Bisphenol A and Tetra Recart for Food Packaging

Info: 2718 words (11 pages) Dissertation

Published: 17th Dec 2019

Tagged: ChemistrySustainability

BPA – Bisphenol A

Introduction:

BPA was first synthesized by chemists in 1891. However, the first mention of BPA was made in a scientific paper in 1905 by a German scientist Thomas Zincke. In 1950’s plastic industry underwent a technology revolution with the introduction of design techniques, new materials and processes, such as injection molding which made BPA relevant to this thriving industry (Caliendo, 2012).

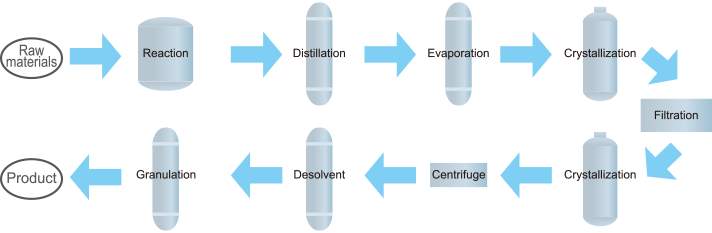

The BPA production process is consisting of several steps as shown in figure 1 below. The key equipment to produce high-quality BPA is DP (Double propeller) crystallizer, Horizontal belt filter, Escher Wyss push type centrifuge (Kikai, 2018).

Figure 1: Process flow of BPA manufacturing (Kikai, 2018)

BPA is Bisphenol A is used to manufacture a common class of epoxy resins, the ones that line the cans of our foods and beverages. Bisphenol A (BPA) is widely used in food packaging such as plastic containers, in the inner lining of metal cans, soda cans, and other food packaging and also for the toys (Guillot, 2018). It is one of the most pervasive chemicals and is not soluble in water, but it dissolves well in alcohols and alkaline solutions. 50 billion pounds are produced every year. Almost everyone (>95%) has some of it in their body (Masson, 2018). The picture on the below shows the white coating which is BPA epoxy resin lining.

Figure 2: BPA Epoxy Resin Lining in Can (Guillot, 2018)

Controversy:

There is a controversy since BPA epoxy resin linings are used in several consumer products including infant formula and food cans and this is toxic to humans. Exposure of BPA to humans is primarily through eating food and drinking liquids that were in contact with this chemical. It can leach into food and beverages leach from food can liner or the plastic container. The extent of leaching is greater when the liquid is heated, or the container is scratched. When ingested it is absorbed readily, but the liver quickly metabolizes the chemical and leaves our body within 24 hours. In other words, it would be entirely gone from the body after a day if someone had a single exposure. Repeated exposures to BPA is harmful to humans (Soloway, 2010).

Bans:

So, initially, bans began saying “defending” the most helpless of people who are infants. “According to U.S. National Toxicology Program (NTP) report (2008), unsafe levels of BPA due to the exposure of baby bottles containing this chemical showed “some concern for effects on the brain, behavior, and prostate gland in children” (Caliendo, 2012). Since 2009, most baby bottles made in the U.S. have NOT contained BPA (Caliendo, 2012).

Environmental impacts:

From industrial smokestacks, thousands of pounds of BPA are released into the air and then settles into streams or rivers near these factories and also deposited on soils (Masson, 2018), (NZFSA, 2006). The main environmental concern associated with releases of BPA in the water sources is that it can mimic the behavior of animal hormones, it is an “endocrine disruptor” (NZFSA, 2006). It also leaches from plastic in landfills into ground water. Also, BPA is excreted in the urine and is released into the environment. It is such a small molecule that it does not get filtered out of the water in waste treatment plants. So once the chemical is released into the environment, it cannot easily escape as it enters the cycle. Luckily, it does not persist in the environment as the half-life is only several weeks or months. At present carbon filters can be used to filter out BPA from water (Masson, 2018).

Effects on human health:

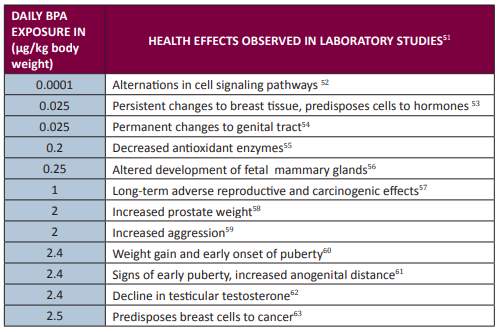

Several studies showed that show Bisphenol A can be harmful to our health. This chemical may mimic human estrogen and it has been linked to breast cancer and early puberty in women. For every 10 servings of canned foods and every 3 cans of infant formula, 11% and 33% respectively are the BPA unsafe levels (Guillot, 2018). According to New Zealand dietary recall data, the average dietary exposure to BPA by New Zealanders from consumption of canned foods has been estimated as 0.008 μg/kg body weight/day, based on actual measurements of BPA in canned foods (Thomson and Grounds, 2005), (NZFSA, 2006).

This toxic chemical can still have many adverse effects when ingested or absorbed into the human body, which occurs via many food and water sources (PF, 2018). In steel canning or plastic industries which involved producing or usage of BPA, workers can be exposed to higher levels of BPA. They are imprinted into our genes and hence these toxic effects can even last for several generations (Masson, 2018). Also, there are no safety and regulatory limits have been set for BPA in New Zealand (NZFSA, 2006).

Figure 3: Daily BPA Exposure and the Observed Health Effects (Wilding, 2010)

Steps to limit the potential negative impacts on the environment and society:

To minimize the negative impacts on the environment and society and for safety concerns over the potential health risks of BPA have led governments and companies to limit the use of the additive in food products and packaging. In 2013, the FDA banned BPA from baby bottles and infant food packaging (Moodie, 2016). BPA-free containers, bottles, and cans were produced by many manufacturers due to consumer demands (Masson, 2018).

Business Impacts:

It created a new business with an alternative chemical which can potentially replace BPA. By 2017, Campbell Soup and many other companies eliminate BPA in the linings of all of its cans and started using alternative linings made from acrylic and polyester (Moodie, 2016). This makes BPA process unattractive for the business and investors are not inclined to in this 21st century.

Tetra Recart

Introduction:

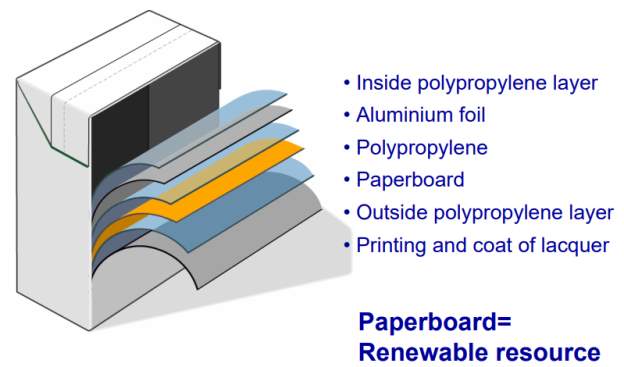

Tetra Recart is the newly launched package evolved from Tetra Pak which addresses the problem of BPA issue. These packages are made using paper exclusively sourced from FSC certified forests and other controlled sources (Franklin, 2018). There figure 4 below shows the different packaging material used in the Tetra Recart.

Figure 4: Tetra Recart Packaging Material (Tetra Pak, 2017)

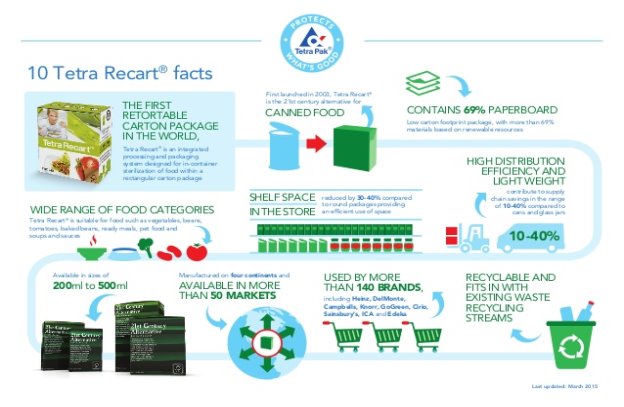

Tetra Recart is the first retortable carton based system designed for shelf-stable products (up to a year) with particles of any size and is BPA free (Protenergy, 2018). It is first launched in 2003 and features polymerized lamination ensuring that any type of food categories can be stored within them such as tomatoes, baked beans, vegetables, etc. (Hunter, 2018). Peer review LCA studies showed that it has a competitive environmental profile with the lowest carbon footprint package (Franklin, 2018) with more than 69% of materials based on renewable resources. It is a rectangular carton package and reduced the shelf space in the store by 30 – 40% compared to round packages providing an efficient use of space. Tetra Recart contributes to High distribution efficiency and is lightweight (TetraPak, 2015). The lower package weight is ideal for consumer handling and the product is easy to store and safe to open. It is available in more than 50 markets globally and is used by more than 140 brands including Heinz, Campbells, Go Green, etc. Further, the Tetra Recart is produced with renewable resources and is completely recyclable and fits in with existing waste recycling streams (TetraPak, 2015) and has minimal effect on the environment and is BPA free. Hence it appeals to producers, customers, and consumers (Franklin, 2018).

Figure 5: Facts about Tetra Recart (Tetra Pak, 2015)

This unique package design showcases the focus of Tetra Recart on the following factors below.

Sustainability and energy efficiency:

Tetra Recart estimates that their packaging requires 60% less weight than cans and 40% less space than cans and jars which allows for Tera Recart cartons to be easily transported. This saves distribution costs and lowers carbon emissions (CNS, 2018).

According to Franklin Associates, there is a 61% reduction when compared to the use of steel cans for tomatoes (Franklin, 2018). It also requires no secondary packaging. In addition, such packing efficiency also enables lower fuel and energy consumption throughout the logistics and transportation of the product (Bowcutt, 2012). Sainsbury’s started selling food in “Tetra Recart” packaging in 2007 instead of tinned items which reduced carbon emissions by 156 tons per year (Smithers, 2010).

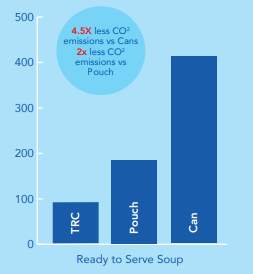

Figure 6: Comparison of Carbon emissions in Different Types of Food Packaging (Franklin, 2018)

Renewable Resource

Paper represents about 69% of materials used to make Recart cartons. In turn, the paper is a product of trees, a renewable resource. However, polypropylene and aluminum foil are both not made from renewable resources. For Recart cartons the paper used in manufacturing is from Forest Stewardship Council (FSC) certified forests. This added measure has helped to ease customers’ concerns on the risk of deforestation associated with the production of paper (Bowcutt, 2012).

Recyclability

Since, Cartons’ main raw material is wood, a renewable source, and paper mills use wood dust and waste as their main source of energy to convert it to paperboard (Bowcutt, 2012). The packs themselves fit into any existing carton recycling process as they are completely recyclable (Hunter, 2018). The paperboard, aluminum and polymer are easily separated. Fibres are turned into paper or cardboard; the fate of the aluminum and plastic depends on the mill. In Sweden, they are used for energy recovery. In other countries (Brazil, Italy, Poland), they can be used together as polyAl, a material used for injection molding, or separated to be recycled individually (Filou, 2010).

But in some countries, due to the multilayer composition of Recart cartons, many waste management firms are unable to recycle the package. According to Tetra Pak, representing only 5% of Recart cartons are actually recycled. The process of recycling Recart cartons is simple. First, the waste management company collects and bales the cartons, and sends these to the recycling facility. Baled cartons are then dropped into a machine filled with water called a “pulper”. Then, the cartons will rub against one another and will begin to delaminate, separating the paper fibers from the polypropylene and aluminum. The mixture, a brown slurry of water and pulp, can be recovered to make new paper products. As paper is recycled, the fibers become increasingly shorter, thereby weakening the strength and limiting the potential uses (Bowcutt, 2012).

Business Impact: (Tetra Recart – A sustainable solution)

Considering raw material, weight and shape Tetra Recart is the better alternative option for food packaging and this is BPA free, there is a huge business potential for Tetra Recart in the beverage and food industry, in addition environmentally conscious world makes it attractive to the future investors (CNS, 2018).

Appendices:

Bowcutt, e. a. (2012). Tetra Recart Cartons. Retrieved from http://mitsloan.mit.edu/actionlearning/media/documents/s-lab-projects/EDF-report-2010.pdf

Caliendo, H. (2012). History of BPA. Plastics Today in Food Safety.

CNS. (2018). Tetra Recart innovates in eco-friendly cartons, as Amazon spot the e-commerce potential. FoodIngredientsFirst. Retrieved from https://www.foodingredientsfirst.com/news/tetra-recart-innovate-in-eco-friendly-cartons-as-amazon-spot-the-e-commerce-potential.html

Filou, E. (2010). How green are tetrapak food cartons? Retrieved from https://theecologist.org/2010/jan/19/how-green-are-tetrapak-food-cartons

Franklin. (2018). Tetra Recart: The evolution of sustainable packaging for a modern world. Retrieved from UK: https://assets.tetrapak.com/static/documents/packaging/infographic-tetra-recart.pdf

Guillot, A. (2018). How Are Food And Beverage Cans Manufactured, And Why Should You Care? Retrieved from https://www.anneshealthykitchen.com/why-you-need-to-avoid-canned-foods-and-beverages/

Hunter, T. (2018). Recyclable Carton Designs. Retrieved from https://www.trendhunter.com/trends/tetra-recart

Kikai, T. (2018). BPA manufacturing plant. Retrieved from https://www.tsk-g.co.jp/en/tech/industry/bpa.html

Masson, D. L. (2018). BPA – why you should be worried about it and how to avoid it. Retrieved from https://littlebirdorganics.co.nz/blogs/little-bird-blog/121862849-bpa-why-you-should-be-worried-about-it-and-how-to-avoid-it

Moodie, A. (2016). Food companies move away from potentially toxic chemicals in cans. Retrieved from https://www.theguardian.com/sustainable-business/2016/mar/31/bpa-chemical-canned-food-general-mills-campbells-soup-del-monte-fda

NZFSA. (2006). BISPHENOL A – INFORMATION SHEET. Retrieved from https://www.mpi.govt.nz/dmsdocument/25685-bisphenol-a-information-sheet.

PF. (2018). The Dangers of BPA in Our Oceans. Retrieved from https://www.plasticsfacts.com/blog/2018/3/29/the-dangers-of-bpa-in-our-oceans

Protenergy. (2018). Tetra Recart Process and Packaging. Retrieved from http://www.protenergyfoods.com/tetraRecart.html

Smithers, R. (2010). Sainsbury’s to switch tomato packaging from tins to Tetra. The Guardian. Retrieved from https://www.theguardian.com/environment/2010/jan/19/sainsburys-tomato-packaging

Soloway, R. A. G. (2010). BPA and the Controversy about Plastic Food Containers. Poison Control.

TetraPak. (2015). 10 facts about Tetra Recart [Infographic]. Retrieved from https://www.slideshare.net/tetrapak/10-facts-about-tetra-recart

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Sustainability"

Sustainability generally relates to humanity living in a way that is not damaging to the environment, ensuring harmony between civilisation and the Earth's biosphere.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: