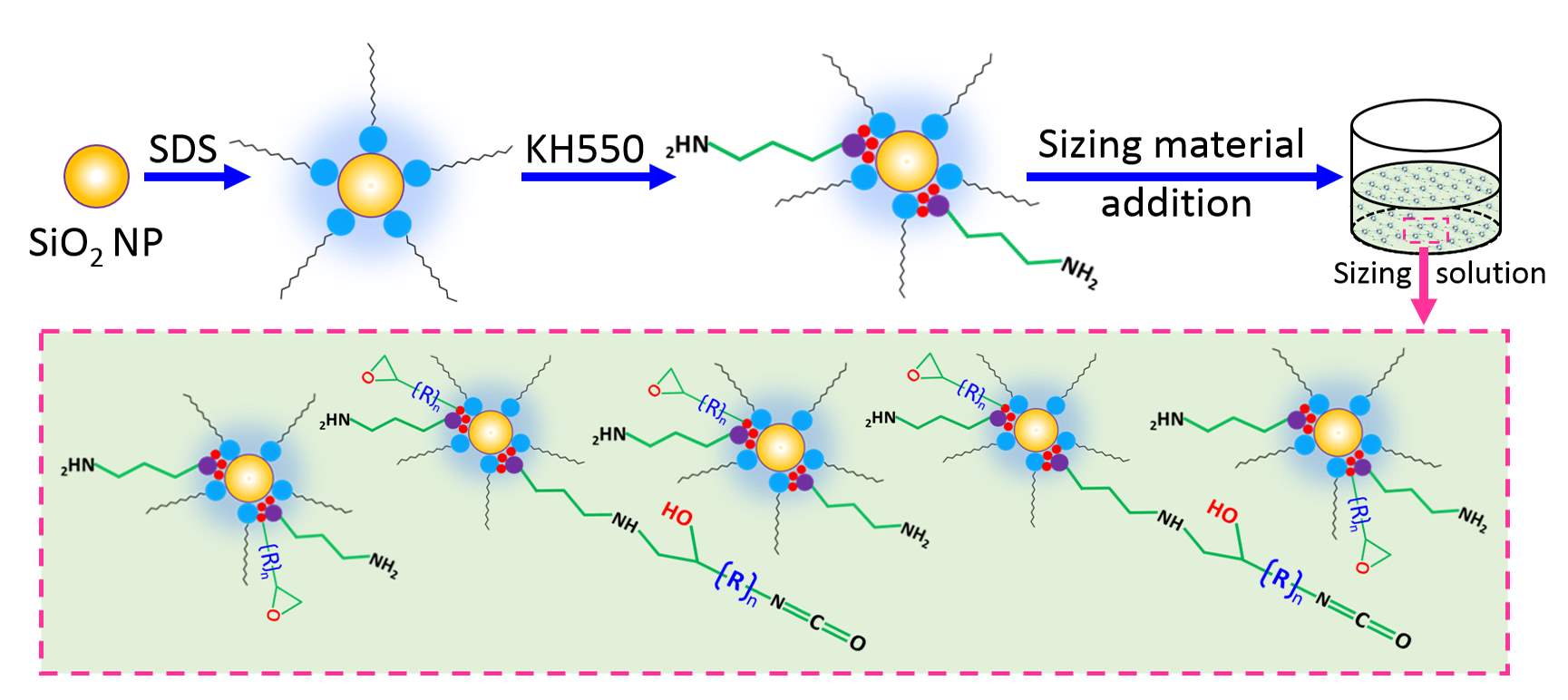

As illustrated in Fig. 3, the excellent dispersion of silica nanoparticles in sizing solutions is closely related to the following aspects. (a) the surface energy decreases due to the presence of surfactant molecules on the surface of each silica nanoparticle. (b) when coupling agent is introduced, one end of the molecules of coupling agent connects with silica nanoparticles and the other end reacts with the reactive additives (epoxide groups) in the sizing solutions [8].

Fig. 3. A schematic showing the dispersion of silica nanoparticles in sizing solutions.

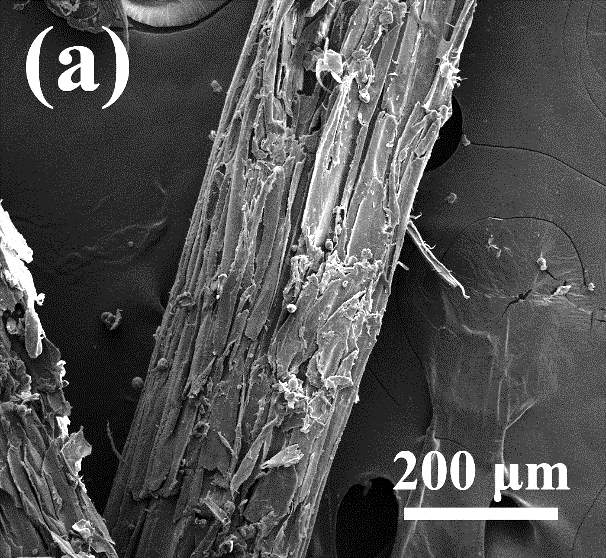

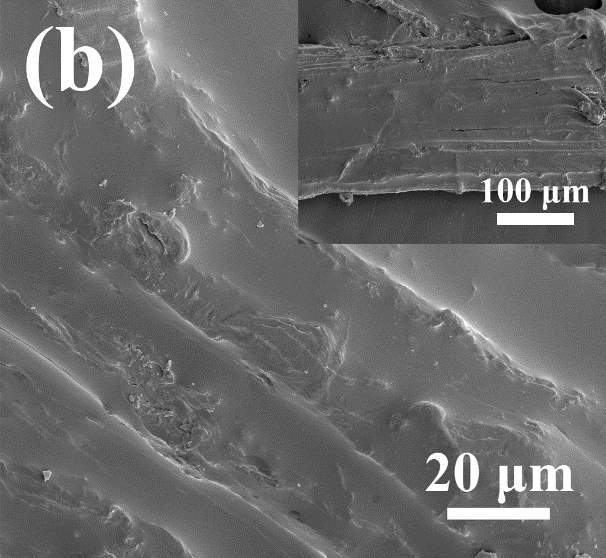

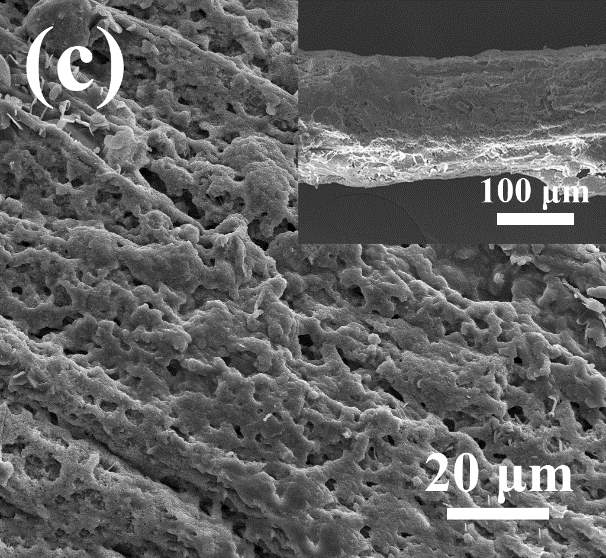

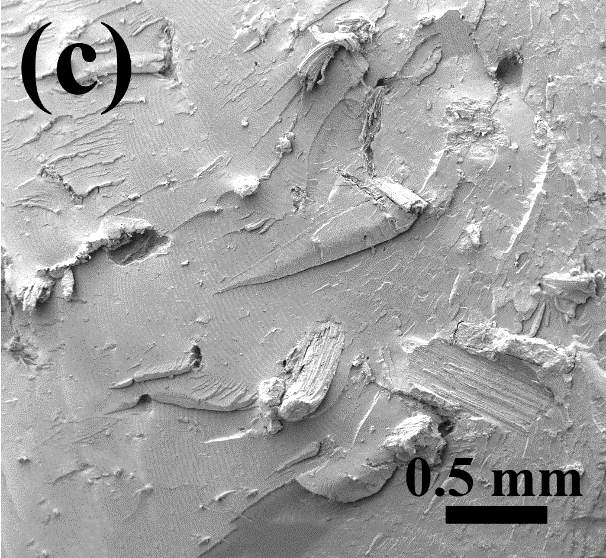

The morphology of corn fibers treated under different conditions was characterized using SEM. As seen in Fig. 4a, rugged surfaces are noted when corn fibers are not sized, which is consistent with our previous report [7]. Fig. 4b and c demonstrate that the corn fibers are covered by a sizing layer regardless of the existence of silica nanoparticles in sizing solutions. Moreover, a comparison between Fig. 4b and c reveals obvious difference in surface roughness, indicating the influence of silica nanoparticles on surface morphology of corn fibers. Similar results were reported in previous work [31, 32].

Fig. 4. SEM images of corn fibers treated by alkali (a), sizing solution without silica nanoparticles (b), and sizing solution with 1 wt% silica nanoparticles (c).

3.2. Mechanical properties of SiO2@CRF/PLA composites

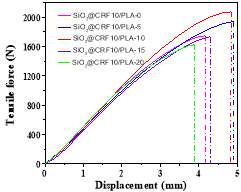

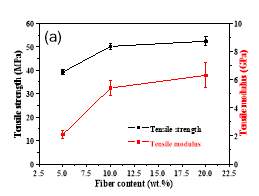

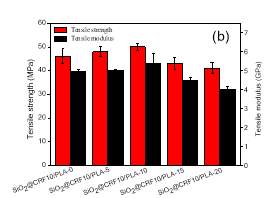

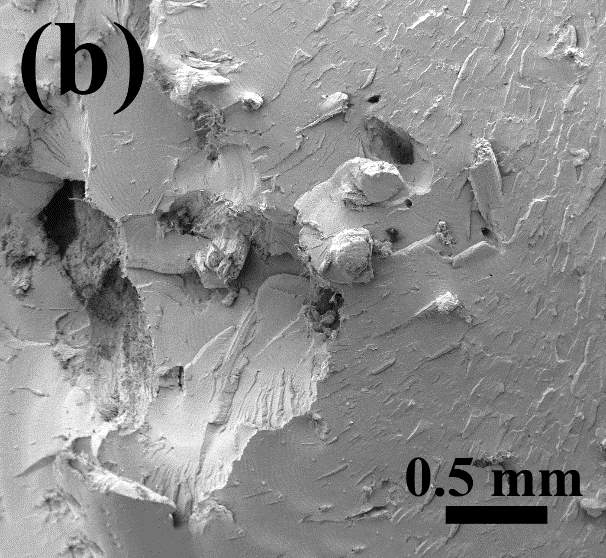

We first tested the mechanical properties of SiO2@CRF/PLA composites containing 10 wt.% corn fibers treated with sizing solutions containing silica nanoparticles with different concentrations. As can be seen from Fig. 5, the five composites show similar load-displacement curves, which are comprised of an initial linear part and a subsequent non-linear plastic portion. However, the peak loads are different among these composites, among which SiO2@CRF10/PLA-10 shows the highest load and displacement. To further compare their mechanical properties, tensile, flexural, and impact properties of SiO2@CRF5/PLA-10, SiO2@CRF10/PLA-10, and SiO2@CRF20/PLA-10 (Fig. 6a) were tested. It is seen that both tensile strength and modulus increase as fiber content increases. However, the increase slows down above 10 wt.%. Therefore, the SiO2@CRF10/PLA composites were selected in the subsequent investigation. Fig. 6b displays the values of tensile strength and modulus of five SiO2@CRF10/PLA composites. Note that, although there is no significant difference in their fracture surfaces (Fig. 7, all showing smooth fiber surfaces and grooves left in the matrix, without PLA matrix stuck on fibers), both tensile strength and modulus show an initial increase and then a decline with increasing content of silica nanoparticles in sizing solutions. The peak strength and modulus values, which are 50.1 MPa and 5.4 GPa, respectively, are observed in SiO2@CRF10/PLA-10. The improvements in tensile strength and modulus are 8.4 and 9.1%, respectively as compared with SiO2@CRF10/PLA-0.

Fig. 5. The load-displacement curves of SiO2@CRF/PLA composites reinforced with corn fibers treated with sizing solutions containing different contents of silica nanoparticles.

Fig. 6. (a) Effect of fiber content on tensile strength and tensile modulus of the SiO2@CRF/PLA-10 composites. (b) Effect of content of silica nanoparticles in sizing solutions on tensile strength and tensile modulus of the SiO2@CRF10/PLA composites.

Fig. 7. Tensile fracture surfaces of SiO2@CRF10/PLA-0 (a), SiO2@CRF10/PLA-10 (b), and SiO2@CRF10/PLA-20.

The flexural strength and modulus of the SiO2@CRF/PLA composites as a function of silica content in sizing solutions are presented in Fig. 8. Obviously, the changing pattern of flexural strength and modulus is similar to that of tensile properties. Likewise, SiO2@CRF10/PLA-10 exhibits the largest flexural strength (96.3 MPa) and modulus (5.0 GPa) among five composites. The improvements are 17.2 and 8.2% for flexural strength and modulus, respectively, as compared to SiO2@CRF10/PLA-0.

Fig. 8. Effect of content of silica nanoparticles in sizing solutions on flexural strength and flexural modulus of the SiO2@CRF10/PLA composites.

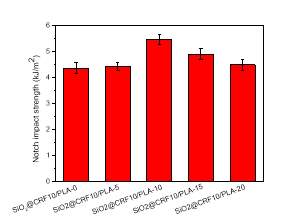

Interestingly, the same changing pattern is also observed for impact strength, as shown in Fig. 9. The highest impact strength of SiO2@CRF10/PLA-10 shows an improvement of 31.2% over SiO2@CRF10/PLA-0.

Fig. 9. Effect of content of silica nanoparticles in sizing solutions on impact strength of the SiO2@CRF10/PLA composites.

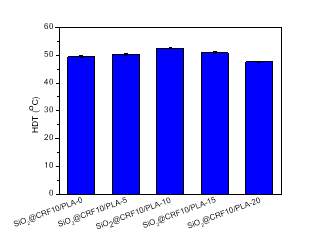

The HDT was measured since it is an important parameter of polymer composites. HDT is mainly related to fiber content and fiber/matrix interface. Fig. 10 reveals that the effect of silica content in sizing solutions on HDT is not substantial. Although SiO2@CRF10/PLA-10 shows the highest HDT among all composites, the difference is not significant (p > 0.05).

Fig. 10. Effect of content of silica nanoparticles in sizing solutions on HDT of the SiO2@CRF10/PLA composites.

3.3. Reinforcing mechanisms

These results suggest that the incorporation of silica nanoparticles in the sizing solutions can effectively improve tensile, flexural, and impact properties of the SiO2@CRF10/PLA composites and the improvements are dependent on the content of silica nanoparticles in the sizing solutions. As mentioned before, the mechanical properties of composites are primarily controlled by their interfacial adhesion. Therefore, we believe that the improvements in mechanical properties as a result of incorporation of silica nanoparticles in the sizing solutions are likely due to improved interfacial nature. We propose that the following aspects contribute to the improved mechanical properties of the SiO2@CRF10/PLA composites.

Firstly, the presence of silica nanoparticles on corn fibers leads to increased fiber surface roughness and enlarged surface area of corn fibers, which increases the mechanical interlocking between the fiber and matrix [26, 31, 36].

Secondly, the enlarged surface area of silica nanoparticles facilitates the absorption of applied energy.

Thirdly, there are chemical interactions between sizing-treated silica nanoparticles and corn fibers, which improve the interfacial adhesion.

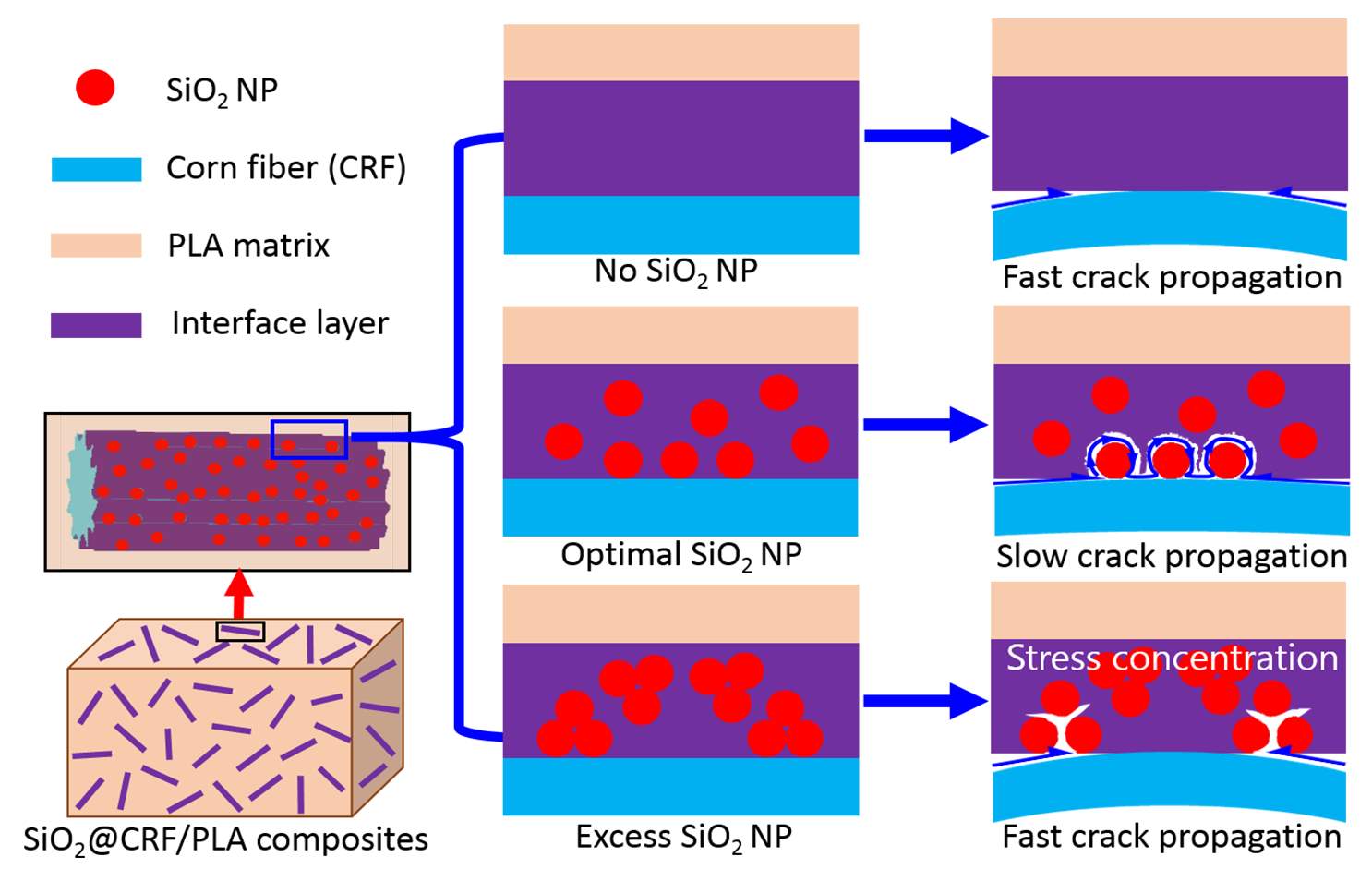

Lastly and most importantly, the silica nanoparticles in the interface layer serve to resist the propagation of cracks.

The proposed mechanisms are schematically illustrated in Fig. 11. As shown in Fig. 11, once the external stress reaches a critical level, cracks may initiate at interface regions which are usually the weakest location compared with the corn fibers and the PLA matrix. Further coalescence and propagation of these cracks depends on the interfacial nature. The homogeneous distribution of the silica nanoparticles on corn fibers may play a significant role in suppressing crack propagation in polymer matrix. However, at a content above 1 wt.%, the silica nanoparticles will agglomerate in the interfacial regions, thus causing cracks and local stress concentration, decreasing the energy dissipation capability, and finally leading to loss of enhancement on the interfacial properties of the composites [28, 37]. This mechanism can explain the reduction of mechanical properties after exceeding the optimum content of silica nanoparticles.

Fig. 11. Schematic illustration showing the reinforcing mechanisms of SiO2@CRF10/PLA composites.

4. Conclusions

We have demonstrated the preparation of PLA composites reinforced with corn fibers that are surface coated with sizing solutions containing silica nanoparticles. The preparation process includes conventional treatment of corn fibers and injection molding, which can be easily scaled up. Measurements of mechanical properties of the SiO2@CRF10/PLA composites demonstrate a silica content dependent change of tensile, flexural, and impact properties. The maximum values of tensile, flexural, and impact strength are achieved in the SiO2@CRF10/PLA-10 composite.

These results indicate that the optimum silica content in sizing solutions is 1 wt.%. The improvements of mechanical properties as a result of silica incorporation in sizing solutions can be mainly ascribed to the resistance of crack propagation during loading as a result of the existence of silica nanoparticles in the interface regions. The enhanced interfacial adhesion between corn fibers and PLA matrix as a result of the increased surface roughness and chemical interactions between silica nanoparticles and PLA matrix may also contribute.

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant nos. 51572187, 51563008, 51662009, 31660264), the Provincial Natural Science Foundation of Jiangxi (Grant no. 20161BAB206149), and the Key Project of Natural Science Foundation of Jiangxi Province (Grant no. 20161ACB20018).

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Organic Chemistry"

Organic chemistry is a branch of chemistry that studies the chemical composition, properties, and reactions of organic compounds that contain carbon.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: